Avtomobil transportida tormoz tizimi eng muhim organ bo'lib, natijada, ularning noto'g'ri ishi, hatto minimal namoyishi, masalan, hushtak chalib, minimal namoyon bo'ladi, masalan, hushtak chalib, o'z vaqtida tashxis qo'yish kerak. Bu tovushlar nimani anglatadi va tormozni buzishni qanday bartaraf etish kerak - maqolada keyinchalik o'qing.

Tarkib

- Yangi tormoz yostiqlari, skrinshotlarning sabablari

- Ba'zi ekspluatatsiyasidan keyin maydalangan tormoz prokladkalari, nima uchun ular siqishdi

- Tebranish, tebranish sabablari, tebranish sabablari, qanday qilib tebranish sabablari, qanday qilib yo'q qilish kerak

- Tormozlar uchun moylash, qanday moylash kerak va undan qanday foydalanish kerak

- Sifatlangan malaka oshirish va xavfni qo'llashda, xavf-xatarni yopish paytida kambag'al yig'ish va maydalash uchun tormoz prokladkalari

- Tormoz disklari iliq, avtomobilning ishlamay qolgan tormoz tizimi bilan amalga oshiriladi

- Xarid qilishda disklarni qanday tekshirish, diqqatni to'lash, diqqatni to'lash uchun minimal toqat

- Tarifni mazl qiling: Haydovchi va avtomobilga hayotni qanday saqlash kerak

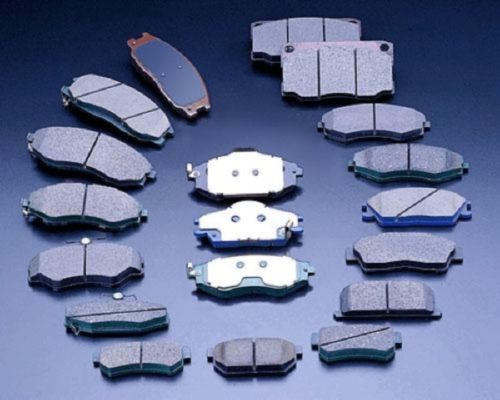

Yangi tormoz yostiqlari, skrinshotlarning sabablari

Postlarni tashlab yuborish - bu asosiy rezonator bo'lgan tormoz diskiga ishqalanish jarayonida uning tebranishi natijasidir. Ushbu jarayonga ko'plab turli omillar ta'sir qiladi. Shovqinni bartaraf etish uchun, quvur ishlab chiqaruvchilari maxsus grajlangan plitalardan foydalanadilar, ammo ular faqat "konveyer poyabzal" dagi "konveyer poyafzal" dagi "konveyer poyabzal" dagi "Sotish" uchun o'rnatilgan - ular o'rnatilmagan.

Skrinshotning eng keng tarqalgan sababi sifatli moddiy materiallardir. Har qanday ishqalanish plakki posti - bu elementlarning massaning polimer tarkibi. Arzon mahsulot ishlab chiqaruvchilarini tejash va prokladkalarni yaratish uchun arzon tarkibni ishlatishadi. Biroq, barcha qo'pol prokladkalar yomon emas. Ularning skripkalarining yana bir sababi tormoz disklari bilan mos emas. Shuning uchun, ishlab chiqaruvchilarning tormoz prokladkalari va disklarini sotib olish kerak.

Agar yangi bo'lsa, faqat tormoz prokladkalari o'rnatilgan bo'lsa, ularga ishlashga vaqt kerak. Bir oz kuting, ehtimol yoqimsiz shovqin o'tishi mumkin. Va bu blokning yuqori qismida, qarama-qarshi tovushni keltirib chiqaradigan aralashmali maxsus qatlamdir. Vaqt o'tishi bilan u yo'q bo'lib ketishi kerak (ushbu qatlamning to'liq aşınmasi bilan). Skrinshotdan tezda qutulish uchun, bir oz qizg'in tormoz qiling.

Agar yostiqlarning ma'lum bir yugurishidan keyin hushtak chalishni davom ettirsa, ularni almashtirishingiz kerak. Shuningdek, tormozlar ularning ifloslanishi yoki suv yostig'i natijasida paydo bo'ladi. Bunday holda, prokladkalarni tozalash yoki tozalash yoki biroz kuting.

Ba'zi ekspluatatsiyasidan keyin maydalangan tormoz prokladkalari, nima uchun ular siqishdi

Har qanday tormoz prokladkalari maxsus kiyim indikatori (T. N. "pisunda") bilan jihozlangan, bu metall plastinkaga o'xshaydi. Kuchli yostiqning kuchli kiyishi bilan, bu plastinka tormoz yoki qichqiriq sodir bo'lganiga o'xshaydi. Bu tormoz prokladkalarini shoshilinch almashtirishni anglatadi.

Bu oqshom, shuningdek, plastinkaning sifatsiz mahkamlash natijasida yuzaga keladigan yangi prokladkalarda o'zini namoyon qilishi mumkin, shuning uchun disk bilan bog'lanish va yoqimsiz ovoz chiqaradi.

Bundan tashqari, tormoz issiqlikdan kelib chiqa oladi. Bu chaqaloq kuchli emas, lekin shunga qaramay, bu mavjud. Shahar atrofidagi intensiv harakat bilan, haddan tashqari overklash va tormozlash, hatto asl prokladkalar bir oz cho'kishi mumkin. Bu avtoulovlarda shamollatilgan tormoz disklari o'rnatilmagan. Binobarin, prokladkalar kamdan-kam hollarda va chop etilgan, ammo yostiq soviganida unchalik ahamiyatsiz va tezda yo'q qilinadi.

Prokladkalarni almashtirish jarayonida, maxsus moylashant yordamida qo'llanma kaliperlarini moylash tavsiya etiladi, chunki bu tormoz ekranining boshqa sababidir.

Shubhasiz, fitnaviyning paydo bo'lishi yoqimsiz hissiyotlarni keltirib chiqaradi, ammo tormoz samaradorligiga ta'sir qilmaydi. Agar siz aqldan ozgan tokchalar, maxsus vositalardan foydalangan holda tormoz tizimini tekshirib ko'ring va tozalang. Asorat-demontaj qilish mumkin, shuningdek, barcha harakatlanadigan elementlarning moylash qismi ekranlardan xalos bo'lishga yordam beradi.

Tebranish, tebranish sabablari, tebranish sabablari, qanday qilib tebranish sabablari, qanday qilib yo'q qilish kerak

Avtomatik tebranish tormoz kaliper yoki diskdan emas, balki tormoz prokladkalaridan olinmaydi. Agar tebranish tormoz tizimining, disklar va kaliperning barcha elementlari shakllanishiga qaramay, tebranish va keyin kamroq amplituda harakatda qoladi, shunda haydovchi va bu tormozlarni eshitadi va Siqish. Bunday holda, siz barcha prokladkalarni umuman ayblamasligingiz kerak, butun tizimni tarqatish va tebranishlarning ma'lumotlarini aniqlash kerak. Aslida, bir nechta sabablar bor:

- Past sifatli tormoz prokladkalari. Ya'ni, bir-biriga zid kelganda, astar yomon yopishtiruvchi aralashmani olib, astar kompozitsiyada ingichradi va hokazo.

- Pistoni kaliper konida butunlay to'g'ri harakat qilmaydi, natijada noaniqliklar tormozlarda paydo bo'ladi.

- Nega tormozlar biroz buralib turadi.

- Tormoz disklari shunchaki eskirgan, natijada "bin" tashqi disk diametri bo'ylab shakllangan.

Ushbu tormoz yostig'i juda oddiy deb topilgan muammolarni hal qiling:

- Biz o'z yog 'yordamida diskda chiqindilarni olib tashlaymiz, faqat ta'mirlash qatlami qalinligi bunday ishni bajarishga imkon beradi. Siz tormoz disklarini almashtirishingiz kerak, chunki hatto eng zamonaviy va tik tormozli prokladka, hosil, hosil va qichqiriqlar hech qachon bo'lmaydi.

- Yangi prokladkalarni o'rnatishdan oldin, muammolar mavjudligi, xususan, qo'llanmalar va pistonlarning ishlashini tekshiring. Ishqozonni kamaytiradigan maxsus material bilan majburiy moylangan qo'llanma.

- Bundan tashqari, yangi tormoz yostig'ini o'rnatishdan oldin, ular uchi, shuningdek, astarli orqa tomondan anti-gradi pastasi yordamida astarning orqa devoridir. Tabiiyki, poyafzalning ish joyiga tegish taqiqlanadi.

Tormozlar uchun moylash, qanday moylash kerak va undan qanday foydalanish kerak

Tormoz moylash materiallarining ikkita navi - keramika va issiqlikka chidamli.

Kaliterlar uchun kokamik moylash materiallari ularning tarkibidagi mikroskopik keramik zarralarni o'z ichiga olgan holda ajralib turadi, ularda turli xil sharoitlarda yuqori tormoz samaradorligi ta'minlanadi. Agar siz tormoz suyuqligini to'g'ri tanlasangiz, nafaqat zarb va kaliper tarkibiy qismlarini siqib qo'yish, balki har qanday maydalash yoki qichqiriqni butunlay yo'q qilishdan saqlanish mumkin. Elementlar axloqsizlik, chang va namlikning xavfli ta'siridan eng qulay tarzda himoyalangan, shuningdek har xil harorat tomchilari.

Bundan tashqari, keramik pastalar yuqori korroziyalarga qarshilik bilan ajralib turadi va xizmatdagi hayot davomida omonatlardan gavjum. Aslida har qanday yostiq materiallari bilan mukammal birlashtirildi. Paste yostiq yoki disk yuzasiga qo'llanilmaydi. Disk tormoz kaliper elementlarini moylash uchun ishlatiladi. Yaxshi tanlash - lyukli moley, Seratex, Presto, Bardaxldan sopol moylash materiallari.

Issiqlikka chidamli pastalardan foydalanish - qarama-qarshi plitalar, sirt prokladkalari va qavslar. Aksariyat modellar uchun ajoyib tanlov - bu Cu-7439 plyus qoplash uchun yuqori haroratli pastadir. Ushbu o'tmish turlari juda yuqori bosim va harorat bilan, shuningdek zang kutilgan joylarda isbotlangan.

Tormoz pastasini tanlashda, shuni ta'kidlash kerakki, u quyidagi talablarga javob berish kerak:

- Turli kimyoviy ta'sirlarga qarshilik.

- Suvga chidamlilik.

- Yaxshi termal qarshilik.

- Plastik bilan moslik.

- Yuqori harorat sharoitida o'zini namoyon qilmasligi kerak. "Kaple Effle".

Sifatlangan malaka oshirish va xavfni qo'llashda, xavf-xatarni yopish paytida kambag'al yig'ish va maydalash uchun tormoz prokladkalari

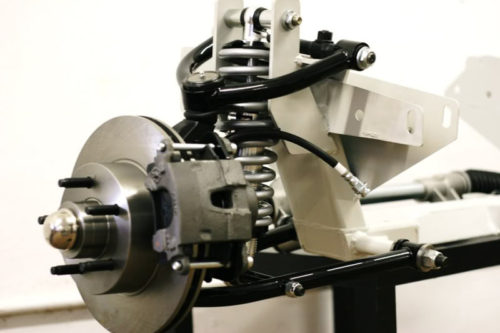

Ishga tushirish materiallari yoki noto'g'ri yig'ish kurtkasi tufayli kamchiliklar diskning ish joyida yuzaga kelishi mumkin, bu esa, burilish va tebranishga olib keladi. Muammoni hal qilish uchun siz diskning yuzasini namlashingiz yoki tormoz diskining tekisligini ta'minlash uchun o'lchovlarni amalga oshirishingiz kerak, ular diskni demontaj qilishimiz, ko'krakning yuzasini ifloslanish va zangdan ehtiyotkorlik bilan tozalang va keyin qayta o'rnating tormoz disk. Diskning periferik qismida biz Beylonni magnit bazaga o'rnatilgan mikrometr bilan tekshiramiz. Agar kaltaklanish qiymati 0,1 mm dan oshsa, tormoz diskini qayta o'rnatishga harakat qiling, uni teshiklarning konfiguratsiyasini sozlash imkonini beradigan HUBga nisbatan 180 yoki 90 darajaga aylantiring. Agar muammo qolsa, tormoz diskini o'zgartiring.

Kamdan-kam mashina egalari ma'lum bir tomon uchun mo'ljallangan mustaqil o'rnatish prokladkalari bilan xato qiladilar, shuningdek, noto'g'ri o'rnatilgan qurilmalarga (astar), balki boshqa jiddiy muammolarga olib kelishi mumkin. Shuning uchun, tormoz prokladkalarini o'rnatayotganda, bunga alohida e'tibor berish kerak.

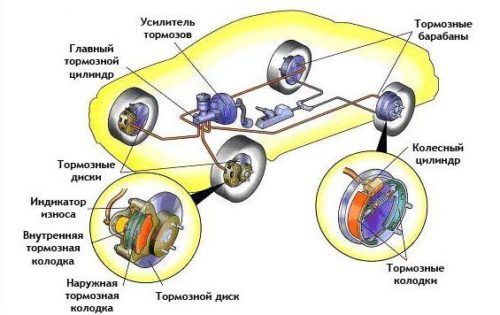

Tormoz disklari iliq, avtomobilning ishlamay qolgan tormoz tizimi bilan amalga oshiriladi

To'rtki, tormoz disklar tormozlashi - tormozni blok bilan aralashgan holda amalga oshiriladigan tormozdir. Ayni paytda disk qizdirilgan. Ta'kidlash joizki, bu darhol paydo bo'ladi, lekin tormoz diskini sovutish uchun vaqt yo'q, ayniqsa shahar rejimida sayr qilish haqida gapiradigan bo'lsak.

Ikkinchidan, disklarni isitishning muhim sababi - haydash uslubi. Har bir haydovchilar individualdir va ehtimol shahar sharoitida tajovuzkorlikning tajovuzkor uslubi bilan, tormoz disklari doimiy ravishda isitiladi.

Va nihoyat, tormoz tizimining ishlamay qolishi mavjud. Aniqroq uning shaxsiy qismlari yoki tugunlari. Ularni batafsil ko'rib chiqing:

- Sifatli tormoz prokladkalari (astar).

- Tormoz yostiqlarining qalinligi va tormoz diskining qalinligi minimal o'lchov ishlab chiqaruvchisidan kamroq.

- Naslchilik tormozli disk.

- Aralash tormoz mexanizmlari tizimidan foydalanish. Orqa tormoz - baraban, old tormozlar - disk. Bu oldingi templi disklarni isitishning muhim sababi, chunki tormoz paytida asosiy yuk old o'qqa tushadi.

Doimiy kuchli isitish prokladkalari va disklari ular tayyorlanadigan material xususiyatlarini o'zgartirishga olib keladi. Shu bilan birga, tormoz disklari va prokladkalari o'rtasida bezakli tormozli va prokladkalar oralig'ida diskning yuzasi haqida tormoz prokladka koeffitsientini sezilarli darajada kamaytirish imkoniyatiga ega. Natijada butun tormoz tizimining samaradorligi sezilarli darajada kamayadi. Haydovchi tormozni zaiflashtirgan bo'lsa ham, har qanday holatda bardoshli tormoz suyuqligi bilan bog'liq muammoni hal qilsa ham, bu mumkin bo'lmaydi.

Bu butun tormoz tizimining taqsimlanishiga olib kelishi mumkin. Ko'pgina hollarda, haddan tashqari qizib ketish tormoz kaliper va prokladkalarning buzilishiga olib keladi. Agar yirtqichlar almashtirilsa, tormoz disklari iliq bo'lsa, tormozli silindrli saqich yonida korroziya sublinking manbai ekanligini tushunish mumkin.

Xarid qilishda disklarni qanday tekshirish, diqqatni to'lash, diqqatni to'lash uchun minimal toqat

Ishlatilgan tormoz diskini sotib olayotganda, birinchi navbatda, u bir nechta joylarda qo'ng'iroq qilish kerak. Nima uchun? Ha, chunki har xil sabablarga ko'ra uchraydigan notekis disk kiyish kabi hodisa mavjud. Shuningdek, diskning ish joyiga chuqur tirnalish, ranglar va boshqa mexanik shikastlanish uchun tramum trakti.

Agar siz yangi tormoz disklarini sotib olsangiz, ularning qiymatiga e'tibor bering. Ma'lumki, sifatli mahsulot qanchalik qimmat bo'lsa, u shunchalik qimmat. Mashhur brendlarga ustunlik berish yaxshiroqdir, chunki yirik kompaniyalar o'zlarining obro'siga va qoida tariqasida, mijozlarga faqat yuqori sifatli mahsulotlarni taklif qilishadi.

Diskning butun ish joyiga og'ishiga kirish 0,0035 millimetrni tashkil qiladi. Agar siz tormoz diskining turg'unligini bag'rikenglikdan tashqarida topsangiz, uni almashtirish kerak, shu jumladan o'qda shakarlamoq. Agar diskning qalinligi bag'rikenglik ichida o'zgargan bo'lsa, qayta sotib olish muammosini bartaraf etishga harakat qiling.

Biroq, agar takrorlash muvaffaqiyatga olib kelmasa, disk maxsus qurilma yordamida namlangan bo'lishi mumkin. Ammo, shu bilan birga, tormoz diskining qoldiq qalinligi buni qilish imkonini beradi va o'rnatilgan diskning xub qismining batareyasi 0,05 millimetrdan oshmaydi. Endi ishqalanish yuzasini tekislash, kerakli pürüzlülünüğü - 3.2. Xo'sh, prokladkalarni almashtirish tavsiya etiladi. Agar disk namlana olmasa, uni o'zgartirish kerak bo'ladi.

Tarifni mazl qiling: Haydovchi va avtomobilga hayotni qanday saqlash kerak

Birinchidan, tormoz tizimining elementlarini tashxislash, ta'mirlash va o'zgartirish kerak. Shuni unutmangki, tormozlar avtomobilning eng muhim tugunlaridan biri bo'lib, hatto bir qarashda ahamiyatsiz muammolar ham halokatli oqibatlarga olib keladi. Sun'iy deformatsiyadan disklarni o'rash. Issiq vaqtida transport vositasini harakatdan keyin darhol yuvish taqiqlanadi. Tormoz disklarini sovutish uchun kerak, aks holda siz tormoz mexanizmining bir qismiga tahdid solasiz.

Tegishli materiallar

- 2110, 2110, VOZ 2110 Isitish tizimini ta'mirlash, o'z qo'llari bilan VOZ 2110 isitish tizimini ta'mirlash

- VOZ 2114 pechkasi sovuq havo bilan, pech 2114, yomon iliq va 1014 isitgichni ta'mirlash va "Vaz 2114" ni olib tashlaydi

- Qanday qilib mashinani quyish kerak. Jekni qanday qo'yish kerak. Avtomobillar uchun jakka turlari.

- Vaz 2109 sug'urta bloki, Vaz 2109 sug'urta bloklari, Vaz 2109 sug'urta bloki, Vaz 2109 sug'urta blushida Vaz 2109 sug'urta bluslari

- Avtomobil chiqindi gaz katalizat, noto'g'ri katalizator, Baliqli katalizator, pog'onadagi samolyotning katalizatorini qanday o'zgartirish mumkin

- Sovuq havo va 2114, pechka 2114, nima uchun pechk 2114 pechni 2114 yog 'bilan urayotganini pechka

- Avtomobilning egasini mashinasi soniga qanday aniqlash mumkin, avtomashinani harakat politsiyasining soni bo'yicha tekshirib turing, avtoulovning davlat raqami bilan avtoulovni bepul tekshiring

- Ishlatilgan shinalar, foydali maslahatlarni qanday tanlash kerak

- Qishki avtomobil yo'li, qishda yo'lovchi avtomobil shinalaridagi bosim, qishda mashina uchun yaxshi batareya, qishda mashinani yaxshi isitish

- Qishda, mashina yomon boshlangan. Qishda mashinani qanday qilish kerak, qishda mashinani isitishingiz kerakmi?

- Iqtisodiyotni yoqish uchun sarflash mashinalari, eng tejamkor avtomobil iste'moli

- Chiruvchilarga yo'lovchilar uchun shinalar brendlari, avtomobil shinalarini yorliqlash, qoldiq yo'lovchilar uchun plastik himoya vositalari, avtoulov markaidagi shinalar, avtomobil shinalari naqshlari

- Ishni uzatish ishi, mexanik tishli debriyalar qutisi, qo'lda uzatmalar qutisi, foydali maslahatlar

- 206 sedan, orqa nurli peugeot 206-sonli Peugleot 206 nosozligi 206 nosozlik 206

- Qishda dizel yoqilg'isi qishda dizel yoqilg'isini qo'shimchalar, eng yaxshi dizel yoqilg'isini qanday tanlash kerak

- Dizel qish boshlanmaydi. Qishda dizelni qanday boshlash, qishda dizelni isitish.

- Yaponiyaliklar Brideston shinalar, Qishki Bridestrone shinalar, Bridestrone shinalar brendi

- Yengil avtomobillar uchun dekodlashni belgilash, yorliqlar g'ildiraklari, disklardagi to'g'ri shinalarni qanday tanlash

- Qishda dizel dvigateli, qishda dizel dvigatelini ishga tushirish, qishda dizel dvigatelini, foydali maslahatlarni

- Avtomobilning orqa qismini, mashinaning pastki qismidagi orqa chiroq, mashinadagi oyoqlarning orqa qismini, mashinaning eshigidagi orqa chiroq, mashinaning orqa chiroqlari yaxshi

- Tirik shinalar, avtobus shinasi, shinalar himoyachisi, mendan foydalanishim mumkin

- Qish shinalaridagi qish shinalarini tanlang, bu qish shinalari qish shinalari bilan belgilanishi kerak, uning o'ng qish shinalarini qanday tanlash kerak, eng yaxshi qish shinalari 2019

- Relizlar temir yo'llari, rizomni urish, boshqaruv panjarasini taqillatish va ta'mirlash sabablari buni o'zingiz bajaring

- Tushunsiz shinalarni ta'mirlash, to'psiz shinalarni ta'mirlash uchun mo'ljallangan kammsiz mashina shinalar

- Rossiya shinalari, rus shinalari Qish, rossiyalik ruslar, Voronej Amtel shinalar, "Mattador Omsk shinasi", Kama-shinalar dunyo miqyosidagi avtobusdir

- Qanday qilib mashinani kalitsiz ochish kerak. Mashinadan nima qilish kerakligini, mashina ichidagi mashinaning kaliti

- Jim shinalar, qishki qish shinalari, tinchlangan avtobus, bu shinalarni tanlash uchun shinalar

- Shinalar va xavfsizlik, avtobusning xavfsizligi, nega avtoulov shinalarini nazorat qilish kerak

- Avtomobilni yomg'ir yog'ishi va sho'rvalikda xavfsiz haydash qoidalari, yangi yangi boshlanuvchilar uchun xavfsiz haydash

- Zang konvertor, zang konvertorlari, zang transduseridan qanday foydalanishni tanlash uchun yaxshiroq bo'lgan zang konvertori

- Avtoulovning jasadini, o'zingizni o'zingiz bajaring, mushakli pastani qanday tanlash kerak

- Dvigatelning chidamliligi, dvigatel hayoti, qanday qilib dvigatel hayotini qanday uzaytirish kerak

- Mashinani taqillating. Mashinani harakatga kelganda taqillatish. Mashinada nima taqillatishi mumkin. Tayyorlanish sababini qanday aniqlash mumkin.

- ABS avtomobili, ABS avtomobili, ABS tizimining nosozlik, ABS tashxislasi

- Avtomobilni bosib olishni boshlaganingizda, transport qoidalarining qoidalari

- VAZ 2110, VAZ 2110 GAZ SHEMI, VOZ 2110 YUQORI Pompasi qurilmasi, VOZ 2110 benzin stantsiyasi ta'miri,

- Radio, avtoulov antenna qurilmasi uchun avtomatlashtirilgan antenna, avtomat antenna buni o'zingiz qiling

- Front Devetenziya Kalina, Front Free Devetme Kalina, oldingi diskinaga taqillatib, kalinadan osma kalinani ta'mirlash

- Shokning norxerjer yog'i, eng yaxshi neft shokning yutbog'i, moy shokning yutbog'i, qanday qilib yog'ni qanday o'rnidan yog 'urishi mumkin

- Debriyaj nosozliklar, debriyajga tegadi, debriyaj nosozligini keltirib chiqaradi, qanday qilib yo'q qilinadi

Izohlar