Vas 2110 mashinangizda pechka salonni isitishni to'xtatsa, bu zarbaning dvigateli isitmasi muvaffaqiyatsiz bo'lishi mumkin. Isitgich tutqichini yoqilganda, shikastlangan dvigatel, bu esa mashinada sovuq bo'lib qoladi. VOZ 2110 isitgichi motor qurilmasining ishlashini tekshirish uchun uni demontaj qilishingiz kerak. Bu haqda maqolada.

Tarkib

- 2110 isitgichning motorli qurilmasi, qurilma va ishlash printsipi

- Motorli vosita Vaz, motorli xo'jayinga zararning belgilari, sabablari

- Asboblar, armatura, ish uchun sarf materiallari

- Micro motorli motor 2110, almashtirish (bosqichma-bosqich ko'rsatma)

- Motorli motor isitgichi 2110, o'z qo'lingiz bilan o'rnatish, bosqichma-bosqich ko'rsatma

- Ishlash natijalarini tekshirish

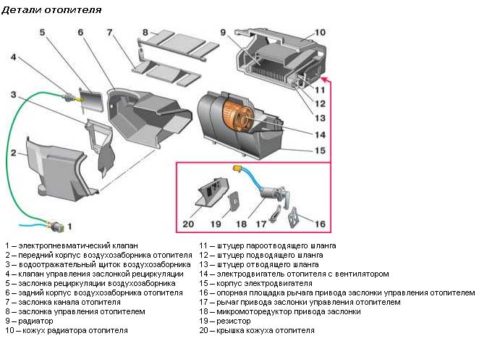

2110 isitgichning motorli qurilmasi, qurilma va ishlash printsipi

Motor echki boshqaruvchisi boshqaruv tizimi signallaridan foydalangan holda isitgich klapanini ochadi va yopadi, natijada kabinaga kiradigan havo isitiladi yoki sovutiladi. Avtotransport yiliga qarab, motorni ajratuvchi konfiguratsiya sezilarli darajada farq qilishi mumkin.

Ushbu birlik ro'paradagi boshqaruv maydonida joylashgan. Uni topish qiyin emas, chunki u tormoz kuchaytirgich yonida o'rnatilgan.

Motorli vosita Vaz, motorli xo'jayinga zararning belgilari, sabablari

Agar siz salonda havo haroratini dastak yordamida boshqara olmasangiz, avval isitgich motorini tekshirishingiz kerak. Ishlash tekshiruvi batareya quvvatini batareyani jihozni jihoz bilan ta'minlash orqali tutqichning o'rta holati bilan amalga oshiriladi. Shu tarzda, siz boshqaruvchining holatini tekshirishingiz mumkin, uning muvaffaqiyatsizligi haroratni sozlashingizga imkon bermaydi.

Ushbu qurilmaning etishmovchiligi sabablari:

- Testbe-ning maqbul haroratini ta'minlamaydigan avtonom blokning buzilishi.

- Elektr kontentining yaxlitligini buzish, batareya bilan to'ldirilgan kuchlanishlar dvigatelga berilmaydi, natijada motorli xo'jayin normal ishlay olmaydi.

Asboblar, armatura, ish uchun sarf materiallari

- Qisqa xoch tornavida.

- Kalitlar to'plami.

- Elementlarni tozalash uchun cho'tka.

- "10" da ratchet bilan bosh kalit.

- Tornavida kesib o'ting.

- Magnit tutqich.

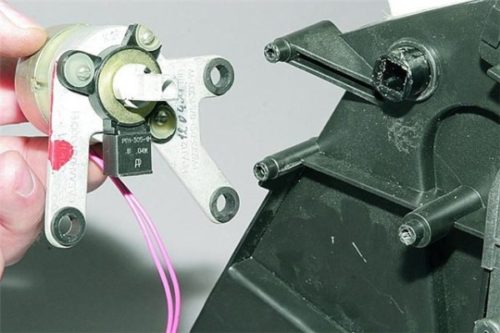

Micro motorli motor 2110, almashtirish (bosqichma-bosqich ko'rsatma)

Agar VAZ 2110 da mikromrotrakak kerak bo'lsa, bir nechta oddiy tadbirlar o'tkazilishi kerak. Siz pedal tugunini, Jobro va Vutni qismlarga ajratishingiz kerak. Keyin eski motorli pechni plastik element bilan demontaj qiling va o'sha kvadrat bo'lgan joyda yangi Mictotorptorini o'rnating. Qoida tariqasida, vites qutisini almashtirish alohida qiyinchiliksiz amalga oshiriladi.

Mikrootor klafini o'rnatish assistent bilan amalga oshirilishi kerak. Birinchi kontaktlarni yangi motorga ulang. Isitgichni teskari tomonga burish sovuq havo ta'minotini ko'rsatadi, shuning uchun yonish yoqilgan bo'lishi kerak, keyin ko'k rang nuqtai nazaridan isitgich boshqaruv tizimini boshqarish tizimini boshqarish tizimini boshqarish.

Siz ham aksincha amalga oshirishingiz mumkin - soat miliga teskari va sensor qizil nuqtaning teskari deb tarjima qilinadi. Shundan so'ng, pechka mickoterasi ko'proq talab qilinadi. O'rnatish normal bo'lib, maydon uchun maxsus moylash vositasidan foydalaning.

Motorni vintlar uchun teshiklar uchun teshiklarni qo'ying. Keyin yordamchi harorat nazoratchisini aylantirishi kerak va shu bilan birga motorga bosing. Agar kvadratlar to'g'ri bo'lsa, almashtirish muvaffaqiyatli amalga oshirildi va vites qutisi kerakli havo oqimini ta'minlaydi.

Agar maydon artistlarning uchdan bir qismida bo'lsa, hech qanday dahshatli narsa yo'q bo'lsa, bu unga ta'sir qilmaydi. Keyin siz vintlarni vintlarni va vitorovni bir necha marta aylantirishingiz kerak - qizil belgidan ko'k va aksincha. Tizim ish doirasini eslab qolishi kerak, natijada motor to'g'ri ishlashi uchun.

Motorli motor isitgichi 2110, o'z qo'lingiz bilan o'rnatish, bosqichma-bosqich ko'rsatma

Motor sektoriga kirish uchun avval Wipers-ni olib tashlashingiz kerak.

Keyin kontakt yong'oqini ochib, jabni bo'shatishingiz kerak, shundan so'ng o'z-o'zini chizish ochiladigandan keyin. Keyinchalik, jabsiyaning yon tomonlarida 2 ta yong'oqni oching va elektronot muhrini elektron sterilingni elektron rejimidan chiqarib oling.

Birinchidan, biz parlamp quvurini ajratamiz, shundan keyin biz vites qutisining issiqlik radiatorlarini ushlab turadigan vintlarni aylantiramiz. Dvigatel qopqoqni kuchaytirgich yaqinida, tim -ent tishli uzat qutisining chap tomonida joylashgan. Yuqori bo'linmada ikkita murvatni oching.

Keyinchalik, pastki qismdan vintni olib tashlang va elektr motorini demontaj qiling. Damper mahsulotlarini teskari tartibda quring.

Ishlash natijalarini tekshirish

Vituborni tekshirish uchun chap tugmachani ko'k rangdagi chap tutunga qo'ying, 10 soniya kuting va motorni boshlang. Kontrolder X1 ulagichidan uzing va qarshiliklar X1.1 va X1.4-kontaktlarni sinab ko'ring. Motor evakkori 833.3854, 1313.3854, 1303.3804, 1323.3854 - 3600-5000 OHM uchun kontroller uchun 800-1200 OVM kuchlanishlari bo'lishi kerak.

Endi biz mikrootorni qizil nuqtada pechka holatida sinab ko'ramiz. WitsBox 3200-3854, 1313.3854, 1303.3854, 1323.3854 - 1200-1600 ohmlar uchun 3200-30005 OVM qarshilik ko'rsatishi kerak.

Agar qarshilik umuman o'zgarmasa yoki umuman bo'lmasa, bu milning nuqtai nazarining o'ziga xosligini anglatadi. Uni alohida sotib olish mumkin emas, shuning uchun siz vites qutisini to'liq o'zgartirishingiz kerak bo'ladi.

Tegishli materiallar

- 2110, 2110, VOZ 2110 Isitish tizimini ta'mirlash, o'z qo'llari bilan VOZ 2110 isitish tizimini ta'mirlash

- VOZ 2114 pechkasi sovuq havo bilan, pech 2114, yomon iliq va 1014 isitgichni ta'mirlash va "Vaz 2114" ni olib tashlaydi

- Qanday qilib mashinani quyish kerak. Jekni qanday qo'yish kerak. Avtomobillar uchun jakka turlari.

- Vaz 2109 sug'urta bloki, Vaz 2109 sug'urta bloklari, Vaz 2109 sug'urta bloki, Vaz 2109 sug'urta blushida Vaz 2109 sug'urta bluslari

- Avtomobil chiqindi gaz katalizator, noto'g'ri katalizator, plitalizator va katalizatorning saldosini qanday o'zgartirish mumkin

- Sovuq havo va 2114, pechka 2114, nima uchun pechk 2114 pechni 2114 yog 'bilan urayotganini pechka

- Avtomobilning egasini mashinasi soniga qanday aniqlash mumkin, avtomashinani harakat politsiyasining soni bo'yicha tekshirib turing, avtoulovning davlat raqami bilan avtoulovni bepul tekshiring

- Ishlatilgan shinalar, foydali maslahatlarni qanday tanlash kerak

- Qishki avtomobil yo'li, qishda yo'lovchi avtomobil shinalaridagi bosim, qishda mashina uchun yaxshi batareya, qishda mashinani yaxshi isitish

- Qishda, mashina yomon boshlangan. Qishda mashinani qanday qilish kerak, qishda mashinani isitishingiz kerakmi?

- Iqtisodiyotni yoqish uchun sarflash mashinalari, eng tejamkor avtomobil iste'moli

- Chiruvchilarga yo'lovchilar uchun shinalar brendlari, avtomobil shinalarini yorliqlash, qoldiq yo'lovchilar uchun plastik himoya vositalari, avtoulov markaidagi shinalar, avtomobil shinalari naqshlari

- Ishni uzatish ishi, mexanik tishli debriyalar qutisi, qo'lda uzatmalar qutisi, foydali maslahatlar

- 206 sedan, orqa nurli peugeot 206-sonli Peugleot 206 nosozligi 206 nosozlik 206

- Qishda dizel yoqilg'isi qishda dizel yoqilg'isini qo'shimchalar, eng yaxshi dizel yoqilg'isini qanday tanlash kerak

- Dizel qish boshlanmaydi. Qishda dizelni qanday boshlash, qishda dizelni isitish.

- Yaponiyaliklar Brideston shinalar, Qishki Bridestrone shinalar, Bridestrone shinalar brendi

- Yengil avtomobillar uchun dekodlashni belgilash, yorliqlar g'ildiraklari, disklardagi to'g'ri shinalarni qanday tanlash

- Qishda dizel dvigateli, qishda dizel dvigatelini ishga tushirish, qishda dizel dvigatelini, foydali maslahatlarni

- Avtomobilning orqa qismini, mashinaning pastki qismidagi orqa chiroq, mashinadagi oyoqlarning orqa qismini, mashinaning eshigidagi orqa chiroq, mashinaning orqa chiroqlari yaxshi

- Tirik shinalar, avtobus shinasi, shinalar himoyachisi, mendan foydalanishim mumkin

- Qish shinalaridagi qish shinalarini tanlang, bu qish shinalari qish shinalari bilan belgilanishi kerak, uning o'ng qish shinalarini qanday tanlash kerak, eng yaxshi qish shinalari 2019

- Relizlar temir yo'llari, rizomni urish, boshqaruv panjarasini taqillatish va ta'mirlash sabablari buni o'zingiz bajaring

- Tushunsiz shinalarni ta'mirlash, to'psiz shinalarni ta'mirlash uchun mo'ljallangan kammsiz mashina shinalar

- Rossiya shinalari, rus shinalari Qish, rossiyalik ruslar, Voronej Amtel shinalar, "Mattador Omsk shinasi", Kama-shinalar dunyo miqyosidagi avtobusdir

- Qanday qilib mashinani kalitsiz ochish kerak. Mashinadan nima qilish kerakligini, mashina ichidagi mashinaning kaliti

- Jim shinalar, qishki qish shinalari, tinchlangan avtobus, bu shinalarni tanlash uchun shinalar

- Shinalar va xavfsizlik, avtobusning xavfsizligi, nega avtoulov shinalarini nazorat qilish kerak

- Avtomobilni yomg'ir yog'ishi va sho'rvalikda xavfsiz haydash qoidalari, yangi yangi boshlanuvchilar uchun xavfsiz haydash

- Zang konvertor, zang konvertorlari, zang transduseridan qanday foydalanishni tanlash uchun yaxshiroq bo'lgan zang konvertori

- Avtoulovning jasadini, o'zingizni o'zingiz bajaring, mushakli pastani qanday tanlash kerak

- Dvigatelning chidamliligi, dvigatel hayoti, qanday qilib dvigatel hayotini qanday uzaytirish kerak

- Mashinani taqillating. Mashinani harakatga kelganda taqillatish. Mashinada nima taqillatishi mumkin. Tayyorlanish sababini qanday aniqlash mumkin.

- ABS avtomobili, ABS avtomobili, ABS tizimining nosozlik, ABS tashxislasi

- Avtomobilni bosib olishni boshlaganingizda, transport qoidalarining qoidalari

- VAZ 2110, VAZ 2110 GAZ SHEMI, VOZ 2110 YUQORI Pompasi qurilmasi, VOZ 2110 benzin stantsiyasi ta'miri,

- Radio, avtoulov antenna qurilmasi uchun avtomatlashtirilgan antenna, avtomat antenna buni o'zingiz qiling

- Front Devetenziya Kalina, Front Free Devetme Kalina, oldingi diskinaga taqillatib, kalinadan osma kalinani ta'mirlash

- Shokning norxerjer yog'i, eng yaxshi neft shokning yutbog'i, moy shokning yutbog'i, qanday qilib yog'ni qanday o'rnidan yog 'urishi mumkin

- Debriyaj nosozliklar, debriyajga tegadi, debriyaj nosozligini keltirib chiqaradi, qanday qilib yo'q qilinadi

Izohlar