Avtomobilda haydash paytida vaqt o'tishi bilan uni bekor qilishi mumkin bo'lgan xarakteristikaning paydo bo'lishi mumkinligini kuzatish mumkin. Bundan tashqari, u yo'l yuzasining holatiga qarab o'zgaradi. Yaxshi yo'lda - kamchilik yo'qoladi yoki kamayadi, shuning uchun tiklanishning hojati yo'qdek tuyulishi mumkin, ammo g'ildiraklar yomon yo'lga borishi bilanoq - Hum yana paydo bo'ladi. Bundan tashqari, yuqori tezlikda siz aniq naqshinkor eshitishingiz mumkin. Ushbu alomatlarning paydo bo'lishining sababi, qoida tariqasida, bu uyil rulmanining aybi. Shuni ta'kidlash kerakki, agar siz ish yuragingizni o'z vaqtida almashtirmasangiz, unda haydashni o'z vaqtida almashtirsangiz, bu juda xavflidir, bu juda xavflidir, shuning uchun yuqorida ko'rsatilgan nosozlik alomatlarining ozgina namoyon bo'lishi bilan, uni iloji boricha tezroq uyali rozetka bilan almashtirish kerak. Bu haqda maqolada.

Tarkib

- Langar rulli, bu qanday vazifalarni bajaradi

- Rolikli rolik, qurilma, afzalliklar va kamchiliklar

- Diagonali rulka, qurilma, afzalliklar va kamchiliklar

- Rivojlanishning siqilishi lahzasi, nima va bu narsa qilish operatsiya davomiyligiga ta'sir qiladi

- Uyilbog 'noto'g'ri, buzilish belgilari

- Xush va xavfsizlik, xavfsizlikni almashtirish uchun asboblar va armatura

- Old g'ildirakli rulni almashtirish, bosqichma-bosqich ko'rsatmalar

- Orqa g'ildirakli rulni, bosqichma-bosqich ko'rsatmalarni almashtirish

- Maslahatlar papi, qanday qilib to'g'ri ish qilish kerak, bu roziyalovchi vosita uchun foydalanish yaxshiroqdir

Langar rulli, bu qanday vazifalarni bajaradi

Qopqoq - bu qo'llab-quvvatlashning bir qismini qo'llab-quvvatlaydigan mexanizm. U mil, o'qni yoki boshqa biron bir elementni ushlab turishga qodir, ammo har qanday holatda, uning bo'sh joyini bo'shatish yoki aylanishini ta'minlaydigan kosmosda milni mahkamlashdir. Xul rulisining ikkinchi vazifasi mexanik yukni idrok etish, shuningdek uning boshqa elementlarga o'tishidir.

Uy egasi - bu rulmanli rulman. U o'q atrofida g'ildirakning silliq aylanishini ta'minlaydi. Bu rozitsiyalar - bir martalik va ikki qatorli qator, shuningdek ochiq va yopiq tur. Ular yo'lovchilar va yuk mashinalarida ishlatiladi. Old va orqa g'ildiraklar uchun g'ildirakli rullar bir-birlaridan farq qiladi.

Avtomobil uyanli rulmi doimiy ravishda haddan tashqari yuklarga duch kelmoqda. Unda yuqori haroratli farqlar, atrof-muhitning ta'siri, pits, boshqaruv, tormozlar, haydovchiga kirishda zarba yuklanishini tashkil etish. Shuni ta'kidlash kerakki, orqaga burilish g'ildirakning aylanishiga to'sqinlik qilmasligi kerak, bu minimal ishqalanish va ruxsat etilgan shovqin bilan aylanishi kerak.

Rolikli rolik, qurilma, afzalliklar va kamchiliklar

Rolikli rolikli roliklar o'rnatishga juda ta'sir qiladi, agar u noto'g'ri amalga oshirilsa, darhol tartibni olib tashlashga qodir. Rolikli g'ildirakli rulman osilgan xususiyat haqida bilmaydigan yangi varaqlar ko'pincha ushbu elementni tez yordam mashinasiga almashtirishni keltirib chiqaradigan STOning vijdonsiz ishchilarini aldaydi.

Diagonali rulka, qurilma, afzalliklar va kamchiliklar

Diagonal rovkalar og'ir yuklarni engishga qodir va ajoyib qarshilikka ega.

Biroq, ularning ishi, rolikli rolik kabi, to'g'ri o'rnatish (kuchli siqish) ga bog'liq, aks holda ular muvaffaqiyatsiz bo'ladi.

Rivojlanishning siqilishi lahzasi, nima va bu narsa qilish operatsiya davomiyligiga ta'sir qiladi

Rokiptiklash lahzasi - transport vositasini ishlab chiqaruvchining tavsiyalariga muvofiq aniq bajarilishi kerak bo'lgan voqea. Yuqorida aytib o'tilganidek, rulni noto'g'ri sozlash uning buzilishiga olib keladi.

Agar ilgari moslashtiradigan maxsus ko'nikmalarni talab qilgan bo'lsa, o'sha paytda topish qiyin bo'lgan maxsus vositalarning mavjudligi, keyin bugungi kunda bugungi kunda muammolar yo'q. Endi har bir mashina egasi kerakli vositani sotib olishi va piktulyatsiyaning holatini va boshqa avtoulovlarning holatini mustaqil ravishda nazorat qilishga imkon beradigan ma'lumotlarni olishlari mumkin.

Uyilbog 'noto'g'ri, buzilish belgilari

Avtoulovlar uyasi ishlamay qolganining asosiy belgilari:

- Transport vositasi orqasidan eshitilgan kuchli odam yoki shovqin. Agar yuk ko'taruvchi uy bo'lsa, burilish burilish paytida shovqin bo'lmaydi.

- Orqa g'ildirakdagi orqa g'ildirakning ko'rinishi, shovqin yoki urish bilan birga keladi.

Xush va xavfsizlik, xavfsizlikni almashtirish uchun asboblar va armatura

- Maxsus tortgich.

- Bolg'a.

- To'xtatilgan halqalarni demontaj qilish uchun.

- 17 yoshdagi kalit.

- 10-dagi kalit Hexagosa.

- Tornavida.

- Chisel.

O'zgartirishdan oldin, orqa g'ildiraklar ostida tattar zonalarini va tana ostidagi diqqat markazida bo'lishini unutmang.

Old g'ildirakli rulni almashtirish, bosqichma-bosqich ko'rsatmalar

- Oldingi g'ildirakli mahkamlash murvatlari.

- Neyvni aylanib yurish.

- Keyin mashinani Jekga ko'taring va old g'ildirakni qismlarga bo'ling.

- Biz boshqaruv uchini tuzatadigan yong'oqni topamiz, keyin uni oching.

- To'qqizishdan foydalanib, boshqaruv uchi bosilgan.

- Oxirgi qirradan oxirgi marta oling.

- Biz ikkita metall kemani topamiz va olib tashlaymiz, kaliper kaliperning mahkamlanishi.

- Kaliper murvatlarini oching.

- Shunday qilib, kaliper xalaqit bermaydi, olib tashlamaymiz, shundan keyin biz simga osilganmiz.

- Keyin to'pni qo'llab-quvvatlash to'pini oching.

- To'pni qo'llab-quvvatlashni biling.

- Tormoz diskini olib tashlang.

- Endi siz xujkadan yong'oqni ochishingiz kerak.

- Kaput ostida bir stakan ichakda taglikni ushlab turadigan ikkita yong'oqni zaiflashtiradi.

- Biz mashinaga qaytib, to'pni qo'llab-quvvatlash dastagini tortib olamiz.

- Keyin, voqea joyidan ustunni torting, ammo bu erda aslida haydovchi milni tortib olish uchun ishlatilishi kerak.

- Endi taglikni to'liq chiqarib oling.

- Ruxsat beriladigan uya cho'zilganda, aslida ichki halqali.

- Ruxsat ochilgan va halqaning kesilgan.

- Yangi element muloyimlik bilan boshqariladi yoki joyiga joylashtiriladi.

Orqa g'ildirakli rulni, bosqichma-bosqich ko'rsatmalarni almashtirish

Orqa uyil rozetani almashtirish bir xil tarzda amalga oshiriladi:

- Orqa g'ildirakni olib tashlang.

- Men tana ostida Mont.

- Biz xub o'q va baraban murvatlarini aylantiramiz. Agar kerak bo'lsa, WD-40.

- Tormoz barabasini olib tashlang.

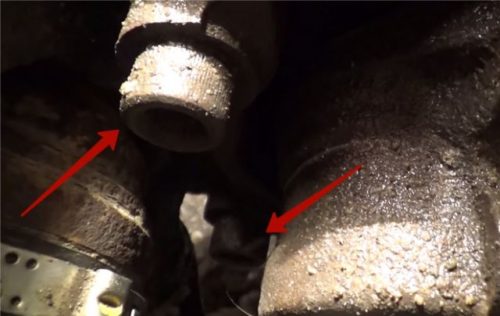

- Biz uy qopqog'ini demontaj qilamiz.

- Biz to'xtab turgan yong'oqni demontaj qildik, ulardan to'xtash kerak. Kirish kerak, shundan keyin forsepsni tortib olish.

- O'q qismini olib tashlash yoki shunchaki teskari yonma-yon burilish bilan o'qni olib tashlang.

- Tornavida bilan biz klipni olib tashlaymiz va chisel yordamida, ehtiyotkorlik bilan o'qdan ichki halqani taqillatamiz.

- Eski iqlim yordami bilan biz yangi rulmanni buyuramiz.

- Anjumandan so'ng, biz biron bir harakatni qo'llasak, yong'oqni sudrab boramiz.

Operatsiyadan keyin u uch yoki to'rt kun haydash kerak. Keyin orqaga burish uchun yana yong'oqni tortib olishingiz kerak.

Maslahatlar papi, qanday qilib to'g'ri ish qilish kerak, bu roziyalovchi vosita uchun foydalanish yaxshiroqdir

- Bu erda bo'lgan qiymat mavjudligidan qat'i nazar, ramzlarni orqa yoki oldingi g'ildiraklarda almashtirish maqsadga muvofiqdir.

- To'g'ri moylash vositasini tinchlantiring.

- Raqobatda bolg'a o'ng tomonini urish mumkin emas, uni yog'och planshet bilan qilish kerak.

- HUB tugunlarida bo'shliq qo'yish mumkin emas, chunki zavodda bo'shliqlarni hisobga olgan holda to'plangan.

- Raqobatni almashtirishda, o'qning holatini va ishning holatini tekshirganingizga ishonch hosil qiling.

- Siz g'ildirak tugunlariga muhrni sozlamasligingiz yoki harakat qila olmaysiz.

Tegishli materiallar

- 2110, 2110, VOZ 2110 Isitish tizimini ta'mirlash, o'z qo'llari bilan VOZ 2110 isitish tizimini ta'mirlash

- VOZ 2114 pechkasi sovuq havo bilan, pech 2114, yomon iliq va 1014 isitgichni ta'mirlash va "Vaz 2114" ni olib tashlaydi

- Qanday qilib mashinani quyish kerak. Jekni qanday qo'yish kerak. Avtomobillar uchun jakka turlari.

- Vaz 2109 sug'urta bloki, Vaz 2109 sug'urta bloklari, Vaz 2109 sug'urta bloki, Vaz 2109 sug'urta blushida Vaz 2109 sug'urta bluslari

- Avtomobil chiqindi gaz katalizat, noto'g'ri katalizator, Baliqli katalizator, pog'onadagi samolyotning katalizatorini qanday o'zgartirish mumkin

- Sovuq havo va 2114, pechka 2114, nima uchun pechk 2114 pechni 2114 yog 'bilan urayotganini pechka

- Avtomobilning egasini mashinasi soniga qanday aniqlash mumkin, avtomashinani harakat politsiyasining soni bo'yicha tekshirib turing, avtoulovning davlat raqami bilan avtoulovni bepul tekshiring

- Ishlatilgan shinalar, foydali maslahatlarni qanday tanlash kerak

- Qishki avtomobil yo'li, qishda yo'lovchi avtomobil shinalaridagi bosim, qishda mashina uchun yaxshi batareya, qishda mashinani yaxshi isitish

- Qishda, mashina yomon boshlangan. Qishda mashinani qanday qilish kerak, qishda mashinani isitishingiz kerakmi?

- Iqtisodiyotni yoqish uchun sarflash mashinalari, eng tejamkor avtomobil iste'moli

- Chiruvchilarga yo'lovchilar uchun shinalar brendlari, avtomobil shinalarini yorliqlash, qoldiq yo'lovchilar uchun plastik himoya vositalari, avtoulov markaidagi shinalar, avtomobil shinalari naqshlari

- Ishni uzatish ishi, mexanik tishli debriyalar qutisi, qo'lda uzatmalar qutisi, foydali maslahatlar

- 206 sedan, orqa nurli peugeot 206-sonli Peugleot 206 nosozligi 206 nosozlik 206

- Qishda dizel yoqilg'isi qishda dizel yoqilg'isini qo'shimchalar, eng yaxshi dizel yoqilg'isini qanday tanlash kerak

- Dizel qish boshlanmaydi. Qishda dizelni qanday boshlash, qishda dizelni isitish.

- Yaponiyaliklar Brideston shinalar, Qishki Bridestrone shinalar, Bridestrone shinalar brendi

- Yengil avtomobillar uchun dekodlashni belgilash, yorliqlar g'ildiraklari, disklardagi to'g'ri shinalarni qanday tanlash

- Qishda dizel dvigateli, qishda dizel dvigatelini ishga tushirish, qishda dizel dvigatelini, foydali maslahatlarni

- Avtomobilning orqa qismini, mashinaning pastki qismidagi orqa chiroq, mashinadagi oyoqlarning orqa qismini, mashinaning eshigidagi orqa chiroq, mashinaning orqa chiroqlari yaxshi

- Tirik shinalar, avtobus shinasi, shinalar himoyachisi, mendan foydalanishim mumkin

- Qish shinalaridagi qish shinalarini tanlang, bu qish shinalari qish shinalari bilan belgilanishi kerak, uning o'ng qish shinalarini qanday tanlash kerak, eng yaxshi qish shinalari 2019

- Relizlar temir yo'llari, rizomni urish, boshqaruv panjarasini taqillatish va ta'mirlash sabablari buni o'zingiz bajaring

- Tushunsiz shinalarni ta'mirlash, to'psiz shinalarni ta'mirlash uchun mo'ljallangan kammsiz mashina shinalar

- Rossiya shinalari, rus shinalari Qish, rossiyalik ruslar, Voronej Amtel shinalar, "Mattador Omsk shinasi", Kama-shinalar dunyo miqyosidagi avtobusdir

- Qanday qilib mashinani kalitsiz ochish kerak. Mashinadan nima qilish kerakligini, mashina ichidagi mashinaning kaliti

- Jim shinalar, qishki qish shinalari, tinchlangan avtobus, bu shinalarni tanlash uchun shinalar

- Shinalar va xavfsizlik, avtobusning xavfsizligi, nega avtoulov shinalarini nazorat qilish kerak

- Avtomobilni yomg'ir yog'ishi va sho'rvalikda xavfsiz haydash qoidalari, yangi yangi boshlanuvchilar uchun xavfsiz haydash

- Zang konvertor, zang konvertorlari, zang transduseridan qanday foydalanishni tanlash uchun yaxshiroq bo'lgan zang konvertori

- Avtoulovning jasadini, o'zingizni o'zingiz bajaring, mushakli pastani qanday tanlash kerak

- Dvigatelning chidamliligi, dvigatel hayoti, qanday qilib dvigatel hayotini qanday uzaytirish kerak

- Mashinani taqillating. Mashinani harakatga kelganda taqillatish. Mashinada nima taqillatishi mumkin. Tayyorlanish sababini qanday aniqlash mumkin.

- ABS avtomobili, ABS avtomobili, ABS tizimining nosozlik, ABS tashxislasi

- Avtomobilni bosib olishni boshlaganingizda, transport qoidalarining qoidalari

- VAZ 2110, VAZ 2110 GAZ SHEMI, VOZ 2110 YUQORI Pompasi qurilmasi, VOZ 2110 benzin stantsiyasi ta'miri,

- Radio, avtoulov antenna qurilmasi uchun avtomatlashtirilgan antenna, avtomat antenna buni o'zingiz qiling

- Front Devetenziya Kalina, Front Free Devetme Kalina, oldingi diskinaga taqillatib, kalinadan osma kalinani ta'mirlash

- Shokning norxerjer yog'i, eng yaxshi neft shokning yutbog'i, moy shokning yutbog'i, qanday qilib yog'ni qanday o'rnidan yog 'urishi mumkin

- Debriyaj nosozliklar, debriyajga tegadi, debriyaj nosozligini keltirib chiqaradi, qanday qilib yo'q qilinadi

Izohlar