Totyatti-da ishlab chiqarilgan transport vositalari bu amaliyot va ta'mirlashning o'ziga xos emas, ammo ba'zi bir mashina bo'linmalari hali ham ortib borishni va parvarish qilishni talab qiladi, xususan, ushbu moddada muhokama qilinadigan translyatsiyalarga tegishli.

Tarkib

- Vaz va u qanday ishlaydi va u qanday ishlaydi

- Vaz 2114, qurilma

- Vallantlarni o'z qo'llari bilan qanday sozlashni sozlash

- Haydovchi g'ildirak haydovchi Vaz 2114

- PPC VAZ 2114, ob'ektlar va printsip tamoyillari, ular talablar

- PPC VAZ 2114, bu mushukning nazorati haydovchisidan iborat

- Tekshiruv punkti 2114-sonli neft

- Uzatish moyining yopishqoqligi, qanday yopishqoqligi kerak

- Yuqori yopishqoqligi bo'lgan neft, nega yog'ni to'ldirish uchun 5w-50 tipidagi yopishqoqligi bilan to'ldirib bo'lmaydi

- Moslar mazhosida: yuqori sifatli moylash vositasi uzoq muddatli muammosiz ish

Vaz va u qanday ishlaydi va u qanday ishlaydi

Vazning yuqishi oldingi haydovchi, vites qutisi va debriyajdan iborat. Avtoulov dvigateli tomonidan chiqarilgan aylanma, uzatilish elementlari tufayli g'ildiraklarga "etib boring" va ularni aylantirishga olib keladi. Transmissiyadan foydalanish, aylanish kuchi harakatga aylanadi.

Vaz 2114, qurilma

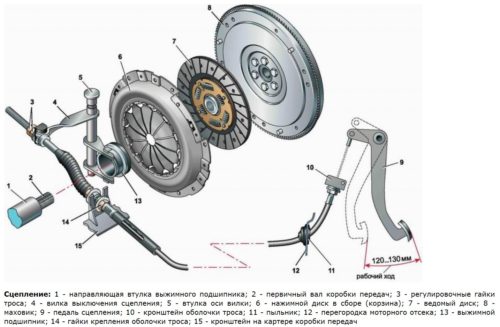

O'g'rilik - bu translyatsiya zanjirida birinchi bo'lgan qurilma. Ushbu avtoulov modelida u bir bo'lak, yopiq va quruq, sho'r va qulonni qulab tushdi. Drayv - bu kabel, bosim bahor va rulo orasidagi bo'shliqsiz. U bitta o'qda tormoz pedal bilan o'rnatilgan pedal tomonidan boshqariladi.

Vallantlarni o'z qo'llari bilan qanday sozlashni sozlash

Voz debriyajni sozlashda quyidagilar uchun mustaqil ravishda amalga oshirilishi mumkin:

- Avtomobilning kesilgan joyida mahkamlash elementini, ya'ni, bu chelak haydovchisining uchida joylashgan yong'oqni aylantiradi, u pedal harakati bilan.

- Kerakli natijaga erishilganda, qulflangan yong'oqni torting va shu bilan pedalning zarur pozitsiyasini o'rnating.

Haydovchi g'ildirak haydovchi Vaz 2114

Old g'ildirakli haydovchi uzatishning yana bir elementidir. Har bir g'ildirak uchun burchakli tezliklar uchun 2 ta aloqa ta'minlangan - ichki va tashqi. Harakatda ular haydovchi g'ildiraklari orqali boshqariladi. Chap g'ildirak uchun mil - bu tayoq va o'ng quvur uchun. Xaritalar qaytarib berilmaydi, muvaffaqiyatsiz bo'lsa, ularni almashtirish kerak.

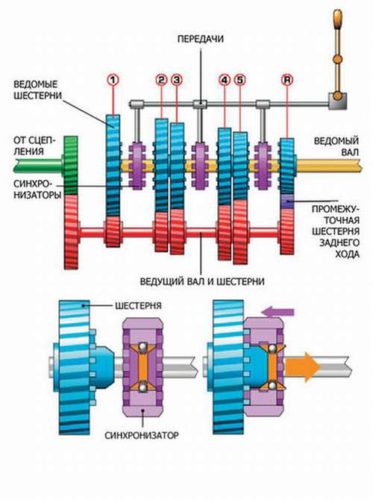

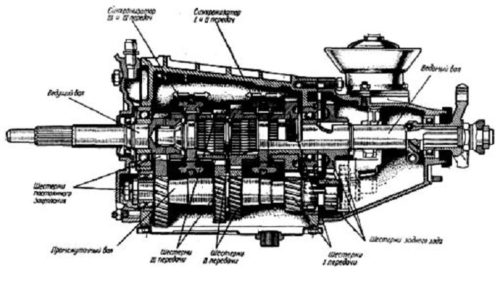

PPC VAZ 2114, ob'ektlar va printsip tamoyillari, ular talablar

Kalitlarni uzatish birligi - bu vites qutisi, ularning barcha asosiy tafsilotlari (vites qutilar, aylanadigan va uzuklar) doimiy ravishda ishqalanmoqda, natijada ular yaxshi moylashant kerak. Quyidagi talablar vites qutisiga taqdim etiladi:

- Haydovchining charchashini maksimal darajada oshirish uchun ular harakatlanishda oson va oddiy nazoratni ta'minlashlari kerak.

- Barcha uzatish agregatlari to'g'ridan-to'g'ri va o'zgarishda harakatlanayotganda yaxshi tortish sa'y-harakatlari va yuqori tezlikni ta'minlash juda muhimdir.

- Kam vazn va o'lcham asosiy talablardan biridir. Dizaynerlar har bir millimetrlik va og'irlikdagi gramm miqdoridagi gramm mishlar uchun kurash olib borish uchun quvvatni oshirish, shuningdek uning samaradorligini oshirishda.

- Ish paytida yuqori ishonchlilik. Hech kim doimiy ravishda shug'ullanish uchun zarur bo'lgan agregatlarga muhtoj emas.

- Umuman olganda, har bir birlik alohida hajmga ega bo'lishi kerak.

- Avtomobilni o'rnatgandan so'ng barcha uzatish moslamalari foydalanishning butun davri davomida saqlanishi va osonlikcha kirish uchun qulay bo'lishi kerak.

- Dizaynning soddaligi yuqori texnologiyali mahsulotni ishlab chiqarishga olib keladi, shunda mahsulot iqtisodiy jihatdan foydali hisoblanadi.

- Yana bir muhim talab - bu uzatishning jim bo'lganidan jim rejani ta'minlash.

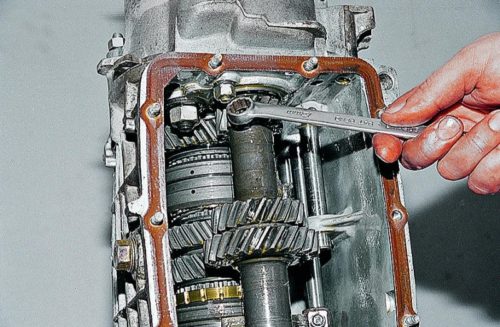

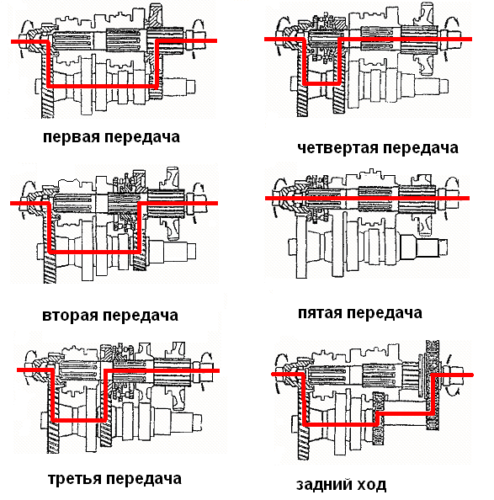

VOZ 2114 vites qutisi qurilmasi ushbu talablarga javob beradi. Sinxronlashtirilgan va beshta qadam bor. Cheklov punkti asosiy uzatish va differentsialga ulangan.

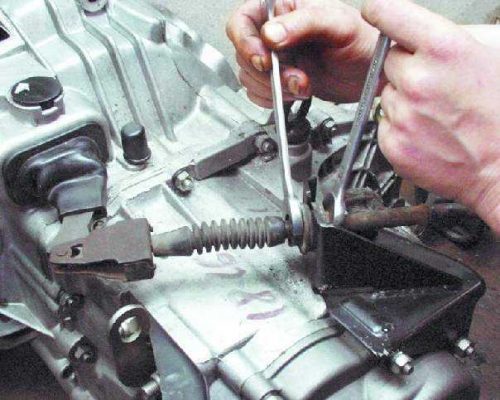

PPC VAZ 2114, bu mushukning nazorati haydovchisidan iborat

Transmissiya nazorati drayveri yoqiladi:

- Skki tanlov.

- To'pni qo'llab-quvvatlash va xohish.

- Tishli siljish dastagi.

- Tanlov mexanizmi, shuningdek kommutatsiya tezligi.

Tekshiruv punkti 2114-sonli neft

VAZ 2114 old g'ildirak uchun GL 4 moyi ts ga mos keladigan eng yaxshisi bo'ladi. Ba'zi avtoulov egalari eng yuqori yopishqoqlikka ega, ammo Muayyan vaqtdan keyin muammolar qutidan boshlanadi. Bu, GL 5 orqa g'ildirakli haydovchi va SUV yoki yuk mashinalarining ko'priklarini uzatish uchun mo'ljallanganligi va old g'ildirakli avtomobillarni uzatishning etarli darajada samarali moyilligini ta'minlash uchun amalga oshiriladi.

Uzatish moyining yopishqoqligi, qanday yopishqoqligi kerak

Old g'ildirakli g'ildiraklar uchun yaxshi, Vaz "jami 7 yoki gl 4/5 75W-80 yoki 80w-85" ning yopishqoqligi bilan "Mavsum" moylari hisoblanadi.

Yuqori yopishqoqligi bo'lgan neft, nega yog'ni to'ldirish uchun 5w-50 tipidagi yopishqoqligi bilan to'ldirib bo'lmaydi

85w-90 ning yopishqoqligi 85W-90 ni va boshqa dvigatel yog'i 5w-50 ni tushirish tavsiya etilmaydi. Yopishqoqlikning kuchayishi qattiq moyli filmni yaratishga qodir, bu tishlari bilan, shuningdek ularning tishlari orasida kirib borish qiyin. Xususan, sinxronizlar azob chekmoqda, chunki ular o'zlari ostidan tor moyni siqishlari kerak va dizayni ma'lumotlar mexanik harakatlari uchun hisoblab chiqilmaydi.

Moslar mazhosida: yuqori sifatli moylash vositasi uzoq muddatli muammosiz ish

Muvaffaqiyatli avtoulov moyi - bu uzoq va muammosiz operatsiyaning garovidir. Shuning uchun avtoulov moylash materiallarini tanlashda, juda ehtiyot bo'ling va transport vositasining kerakli modeli uchun moylash vositasini tanlashingizga yordam beradigan mutaxassislarga murojaat qiling.

Tegishli materiallar

- 2110, 2110, VOZ 2110 Isitish tizimini ta'mirlash, o'z qo'llari bilan VOZ 2110 isitish tizimini ta'mirlash

- VOZ 2114 pechkasi sovuq havo bilan, pech 2114, yomon iliq va 1014 isitgichni ta'mirlash va "Vaz 2114" ni olib tashlaydi

- Qanday qilib mashinani quyish kerak. Jekni qanday qo'yish kerak. Avtomobillar uchun jakka turlari.

- Vaz 2109 sug'urta bloki, Vaz 2109 sug'urta bloklari, Vaz 2109 sug'urta bloki, Vaz 2109 sug'urta blushida Vaz 2109 sug'urta bluslari

- Avtomobil chiqindi gaz katalizator, noto'g'ri katalizator, plitalizator va katalizatorning saldosini qanday o'zgartirish mumkin

- Sovuq havo va 2114, pechka 2114, nima uchun pechk 2114 pechni 2114 yog 'bilan urayotganini pechka

- Avtomobilning egasini mashinasi soniga qanday aniqlash mumkin, avtomashinani harakat politsiyasining soni bo'yicha tekshirib turing, avtoulovning davlat raqami bilan avtoulovni bepul tekshiring

- Ishlatilgan shinalar, foydali maslahatlarni qanday tanlash kerak

- Qishki avtomobil yo'li, qishda yo'lovchi avtomobil shinalaridagi bosim, qishda mashina uchun yaxshi batareya, qishda mashinani yaxshi isitish

- Qishda, mashina yomon boshlangan. Qishda mashinani qanday qilish kerak, qishda mashinani isitishingiz kerakmi?

- Iqtisodiyotni yoqish uchun sarflash mashinalari, eng tejamkor avtomobil iste'moli

- Chiruvchilarga yo'lovchilar uchun shinalar brendlari, avtomobil shinalarini yorliqlash, qoldiq yo'lovchilar uchun plastik himoya vositalari, avtoulov markaidagi shinalar, avtomobil shinalari naqshlari

- Ishni uzatish ishi, mexanik tishli debriyalar qutisi, qo'lda uzatmalar qutisi, foydali maslahatlar

- 206 sedan, orqa nurli peugeot 206-sonli Peugleot 206 nosozligi 206 nosozlik 206

- Qishda dizel yoqilg'isi qishda dizel yoqilg'isini qo'shimchalar, eng yaxshi dizel yoqilg'isini qanday tanlash kerak

- Dizel qish boshlanmaydi. Qishda dizelni qanday boshlash, qishda dizelni isitish.

- Yaponiyaliklar Brideston shinalar, Qishki Bridestrone shinalar, Bridestrone shinalar brendi

- Yengil avtomobillar uchun dekodlashni belgilash, yorliqlar g'ildiraklari, disklardagi to'g'ri shinalarni qanday tanlash

- Qishda dizel dvigateli, qishda dizel dvigatelini ishga tushirish, qishda dizel dvigatelini, foydali maslahatlarni

- Avtomobilning orqa qismini, mashinaning pastki qismidagi orqa chiroq, mashinadagi oyoqlarning orqa qismini, mashinaning eshigidagi orqa chiroq, mashinaning orqa chiroqlari yaxshi

- Tirik shinalar, avtobus shinasi, shinalar himoyachisi, mendan foydalanishim mumkin

- Qish shinalaridagi qish shinalarini tanlang, bu qish shinalari qish shinalari bilan belgilanishi kerak, uning o'ng qish shinalarini qanday tanlash kerak, eng yaxshi qish shinalari 2019

- Relizlar temir yo'llari, rizomni urish, boshqaruv panjarasini taqillatish va ta'mirlash sabablari buni o'zingiz bajaring

- Tushunsiz shinalarni ta'mirlash, to'psiz shinalarni ta'mirlash uchun mo'ljallangan kammsiz mashina shinalar

- Rossiya shinalari, rus shinalari Qish, rossiyalik ruslar, Voronej Amtel shinalar, "Mattador Omsk shinasi", Kama-shinalar dunyo miqyosidagi avtobusdir

- Qanday qilib mashinani kalitsiz ochish kerak. Mashinadan nima qilish kerakligini, mashina ichidagi mashinaning kaliti

- Jim shinalar, qishki qish shinalari, tinchlangan avtobus, bu shinalarni tanlash uchun shinalar

- Shinalar va xavfsizlik, avtobusning xavfsizligi, nega avtoulov shinalarini nazorat qilish kerak

- Avtomobilni yomg'ir yog'ishi va sho'rvalikda xavfsiz haydash qoidalari, yangi yangi boshlanuvchilar uchun xavfsiz haydash

- Zang konvertor, zang konvertorlari, zang transduseridan qanday foydalanishni tanlash uchun yaxshiroq bo'lgan zang konvertori

- Avtoulovning jasadini, o'zingizni o'zingiz bajaring, mushakli pastani qanday tanlash kerak

- Dvigatelning chidamliligi, dvigatel hayoti, qanday qilib dvigatel hayotini qanday uzaytirish kerak

- Mashinani taqillating. Mashinani harakatga kelganda taqillatish. Mashinada nima taqillatishi mumkin. Tayyorlanish sababini qanday aniqlash mumkin.

- ABS avtomobili, ABS avtomobili, ABS tizimining nosozlik, ABS tashxislasi

- Avtomobilni bosib olishni boshlaganingizda, transport qoidalarining qoidalari

- VAZ 2110, VAZ 2110 GAZ SHEMI, VOZ 2110 YUQORI Pompasi qurilmasi, VOZ 2110 benzin stantsiyasi ta'miri,

- Radio, avtoulov antenna qurilmasi uchun avtomatlashtirilgan antenna, avtomat antenna buni o'zingiz qiling

- Front Devetenziya Kalina, Front Free Devetme Kalina, oldingi diskinaga taqillatib, kalinadan osma kalinani ta'mirlash

- Shokning norxerjer yog'i, eng yaxshi neft shokning yutbog'i, moy shokning yutbog'i, qanday qilib yog'ni qanday o'rnidan yog 'urishi mumkin

- Debriyaj nosozliklar, debriyajga tegadi, debriyaj nosozligini keltirib chiqaradi, qanday qilib yo'q qilinadi

Izohlar