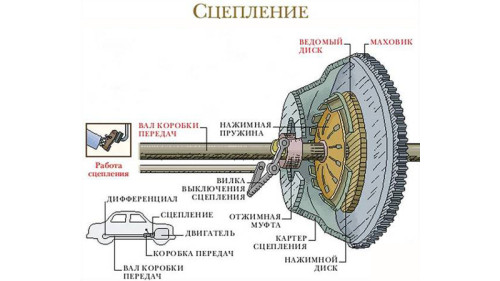

avtomobil qadrlashi avtomobil eng asosiy tarkibiy qismlarining biri hisoblanadi. Uning asosiy maqsadi - bu translyatsiyadan, uzatish va ular translyatsiyalarni almashishda bir-birlari bilan silliq ulanishdir. Avtomobillarni avtomatlashtirish, shuningdek, translyatsiya komponentlarini ortiqcha yuklardan himoya qiladi. Ushbu tarkibiy element motor va PPC o'rtasida joylashgan.

Tarkib

Debriyaj apparati, avtoulovli avtoulov

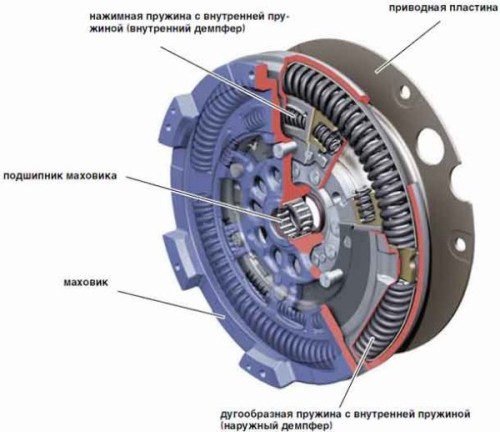

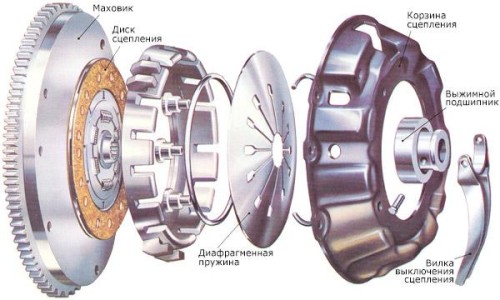

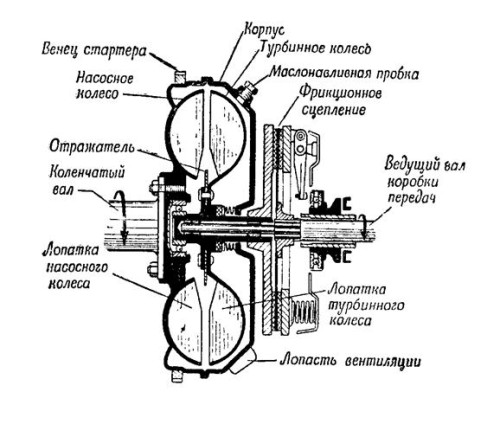

Debriyaj elementlari:

- PPP va birinchi navbatda.

- Motorli planel.

- Chaqirilgan vilka.

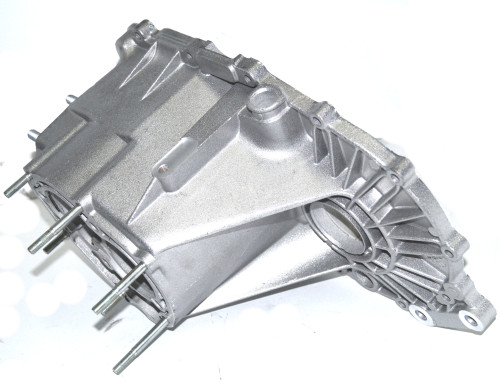

- Karter nazorat punkti.

- O'tkazgichlarni aylantiring.

- Tishli uzatmalar qutisi.

- Qabul qilish.

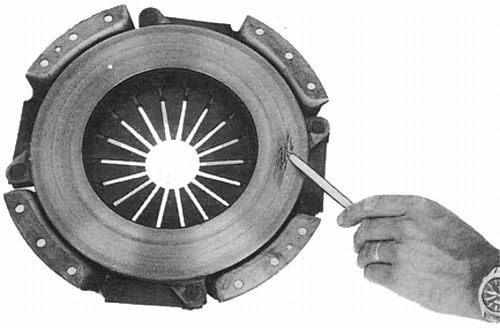

- Bosimli disk.

- Springs.

- Debriyaj korxonasi.

- Karter debriyaj.

moslamaning maqsadi tushunish uchun, siz "trafik" kabi bir tushuncha bilan, mexanizmi ishlashini solishtirish kerak. Agar vosita volanı bevosita Haydovchilik etakchi ko'prik ulangan tasavvur bo'lsa, keyin motor boshladi bo'lsa, avtomobil, darhol borish kerak. Shunga ko'ra, mashina to'xtatish uchun, vosita chiqib g'arq kerak. Bu harakat boshida vosita energiya olish yoki stop avtomobil uchun bu jarayonni to'xtatish imkonini beradi tushunish oladi, deb, bu uchun.

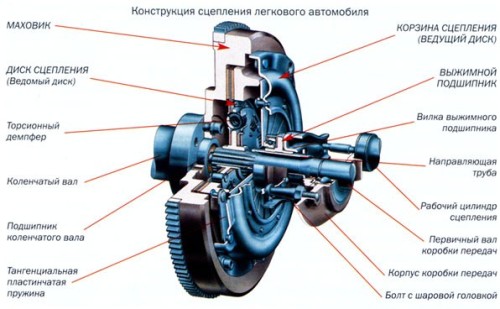

mumtoz, ogohlik bandasi va bosim disklar, shuningdek, bir-biri bilan ularni bosing yoki tugatish qiladi bir diskda iborat. Bu dizayn mustahkam tirsakli val volanı biriktirilgan Koson, belgilab qo'yilgan. Maqsad disk juda katta va ham mustahkam mahfaza biriktirilgan bo'ladi. Bu qul disk ko'p xushqomat va CAT avtomobil asosiy (birlamchi) mil uyalariga joylashgan ta'kidlash joiz. Uyalar, bir milga bir qattiq mash'um uchun, shuningdek, mil o'qi bo'ylab uning harakat ta'minlash uchun mas'ul bo'lgan. bosim diskda kelsak, u bir transmissiya bilan bunday kechgacha yo'q.

standart operatsion holatida, bosim va gijgijlash disklari qizlar bilan kuchli kamon yordamida va daxli qanchasi bir-biriga bosdi etiladi. Binobarin, bu disklar orasidagi ishqalanish kuchi natijasida, bir moment volanı dan postida asosiy mil uzatiladi. Agar qul bosimi disk olib bo'lsa, moment, vosita va milya bilan qul disk aylanish bekor dan kesiladi.

disklari ajratish o'z turiga bilan bolalar salıncaklar o'xshaydi bir ogohlik vilkasini yordamida amalga oshiriladi. vilka o'zi kabinasida joylashgan qo'llarini zanjirining va debriyajı, faol bo'ladi.

vosita ishga tushirish oldin, avtomobilchi tortish tomonidan rozetkasi bo'yicha harakat va qarama-qarshi tomondan ham markazga nisbatan ko'chib o'tishga uning qarama-qarshi uchlari majbur debriyajı bosadi. rozetkasi oqibati qo'llarini orqali bosim diskda bosim bor buloq qiladi, relizlar to'shak, bosim qo'yadi. ikkinchisi moment uzatish kesadi qul disk, ajratilgan. Natijada, debriyaj o'tdim siqib, vosita va faqat Volan hajda, yugurib edi. harakat boshlash uchun, u silliq vilkasi navbatida, qizlar bosim yumshatish bo'ladi, bosim to'shak, uning ta'sir ta'minlash uchun to'xtaydi nega tushunish, ozod qilish uchun zarur. So'ngra buloq bandasi va bosim disklar volanı qo'shiladi qaysi natijasida, siqish boshlaydi. qul haydash mahkam uzatmalar qutisi birlamchi mil uyalariga biriktirilgan ekan, motor dan moment haydash g'ildiraklar uzatish uzatiladi qilinadi va avtomobil harakat boshlanadi.

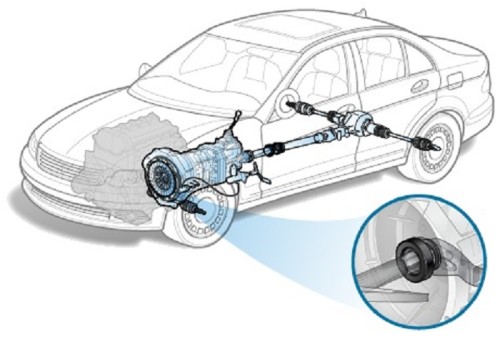

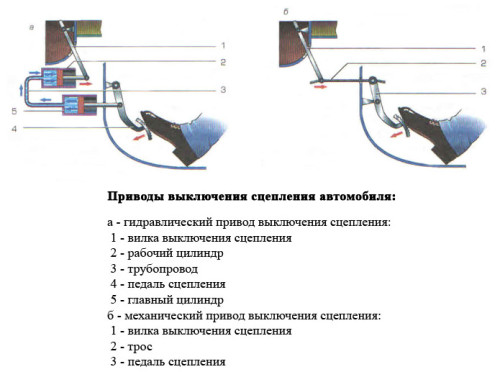

gidravlik va mexanik - Bu, tushunish diskda ikki xil bo'ladi, deb ta'kidlash lozim. mexanik versiya avtomobil qadrlashi ishida eng oson bo'ladi. Bu holda, mototsikl, o'tdim tugmasini bosib, surish va kabel orqali yopishish sanchqiga ta'sir bor. gidravlik variant suyuq bilan bo'lgan piston beradi. Eng tez-tez u haydovchilik faoliyatiga ko'maklashish uchun og'ir yuk mashinalari ishlatiladi.

Nima avtomobil bir grip, yo'lovchi va yuk avtomobillari uchun changalidan tasnifi

elektromagnit, ishqalanish va gidravlik - ogohlik dizayni qarab, bunday turlari bor.

ishqalanish, tushunish variant ishqalanish kuch yordamida Turk uzatish amalga oshiradi. elektromagnit turlarining yopishish bir magnit maydon tomonidan nazorat qilinadi. gidravlik tartibga solishga, aloqa bir suyuqlik xar bilan taqdim etiladi.

tushunish ishqalanish turi eng keng tarqalgan. disklar soniga qarab, ishqalanish tushunish kabi turlari ajralib turadi - bir nechta disk, bir-parcha va ikki-disk.

tushunish, ho'l va quruq bo'ladi. quruq moslama, u quruq ishqalanish ishlash disklar bilan qabul qilinadi. Nam, tushunish suyuqlik ichida disklar ishlashini o'z ichiga oladi.

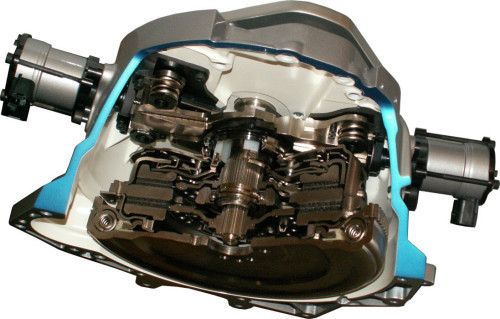

qoida tariqasida, zamonaviy avtomobillar quruq bitta-o'lchamli ogohlik bilan jihozlangan. moslamaning barcha komponentlar murvat bilan dvigateli ilova qilinadi karterine, joylashgan.

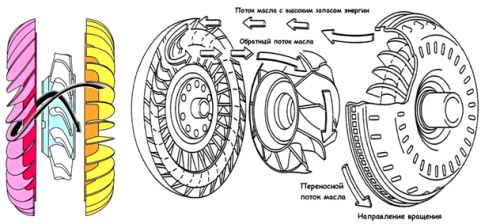

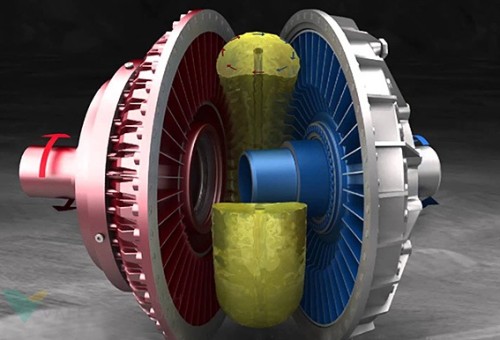

Gidravlik, ogohlik. aylanma Ayni uzatish etakchi va qul komponentlar orasidagi aylanayotgan gidravlik, ogohlik, deyiladi suyuqlik va gidrodinamik bosim tomonidan amalga oshiriladi Hydromefta.

u ancha tishli Shift qiyinlashtiradi mutlaq yopish, ta'minlash imkoniga ega emas, chunki Hydromefta, mustaqil ogohlik kabi transport vositalari haqida amal qilmaydi. hydrumufts qo'llash natijasida, bir ishqalanish, tushunish faqat tishli kommutatsiya uchun mo'ljallangan bo'lib, u bilan o'rnatilgan. Shu bilan bir vaqtda, yumshoq va plastik bosim buloq osonroq tushunish o'chirishingiz qiladi ishqalanish moslamasining, o'rnatilgan etiladi.

Elektromagnit grip. etakchi va qul elementlar siqish elektromagnit kuchlari orqali amalga oshiriladi, agar grip elektromagnit hisoblanadi. Elektromagnit tushunish, ochiq holatda doimo bo'ladi.

kuchli motor bilan yuk va yo'lovchi tashish vagonlarini doimiy hajmi bilan, tarjimalar sezilarli darajada katta moment, shuningdek, ancha katta qurilish resurs beradi, ikki diskli, tushunish bilan jihozlangan. Bu joylashgan o'rtasida, ikki qul disklar foydalanish orqali erishiladi. Natijada, to'rt ishqalanish yuzalar olingan.

Qadrlashi nosozliklar, tushunish, ishlamay belgilari

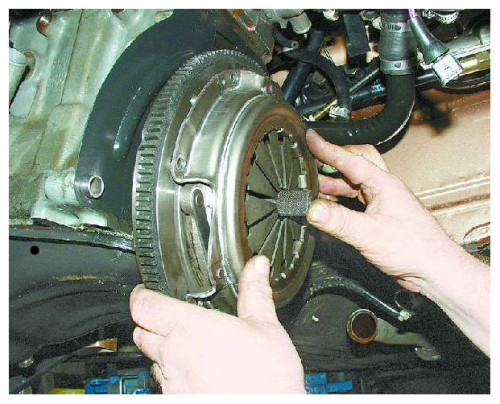

- qadrlashi to'liq silliqlash yoki qul disk yigirish kolodkalari, buloqlar, pedal insult qoniqarsiz kattaligi birikib, eskirish natijasida ( "emicilere"), shu jumladan, emas. , Qul disk o'rniga, Bu, bir ishlamay bartaraf disklar ustida disklari olib tashlash uchun, buzuq disk tugunlari o'zgartirish.

- qadrlashi to'liq juda katta bepul tushunish, yugurish, bir buloq parchalanishi, qul disk ogohlantirish yoki bosim diskda bir nodavlat mos joylashishni natijasida ( "olib") o'chirilgan emas. Bu, ogohlik arızalanmasına bartaraf etish, havo gidravlik diskda ko'tarilishi kerak, non-ish disklari va buloqlar o'rniga, bosib o'tdim bepul insult rostlash.

- tormoz suyuqligi asosiy va ishchi ballon dan, shuningdek, bog'lovchi quvurlar mumkin, ogohlik yopish qurilmasi bilan mos keladi. bunday noto'g'ri bartaraf qilish ingl oqish o'rnini topish va keyin butunlay gidravlik qurilma urishi, yangi buzuq tugunlari o'zgartirish.

Maslahatlar Profi, qanday qilib, tushunish buzilmaydi uchun

Yuqorida muhokama qilingan debriyaj nosozlarini oldini olish uchun, oddiy ishlash qoidalariga rioya qilish kifoya. qadrlashi faoliyat bo'lsa, u vaqti-vaqti bilan idishda tormoz suyuqlik darajasini tekshirish uchun zarur. Agar darajasi normadan past bo'lsa, uni tiklashga ishonch hosil qiling.

Tormoz suyuqligining pasayishi yoki noto'g'ri debriyaj rossiyasining pasayishi, sizning avtoulovingizdagi uzatish umuman yoqish yoki to'xtatish qiyin bo'lishiga olib keladi. Harakatlanayotganda, haydovchi doimiy ravishda siqib chiqarishi va bosim diskining yuzasini siqib chiqarishi kerak, bu esa bosimli pedani chiqaradi, natijada vaqt o'tishi bilan, vaqt o'tishi bilan qul diskining eskirishi. Bu avtomobilni dizayni bilan ta'minlanadigan oddiy jarayon. Har qanday mashina o'zingizga e'tibor beradi. O'rtilgan diskning to'g'ri ishlashi bilan o'rtacha 80 ming kilometr haydashdan keyin zarbani almashtirish kerak.

Tegishli materiallar

- 2110, 2110, VOZ 2110 Isitish tizimini ta'mirlash, o'z qo'llari bilan VOZ 2110 isitish tizimini ta'mirlash

- VOZ 2114 pechkasi sovuq havo bilan, pech 2114, yomon iliq va 1014 isitgichni ta'mirlash va "Vaz 2114" ni olib tashlaydi

- Qanday qilib mashinani quyish kerak. Jekni qanday qo'yish kerak. Avtomobillar uchun jakka turlari.

- Vaz 2109 sug'urta bloki, Vaz 2109 sug'urta bloklari, Vaz 2109 sug'urta bloki, Vaz 2109 sug'urta blushida Vaz 2109 sug'urta bluslari

- Avtomobil chiqindi gaz katalizat, noto'g'ri katalizator, Baliqli katalizator, pog'onadagi samolyotning katalizatorini qanday o'zgartirish mumkin

- Sovuq havo va 2114, pechka 2114, nima uchun pechk 2114 pechni 2114 yog 'bilan urayotganini pechka

- Avtomobilning egasini mashinasi soniga qanday aniqlash mumkin, avtomashinani harakat politsiyasining soni bo'yicha tekshirib turing, avtoulovning davlat raqami bilan avtoulovni bepul tekshiring

- Ishlatilgan shinalar, foydali maslahatlarni qanday tanlash kerak

- Qishki avtomobil yo'li, qishda yo'lovchi avtomobil shinalaridagi bosim, qishda mashina uchun yaxshi batareya, qishda mashinani yaxshi isitish

- Qishda, mashina yomon boshlangan. Qishda mashinani qanday qilish kerak, qishda mashinani isitishingiz kerakmi?

- Iqtisodiyotni yoqish uchun sarflash mashinalari, eng tejamkor avtomobil iste'moli

- Chiruvchilarga yo'lovchilar uchun shinalar brendlari, avtomobil shinalarini yorliqlash, qoldiq yo'lovchilar uchun plastik himoya vositalari, avtoulov markaidagi shinalar, avtomobil shinalari naqshlari

- Ishni uzatish ishi, mexanik tishli debriyalar qutisi, qo'lda uzatmalar qutisi, foydali maslahatlar

- 206 sedan, orqa nurli peugeot 206-sonli Peugleot 206 nosozligi 206 nosozlik 206

- Qishda dizel yoqilg'isi qishda dizel yoqilg'isini qo'shimchalar, eng yaxshi dizel yoqilg'isini qanday tanlash kerak

- Dizel qish boshlanmaydi. Qishda dizelni qanday boshlash, qishda dizelni isitish.

- Yaponiyaliklar Brideston shinalar, Qishki Bridestrone shinalar, Bridestrone shinalar brendi

- Yengil avtomobillar uchun dekodlashni belgilash, yorliqlar g'ildiraklari, disklardagi to'g'ri shinalarni qanday tanlash

- Qishda dizel dvigateli, qishda dizel dvigatelini ishga tushirish, qishda dizel dvigatelini, foydali maslahatlarni

- Avtomobilning orqa qismini, mashinaning pastki qismidagi orqa chiroq, mashinadagi oyoqlarning orqa qismini, mashinaning eshigidagi orqa chiroq, mashinaning orqa chiroqlari yaxshi

- Tirik shinalar, avtobus shinasi, shinalar himoyachisi, mendan foydalanishim mumkin

- Qish shinalaridagi qish shinalarini tanlang, bu qish shinalari qish shinalari bilan belgilanishi kerak, uning o'ng qish shinalarini qanday tanlash kerak, eng yaxshi qish shinalari 2019

- Relizlar temir yo'llari, rizomni urish, boshqaruv panjarasini taqillatish va ta'mirlash sabablari buni o'zingiz bajaring

- Cameless Avtomobil shinalar, tubeless shinalari ta'mirlash uchun bir to'siq, to'p-bepul buzilib ta'mirlash o'zingiz

- Rossiya shinalari, rus shinalari Qish, rossiyalik ruslar, Voronej Amtel shinalar, "Mattador Omsk shinasi", Kama-shinalar dunyo miqyosidagi avtobusdir

- Qanday qilib mashinani kalitsiz ochish kerak. Mashinadan nima qilish kerakligini, mashina ichidagi mashinaning kaliti

- Jim shinalar, qishki qish shinalari, tinchlangan avtobus, bu shinalarni tanlash uchun shinalar

- Shinalar va xavfsizlik, avtobusning xavfsizligi, nega avtoulov shinalarini nazorat qilish kerak

- Avtomobilni yomg'ir yog'ishi va sho'rvalikda xavfsiz haydash qoidalari, yangi yangi boshlanuvchilar uchun xavfsiz haydash

- Zang konvertor, zang konvertorlari, zang transduseridan qanday foydalanishni tanlash uchun yaxshiroq bo'lgan zang konvertori

- Avtoulovning jasadini, o'zingizni o'zingiz bajaring, mushakli pastani qanday tanlash kerak

- Dvigatelning chidamliligi, dvigatel hayoti, qanday qilib dvigatel hayotini qanday uzaytirish kerak

- Mashinani taqillating. Mashinani harakatga kelganda taqillatish. Mashinada nima taqillatishi mumkin. Tayyorlanish sababini qanday aniqlash mumkin.

- ABS avtomobili, ABS avtomobili, ABS tizimining nosozlik, ABS tashxislasi

- Avtomobilni bosib olishni boshlaganingizda, transport qoidalarining qoidalari

- VAZ 2110, VAZ 2110 GAZ SHEMI, VOZ 2110 YUQORI Pompasi qurilmasi, VOZ 2110 benzin stantsiyasi ta'miri,

- Radio, avtoulov antenna qurilmasi uchun avtomatlashtirilgan antenna, avtomat antenna buni o'zingiz qiling

- Front Devetenziya Kalina, Front Free Devetme Kalina, oldingi diskinaga taqillatib, kalinadan osma kalinani ta'mirlash

- Shokning norxerjer yog'i, eng yaxshi neft shokning yutbog'i, moy shokning yutbog'i, qanday qilib yog'ni qanday o'rnidan yog 'urishi mumkin

- Debriyaj nosozliklar, debriyajga tegadi, debriyaj nosozligini keltirib chiqaradi, qanday qilib yo'q qilinadi

Izohlar