Mutaxassis va dvigatelning normal ishlashi yonish lahzasini belgilashning to'g'riligiga bog'liq. Shuning uchun ushbu tadbir elektr stantsiyasini sozlash bo'yicha eng muhim jarayonlardan biridir. Aslida, darhol avtoturarmaning ishlashiga salbiy ta'sir ko'rsatishi mumkin. Shuning uchun, bu operatsiya kech yoki erta yonishning oldini olish uchun maxsus triklash va e'tibor bilan bog'liq bo'lishi kerak. Bu haqda maqolada.

Tarkib

- Avtomatik, qurilma va printsipga e'tibor berish

- Erta va keyinchalik yonish nima degani

- Erta yonish belgilari

- Kechikkanlik belgilari

- Yonish burchagi, yonishning tartibsiz burchagi belgilari

- Avant burchagi o'zgarishi, bu noto'g'ri ateşleme bilan avtomobilning ishlashining oqibatlari

- Atish jarayoni qanday bo'lishi kerak va burchakni bo'sh joyni sozlashi kerak

- Siz foydalanadigan stroboskop

- Strobe uchun yoqish, bosqichma-bosqich ko'rsatma

- Boshqaruv chiroqiga ateşleme o'rnatish

- Dvigatelning ishlashi nuqtai nazaridan Spark-da yoqilgan

- Profil Profi, Avans Avans Awece burchakli sozlash (UAZ) sifatini qanday tekshirish mumkin

Avtomatik, qurilma va printsipga e'tibor berish

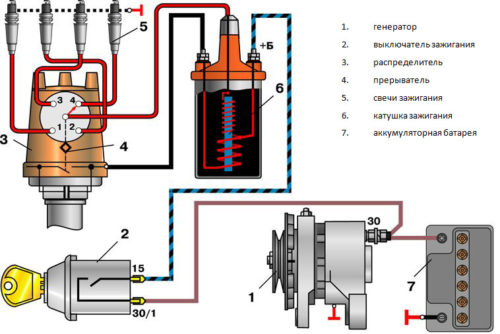

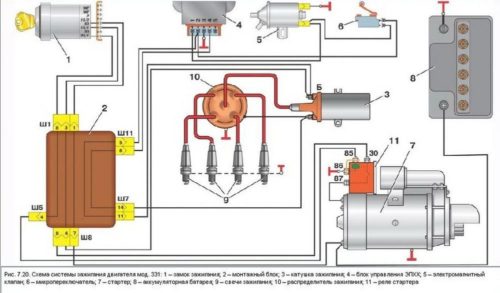

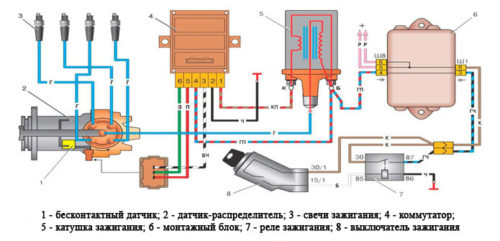

Gaziatsiya tizimining maqsadi benzinli dvigatelining havo yoqilg'ining yonishi haqidagi o'limi. Aralashmaning yonishi uchqundan amalga oshiriladi, shuning uchun boshqa tizim, shuningdek, Spark-reyting tizimi deb nomlanadi. Agange jarayonini boshqarish usuliga qarab, ateşleme tizimlari - elektron (mikroprosessor), aloqada bo'lmagan (tranzistor), kontaktlar mavjud.

Kontakt tizimida to'planishni boshqarish tizimi, shuningdek, silindrlar ustidan elektr energiyasini taqsimlash mexanik qurilma - distribyutorning distribyutori yordamida amalga oshiriladi. Ushbu ateşentsiya tizimining keyingi rivojlanishi tranzistor aloqa tizimi, yonish tugmachasini o'z ichiga olgan birlamchi zanjir edi.

Aloqa tizimiga nisbatan, kontaktsiz yondashuv tizimida, tranzistor kaliti aloqasiz pulse sensori bilan o'zaro ta'sir qiladigan energiya to'plashni boshqarish uchun ishlatiladi. Ushbu tizimdagi tranzistor kalitionni buzuvchi rolini o'ynaydi. Yuqori kuchlanish oqimining taqsimlanishiga kelsak, u mexanik distribyutor yordamida amalga oshiriladi.

Elektron boshqaruv birligi elektr energiyasini to'plash va taqsimlash nazorati olib boriladi. Ushbu tizimning dastlabki tuzilmalarida, bir vaqtning o'zida yoqilg'i in'ektsiya tizimini va ateşleme tizimini (elektron lashim va in'ektsiya deb atash deb atash) bilan bir vaqtda elektron blok. Bugungi kunga qadar yonish boshqarmasi dvigatelni boshqarish tizimiga kiritilgan.

Biroq, tarkibiy farqlarga qaramay, siz qo'shma shamollatish tizimini tanlashingiz mumkin:

- Spark vilkasi.

- Yuqori kuchlanishli simlar.

- Energiyani taqsimlash moslamasi (elektron boshqaruv birligi yoki mexanik distribyutor).

- Energiyani saqlash (i.e ga yoqish zimmasi).

- Energiya to'planishini boshqaradigan qurilma (turli yonish tizimlarida, bu rol elektron boshqaruv birligi, tranzistor almashtirish yoki o'zaro bog'liqlikni amalga oshiradi).

- Ateşleme kaliti.

- Elektr ta'minoti (batareya va avtomobil generatori).

Geganing tizimining ishlashi quyidagi bosqichlarni ta'minlaydi:

- Elektr energiyasini to'plash.

- Energiya konversiyasi.

- Ushbu energiyani taqsimlash.

- Uchqunlarning shakllanishi.

- Havo yoqilg'isi aralashmasining yallig'lanishi.

Erta va keyinchalik yonish nima degani

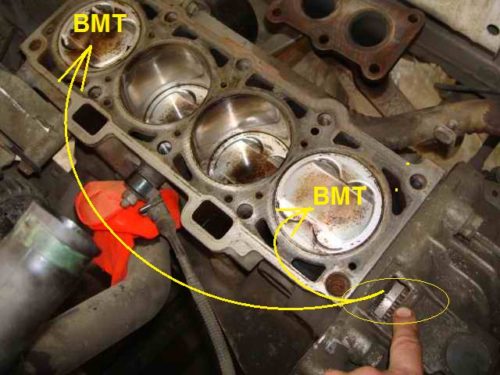

Erta yonish, pistonning pozitsiyasiga kelguniga qadar dizel yoqilg'isining yonishi tugashi bilan ajralib turadi. Loop ichidagi maydon, salbiy ish bilan bog'liq bo'lgan ekvivalent hisoblanadi. Va bu gazlarning siqilishi paytida yonish jarayoni, uning kengayishidan keyin paydo bo'lgandan ko'ra ko'proq kuch sarflaganligi sababli.

Keyinchalik ateşleme - bu ertadan kamroq xavflidir. Uning asosiy xususiyati shundaki, aralashmaning yonish protsedurasi baland ovoz ostida va tsilindrda bosim darajasida amalga oshiriladi. Bunday vaziyatda, silindrli izlar uzatilgan jarayonda aralashma.

Erta yonish belgilari

- Haddan tashqari portlash (novdalar, piston nuqsonlarini yo'q qilish).

- Quvvat birligida yaxshi ovozli taqillatilgan (ko'tarilgan kiyim).

- Yoqilg'i sarfini ko'paytirish.

- Quvvat yo'qotish (ayniqsa kichik inqiloblarda sezilarli).

Kechikkanlik belgilari

- Dvigatel qizdirish (uni kuchaytirishi mumkin).

- Yoqilg'i sarfini ko'paytirish.

- Yomon boshlanish (natijada batareya azoblanadi).

- Quvvat yo'qotish.

Yonish burchagi, yonishning tartibsiz burchagi belgilari

- Portlash.

- Karbonatorda yoki salfonda tortishish.

- Haddan tashqari qizib ketish.

- Gaz pedaliga bosilganda cho'kadi.

- Zaif bo'sh.

- Quvvat darajasini pasaytirish va pikap.

- Yoqilg'i sarfini ko'paytirish.

- Boshlanish bilan bog'liq muammolar.

Avant burchagi o'zgarishi, bu noto'g'ri ateşleme bilan avtomobilning ishlashining oqibatlari

Juda erta yoki keyinchalik ateşleme - bu dvigatelning normal ishlashi tugallanganligi simptomidir. Motor kerakli kuchni berish uchun silindrning uchquni silindrda siqilgan holda siqilgan butunlay mustahkamlikning butun kuchi maksimal darajada ishlatilishi mumkin.

Agar siz keraksiz vaqtni keraksiz ravishda oldingizda yuborsangiz, muvofiqlik inobatga olinmasa yoki juda erta (bu holda, energiyaning ma'lum bir qismi pistonning ma'lum bir qismi) yoki juda kech (bu holatda ma'lum bir qismi) Energiya egzoz quvuri tomonidan chiqariladi). Shu sababli, mashina egasi erta va kechakni atdirlik alomatlari, shuningdek ushbu hodisaning paydo bo'lishining oldini olishga majburdir.

Atish jarayoni qanday bo'lishi kerak va burchakni bo'sh joyni sozlashi kerak

Avans Avans burchagi maqbul bo'lishi kerak, ya'ni erta emas va kech emas. Ichki yoqish lahzasini sozlash quyidagicha (dvigatel, bir vaqtning o'zida isitilishi kerak):

- Trimer tanasini tuzatadigan yong'oqni zaiflashtiring, shundan keyin u asta-sekin turli tomonlarga aylana boshlaydi.

- Motor parborotini maksimal darajada amalga oshiradigan holatda, siz "to'lashga" harakat qilishingiz kerak. Agar pedalning keskin bosish paytida hech qanday zarba, paxta va uzilishlar bo'lmaydi va ayozlar tez tezlashadilar, bu kerakli pozitsiya topilishini anglatadi.

- Shu nuqtada, bir yoki ikki daraja soat yo'nalishi bo'yicha bir yoki ikki darajani tekshiring va keyin uni ushlab turuvchini mahkamlang. So'nggi elementni yoqish juda "erta" emasligini ta'kidlash kerak, natijada bu krankshrafning aylanishiga haddan tashqari qarshilik paydo bo'ladi.

Siz foydalanadigan stroboskop

Avtoulov strobi asosiy maqsadi yonish avans burchagini sozlashdir. Bundan tashqari, stroboskoplar oldinga burchakni tekshirish uchun ishlatiladi. Bizning zamonamizda biz professional avtomobilsozlik stroboskoplari ko'p turamiz. Biroq, o'zini o'zi tayyorlamaydigan qurilma tuzilishi mumkin.

Strobe uchun yoqish, bosqichma-bosqich ko'rsatma

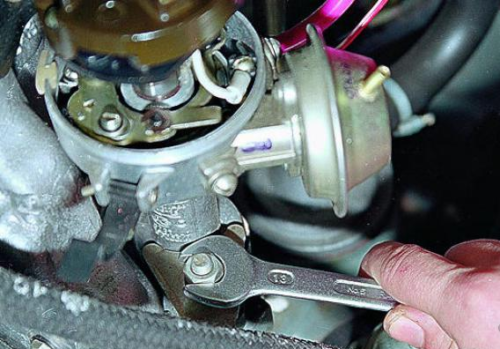

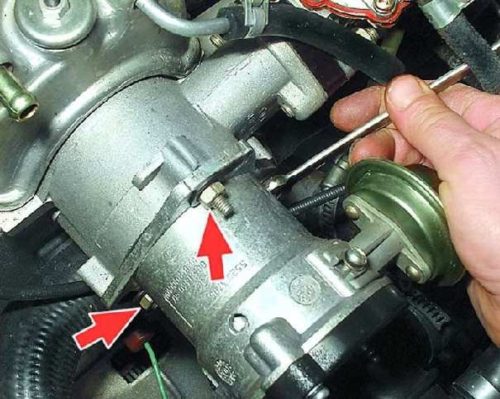

- Birinchidan, "13" tugmachasini bosib, biz yonish tarqalishidagi cho'zish yong'og'ini susaytirishimiz kerak.

- Keyin, biz batareyani batareyaga "plyus" terminaliga ulaymiz (ortiqcha belgi bilan) va biz "minus" terminaliga massani bog'laymiz.

- Agar tizim vakuumning takroriy regulyator bo'lsa, bu siz vakuum shlangini qismlarga ajratish kerakligini anglatadi.

- Keyin qurilmadan kasri chiroqiga e'tibor qaratishingiz kerak.

- Endi elektr stantsiyasi ishga tushirilishi va daqiqada taxminan 820-900 insultlar sonini ta'minlash kerak.

- Ish jarayonida strobe ushbu chastotada flesh chiroqlarni chiqaradi, bu sizga harakatlanmaydigan kasrga qarab turishga imkon beradi.

- Shundan so'ng, kassirda o'rtacha diniga teng bo'lgan tartibda dispenser korpusini o'rash kerak.

- Xo'sh, qilish kerak bo'lgan oxirgi narsa - bu dispenserning uzluksiz yong'og'ini mahkamlash.

Boshqaruv chiroqiga ateşleme o'rnatish

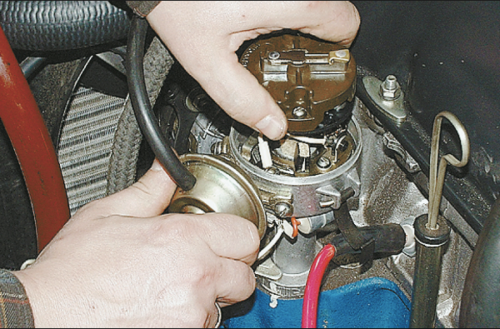

- Biz krankshrafni kasr yorlig'i bilan belgilangan yorliqqa to'g'ri keladigan tarzda aylantiramiz va ateşlementsiya operatori birinchi tsilindrning yuqori kuchlanishli simini ko'rsatdi.

- Keyinchalik siz trimmer tanasini tuzatadigan yong'oqni zaiflashtirishingiz kerak.

- Keyin Boshqarish chiroqining bir simlari simga ulangan, bu qulevner va boshqa birovning yonidagi "massa" dan "boshqa" dan "massa" ga o'tadi.

- Ateşleme qo'shganingizga ishonch hosil qiling.

- Shundan so'ng, karderning zanjirini soat yo'nalishi yo'nalishi yo'nalishi bilan aylantiring.

- Keyin sekin kauchukni boshqa tomonga, ya'ni soat miliga teskari tomonga burang.

- Boshqarish chiroqining yonishi qayerdan burilgan karverning o'rnini tuzating.

- Dispenserning mahkamlashiga to'sqinlik qilish.

Dvigatelning ishlashi nuqtai nazaridan Spark-da yoqilgan

- Biz krankshrafni kasr yorlig'i bilan belgilangan yorliqqa to'g'ri keladigan tarzda aylantiramiz va ateşlementsiya operatori birinchi tsilindrning yuqori kuchlanishli simini ko'rsatdi.

- Keyinchalik, yong'oqni buzish bilan bog'liq yong'oqni susaytirishingiz kerak.

- Tumber qopqog'idan markaziy yuqori kuchlanishli simni olib tashlang va uning kontaktining massas massasidan besh millimetr masofada joylashgan.

- Yoqishni yoqing.

- Vaqt-soatlik burilish jismini yigirma darajaga aylantiring.

- Sekin ikkinchisini boshqa tomonga aylantiring.

- Qo'qonning o'rnini tuzating, unda Markaziy simning massasi va aloqasi bor.

- Bog'lanish yong'oqini torting.

Profil Profi, Avans Avans Awece burchakli sozlash (UAZ) sifatini qanday tekshirish mumkin

Kontaktlarning avans to'g'ri sozlanganligini tekshirish uchun, siz quyidagi xususiyatlarga ega bo'lishingiz kerak:

- Issiqlik elektr blokining ishida, bekor qilinganda "muvaffaqiyatsizliklar" ni sezmaslik kerak.

- Agar benzin pedalida keskin portlash (taxminan 3-5 soniya) bo'lsa, harakatning hatto to'rtinchi tishli va soatiga 50 kilometr tezlikda harakatning eng ko'p qismida harakat bo'lishi kerak. Ya'ni barmoqlar urishi eshitilishi kerak. Agar bu sodir bo'lmasa, unda atash juda kech. Agar bu hodisa kuzatilgan bo'lsa, lekin u o'tmasa, yonboshi juda erta.

Tegishli materiallar

- 2110, 2110, VOZ 2110 Isitish tizimini ta'mirlash, o'z qo'llari bilan VOZ 2110 isitish tizimini ta'mirlash

- VOZ 2114 pechkasi sovuq havo bilan, pech 2114, yomon iliq va 1014 isitgichni ta'mirlash va "Vaz 2114" ni olib tashlaydi

- Qanday qilib mashinani quyish kerak. Jekni qanday qo'yish kerak. Avtomobillar uchun jakka turlari.

- Vaz 2109 sug'urta bloki, Vaz 2109 sug'urta bloklari, Vaz 2109 sug'urta bloki, Vaz 2109 sug'urta blushida Vaz 2109 sug'urta bluslari

- Avtomobil chiqindi gaz katalizator, noto'g'ri katalizator, plitalizator va katalizatorning saldosini qanday o'zgartirish mumkin

- Sovuq havo va 2114, pechka 2114, nima uchun pechk 2114 pechni 2114 yog 'bilan urayotganini pechka

- Avtomobilning egasini mashinasi soniga qanday aniqlash mumkin, avtomashinani harakat politsiyasining soni bo'yicha tekshirib turing, avtoulovning davlat raqami bilan avtoulovni bepul tekshiring

- Ishlatilgan shinalar, foydali maslahatlarni qanday tanlash kerak

- Qishki avtomobil yo'li, qishda yo'lovchi avtomobil shinalaridagi bosim, qishda mashina uchun yaxshi batareya, qishda mashinani yaxshi isitish

- Qishda, mashina yomon boshlangan. Qishda mashinani qanday qilish kerak, qishda mashinani isitishingiz kerakmi?

- Iqtisodiyotni yoqish uchun sarflash mashinalari, eng tejamkor avtomobil iste'moli

- Chiruvchilarga yo'lovchilar uchun shinalar brendlari, avtomobil shinalarini yorliqlash, qoldiq yo'lovchilar uchun plastik himoya vositalari, avtoulov markaidagi shinalar, avtomobil shinalari naqshlari

- Ishni uzatish ishi, mexanik tishli debriyalar qutisi, qo'lda uzatmalar qutisi, foydali maslahatlar

- 206 sedan, orqa nurli peugeot 206-sonli Peugleot 206 nosozligi 206 nosozlik 206

- Qishda dizel yoqilg'isi qishda dizel yoqilg'isini qo'shimchalar, eng yaxshi dizel yoqilg'isini qanday tanlash kerak

- Dizel qish boshlanmaydi. Qishda dizelni qanday boshlash, qishda dizelni isitish.

- Yaponiyaliklar Brideston shinalar, Qishki Bridestrone shinalar, Bridestrone shinalar brendi

- Yengil avtomobillar uchun dekodlashni belgilash, yorliqlar g'ildiraklari, disklardagi to'g'ri shinalarni qanday tanlash

- Qishda dizel dvigateli, qishda dizel dvigatelini ishga tushirish, qishda dizel dvigatelini, foydali maslahatlarni

- Avtomobilning orqa qismini, mashinaning pastki qismidagi orqa chiroq, mashinadagi oyoqlarning orqa qismini, mashinaning eshigidagi orqa chiroq, mashinaning orqa chiroqlari yaxshi

- Tirik shinalar, avtobus shinasi, shinalar himoyachisi, mendan foydalanishim mumkin

- Qish shinalaridagi qish shinalarini tanlang, bu qish shinalari qish shinalari bilan belgilanishi kerak, uning o'ng qish shinalarini qanday tanlash kerak, eng yaxshi qish shinalari 2019

- Relizlar temir yo'llari, rizomni urish, boshqaruv panjarasini taqillatish va ta'mirlash sabablari buni o'zingiz bajaring

- Tushunsiz shinalarni ta'mirlash, to'psiz shinalarni ta'mirlash uchun mo'ljallangan kammsiz mashina shinalar

- Rossiya shinalari, rus shinalari Qish, rossiyalik ruslar, Voronej Amtel shinalar, "Mattador Omsk shinasi", Kama-shinalar dunyo miqyosidagi avtobusdir

- Qanday qilib mashinani kalitsiz ochish kerak. Mashinadan nima qilish kerakligini, mashina ichidagi mashinaning kaliti

- Jim shinalar, qishki qish shinalari, tinchlangan avtobus, bu shinalarni tanlash uchun shinalar

- Shinalar va xavfsizlik, avtobusning xavfsizligi, nega avtoulov shinalarini nazorat qilish kerak

- Avtomobilni yomg'ir yog'ishi va sho'rvalikda xavfsiz haydash qoidalari, yangi yangi boshlanuvchilar uchun xavfsiz haydash

- Zang konvertor, zang konvertorlari, zang transduseridan qanday foydalanishni tanlash uchun yaxshiroq bo'lgan zang konvertori

- Avtoulovning jasadini, o'zingizni o'zingiz bajaring, mushakli pastani qanday tanlash kerak

- Dvigatelning chidamliligi, dvigatel hayoti, qanday qilib dvigatel hayotini qanday uzaytirish kerak

- Mashinani taqillating. Mashinani harakatga kelganda taqillatish. Mashinada nima taqillatishi mumkin. Tayyorlanish sababini qanday aniqlash mumkin.

- ABS avtomobili, ABS avtomobili, ABS tizimining nosozlik, ABS tashxislasi

- Avtomobilni bosib olishni boshlaganingizda, transport qoidalarining qoidalari

- VAZ 2110, VAZ 2110 GAZ SHEMI, VOZ 2110 YUQORI Pompasi qurilmasi, VOZ 2110 benzin stantsiyasi ta'miri,

- Radio, avtoulov antenna qurilmasi uchun avtomatlashtirilgan antenna, avtomat antenna buni o'zingiz qiling

- Front Devetenziya Kalina, Front Free Devetme Kalina, oldingi diskinaga taqillatib, kalinadan osma kalinani ta'mirlash

- Shokning norxerjer yog'i, eng yaxshi neft shokning yutbog'i, moy shokning yutbog'i, qanday qilib yog'ni qanday o'rnidan yog 'urishi mumkin

- Debriyaj nosozliklar, debriyajga tegadi, debriyaj nosozligini keltirib chiqaradi, qanday qilib yo'q qilinadi

Izohlar