Each owner of the vehicle, regardless of its brand and dimensions, is certainly aware of what a significant role will play shock absorbers in the design of the car. Their main tasks are the trimming of the suspension vibration, increasing control of controllability by road, improving the contact of the wheels with the roadpapers. Shock absorbers, exactly as any other parts of the car require careful and careful relationship, systematic service, careful selection, as well as the right installation. About this further in the article.

Content

- Shock absorbers for what they need and where they are installed

- What oil shock absorbers are better

- Pumping the shock absorber, why need to pump the shock absorber before installing

- Pumping shock absorber, general rules for pumping

- Pumping oil shock absorbers, how to make oil shock absorbers

- Tips Prof.

Shock absorbers for what they need and where they are installed

The vehicle during overclocking "cries" back, unloading the front and loading rear wheels, which reduces their grip with a road surface. When braking, the other way around. Both in the first and in the second case, it would be ideal for the position at which the machine would retain their normal "horizontal" position.

Approximately the same picture is observed during maneuvering, but the load is shifted here on the sides of the car, and not along the axes.

Shock absorbers hold the wheels in constant contact with the roadbed so that the driver does not lose control of the vehicle. Install racks directly near the vehicle wheels.

What oil shock absorbers are better

- Koni is the most expensive shock absorbers, however, the most durable. These racks are the development of the Dutch company of the same name. Apply actually on all types of transport. Available in the possibility of adjusting the characteristics.

- Bilstein - a symbol of reliability and quality. Are rather common. Installed on the following brands of cars - Ferrari, "Jaguar", "Lamborghini".

- BOGE - produces a well-known company from Germany. Completed for mounting on cars of the following concerns - "Volkswagen", "Audi", "BMW", "Alpha Romeo", "Volvo". They differ available to the cost and actually do not change the characteristics of suspension of modern foreign cars.

- Monroe is one of the best American companies. Its products are mounted on new vehicles of America and all of Europe. One of the best developments is the "Reflex" series shock absorbers, which are able to provide maximum contact with the roadpapers.

- Tokico is one of the largest manufacturers of racks in Japan. The reasons for the popularity of this product are low price, high quality and long service life. However, when purchasing these products, beware of Chinese fakes.

- Sax - These products manufactures the German company. As it should be, all products are distinguished by reliability and high quality.

- Kayaba - a Japanese company manufacturing this product appeared on the market in 2000 and in fact immediately won wide popularity. The main visories of the company are good quality, rich product aunts and low cost. Kayaba delivers its products for Mazda, Toyota and Honda.

Pumping the shock absorber, why need to pump the shock absorber before installing

Pumping oil shock absorbers are produced to bring them into the working condition:

- In order not to be left oil or air (gas supply) in the inner liner sleeve, which can lead to the exit of the shock absorber.

- To diagnose a likely jamming of the valve mechanism of the rack or other faults.

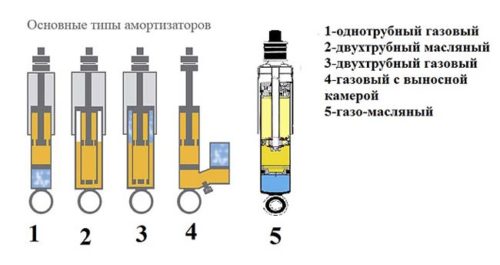

If the usual two-pipe shock absorber before installing the vehicle does not pump, it may fail its piston group. In addition, in this case, the warranty on the product does not apply, that is, it is simply "money to the wind".

It is important to know that insignificant failures may be observed in the resistance of the valve mechanism, which is not considered a malfunction, since this is not reflected in the overall performance of the device.

Pumping shock absorber, general rules for pumping

- Shock absorbers pump up vertically (rod up).

- After performing the pitching of the rack, it should be kept in a vertical position, stock up until you install it on the vehicle.

- Some structures of shock absorbers provide a system for draining oil. Methods: either using a technological groove, which is located at the top of the rod, or by the failure of the rod inside the rack. In the latter case, the rod of the rack should be left uncompressed by 2-3 centimeters. In the first case, the rod is compressed to the technological groove, which is located on it.

Pumping oil shock absorbers, how to make oil shock absorbers

Mac-Fersson shock absorbers are standard for modern cars.

Therefore, we consider the technology of pumping racks on their example:

- I turn down the shock absorber to the rod and smoothly, squeeze it without jerks.

- Fix the shock absorber in this position for three seconds.

- I turn over the shock absorber up the rod, holding the rod, and fix it for six seconds in this position.

- Next, smoothly put forward the rod until the end of the stroke.

- I turn down the robes down again, we make a small pause (three seconds) and repeat the procedure. The number of approaches is from 1 to 6.

With the third approach, make a control action - the shock absorber is located vertically, stock up, short sharp movements are convinced that the stroke of the rod smooth. The piston should also move smoothly, without failures.

Tips Prof.

Pumping the shock absorber can be considered complete, if everything is fine and the movement of the rod smooth. Similar activities for pumping and other racks before mounting on the vehicle. It is recommended, however, it is not necessary to replace the shock absorbers in pairs, i.e. simultaneously on the same axis.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving a car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

- Viscounts of the fan, work uniforms of the fan, malfunction of the ventilator fan, repair of the ventilator fan

Comments