For the first time in the Russian market, Lada Kalina appeared in November 2004. It is this car that marked the beginning of a new era in the development of the Volga autocontraser. This car was produced until 2013, and its overall circulation reached a volume of 600 thousand pieces. The vehicle has become new in everything, from the platform to the Ergonomics of the cabin. The front suspension of this car is independent, such as MacPherson, which is considered to be a significant promotion of the company Lada forward.

Content

- Front suspension Kalina, Device diagram with decoding

- Signs of malfunction of the front suspension Kalina

- Knock in front suspension on Kalina, reasons for knocking

- Silent blocks front suspension Kalina

- Tools, fixtures, consumables

- Choosing a workplace

- Substitution of silent blocks on Kalina Stephago

- Spring front suspension Kalina how to change the spring

- Tips Pros: If the steering rack is faulty, who entrust repair

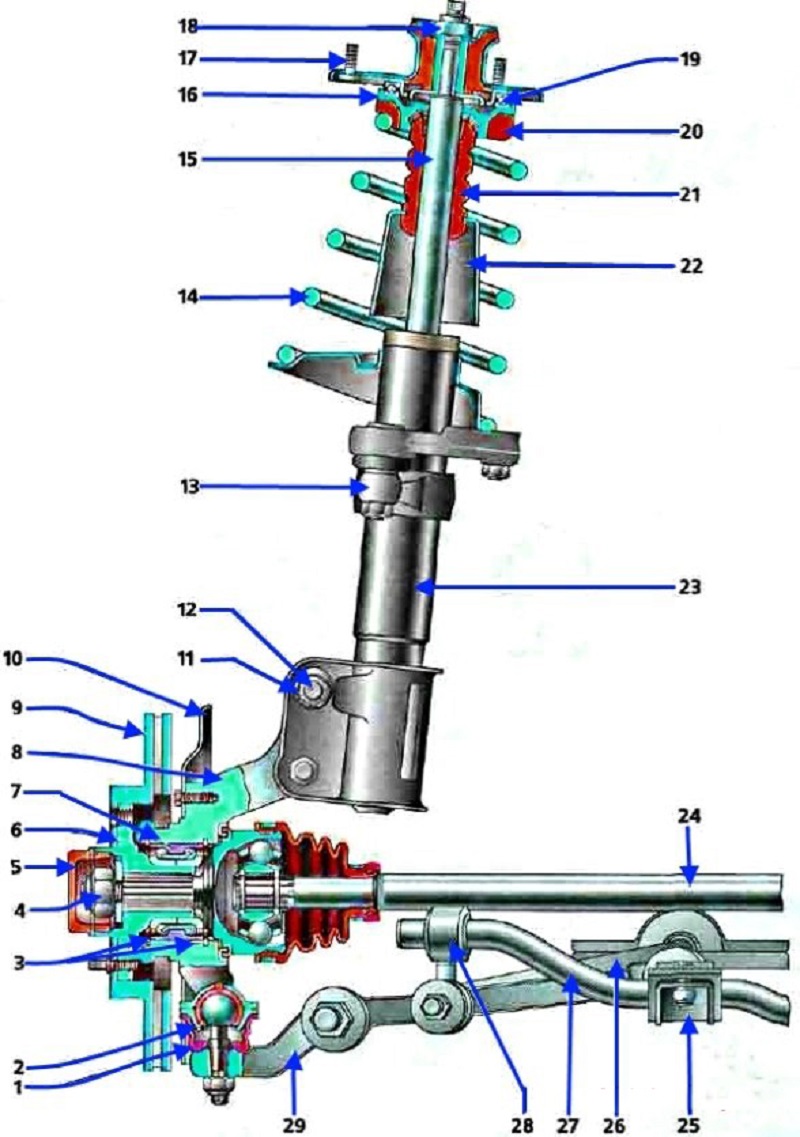

Front suspension Kalina, Device diagram with decoding

Case (1), ball support (2), locking ring (3), nut bearing nut (4), protective cap (5), hub (6), wheel bearing (7), swivel fist (8), brake mechanism disk front wheel (9), brake mechanism shield (10), nut (11), eccentric bolt (12), rotary lever (13), front suspension spring (14), shock absorber rod (15), top cup of spring (16), Upper shock absorber strut support (17), shock absorber (18) rod nut (18), shock absorber rack bearing (19), spring gasket (20), compression buffer (21), protective casing (22), telescopic rack (23), driving The front wheel shaft (24), the fastening bracket of the bar stabilizer stabilizer (25), stretching the front suspension (26), the rod of the transverse stability stabilizer (27), the rack of the transverse stability stabilizer (28), the front suspension lever (29).

Signs of malfunction of the front suspension Kalina

About the faults arising in the front suspension indicate knock and creaking, which increase with raising speed.

Knock in front suspension on Kalina, reasons for knocking

There are four main reasons for the appearance of squeaks and knocks in the front suspension:

- Road canvase quality. Yes, even the newest and ideal suspension can knock and tripping on bad roads, even if it was not previously observed. To check this theory, pass several hundred meters along a well-asphalt road. If the knock is not, then the suspension is in order. Otherwise, see the second reason.

- If the knock is accompanied by vibration in the steering wheel, it means its reason is the malfunction of the steering rack or thinning the brake discs.

- The third reason - lost the tone of the spring, which is why the car body actually beats about the suspension.

- Embroidered sienent block, designed to clean the knocks and vibrations when driving.

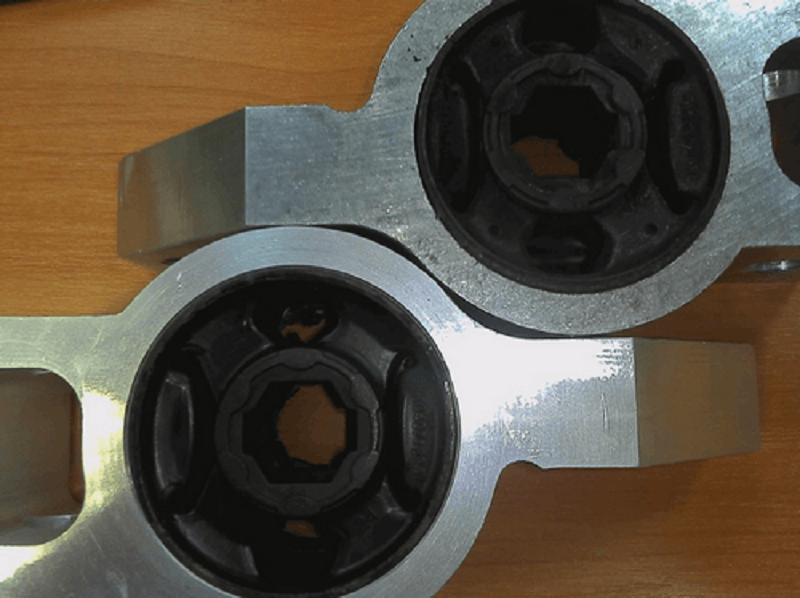

Silent blocks front suspension Kalina

The replacement of silent blocks in the front suspension of viburnum is needed 15-17 thousand km, since in most cases they lose their functions after passing this kilometer. Therefore, if the knocks in the suspension appeared at a given period of kilometers, then the problem is in faulty silent blocks.

Tools, fixtures, consumables

To replace silent blocks you will need such tools:

- Jack.

- Set of wrenches.

- Screwdriver.

- Lubrication for silent blocks.

- WD-40.

- Chisel.

- Hammer.

Choosing a workplace

To replace silent blocks to new, you need to drive the car on the lift or the observation pit.

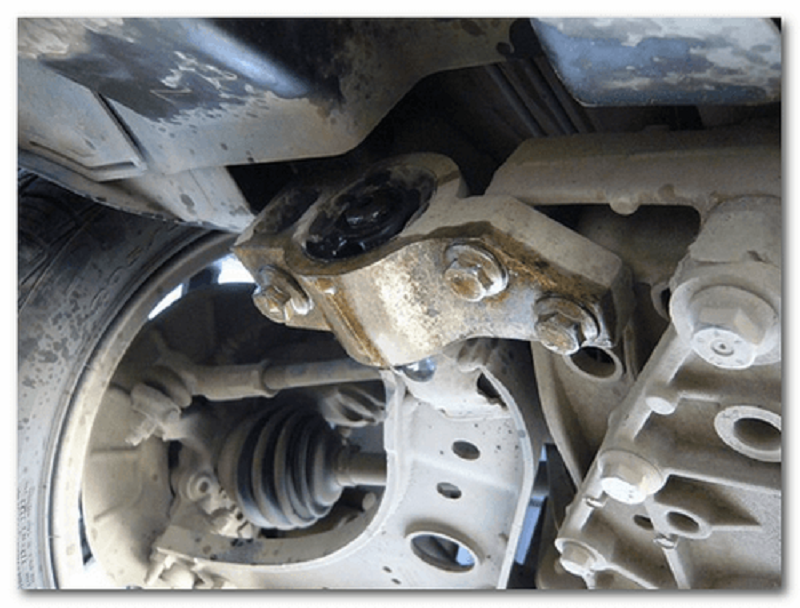

Substitution of silent blocks on Kalina Stephago

First dismantle the transverse lever:

- Remove the wheel and spray all the transverse lever connections using WD-40.

- When the lubricant penetrates in hard-to-reach places, start unscrewing the bolts.

- Remove the bolt of the ball support, however, you remove it with a pin from the bolt.

- Next, unscrew the hinge fastening bolt of the longitudinal stretching and remove it.

- Then unscrew the bolt with the nut fixing the stabilizer rack.

- The next step is the transverse lever bolt. After dismantling the bolt with the nut, you can remove the lever.

Next, go to the rubber-metal hinge of the longitudinal stretching:

- After closing the lever in the vice, you throw out the silent blocks using a thin flat screwdriver or chisel.

- If during the removal of the lever, its metal base will remain, it will also have to beat it and purify the seat of dirt.

- The installation of new silent blocks is performed by using them to the lever using vice, with full fixation, having applying blows every 5-8 mm by the hull.

Pillow and Stabilizer Rack:

- Remove the stabilizer rack is very simple. It is enough to unscrew the fastening bolt from the transverse lever, the second end is simply released from the stabilizer with simple swinging.

- To free the pillow, take the key to "13" and unscrew the two mounting bolts of the bracket, and then free it.

- When it is released, it can be removed by cutting the knife in the thinnest place, or remove from the stabilizer, lubricating it with WD-40 or soapy.

Bracket of the transverse lever:

- The largest Silent Block lever is at the very base.

- The easiest way to remove it is arson. When the rubber will be prohibiting on it, get it out and clean the seat. Of course, it can be pressed through vice, but it will take time.

- New silent blocks Lubricate WD-40 or soap solution and set to the place with the head to "30" and vice, pressing it.

Spring front suspension Kalina how to change the spring

Order of work:

- First open the hood and loosen the top mounting nut support to the rack: Take the key on the nut on the "22" and loosen the mount by holding the rod from turning the key to "9". It is enough to make several revolutions.

- Next, lift the front of the car by jack and remove the wheel.

- Remove the brake hose with the engagement on the rack and remove it to the side.

- Next, apply to all connections penetrating lubrication.

- Then unscrew the nut that crept the steering tip to the rotary lever, and select the tip from there with a hammer and mount, or dissect using the puller.

- Now proceed to the bottom mounting of the rack, where you need to unscrew the two nuts using keys to "17" and "19".

- It remains to unscrew the three fastening nuts of the front support to the glass (body).

- Last nut unscrew to the end so that the rack is kept. When you disconnect the rack with a swivel fist, you can unscrew the last nut, and lower it down, holds the other hand.

- Now you need springs springs. They can be purchased in any auto shop.

- Dress them on both sides to the springs turns and with the help of accessories, perform their compressive.

- When the spring is fast enough and will not rest in the support of the rack, unscrew the top nut.

- Remove the support together with rubber band, cup and bearing.

- Then you can remove the spring.

- The assembly is performed in the reverse order.

- New springs roll to the required moment and dressed on the rack. The extreme lower round should get exactly in the recess.

Tips Pros: If the steering rack is faulty, who entrust repair

If the steering rack is malfunctioning, it is not necessary to deal with this problem, it is better to immediately bring the car to a hundred, to avoid more serious problems in the future.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

- Viscounts of the fan, work uniforms of the fan, malfunction of the ventilator fan, repair of the ventilator fan

Comments