Engineers a lot of time pay attention to the improvement of such an important part of the car as a tire, since this element has an impact on the driving characteristics of the car.

Content

- Important tire information

- Proper tire pressure, how to find out

- How to check the degree of wear of tires with coins, 2 rubles and 10 rubles

- Tread wear depending on climate and mileage

- Shin wear indicator

- What does the statistics of the accident on the effect of the tread depth of less than 4 mm on an accident

- Minimum Tread Depth of Summer and Winter Rubber

- Decoding tire marking

- Council Prof.

Important tire information

Each car owner perfectly understands the importance of such an element of the design of any modern car as a tire. This wheel element is an elastic and durable component that dresses on a car disk. The tire allows you to create contact with the road surface, quenching small oscillations from the irregularity of the road and keeping it securely while driving.

Any bus consists of a metal frame, the inner detail of the tires - breaker, sideboard with a side part, as well as a cutting protector. The main material from which the Cord is manufactured is synthetic or natural rubber. From the quality of rubber will depend on the durability and driving characteristics of the car. Cord wheel consists of several important elements - polymer and textile threads, and the elastic base consists of a metal frame.

Each car owner either later faces the fact that you have to choose a new rubber for your four-wheeled friend. To date, there are a huge number of manufacturers and tire models, which differ not only by external and internal dimensions, but also the manufacturer material, a tread pattern and other parameters. Each parameter has a direct impact on the running characteristics and for the duration of operation.

Also, you should not forget that tires are produced today that have improved characteristics under certain conditions - winter, summer, all-season, high-speed. When choosing new tires for your car, it is also necessary to have the concepts of their conditions.

tire size and wheel disk size

All important information that is available about any type of tire is applied to the side of the wheel. This alphanumeric designation is called marking. Knowledge of these important parameters will be necessary in cases where old tires have already been worn out and have to acquire new, replacement of rubber as a result of the transition to the winter or summer season should be significantly improved by the driving characteristics of the car, etc.

The internal and outer diameter of the wheel is 2 most important indicators that are taken into account by the plant manufacturer and are recommended parameters when purchasing new tires. The inner diameter of the tire fully corresponds to the size of the disc, because it must be accurately observed. Also, do not forget about the outer diameter of the wheel, since these characteristics are also provided by the plant and affect the safety of motion.

By installing the tires with an external diameter of less than the stated, you can get significant damage to the discs, as well as worsen the running characteristics. In the case of the installation of a larger diameter of the tires, the rubber can be drown about the car's liners, gradually destroying it. To avoid this, it is necessary to consider the size of the tires and the wheel disk when choosing rubber for its car.

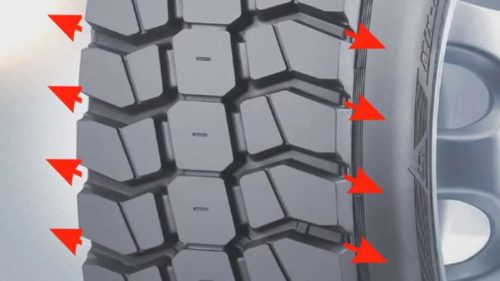

figure of the tread, can the drawing of the tread be different on the wheels of the car

Definitely no. The pattern of the tread wheel of any car is not an ornament and not a decorative part, but a complex thought-out pattern of drawings on the outside of the wheel, which improve the grip with the road surface. Modern engineers and car tire designers pay a lot of attention to this element, since it significantly improves the many characteristics of the car, significantly increasing efficiency during movement and emergency braking.

Different tire tread pattern contributes to the different efficiency of water removal from under them and improves car aquaplaning, due to a reliable clutch with a road surface. In addition to the water, the protector helps to take dirt, snow, soil, etc. From under the wheels, making the car is more stable while driving directly and when turning. Also, the deep protector reduces the braking path, affects the noise level in the cabin of the car and the consumption of gasoline.

seasonal tires

Each car owner knows perfectly well that automobile tires must be changed not only with their wear, but also when changing the seasons of the year - winter and summer. Winter tires differs from summer as externally - drawing and depth of the tread and internal characteristics - quality and material.

Winter tires is characterized by the presence of greater tread depths and a large number of slices. Such changes made it possible to obtain improved handling while driving on snow-covered and slippery roads. In addition, the protector slits are done at a low angle, which makes it possible to significantly improve the grip with a slippery surface. The tires are clinging for unstable and loose snow, thanks to more lenels. The last 50 years of the lamelles are constantly upgraded, thereby improving comfort while driving.

Another distinction of winter rubber from summer is the presence of several wide longitudinal grooves, providing an effective removal of water from under the vehicle wheels. In the absence of grooves on tires, the slots are made in the form of the letter V, each of which also contributes to the removal of water on the surface of the road from under the wheels. Such a type of tread becomes more and more popular and it is focusing the designers more attention. Reducing noise level is the most important indicator.

However, the main difference is the composition of the material from which tires are manufactured. Not in vain the rules of the road movement provides for a change of summer rubber on the winter with a decrease in air temperature below 8 degrees Celsius. At low temperatures, summer tires becomes more rigid, which worsens contact with the road. The car on summer tires in winter is becoming poorly controlled, and riding such rubber entails a danger of both for the transport itself and for passengers inside.

all-season tires

All-season tires are a type of automotive wheel rubber, which has properties that allow you to determine the good running characteristics of the machine both in the winter and in summer. Such characteristics are not optimal for reliable control of the car, but only allow them to move on them at any time of the year.

To date, it is not possible to create a universal bus that will have excellent characteristics in any weather. Winter tires differs from summer not only composition, but also the depth of the pattern cutting the tread. Winter tires often has a directional pattern and a large tread depth and the number of lamellae. Also, the composition of winter rubber allows not to dub at low temperatures. In turn, the summer tread has a smaller cutting depth and tougher tires, which is well tolerating the hot pavement, but quickly dubies during the cold.

All-season rubber allowed to combine the characteristics and properties of two types of tires. Engineers combined wide slots and a large number of lamellae, while using the middle depth between the winter and summer tires. All models of all-season tires wear more faster in the summer than in winter.

radial tires, pros and cons

Those who at least once in his life chose tires for their car, have the concept of radial tires. Such tires are such a type that is installed on various types of cars. In the radial tires, the cord threads are located along the entire wheel, and this is the only constructive difference.

This type of tires is very easy to distinguish visually from diagonal rubber, since the lathe latin r is lathe in the labeling of such tires. On the side of such tires, the number of cord layers located inside the rubber, as well as manufacturing material, is indicated.

All radial tires have a number of positive properties in comparison with the diagonal cord. Such rubber has a greater carrying capacity and are more often used as high-speed wheels. Radial tires have significantly smaller weight, in comparison with diagonal, and have significantly greater elasticity, as well as not so much exposed to heat during movement. The car with such a type of wheels is more stable and better keeps its position while driving.

Radial wheels are most often installed on cars in those regions where a more wet environment. This type of tire has the best contact with the road surface, and also reduces the probability of puncture. A significant reduction in the weight of the wheels was achieved due to a smaller number of cord layers, since the cord of such tires perceives only one type of load.

The design of radial tires was laid for the use of multi-module types of cord for breaker production. This allows the protector to be clinging to the road surface, and also reduces the level of deformation of the tread.

Despite a number of positive characteristics of radial tires, they are not an absolute ideal for car enthusiasts. This type of tires has reduced elasticity on the sides of the wheels. In case of movement on roads with deep rings, this type of tires can be significantly lighter damaged. The same cause leads to the fact that this type of wheels does not tolerate the pushed pressure.

The last and rather significant lack of radial tires is their high price.

diagonal tires, pros and cons

Diagonal rubber has significant differences from the structure of radial in that the metal frame of Cord is laid from one side to another diagonally, while they crossed together with each other. Such a simple, but at the same time the reliable design of radial wheels allowed to create excellent properties for the movement of the car through the most complex road surfaces.

Automotive tires for SUVs have a multi-layered structure in which 6 and even 8 crossed layers of each other can be found. Such a device of diagonal tires made it possible to make wheels almost eternal. It belongs to the most dignity, the fact that they have strong side parts, and it is almost impossible to apply serious lateral damage. Also, rubber with diagonal cord makes it possible to significantly reduce the load during shocks.

Such tires have some disadvantages, including high deformation of rubber while driving. As a result, the protector becomes less deep and the protrusions begin to slip over the road. Such an effect makes movement less secure while driving at high speeds. Also, this type of tires may be prone to deformation during long standing, it is especially manifested at reduced pressures in wheels. Such a distortion of the normal shape of the wheel will lead to the steering wheel while driving.

delicious tires, pros and cons

Delicious tires are one of the types of automotive tires installed on cars of various types. The process of manufacturing tubeless tires is more complicated than chamber. Special requirements relate to the material from which the tires are manufactured. The material must be better in order to ensure the tightness of the rubber from the penetration of air under high pressure.

The rubber layer should be simultaneously dense and uniform, which will avoid folds and curvature of the forms of the wheel. This will significantly extend the operation time of the tubeless tires. In the tire design, a special hermetic layer is put, the thickness of which is about 3 mm, securing to the inner walls of the tire.

Such wheels are pumped with a special nipple, which is tight and hermetically embedded into the car disk. For greater tightness and density of the bus installation, a special rubber tape is used to disk. Such a tape is very elastic and durable at the same time, since it experiences colossal loads while driving.

During the production of tubeless tires, threads from Cappon are used as a frame, which are withstanding high pressure, several times better than steel.

Belessless wheels have a number of positive and negative characteristics that can highlight this type of tires. When moving on the tubeless tires, the friction force acts less, while the heat exchange of the wheels is increasing. This leads to the service life of such tires becomes much more.

The smaller weight of such tires will have less negative effect on the car suspension, which will reduce the cost of their maintenance. This type of tires is much easier to repair with minor damage, in some cases can be eliminated by the puncture without moving the wheel.

The weakest place in the tubeless wheels is the side part, which is less rigid and can be damaged with minor strokes. Very often in the tires are formed a airbag between the hermetic layer and the camera itself. Such a defect can lead to a rapid failure of a tubeless wheel.

chamber tires, pros and cons

Chamber tires are another type of automotive rubber, which also have a number of advantages and disadvantages. The production of such tires is simpler, because, unlike the tubeless tires, the chamber is not needed to protect the wheels from passing high pressure from them.

The main advantage of such tires includes their relative cheapness, in comparison with the beless. This was achieved due to the simplified design. They are protected from lateral cuts, under which it will be enough to replace only the inner air chamber.

The main disadvantage can be attributed to the fact that even a small cut or puncture of the wheels will lead to a gradual decrease in air pressure. In this case, further movement can only be made after complete replacement of the tires or the camera. The weight of such tires is more damaged, and the latling of small damage is more difficult than the delicious rubber.

brands tired

Today in the automotive market you can find a huge set of different brands of tires that can come practically to any car. An ordinary buyer who first chooses a new rubber for his four-wheeled friend, can be very easy to get confused in the variety of brands of manufacturers.

In fact, all brands can be relatively divided into several categories, some of which take their beginning since the appearance of the first cars. Today, a large part of such companies represent huge plants with multi-million editions who have gained great experience in the production of wheels around the world. Such tires are most often distinguished by the highest quality, reliability and durability, but also the cost of them is an order of magnitude higher than other brands.

This group includes brand such as Continental, Michelin, Goddyear, Pirelli, Bridgestone and some others. It is also not worth missing such brands like Nokian and Hankook.

The second largest group is the subsidiary companies of the most popular wheels. The drawing line of such companies is their orientation to the domestic market, because these brands are less weighty and are known.

The third group is occupied by brands that are gradually entering the market, but they managed to surprise many car owners for high quality products. Most of all such companies are in Korea, China and Taiwan.

Thus, it is possible today in the world there are a huge number of companies that are engaged in the production of tires for cars. And who in this race will become more sought after time.

Proper tire pressure, how to find out

Tires are one of the main elements that allows you to maintain a steady position of the car on the road surface. However, it is the correct pressure in wheels that allows normalize fuel consumption, to increase the resistance of the car while driving, as well as increase the operation time. In addition to these characteristics, the correct pressure will affect the safety of the movement, and will also save the wheel trifles. In order for tire pressure to be optimal, constant control is needed. Specialists and experienced drivers recommend checking the pressure in wheels at each car refueling.

Incorrect pressure in wheels can lead to the fact that the wheel protector will be unevenly stitched, which will lead to a rapid failure of the tire.

In order to check the correct air pressure in the tires, it is necessary to use a special device - a pressure gauge. Such a device can be purchased at any automotive store, as well as at any maintenance station. The pressure gauge is part of any compressor, with which the wheels are pumped.

Checking tire pressure must be carried out on a slightly cooled wheels, but the best option will be measured in the morning or before the start of the trip. Since the tire heating occurs with intensive ride and, respectively, the air inside is gradually starting to expand, which will lead to errors when checking.

On each wheel there is a special air valve through which air pumping is performed. In order to measure pressure, you need to unscrew the protective plastic cap, and then put the pressure gauge on the valve. During the winding or putting on the pressure gauge, a small sound of the outgoing air from the wheels will appear, while the pressure indication will appear on the measuring instrument.

The manufacturer's manufacturer provides recommended tire pressure parameters with different car load. After measuring the pressure, it is necessary to compare it with the recommended numbers and, if necessary, roll up, or reduce the pressure inside the tire. Bring the pressure in the wheel to normal is possible with the help of a compressor, a manual or foot pump, or compressor.

Thus, the pressure is checked in each wheel and communicate to the same recommended value. After checking, you should return the protective cap to the place.

how often do you need to control tire pressure

Experts recommend checking the air pressure on tires regularly. The most correct will be control of at least once a month, as well as the planned long trips and after them. Tire pressure leads not only to increased fuel consumption, but in addition to this tire protector will have uneven wear. This is one of the obvious signs of improper tire pressure, which can be seen visually.

Even during the perfect and calm ride, tire pressure can gradually decline about 0.65 bar per month. However, with hot weather, when the asphalt temperature increases significantly, the pressure reduction rate can accelerate significantly.

How to check the degree of wear of tires with coins, 2 rubles and 10 rubles

Movement on the car has a large number of nuances that can affect the safety of all passengers. One reason is the degree of wear of automotive tires, over the level of which it is necessary to maintain constant control. Unfortunately, many drivers do not have the concept of how to properly conduct this control, therefore it is necessary to do this with the help of improvised ways. It is possible to diagnose the degree of wear of automotive tires using a conventional coin.

In Russia, 2 and 10 ruble coins are most often used for these purposes, in the absence of a special measuring instrument. The coin should be placed in the protector so that the head of the coat of arms was pointing down. If the head of the eagle is barely concerns the level of the tread, or is more immersed in it, then such wheels are still in good condition. Otherwise, it is necessary to think about replacing rubber.

Tread wear depending on climate and mileage

Each automotive tire has its own service life, during which a large number of all kinds of factors affect them. The climatic conditions and the number of run are the main causes of tread wear.

Each tire has its own margin of durability, which is determined not only by the quality of the material used, as well as on the size and season of use. The reserve of safety approximately 30,000-70.000 km. Various factors are affected on the tire: a significant overload of the car by weight, unpainted either pounded tires, poor installation of wheels, malfunction in the steering and hodovka, unbalanced wheels, climatic conditions and driving manner.

Each this cause leads to accelerated wear and leads to a premature replacement.

Shin wear indicator

The tread depth is one of the most important indicators that affect the safety of the car movement. The tread depth has an impact on car handling, clutch quality with expensive, fuel consumption, etc. Therefore, after this parameter, it is necessary to conduct constant control, which can be achieved by diagnosis and visual inspection.

However, modern tire manufacturers have developed a system with which it is possible to examine the state of the tread tread depth. For these purposes, special indicators that have a convex pattern on the surface of the tires, or a digital indicator have been built into the tires.

Volumetric indicators represent the easiest form of informing about the degree of wear, with the informativeness and accuracy of high-level data. Gradually, wearing the depth of the tread becomes less, which can be traced using a special indicator. Thanks to them, the driver will be aware that tire wear is critical and necessary to take care of the replacement of the wheels.

Digital indicators have a different device and, in contrast to volume, are squeezed out in rubber. They have different depth of penetration deep. Most often, the figure 8 represents the smallest tread depth when the number 2 for summer rubber and 4 for winter represents the minimum rubber wear.

What does the statistics of the accident on the effect of the tread depth of less than 4 mm on an accident

Manufacturers of automotive rubber carry out permanent research on quality, as well as traffic safety in various conditions. The most optimal depth of the car rubber tread is a digit equal to more than 5 mm. Such depth does not have a practical impact on emergency formation. With a decrease in depth to 3-5 mm, the risk of getting into an accident increases by 10%.

If we talk about the depth of Figure 2-4 mm, the accident rate increases by another 10%, unlike deeper patterns. 2-3 mm tread depths are essentially an increase in the possibility of entering an accident, which is 20%. With more "bald" automotive rubber, transport operation is not recommended and besides, it is a violation of the rules of the road.

Minimum Tread Depth of Summer and Winter Rubber

When choosing a new automotive rubber, it should be understood that the depth of the tread for asphalt roads should be 7.5-8.5 mm. This depth is enough for normal and safe movement. In the case of buying tires for SUVs, the depth of the pattern should be significantly deeper and equal to about 17 mm.

In 2015, minimum standards were changed for the depth of a tread pattern of a passenger car. Now the car operation is prohibited at a tread depth of less than 1.6 mm. Such characteristics and requirements refer both to summer and winter tires. However, experts recommended digit is at least 2 mm, below which movement on the car will be unsafe.

Experienced drivers recommend carefully follow the depth of the winter tires are much more carefully. Since in winter, the car's contact with the surface of the road coating deteriorates, respectively, the tread depth must be at least 4 mm. It is this depth that reduces the risk of falling into an emergency and improve car handling.

Decoding tire marking

Each manufacturer of automotive tires has its own tire names that allow you to convey important information about the tire characteristic to the final consumer. For example, very often in the names of winter tires, the word Ice can be found, which will report to their belonging to ride in the winter.

You can also meet information about the maximum load on one wheel. Some manufacturers may indicate a small font of the "Max Load" phrase, which means the maximum allowable weight. This parameter can be both in kilograms and English pounds. In order to calculate this parameter, it is necessary to flicker 20% of the specified load, in the event of an auto-car tire and take 30% for SUVs.

Also indicated on the tires the maximum allowable pressure to which you can pump the wheel. Pumping can lead to increased fuel consumption, as well as to a possible break wheel. Also on wheels may indicate that such rubber can be operated in dirt and on snow-covered roads. For this, there are designations in the form of a Latin Liter "M + S". Winter's inscription is used to designate winter rubber, for the scaplating-resistant bus - Aquatred or Aqua Contact, all-season is indicated in the form of AS abbreviation, AW are suitable for any weather.

The most common marking for wheels is the designation of the profile width, as well as the ratio of the profile height to width. This parameter is immediately by fraction with the profile size. The latest data in this label is to specify the type of tires and the diameter of the disk. This type of marking has the following form 210 / 60R15.

Council Prof.

Car tires are an essential element of any car, to whose selection it is necessary to approach the knowledge of the case. Thanks to the advice of professionals, you can make the right choice of tires for any car model.

For automotive tires, it is necessary to continuously control, since thanks to a good protector state, you can guarantee good grip with a road surface, the best stability of the car, as well as safety while driving.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

- Viscounts of the fan, work uniforms of the fan, malfunction of the ventilator fan, repair of the ventilator fan

- Corrosion of car thresholds, film on car thresholds, how to stick a film on the thresholds of the car

- Gas or oil shock absorbers, which shock absorbers to choose, the top 10 of the best manufacturers of shock absorbers

- Speedometer machine, why speedometer does not work, repair speedometer

Comments