It's hard to imagine how the car was driving and what sensations would be experienced by the driver and passengers in the cabin, if the vehicle was not equipped with special devices capable of repayment, or at least as much as possible to reduce the oscillatory movements transmitted by springs, stems, torsion. To this end, shock absorbers are used, they are completely substantiated to consider it one of the most important elements of the automotive suspension, they are intended to eliminate the vertical sidelines of the body.

Content

- Top 10 best firms of shock absorbers

- Shock absorber, principle of operation, where installed

- What are the main indicators of shock absorbers

- Shock absorbers and working substance

- Shock absorbers and number of pipes

- Ride style as it affects the choice of shock absorber

- How to check in what state the shock absorber on your car

- Useful advice

Top 10 best firms of shock absorbers

To choose the best shock absorbers for your car, it is advisable to first familiarize yourself with the manufacturers who are recognized worldwide.

Koni.

Shock absorbers are the only product produced by the Dutch company. The main difference is the adjustability of the characteristics of the models, and there is a difference of 100% between the zero and maximum adjustment position, i.e. There is a real possibility of adapting the device to any type of road, any car model and driving style.

The range of firms is 2500 different models that differ in constructive schemes. Their cost in the market is the highest, as well as reliability, there is a chance that they will fail with a car.

The most popular models:

- Koni Load-A-Juster - for a solid loaded body

- Koni Special - For Soft Machine Auto

- Koni Sport - for lovers to tham at high speeds

Bilstein.

Installed by manufacturers for cars Lamborghini, Jaguars, Ferrari, which is already evidence of the highest quality.

The most popular Bilstein Sport Models, Bilstein Sprint, Bilstein Rally - are designed for high-speed, sports cars, they choose lovers to show the master class on driving. There were no complaints about the quality of products of the company Bilstein.

Kayaba.

Kayaba Japanese Food Products prefer worldwide car manufacturers: Renault, Ford, Seat, Peugeot. Sympathy drivers Kayaba shock absorbers won the available cost and quality corresponding to international standards.

Among the most popular should be noted gas-hydraulic models of Ultra SR with high particulate characteristics, stabilizing adhesion with the surface of the track, with good controllability characteristics when using low-profile tires, in the absence of attenuation. Such preferred driving lovers prefer.

Boge.

The main consumers of the manufacturer of the German company are leading European concerns producing BMW cars, Volkswagen, Volvo, Alferomeo, Audi.

The price policy of the manufacturer of shock absorbers is quite a pocket owners who truly take care of the technical condition of their cars. Installed on a foreign car, BOGE shock absorbers do not have a negative impact on the characteristics of the suspension.

Most in demand:

- BOGE PRO-GAS, gas-filled, for a comfortable ride

- BOGE TURBO24, single-tube, allowing to ride in roads on the all-wheel drive car

- BOGE TURBO-GAS, for sports cars

- BOGE NIVOMAT supporting optimal road clearance even with essential body loading

Monroe.

Belgian firm is a manufacturer of shock absorbers known worldwide.

The exact and instantaneous reaction provides the original design of gas models, it allows:

- easily adapt to ride in different, even difficult conditions,

- support control,

- adequate car behavior with complex maneuvers at speed

The American company enjoys the best recommendations not only in his homeland, but also around the world.

A particularly popular series of products is Reflex, the model of which is guaranteed maximum contact with the road surface.

Tokico (Hitachi)

The Japanese company produces damper devices for the automotive industry in the United States and Japan. Products are high-quality, with a long service life, the cost has low - sufficient prerequisites for popularity.

But when buying, the Chinese fakes should be feared, there are quite a lot of them in the domestic market, it is quite difficult to distinguish visually from the original.

Produces brake systems, hydraulics and pneumatic equipment for cars, shock absorbers. The market has been successfully operating for about 80 years, occupying leading positions. The special merit of the company is the development of a two-pipe gas model of a low-pressure shock absorber, which has advanced the entire industry as a whole.

Since 2005, Tokico began working as part of the Hitachi Concern, its products are used when assembling sports motorcycles, as one of the most reliable in the world.

Sachs.

The German manufacturer specializes in the manufacture of clips and shock absorbers, universal, high-quality and reliable products. Today the company pays more attention to the production of suspension.

Most popular modifications:

- Super Touring - For a comfortable ride on a car of different types

- Sachs Advantage - for sports type driving, for comfortable driving on the roadway of any complexity

Kyb.

For a relatively short period of existence (about 20 years), the Japanese company managed to conquer confidence and popularity, its products are equipped with Mazda cars, Toyota, Honda.

Al-Ko.

The company's products continue to delight motorists inexpensive, but high-quality products for four decades.

Al-Ko dampers are installed on expensive motorcycles and cars, for the most part they are oil, they prefer to buy owners of used motor vehicles.

Delco

Made in the United States, mostly used by American manufacturers of motor vehicles. In an open sale, it is practically impossible to meet them, the main consumers of Delco products are assembly auto.

Nevertheless, Delco shock absorbers are widely known, use good recommendations due to their reliability. Under off-road conditions, use is irrational.

Shock absorber, principle of operation, where installed

And now we will continue the conversation about the shock absorbers, clarify what principle they work and continue the topic on how to make the right choice of the device for your car.

The shock absorber is a damping device, quenching oscillations, absorbing shocks and blows of moving structural elements (suspension, wheels), housing. The action is based on the process of absorption of the mechanical energy of oscillatory movements and transform it into thermal.

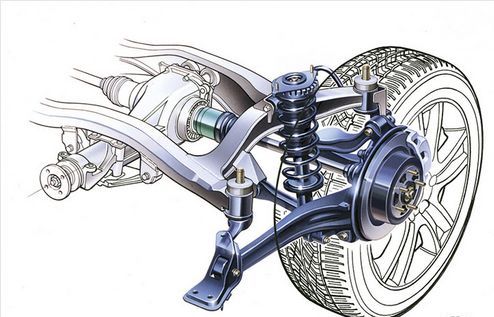

The interaction of parts with springs, pillows, torsion, springs allows you to extinguish free movements of large masses and prevent relatively high speeds of smaller masses associated with elastic elements.

The wheels of the car should be able to freely move down and up the body relative to the body. The body weight should be distributed on the pendant springs, keep them in compressed to a certain state.

The implementation of these conditions will allow you to maintain contact between the bus and the surface of the road coating, regardless of what will be under the wheel - convexity or vp. If you remove the shock absorbers from the design, constant contact will be impossible due to springs fluctuations.

For example, the malfunction of the damper device driver can feel even when driving at a speed of 30 km per hour:

Wheels bounce from the slightest irregularities

Control over the car worsens

One of the important points is the location of the part. The most efficient operation will ensure the minimum distance of their installation from the wheel.

Experts emphasize that shock absorbers should be installed strictly vertically, i.e. perpendicular to the plane of the suspension. Even with minimal deviation, damping efficiency will decrease.

To adhere to the opinion that this device is simple on the principle of action and primitive design - extremely harmful. In fact, the correct installation of the node and ensuring its excellent work is quite complex science, requiring multifaceted knowledge in the field of physics and mechanics.

What are the main indicators of shock absorbers

Like any other car node, the shock absorber has certain performance. They have considerable importance to the car management process itself, its obedience to management, the comfort of the trip and its safety.

braking distances

The operation of the damping device affects the speed of overclocking and braking cars. If we consider the condition of the car at the start, it turns out that when the speed set is primarily the load on the rear wheels and decreases - to the front, i.e. Reduces the force of their clutch with the surface of the road. Braking is accompanied by opposite loads. Ideally, in both situations, the body must maintain a natural horizontal position for it.

Efforts will be directed precisely to the stabilization of the position of the body. But different on the design and type of damper filler will work in different ways at different speeds.

For clarity, you can give an example: at a distance of a dozen meters in front of the car, an obstacle raises sharply (a cat, a dog, a dog running on the road, suddenly fell by the road, but something else can happen).

If the car is equipped with oil models - it is hardly possible to avoid tragic outcome. Gas-filled devices will make it possible to reduce the brake path. The incident will end safely, and the driver will be able to boast of his experiment and an excellent reaction.

But even taking into account such reasoning, experts do not recommend installing gas-filled models into used, especially domestic cars, - destructive processes in such cars immediately are activated.

the ability of the shock absorber to extinguish oscillations on an uneven road

We have already mentioned that the most important requirement for shock absorbers is the ability to quench the body oscillations during traffic. Those. A high-quality shock absorber must ensure constant contact of the surface of the road surface and the surface of the wheel, it will warn the possibility of losing control over the car.

In the case of a serious difference in the height of the road surface (tuberculos or dents), the wheel should be swollen as soft as possible and quickly, it is clear to contact with the road coating.

Since the devices filled with oil act slowly, it will be fully increasing the oscillations on the poor quality of the road. Off-road driving such cars should be avoided, rides in bad roads are fraught not only by noncomfort, but also by quick wear of the shock absorbers.

the stiffness of the shock absorber, how it behaves on steep turns

The situation with the displacement of loads, but only on the sides of the car, will arise during the execution of the car maneuvers, for example, passage of steep turn.

More rigid, gas-filled devices are capable of a faster reaction, with an increase in pressure inside the shock absorber, the response speed increases. They give stiffness to the suspension, at high speeds it is expressed by a decrease in body fluctuations.

The same when performing a steep turn - a rigid and high-speed shock absorber will have time to compensate for emerging loads and passengers will be sprinkled to a lesser extent.

The installation of such high-speed damping devices is made on auto speed, such as sports, all-wheel drive and SUVs.

Among the best representatives can be called the MONOMAX series with high strength and pressure and adjustable models Kayaba - AGX.

Shock absorbers and working substance

If we take into account the type of working filler, then all the models are customary to:

- gas

- oil

- gas and oil

If the answer is subject to logical analysis, it will change slightly, because oils and gases are used as a working substance in shock absorbers.

The gas models housing is filled with inert gases, more often - nitrogen. Press it under pressure 2 - 3 atmospheres. Working space of models operating on oil is filled with hydraulic oils and air.

Shock absorbers and number of pipes

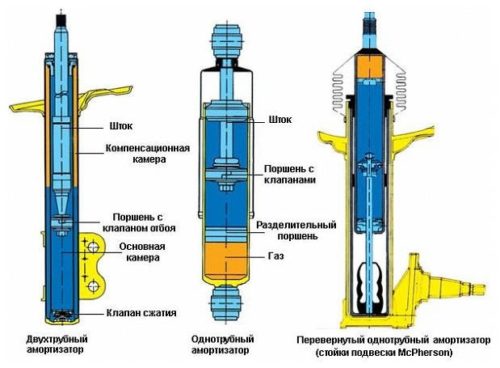

In accordance with the design features, shock absorbers are divided into several types: single-tube and two-pipe.

oil shock absorbers pluses and cons

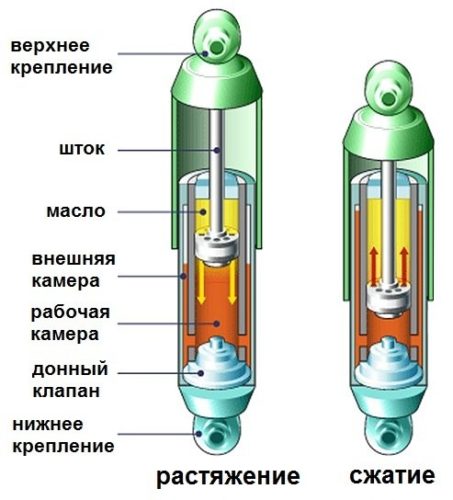

Let's start with the most simple version - hydraulic two-pipe. Its cost is not high, but it does not differ in the stability.

This type is characterized by the location of the working cylinder inside the case. The housing is a cylinder filled with some oil. Working on compression, the piston located inside the cylinder moves down, displaces the oil filler through the valve.

The air located in the top of the cylinder is tested. The piston code works on the back - makes the reverse movement, the oil through the reverse stop valve returns from the housing, goes into the operating part of the cylinder.

The design and principle of its work is fairly simple, but simplicity does not always guarantee sufficient efficacy - in the process of repayment of one energy, another is formed, compensation of spring fluctuations is accompanied by the release of heat energy, which leads to heat heating and changes in its viscosity parameters.

Oil heating occurs quickly, and cooling slowly, heating and constant movement of oil when air access is often the cause of foaming. There are no methods for combating this phenomenon. Sometimes get rid of the problem trying to fill the new shock absorber "under the string", i.e. to maximum completion.

But such actions will not lead to anything good, the oil will still look for a way out out, as a result, the shock absorber will rather fail. It turns out that aeration is an incurable disease of oil shock absorbers.

gas shock absorbers, pros and cons

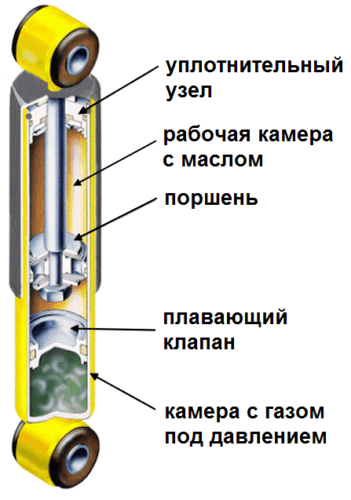

gas one-tube

This type is characterized by a special design, which provides for complete insulation of the oil from the gas filler.

Such models consist of:

- corps

- stock

- piston located in conjunction with a rod and equipped with valves of the back and direct strokes

- piston float that separates gas from oil

Of the significant differences, the lack of a working chamber should be called, the role of it is the case. The separation on the camera occurs with the float piston.

The lower part of the housing is filled with nitrogen, under high pressure. In the upper part there is oil, it is in it that the piston is moving with a rod.

Since there is no operating chamber in the design, the direct stroke valve is located directly near the pen valve, on the piston.

The design of one-tube models allowed to increase the volume of gas and oil, while the size of the shock absorber has not changed. Such design improvements have eliminated the device from heating. The exclusion of contact of gas and oil warns the aeration process, i.e. Foaming oil.

Among the disadvantages of such models should be noted:

- changing stiffness depending on the temperature of the gas,

- increase the temperature enhances the stiffness of the suspension

- the accidentally formed dent on the case will lead to the fact that the shock absorber is broken, i.e. He fails, fortunately, such precedents happen often.

gas and oil shock absorbers, pros and cons

Representatives of this species are known as gas-oil. Their design is similar to the design of hydraulic models. The difference lies in the fact that the cavity is filled with gas, nitrogen usually use.

Gas accumulates pressure and does not allow foaming of oil. But from the problem of heating to get rid of thus failed.

When buying a gas-filled shock absorber differs from hydraulic in stock - the gas pressure seeks to squeeze it out.

calling

You should also remember the shock absorber of a special design, the so-called. Pottle. It differs in the fact that the installation is performed in the inverted state. If for conventional shock absorbers, the direction of the rod stand is typical, then the rod is directed down, the mounting of it is made to the rack housing.

The pseudochka has a large thickness, is on top. It works such a device due to the presence of several sliding bearings. Among the advantages of the design should be noted a significant reduction in the vertical and lateral load on the rack.

Ride style as it affects the choice of shock absorber

Considering the fact that different types of shock absorbers have several different characteristics, when choosing, take into account the style of driving, which prefers a car enthusiast.

If there is a calm movement in plans, it is not particularly bothering - oil shock absorbers will be enough. Although there is an opinion that such models are less than, but there was no official confirmation of this version.

If the driver prefers to aggressive, sports style, it is best to give preference to models from special series, such shock absorbers are distinguished by increasing efforts to compress and hang.

Such improvement makes it possible to obtain the increased stability of the car when driving at high speed, in particular, when turning turns. But moving in calm mode will become comfortable.

Lovers of aggressive sports style driving can also use high stiffery shock absorbers with adjustable parameters. A positive moment - such models have very high strength and reliability.

If the car is used for infrequent and non-evaluable trips, then buying expensive shock absorbers is not at all necessary. For example, quite enough QH or Al-Ko, or similar.

For daily trips, it is recommended to pay attention to high-quality and reliable models with a long service life. To speak more specifically, the products of brands have such quality: Monroe, Kayaba, Boge, Sachs.

How to check in what state the shock absorber on your car

Experienced drivers argue that the main signs of the health of the shock absorbers are:

- obiability car management

- modeality noise in the cabin

- no shaking and vibration while driving

At the same time, shock absorbers affect the speed of overclocking the car, give smoothness, braking, turning turns, overcoming descents and lifts.

They eliminate vibration, the increase of which can lead to slippage of the wheels in extreme conditions, i.e. Their action is aimed at increasing the safety of movement on the highway and minimizing the threat of accidents.

But, unfortunately, any detail of the car is wearing over time, requires replacement. The question arises: for what symptoms the motorist can determine the malfunction of the shock absorber.

Make diagnostics is possible independently:

- to determine whether fluid flows are present on the housing (in good condition should not be)

- by pressing each of the corners of the body, a car should be shown, only one return movement should occur as a response, the machine should return to its normal position.

- in the event of a malfunction of the shock absorbers when swaying the car, the knocks will be clearly listening to

Such uncomplicated testing will allow you to identify a malfunction, and therefore the offensive of its replacement time.

Useful advice

In order not to make a mistake when choosing shock absorbers, it should be considered:

- many models are designed for certain car brands, so it is desirable to explore the catalogs that are in specialized stores

- type of previously used models

- preferred driving style

- the condition of the roads for which you have to ride in most cases

- cost, especially if the replacement will be carried out on a used car

- replacing oil shock absorbers on gas, or vice versa, should be carried out on both axes at the same time, otherwise there is a risk of obtaining significant changes in the behavior of the car

None of the implementative firms can guarantee the quality and long period of the shock absorbers in the event that they are installed on a car with a faulty suspension, without anthers and bumps, and the installation itself will be carried out with a violation of technology.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving a car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

I would also add HOLA here, the cheutsight do well, chasing it on such.