If the vehicle ceased to dial the speed normally, the overclocking dynamics disappeared, and in the cabin, from time to time, a rather unpleasant grown smell is felt, which means that soon the part of the vehicle fails, the clutch. What to do if it sinks?

Content

- How the clutch works, the clutch device

- Slises clutch or not how to determine

- Coupling, reasons for tonv

- Clutch pedal, how to adjust the clutch pedal

- Friction pads, how to change friction linings if they wear out

- Oil on overlays, how to remove oil with overlays

- Purpose springs lost elasticity, driver's actions

- Tips of professionals

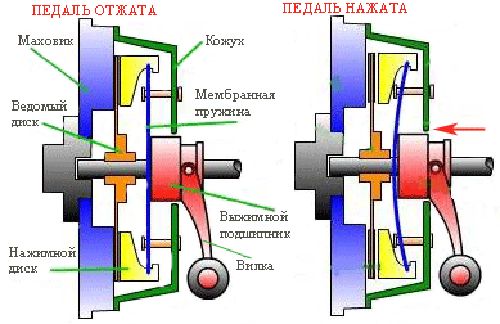

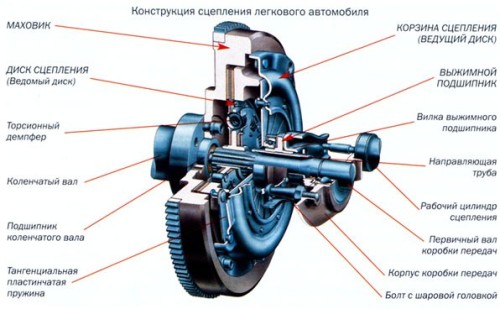

How the clutch works, the clutch device

The grip is a constructive dedicated element, which allows for a short turning off the drive shaft of the internal combustion motor from the mechanical drive of the wheels to lower or increase the transfer number of the dispensing box. It also makes it possible to achieve a smooth shutdown or turning on the load on the motor, which prevents mechanical damage to the crankshaft.

For vehicles with any type of gear shift, such a clutch system composition is standard:

- Clutch pressure disc.

- Slave clutch disc.

- Leading disc clutch or flywheel.

- Mechanical refrigerated bearing.

There are such types of clutch for variation of switching gear:

- Mechanical - the transfer number of the dispensing box The driver chooses manually.

- Electrical - the principle of operation is similar to a mechanical clutch, only it squeezes it with an electric motor, and not the driver's enhancement.

- Hydraulic - used in transport with automatic checkpoint.

- Variatorial - due to the high cost of the service and complexity of the structure, is very weakly distributed. It is a device in which certain hooks converge under the influence of the centrifugal force and during contact, the wedge belt is scrolled.

- Combined - To optimize the control of the gearbox, use the hydraulic and muscular type of switching simultaneously.

Slises clutch or not how to determine

No vehicle breakdown occurs instantly.

As a rule, the malfunction is preceded by changes in the operation of the motor, to which the car owner must necessarily pay attention. Ignore such changes is unreasonable, and in some cases, even dangerous.

- The vehicle behaves inadequately on the road. When acceleration is very tupit.

- If you squeeze the clutch on the plugged vehicle, it can be heard, and the pedal is hardly moving.

- When moving on high motor turnover, a specific humor is heard, which stops if squeeze the clutch pedal.

- After warming up the motor and switching on the transfer, the vehicle is moving with jerks.

To check whether the clutch is regularly:

- Heat the motor so that as a result of thickened oil, additional resistance occurred.

- We put the vehicle on a flat surface so that there are no significant slopes, and turn on the parking brake (handbrake).

- Using the throttle control pedal, we specify the following motor turnover - 1500-1700 rpm.

- Up to the stop, squeeze the clutch control pedal and turn on the first gear.

- Now smoothly let go of the clutch.

If after this procedure, the pedal will not stall, then the adhesion clearly requires repair.

Coupling, reasons for tonv

There are a number of major reasons for which the clutch is sinking:

- Outflows on frictional tabs through loose glands.

- Diaphragm springs are broken with fixed refrigerated bearing.

- Deformed drive disc, usually, as a result of incorrect assembly.

- Mechanical wear of the slave friction disk under the influence of time or as a result of improper use of vehicle motion modes.

- The complete absence or reduction of the free movement of the clutch inclusion pedal.

Clutch pedal, how to adjust the clutch pedal

To adjust the clutch pedal, you must perform a number of the following actions:

- Open the driver's door, we find the clutch pedal, press it until it stops and measure the distance to the most extreme point of the pedal.

- Next, let go of the clutch pedal and again measure the distance to the most extreme point of the pedal.

- Then you should calculate the difference between these values. The resulting indicator should be approximately 12.5-13.5 centimeters. The maximum pedal pass is not more than 16 centimeters. If the value is different from the required range, you need to adjust the clutch, that is, the free course of the pedal.

- Open the vehicle hood and on the gearbox we are looking for a lever with a clutch cable, which goes to the pedal. Near the lever there is an iron rod, fixed with two nuts and to which the cable goes.

- After that, we take the horned keys and unscrew the nut data slightly. For easy unscrewing and lubrication, you can apply the WD40 liquid lubricant. To adjust the clutch pedal, you need to use the nut, which is located closer to the pedal. If the nut is screwed to the clutch pedal, its free move will increase, and vice versa.

- Now you should measure the pedal stroke inside the vehicle again.

- After the desired pedal move is set, tighten the second, warning nut to fix the adjustment.

- At the end stage, it is necessary to make a control measurement and check the clutch pedal. When you click on this pedal, there should be no extra friction and sounds, the pedal should be easily pressed. During the ride there should be no slip and smell of Gary in the cabin.

Friction pads, how to change friction linings if they wear out

If the slaves of the slave disk wear out, the free course of the pedal decreases significantly, and it means that the clutch may slip. In this case, it is necessary to replace the friction linings, if they struggled in separate places or cracks appeared on their surface.

Oil on overlays, how to remove oil with overlays

This problem occurs as a result of a number of reasons:

- If the tightness of the hydraulic drive is broken.

- As a result of excess lubricant on the crankshaft shaft or on the gearbox shaft.

- When damaged the gearbox sealer or motor.

If the pedal move is normal, but the clutch still sinks, then, apparently, oil fell on the lining. Dismantling the clutch and pay attention to the slave disk with overlays. As a rule, on the lining and disk oil penetrates its excess in the gearbox, as well as, as a result of contamination of the drainage clearance of the flywheel.

To remove oil from lining, it is necessary to rinse them well with gasoline or kerosene, after which the parts should be wiped dry and clean the sandpaper.

Purpose springs lost elasticity, driver's actions

Under the influence of time, push springs are able to lose their elasticity. In this case, they create insufficient pressure and clutch sinks. Spring data status must be checked for a service station - to check them yourself is not independently impossible, since a specific equipment is required to check. If the springs weakened, it should be replaced.

Tips of professionals

It is necessary to solve the problem with the clutch problem immediately. Otherwise, when driving on a complex road surface, there is a significant risk of a motor breakdown.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Viscounts of the fan, work uniforms of the fan, malfunction of the ventilator fan, repair of the ventilator fan

Comments