The processes of wear and destruction concern even products from such a durable material as a metal. Therefore, the owners of the car with experience with corrosion of metal parts of the body are not known for the heal.

The change in the original characteristics of metal structures during damage to corrosive processes is extremely undesirable - after all, the body is the placement of numerous aggregates and parts, the fastening of which should be distinguished by reliability.

To ensure your car a long life requires timely adoption of measures to prevent the emergence and development of rust, because the recovery of methala is the case is quite problematic.

Content

- Metal corrosion of car, general information

- Corrosion protection methods

- Film coating

- Rust converter from which it consists

- Principle of Rust Converter

- In what form manufacturers produce rust converters

- In what places of the body you can use rust converters

- Movil with rust transducer, pros and cons

- Rust Converter Zincar Pros and Cons

- Rust Transmitter Antiruster, Pros and Cons

- Hi-Gear Rust Converter, Pros and Cons

- Rust Rust Converter, Pros and Cons

- Sonax Rust Converter, Pros and Cons

- Rust converter SF-1, pros and cons

- Rust Converter Runway, Pros and Cons

- PERMATEX Rust Converter, Pluses and Cons

- Bitumast rust converter, pros and cons

- Rust converter phosphomed, pros and cons

- Safety regulations when working with rust converters

- Tools, fixtures, consumables

- How to use rust transducer

- Tips of professionals

Metal corrosion of car, general information

The most common cause of corrosion is the electrochemical effect resulting from the effects of vapor of electrolytic solution on metal body parts that have minimal protection.

In addition, condensate can accumulate in hard-to-reach places and provide its destructive impact over a long period of time. Electrochemical corrosion is also associated with the formation of currents flowing in a metal and an electrolyte solution to form closed electrical circuits.

The state of the atmosphere is negatively affecting the state: a thin film is formed on an unprotected surface, containing chlorine and sulfur impurities, oxygen molecules condensed with moisture. It is influenced by the temperature and humidity of the environment. As a result of the effect of dry corrosion, the metal fades, but not destroyed.

A completely different picture is observed in the case of high humidity - the wet film thickens, its electrical resistance is reduced to minimum values, corrosive electrochemical processes begin.

For the start of the wet corrosion, it is enough to increase air humidity up to 70%, but it is impossible to lose sight of air pollution and standing of the metal surface of the parts. The smallest particles of solids, i.e. Dust or dirt can condense moisture, larger - it is adsorbed.

Corrosion by the nature of the defeat is divided not several species:

- spotted when the depth of the lesion is significantly inferior to the diameter of the spots

- contact, occurring at points of touches of metals with different properties

- ulcerative, at which the depth and diameter of defective areas are approximately equal

- fatigue, arising at points exposed to constant mechanical stress and the effects of aggressive media

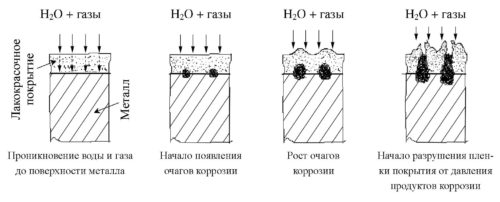

- fitting, occurring under the layer of paintwork

- slotted, the location of which is in hard-to-reach gaps or cracks.

For car bodies are characteristic:

- slit corrosion, to detect which in the initial stages is difficult, as a result - over time there may be severe damage;

- the punch, which is manifested by poor swollen on the surface of the paint, to detect such places is sometimes difficult, but in the place of the damage can be observed quite deeply damage to the structure of the metal, up to through through.

A clocking phenomenon is the damage to the corrosion of points, in which mechanical damage to the paint, chips or micro-soles are observed, to notice corrosion in this case, in order to appear on the surface of rust.

In addition, the corrosion of the automotive body is divided into:

- cosmetic, which is easy to notic on the surface, it does not affect the performance, but eliminate the foci of such a damage should be timely.

- the penetrating, arising in places of special pollution, under the influence of moisture, notice it is more difficult, the damage caused to it can be quite serious.

- structural, which negatively affects the rigidity and strength of the entire carrier structure.

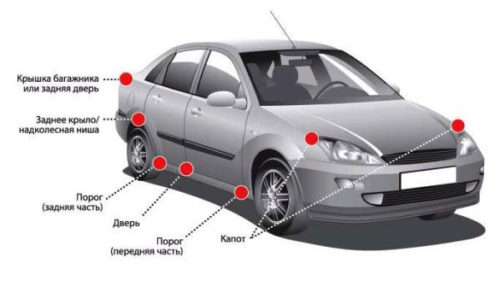

Practice shows: most often corrosion amazed:

- body contact points with overhead details

- metal edges of flanges on doors, hood, lid trunk

- places of welding seams connecting body panels

- lower parts of the door panels

- bottom body

Corrosion protection methods

Since the phenomenon occurs quite often and delivers a lot of harvest to motorists, then a lot of ways to combat it and its warning is developed.

It makes sense to consider the most effective of them.

autogrurtovka

Applied to metal surfaces as the first layer. The main task is to create a good grip between the metal and paint, the protection of the metal surface from the devastating effects of rust.

The coating created by primers is not able to completely isolate the metal surface with a wet environment, but it will help slow the corrosion processes.

phosphating

To obtain a more pronounced protective effect, it is recommended to use phosphate primers that create a durable layer of oxide film. You can apply phosphate primer by dipping parts into a special container.

ocinkovka

This type of protection has two functions:

- electrochemical

- barrier

For applying a layer of galvanizing, parts are placed in a tank with a melted zinc. As a result, a layer of ferricular alloy is formed on the parts of the body, a thickness of about 1-2 microns.

autocrats and varnishes

To the paints and varnishes for the car body requires special, they should:

- form high strength film

- resistant to abrasion

- have a high adhesion in relation to the primer

- being resistant to direct sunlight

In modern car market, high-quality paints and varnishes are presented quite wide.

Film coating

Work on the application of the protective polymer film is performed by car service masters. Film This colorless and absolutely transparent, lamination may be subject to any surface.

More efficient protection today failed.

The film application technology is quite simple, but before proceeding to sticking, it will be necessary to completely remove traces of corrosion, eliminate the chips and secure and paint the scratch.

Next, the protective layer is removed from the polymer film and it is simply pressed by sticking side to the dry and clean surface of body parts.

Such a film can serve for about three years, then it will have to be removed and in the same way to stick a new one.

And as a means of protection, it is used: bitumen mastic, liquid polymers and oils, wax and paraffin.

Rust converter from which it consists

To carry out a procedure for restoring detected rusty areas, preliminary preparation will be required, often resorted to the use of modifiers.

Converters can cope with a rust layer thickness of which does not exceed 100 microns if the corrosive layer is thicker - it is recommended to use gel compositions.

Important condition: The adhesion of the coating paintwork materials relative to the transformed layer should be high enough and exclude the possibility of an electrochemical reaction.

By chemical composition, converters are divided into:

- neutral and acidic

- multicomponent and single-component

- film-forming

As a result of their exposure, the primer layer can form, in some cases the transformed layer is removed.

The active substance of almost all rust modifiers is orthophosphoric acid. Under its impact on the surface of the metals, phosphate film is formed, characterized by protective abilities and having high adhesion relative to autocrasors and varnishes.

Orthophosphoric oxides orthophosphoric acid acts on the scale and nonhyrated oxides.

In addition to orthophosphoric acid, as part of modifiers may be attended by:

- Oxycarboxylic acid (Tannin). Among the positive properties of Tannin - the ability to inhibit influence. If plant tannins are used in the manufacture of modifiers, they are related to neutral products.

- Zinc monophosphate in combination with phosphoric acid, such a mixture is capable of forming a zinc phosphate layer capable of creating a positive electrode potential, higher than the one that is characterized by iron.

- Substances that are inhibitors of corrosion, their purpose is to slow down corrosion processes. Compositions with pronounced oxidative properties are used as passivating substances. If the metal is covered with passivating composition, the process of destruction of its corrosion slows down significantly. The purpose of adsorption inhibitors is the creation of an additional layer that enhances resistance to corrosive processes.

- In aqueous compositions, epoxy or alkyd film-forming substances may be present.

Principle of Rust Converter

The work of the rust modifier is:

- splitting rusty particles

- giving them neutrality with respect to pure metal

The formation of a polymer-latex layer

In the resulting coating, zinc and pigments can be kept, the paint or varnish can be applied to the dry layer, the primer does not need.

Due to the simplicity of application and practicality, transforming modifiers have high demand and popularity of motorists.

The masters are more likely to resort to traditional techniques: first carefully cleaned rust, then high-quality primers are applied.

In what form manufacturers produce rust converters

The conveyor consistency can be gel, liquid, pasta-like.

It is on this factor, as well as the packaging format, it is recommended to pay attention when purchasing. If the surface area is small, then the liquid product can be purchased - it will be possible to immerse the part entirely.

For vertical surfaces, the optimal option will be using a modifier in a state of gel. If you need to apply to large areas, you should pay attention to the products, packaged in the canopy - to apply them much easier.

Before applying paint, one-component compositions are washed off, but not water, but solvents is recommended as a wash. They degrease the surface and simultaneously dried it, prepare to paint.

In what places of the body you can use rust converters

The place of using rust converter can be any metal part of the body, which has become a platform for the start of the corrosion process. The main thing is to notice in a timely manner and eliminate damage to the coating - the process of corrosion has the property to quickly distribute and capture all large areas.

Naturally, the cost of repair in case of significant corrosion damage will be considerable.

Movil with rust transducer, pros and cons

You can apply Movil into painted or pure metal surfaces, dry the treated surface will not need. The resulting protective layer is moistureproof and has moisturizing properties.

The remedy is quite effectively fighting with rust, but does not have a detrimental effect on the paints and the surface of the metal. A positive point - the remedy is suitable for use in hard-to-reach areas, because Differs good fluidity.

Rust Converter Zincar Pros and Cons

The processing of the rust metal surface of the zincarem began to destroy iron oxides, convert them to phosphates. The orthophosphoric acid, manganese and zinc salts in the process of chemical reactions occurring on a corrosive surface are present in the composition of the cincar, contribute to the formation of an active protective layer on it.

The high strength of the protective coating provides accurately sustained ratio between its terms.

In the process of creating and testing the drug, additives of organic and inorganic origin were identified, which have positively affected the quality of the anticorre, allowing:

- perform a uniform distribution of the product on the treated surface, which allows you to get the economical consumption of the means

- aerosol packaging makes it possible to apply the drug in hard-to-reach places and hidden cavities

- the tool is fireproof

- ergonomic balloon shape, makes the spraying process quite comfortable

An attractive moment is a relatively low cost. Consumption rate is about 110 - 340 g per 1 square meter. M processed area.

How to remove rust with cincar, watch the video:

Rust Transmitter Antiruster, Pros and Cons

ACT-472 Antiruster processed by the preparation of ASTROCHIMA acquires reliable protection in the form of a film that provides a durable coating and preventing corrosion, which can serve as the basis for applying paints.

Phosphating and galvanizing surface prevents the possibility of electrochemical corrosion. The active crystallohydrates in the formula are a positive effect on the duration of the metallic parts service.

Hi-Gear Rust Converter, Pros and Cons

Hi-Gear uses both lovers and professionals. Applied easily and quickly, because It comes in the form of a spray. But high acid content requires careful treatment with the means - when processing, it is possible to very rapidly destroy the paint coating.

Do not neglect precautions - leather and eyes require additional protection.

Apply to a few approaches, after processing it takes a wash, it is recommended to produce it with alcohol. It is very difficult to remove the resulting film, but the paint applied to it will not be worn, recurrences of corrosion do not arise, therefore, the means there are high-quality corrosion inhibitors.

Rust Rust Converter, Pros and Cons

Kolchuga can be rightfully attributed to the number of the best transducers of domestic production, and both in quality and given its democratic cost. He is able to combat rust varying degrees of complexity.

The processing of the metal surface of the Kolchuga leads to the formation of a durable zinc-oxide-phosphate film. The tool is perfectly withstanding sharp temperature differences.

Sonax Rust Converter, Pros and Cons

Sonax manufacturers include their product to the discharge of unique, because It is intended not only for the conversion of rust, but also to create a stable soil layer with excellent adhesion, which is an ideal base for subsequent repair work and painting a car.

The main advantage of the means is the absence in its formula of chromium acid salts, mineral acids and lead. The basis of its original formula is water.

Before applying, it will be necessary to work as a brush to remove rust, which is included. In the package with the converter, there is also a brush for a comfortable application on metal surfaces.

Rust converter SF-1, pros and cons

It is possible to use SF-1 for processing the surface of any metals, including aluminum, steel, cast iron, galvanized. The composition successfully converts rust and densitized rolling scale into the amorphous film of a dark color capable of withstanding the temperature differences in the range from -60 to + 600C, and the voltage of the order of 300-500 V.

The film is able to slow down the corrosion process, provoked by the wandering currents, and ensure the protection of the surface of metal parts in the event that they are stored in the outdoor, provided that the air humidity is within 90%.

The SF-1 agent is compatible with most varnishes and paints that are applied without pre-primer.

Rust Converter Runway, Pros and Cons

It should be noted that along with the ability to form a rust waterproof layer Rust modifier RUNWAY refers to the vapor means (concerns temperature drops) and expensive.

Despite the fact that the Runway Reviews are most positive, the film received after Runway processing requires stripping - problems with adhesion may occur.

PERMATEX Rust Converter, Pluses and Cons

Permatex is produced in the form of a gel, the means can be applied using a spatula, the resulting layer is not prone to the runoff. The drug acts pretty quickly, as a result forming a layer, which completely replaces the primer. A significant layer of rust will require double processing, which can be made with a break at half an hour.

Additional convenience - no wash need, but before applying paints, a layer is recommended before applying the paint to the gel tool.

Of the disadvantages, you can specify the cost, which, however, is fully justified by high quality, speed and ease of use of this converter.

Bitumast rust converter, pros and cons

The Bitumast means is designed to transform iron oxides and the formation of phosphate film can slow down the process of bearing corrosion after applying paints and varnishes.

Before applying the means, removal of dirt, loose and plastic rust, degreasing. You can process wet surfaces.

Application is made by spraying or wetting surfaces. Operating temperature - within + 5C - + 40C. Freezing of the composition is allowed, while it does not lose its properties.

Rust converter phosphomed, pros and cons

The phosphomed converter is a phosphating agent, designed to process the surface of parts from cast iron, steel, aluminum and galvanizing in order to obtain a protective chemically bound layer of insoluble manganese salts, zinc, iron.

Feature - phosphoma winter can be used to work at temperatures of order -15 C and higher. It is assumed to use the modifier both for coated rust surfaces and for new, which will be subjected to primary color.

For processing 1 m square. Surfaces will be required from 50 to 80 g. Produced by the domestic industry, the cost has a low.

Safety regulations when working with rust converters

It should not be allowed to enter the modifiers to the skin, it is desirable to protect your hands with gloves, wear protective clothing, glasses and respirator - a pair containing toxic substances are formed when working.

It is advisable to use a well-ventilated room for work, it is prohibited for a long-term location in the room where work is performed - to avoid the negative effect of harmful substances on the respiratory organs.

Avoid a long stay in the room, which carries out the car processing by the converter, since the pairs of means are able to fall into the lungs when applied.

Tools, fixtures, consumables

To perform work on the removal of corrosion traces may be required:

- nazcachka

- grinding machine or drill with nozzles

- putty knife

- pure rubbish

- degreaser

- dye

- rust converter

- primer

- scotch

How to use rust transducer

Works should be carried out:

- a day when there are no precipitation

- at air temperature above + 15c

- on a well purified and dried surface

Stages of work:

- With the help of coarse sandpaper, clean the surface from traces of rust, then process the surface of the fine-grained sandpaper

- If rust lesions are essential to use drill with nozzles

- For softening the rust layer, you can use a special acidic remover of rust, it should be used according to the instructions

- Next, proceed to apply the rust converter, in accordance with the instructions, it is required to be applied to a dry or wet surface.

- In accordance with the viscosity of the converter to apply brushes, spatulas, spatulas, spat

- If necessary, rust modifier is applied 2-3 times

- Before performing the following works, it is recommended to wait for a complete drying of the treated surface.

- If the body repair is performed - the surface is aligned, putty can be used, then a layer of paintwork material can be applied, preferably a day after the rust modifier processing.

About how the rust converter works - -n video:

Tips of professionals

Do not fully trust advertising and believe that transducers are the means of magical, which can be used without observing the rules, treat them contaminated or raw, painted surfaces.

In fact, even high-quality funds will not be able to remove moisture and transform dirt and rust in a clean metal.

In this way, you can only hide corrosion processes, but after time the oxidation processes will again appear, even more actively.

Experts argue that proper preparation is 80% of the successful result.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

- Viscounts of the fan, work uniforms of the fan, malfunction of the ventilator fan, repair of the ventilator fan

Comments