Most recently, car owners had many times during the entire service life of the car to carry out small or engine overhaul. Today, motorists prefer car brands on which mechanisms that do not require systematic repair or maintenance are mounted. However, unfortunately, all aggregates and vehicle nodes wear out at the same time. The most short-lived element of the car is a motor that fails in the first place. About this further in the article.

Content

- Auto engine, why it fails faster than the machine itself

- Causes of engine wear

- How fuel affects the engine

- Embossed engine oil like oil affects the engine

- Bad coolant

- Oil filter, air and fuel - dirty filter, late replacement, as it affects the engine

- Abrasive wear of engine parts, causes

- Mode of operation, influence on engine durability

- Start and engine warming, how they affect the life of the engine

- Long sucks, good or bad

- Maintenance and timely repair

- Design solutions as they affect the durability of the engine

- Tips Pros: Let's sum up the above

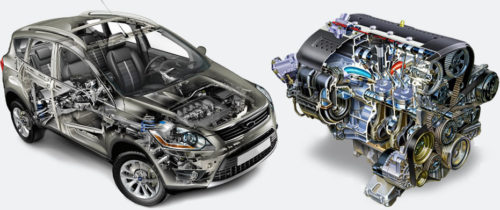

Auto engine, why it fails faster than the machine itself

The automotive engine is able to quickly fail as a result of the impact on it of various external and internal factors, such as poor-quality fuel or oil, extreme operating conditions, and so on.

Causes of engine wear

To reasons of accelerated wear of the power unit include:

- Unexpected oil change.

- The use of low-quality oil.

- The use of low-quality fuel.

- Unsatisfactory condition of the fuel or air filter.

- Fine removal of motor faults.

- Incorrect operation of the power unit.

- The presence of production defects.

How fuel affects the engine

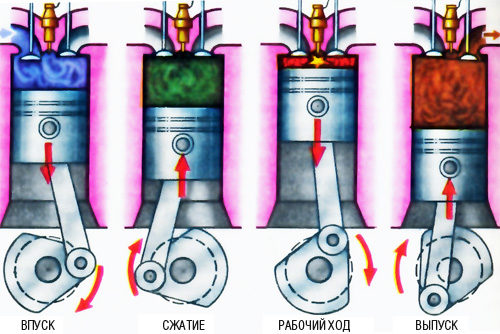

The quality of fuel is the most important factor affecting the "driving quality" of the vehicle and to work the engine. Strict requirements that regulate emissions of harmful substances by machines are predetermined by some characteristics of the fuel used.

Fuel characteristics that affect the operation of the motor:

- Fuel evaporation.

- The presence of aromatic hydrocarbons.

- The content of water or alcohols in the fuel.

- Octane number.

Fuel evaporation characterizes its ability to move into a steam phase from a liquid state. Gasoline does not burn in liquid state, so it should evaporate before entering the combustion chamber. Since the ambient temperature affects the operation of the motor, then at various times the year different types of fuel are used. With a sharp change of air temperature, there may be different faults that are due to the inconsistency of fuel and weather conditions.

High evacuation:

- The formation of steam plugs.

- Overload adsorber steam phase.

- Allocation of malicious steam phase.

Low evaporation:

- Bad engine operation in cold weather.

- Slow engine warming.

- Difficult launch of a cold power unit.

As a rule, aromatic hydrocarbons are added to the fuel to increase the octane number. As a result of their too high concentration in the combustion, soot deposits are formed on the inlet valves, which is the reduction of the power of the motor, the deterioration of fuel economy and the increase in the exhaust gases of harmful components.

Adding alcohols in fuel increases the octane number and reduces emissions of CO. The most common additives in the form of isopropyl alcohol, methanol and ethanol. Excessive concentration of alcohols in a combustion is capable of damaging the components of the fuel supply system and worsen the "driving quality" of the vehicle.

Faults that cause water in fuel:

- Uneven operation of the motor in idle mode.

- Increased fuel consumption.

- Slugging or jerking during acceleration.

- Difficult engine launch.

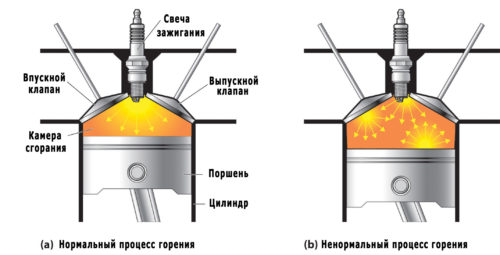

The octane number predetermines the ability to fuel to resist the appearance of detonation. Fuel with a large octane number (for example, gasoline AI-95) resists detonation than fuel with a low octane number (for example, gasoline AI-92). The emergence of detonation reduces fuel efficiency and worsens the operation of the power unit. Strengthening detonation is able to seriously damage the motor.

Embossed engine oil like oil affects the engine

The use of poor-quality oil is able to leave the accelerated wear of the power unit. The oil that does not have the entire properties of the properties needed for the normal lubricant of the elements is not able to prevent the formation of scaling, as well as the destruction of the working surfaces of the highly loaded parts (turbocharger bearings, crankshaft liners, piston skirts, piston rings, gas distribution mechanism, and so on. Increased The inclination of poor-quality lubricants to the appearance of resinous sediments can lead to blockage of oil channels than to leave the friction pair without lubrication, which will cause their rapid wear, jamming and education of scaling. These effects are possible when applying a lubricant, which in terms of quality class does not comply with this power unit. . For example, if instead of the recommended oil applies cheaper.

Bad coolant

When choosing Tosola, it is necessary to be extremely attentive, since the use of dubious or poor-quality coolant for several months can "kill" a car engine. This will be preceded by the destruction of the body of the water pump, the tube of the radiator and the head of the cylinder block. It is worth saying that any violations in the operation of cooling and lubrication systems lead to the rapid wear of the components and, consequently, to an expensive and time-consuming repair.

Oil filter, air and fuel - dirty filter, late replacement, as it affects the engine

The increase in the resource of the power unit also affects the provision of high-quality oil purification, fuel and air, which come to the motor. A polluted oil filter cannot clear the oil that can easily penetrate through the bypass valve into the motor. Pollution of fuel and air filtration components leads to an increase in hydraulic pressure, as well as to reduce the power of the power unit. Ultimately, the filtering component does not withstand and burst, however, that the saddest, the car owner may not even notice.

Abrasive wear of engine parts, causes

All the above factors over time lead to the most detrimentable outcome for the engine - abrasive wear of its parts. And purging and flushing of an element of a solid large particle embodied into the soft surface is not able to help.

In other words, abrasive wear is the result of cutting or scratching effects of solid particles of conjugated elements or the result of the dust from the dust parts brought with lubricant or by air. Abrasive wear of the motor is usually manifested in the form of an overestimated oil consumption.

The study of damaged elements reveals a different nature of damage:

- Education on the piston skirt of a wide matte spack of contact from the maximum side load, as well as from the opposite side.

- The occurrence of the processing profile wear piston skirt.

- Education on piston rings, sleeve or cylinder wall, as well as piston skirt, thin furrows in the course of movement.

- The occurrence of wear in height on the piston rings and their grooves.

- Increase the thermal gap on the piston rings. The edges of the rings are made extremely sharp.

- Wearing the working edges of the low-pressure ring.

- On the piston finger there are furrows of a wavy profile.

- Traces of abrasive wear are observed on other elements, for example, on the valve terminal.

Mode of operation, influence on engine durability

On the extension of the motor resource and on the quality of its work also affects the mode in which the vehicle is operated. Manufacturers cannot insure their strength units from all abnormal modes of operation, in which the engine is operated. Torn ride mode, sharp starts from the scene do not help increase the resource of the motor, and, on the contrary, it is reduced. To extend the resource of the power unit, it is necessary to choose a uniform motorway to drive without sudden stops and starts.

Start and engine warming, how they affect the life of the engine

The operation of the power unit at the high frequencies of the crankshaft rotation and maximum loads can significantly reduce its resource (by 30 percent or more). It is worth noting that the exceeding the permissible number of revolutions leads to the destruction of the engine elements.

About 70 percent of the motor wear falls on the launch mode. It is especially helping to reduce the resource cold launch, if a lubricant with inappropriate viscosity characteristics is covered in the power unit. First of all, it is connected with a high viscosity of lubricating material at low temperature - so that it entered the friction pairs is needed more time.

Short trips in winter on an immentable engine contribute to the emergence of deposits in the lubricant system and corrosion wear of cylinders, pistons and their rings.

Long sucks, good or bad

Significantly reduce the resource of the engine of violation of the bearing lubrication conditions, as well as the entire cylindropore system. A negative impact has a negative impact of short trips with long stops. At the same time, the properties of the lubricant deteriorate deteriorate, and deposits arise on the walls of the channels. Remember that before putting a vehicle to "wintering", several events should be held, which will protect the motor cylinders and the power unit itself from corrosion. It should be noted that the long inaction of the motor and the car as a whole leads to the emergence of malfunctions and defects, which significantly reduces the "life" engine.

Riding around the city also significantly reduces the resource of the power unit, since the driver has to slow down very often. The resource of automotive engines moving to significant distances is much higher, since the motor is not exposed to high loads.

Maintenance and timely repair

It is necessary to provide a timely maintenance and diagnostics of the engine. On time change the cooling fluid, lubricant and adjust the desired nodes and units. Reducing the filter and oil replacement interval in winter significantly increases the motor resource. However, only high-quality filters and oils need to use.

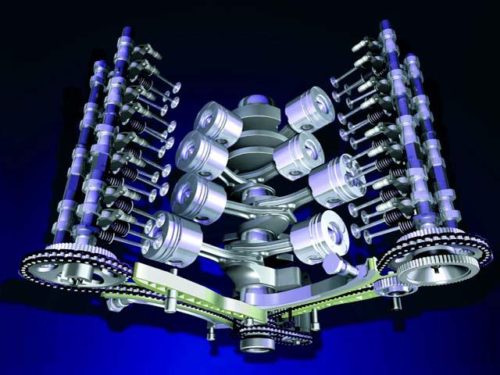

Design solutions as they affect the durability of the engine

Motor constructive solutions are able to become a decisive factor affecting the life of the power unit. In fact, each model of this mechanism has its own defined design features. When for one vehicle, small disorders in the system of nutrition, lubricant or ignition are not essential, then for another motor, they can become destructive. Compliance with the manufacturer's recommendations and the proper operation of the car is the key to the durability and reliability of the engine.

Tips Pros: Let's sum up the above

Of all the above, it can be concluded that the extension of the resource of the power unit has an impact of a mass of factors that either exist initially or occur during operation. There are no trifles in this matter. In most cases, the increase in the resource depends on increased attention to the state of important mechanisms and on the conditions of operation of the power unit.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

- Viscounts of the fan, work uniforms of the fan, malfunction of the ventilator fan, repair of the ventilator fan

Comments