Modern car is a complex mechanism, and not just a vehicle for movement. Requirements of comfort, economy and security cause automakers all the time to look for new technical solutions. That is why cars are changed from year to year and evolve. However, despite this, some units in vehicles remain unchanged, albeit substantial upgrades.

Content

We can say that the most traditional unit since they released the first car with the engine of internal combustion, is the gearbox. Despite significant changes in the design, the gearbox performs the same functions - transmits torque from the motor to the wheels in the efficient engine operation mode. However, if the campaign MCPP was previously released, today cars close to sports are completed with a sequential mechanical transmission. From cams, they differ in the inability when switching to jump over one transmission. In addition, the MCPP with double adhesion has become enormous popularity. Although most of the overseas manufacturers produce automatic transmission, in Russia and Ukraine the greatest prevalence still have boxes of mechanical type. But it is worth saying that the operation of the vehicle with the MCP requires certain skills and skills.

Machines with manual gearbox

Manual gearbox can be performed in a two-channel or trivial concept. The boxes of the first type are mainly installed on the front-wheel drive and rear vehicles, and the latter are used on rear-wheel drive machines. The transition scheme of each type has its own certain differences, so they should be considered separately.

The scheme of the trust gear implies the presence of three shafts - presenter, intermediate and slave. In any modern manual transmission, all three shafts are in contact with the gear. The slave shaft during the included neutral transmission is not fixed and rotates freely. As a result of the transmission on, the synchronizer is longitudinally moved to the connection with the gear, which provides a rigid clutch of the slave shaft and the entire gearbox with the motor. This makes it possible to start transmitting the required torque on the wheels. To turn on the reverse, a separate shaft is used with an individual gear.

Usually, a trivial gearbox has an osostic gear, which ensures their wear resistance, noiselessness and durability.

In a two-channel gearbox on the drive shaft, connected to the clutch, placed relative to it fixed gears. The main difference with the pre-design - no intermediate shaft, since parallel to the leading shaft immediately goes the slave, also endowed with moving gears, which are constantly in contact with the components of the driving shaft.

device gearbox

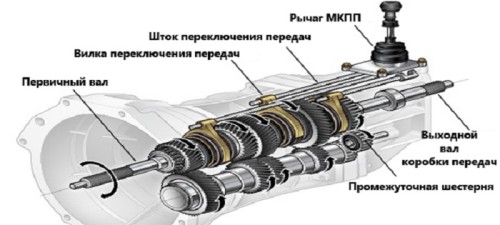

MCPP is as follows:

- At the bottom of the box is the Carter.

- Inside the primary, intermediate and secondary shafts with gears.

- Also in the mechanical transmission there is an additional shaft and reverse gear.

- From above the box is the gear shift mechanism with locking and locking devices.

- Synchronizers.

- In the cabin there is a gear shift lever.

Carter together with the housing contains all the main parts and nodes. It is half filled with transmission oil, very necessary for lubricating the inner mechanism, since when the gearbox is running, the gearbox is subject to considerable loads and must be constantly lubricated to cool the parts and exclude friction.

In the crankcase, bearings are pressed, where the shafts rotate. In the shafts of the gearbox there are large sets of gears with a variety of teeth.

Synchronizers are needed for smooth and silent gear shifting, by adjusting the angular speeds of the gear.

The gear shift system is designed to replace the transmission and control it from the salon with the lever. At the same time, the locking device does not allow you to simultaneously include two transmissions, and the locking does not give the transmission to spontaneously turn off.

Driving a car with a manual transmission

Manageing MCPP is performed using the switching lever and control pedals.

Each transmission corresponds to a specific lever position. They should be remembered by heart, so that during switching is not to be distracted from the vehicle management. This gearbox requires an automotive of self-selecting speed and range of each transmission. It is worth noting that when operating a vehicle with manual transmission, reduced transmissions have a smaller speed, but greater power. Therefore, they are most effectively applied with difficulty driving modes - touching, movement from the slide, under the slide and so on. Accordingly, increased transmissions are used to drive at high speeds on a flat road. Timely switching of gears when driving, makes it possible to move the movement comfortable and smoothly without a supervolor operation of the motor on the boundary turnover.

speed \u200b\u200bon a manual transmission

- First transmission - up to 15 - 20 kilometers per hour.

- Second - up to 30 - 40.

- Third - up to 50 - 60.

- Fourth - up to 80.

- Fifth gear - more than 80.

how to touch on a manual transmission

- First of all, it is necessary to adjust the position of the seat so that the driver can squeeze the clutch pedal without obstacles, near the brake.

- Then it is necessary to set the mechanical box lever to the neutral transmission, having previously pushed the clutch. This is done before starting the motor. It is worth noting that gear shift without squeezed clutch is unacceptable. Constantly so making, the car owner exposes the manual failure.

- Next, we start the motor, turning the key on the watery.

- It is desirable to warm up the motor to the operating temperature.

- In order for the car to start moving, it is necessary to lift the foot from the clutch and click on the gas. It must be done when the motor turnover is reduced. The driver must learn how to properly balance the pedals. So that the vehicle is not "stood" when the clutch is released, the engine should have enough revolutions. To add them, click on the gas pedal.

how to ride on a manual transmission

- When switching to third gear and above, release the clutch a little faster than at the beginning of the movement or when switching to the second speed.

- The higher the speed of the ride, the longer the brake path will be.

- When the fourth transmission is turned on, the vehicle must be overclocked at least up to 60 kilometers per hour.

- When the fifth transmission is turned on, the vehicle speed should be 90 kilometers per hour.

how to brake on a manual transmission

Motor braking. It is used when it is necessary to reset the engine turnover and stay in difficult weather conditions (in the rain or ice):

- We let go of gas.

- Slowly press the brake.

- Before complete stop, quickly squeeze the clutch, otherwise the motor will stall.

- Turn on neutral transmission and let go of the pedal.

Brake in dry weather conditions. If the motorist needs to slow down dramatically while driving on dry asphalt:

- Completely release gas.

- Click to half a clutch pedal.

- Click on the brake until the vehicle stops.

Smooth braking:

- We let go of gas.

- We click on the brake for a while, not the touched clutch pedals. It is necessary to do it very smoothly, gently and carefully.

- When the speed is reset, squeeze the clutch and turn on the necessary transmission.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving a car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

- Viscounts of the fan, work uniforms of the fan, malfunction of the ventilator fan, repair of the ventilator fan

Comments