If your car has tubeless tires and on the road bus received a small puncture, no more than 5 mm, you can fix this problem with your own hands. But, you must understand that it is only temporary, and then the wheel must be given to repair on the tire. We will figure it out how to make the repair of the cannon-free tire on your own.

Content

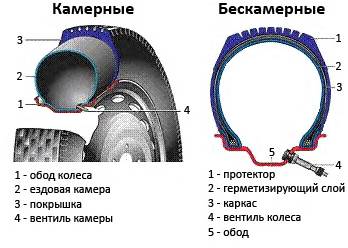

Cameless passenger tires, set for repair of tubeless tires

A set for repair of tubeless tires is best to have always in the store at hand.

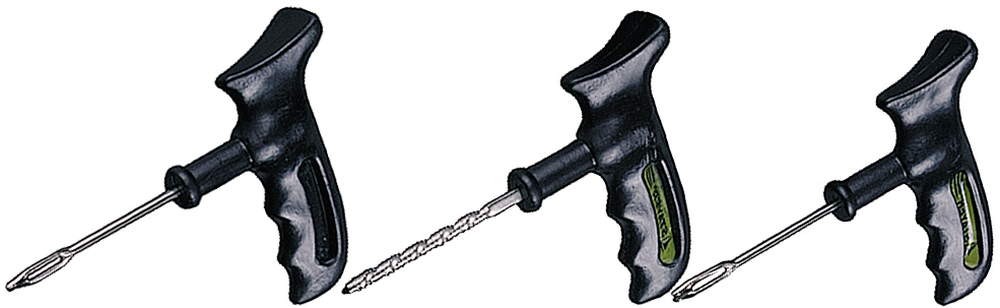

The set includes special harnesses, in the amount of 3-4 pieces, for repair of tubeless tires and two special devices.

The first device is a file, this item must prepare a hole in the form of a puncture to repair, i.e. Expand her and clean the edges.

The second device, looks like sewed, with the help of this sewn, in the future, you set into the hole, special harness.

A set for repair of tubeless tires, can be of different configuration, purchasing such a set, it is better to choose the one that includes a knife for trimming the harness.

The knife should be acute, as it will have to trim the harness, which includes a set of reinforced metal fibers.

If the knife is stupid, it will not master the reinforced cord.

In this case, you can use the stationery knife.

For repair, the glue in the form of a vulcanizing mixture may be needed. By purchasing a set for repair of tubeless tires, do not save and choose a high-quality tool.

For repair, you need a particularly durable metal and a strong handle.

The cannon tire is a variety of layers and under the tread is a cort of metal and all this needs to flow to the instrument.

And since the solid layers will have to prick, to prepare a hole for a cord, the tool must withstand a large load.

Cameless car tires, tool for repair of tubeless tires

Consider a file.

This tool must have a sharp end, round shape and comfortable strong handle.

The file is an expanding hole tool, it should expand the hole so that the harness fit there.

Special requirements: hardened steel, high strength, comfortable strong handle.

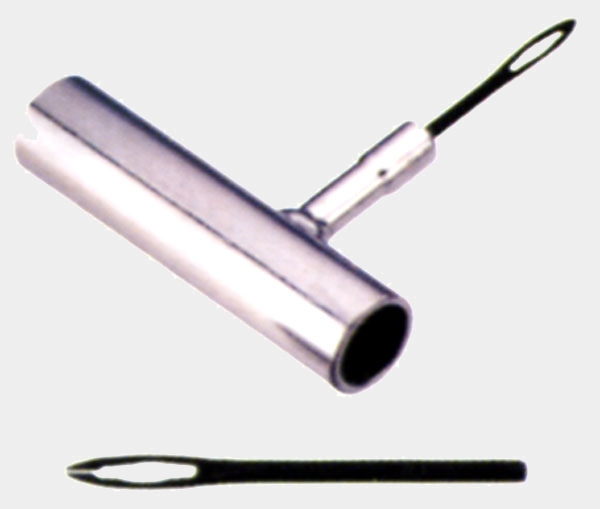

Consider the second tool - awl.

Using sewed, a harness is installed in the hole. At the end of the sewn there is a special cut that resembles a needle ear.

The task of the cut includes: pulling out awl, the cord must slip through the incision and the harness should remain inside.

Requirements for this tool: tempered steel, high metal strength, comfortable, tightly sitting handle.

Consider from what flashes, and they consist of raw rubber and reinforcing fibers.

Once again, I want to pay attention to the instrument handles, it is better if it is wide, comfortable handles, which during work that requires great efforts will not slip out of the hand.

Delicious car tires, repair of a tubeless tire do it yourself

First of all, find the place of the puncture.

Quite often at the point of puncture, there is an extraneous subject.

It can be like a nail and glass or a sharp stone.

It is necessary to remove a foreign object.

Mark this hole, otherwise it closes and you can not find it.

To do this, use the chalk or marker.

The discovered puncture sulfice from dirt and visually inspect the hole, rate the size of the hole.

If the hole is more than 5 mm.- straight road to the workshop.

If there is no spinner and there is no closer near the tire, try in the hole insert two harnesses, sometimes it helps.

In order to install in the hole harness, lower the air pressure in the wheel to 0.5 atm.

Filling the air, you will reduce the tension on the wheel design and do not spoil the court.

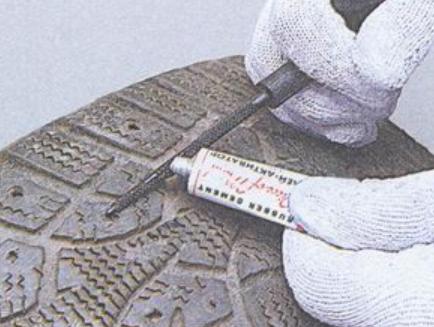

In the discovered hole, stick a file and make several circular movements with a file.

As a result, you must get a hole of this size in which you can push the harness.

One end of the harness to the crawl into the incision, just inhale, like a thread in a needle. If there is a glue, dear the shower harness.

Plug the shine with the harness in the hole on the wheel, the seer must log in somewhere on ⅔. Now your task is to remove sewed out of the hole, but the harness should stay inside.

Since the sewing ear has on the acute end of the incision, you should carefully pull out the instrument so that the harness remains, coming through the cut, inside the tire.

At the same time, the important part plays the length of the harness, the bulk of the harness should be outside the hole outside, and the small part, folded in two layers, should remain inside.

If you all happen, pumped the wheel and check if there is no leakage in the hole.

If air leakage continues, it is necessary to repeat the entire operation again.

The work is not complicated, does not require great mental effort and if everything is done correctly, harness firmly closes the hole and stop the air outlet.

If everything is done correctly and the air does not leave, remove the surplus of the harness from the outside. Work carefully, without cuts.

Correctly performed work will help you get to the repair shop.

Since the tubeless tires renovated in this way are not very reliable, go cautiously at low speed and on a flat road.

And remember that in the nearest service item, it is necessary to produce vulcanization of the tubeless tire, make a complete repair or replace the tire.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

- Viscounts of the fan, work uniforms of the fan, malfunction of the ventilator fan, repair of the ventilator fan

Comments