Shock absorbers - an integral part of any modern vehicle, providing the driver smoothness and lack in the salon shaking. However, the elements of the suspension over time are able to fail, because of which the irregularities of the road canvase begin to annoy even more. Not only the comfort, and the safety of the driver and passengers depends on the state and performance of the shock absorbers. The timely replacement of shock absorbers who have worked out, is an important step towards ensuring the optimal operating conditions of the vehicle. To fulfill this procedure, it is not necessary to access specialists, if you wish, you can perform the work yourself. About this further in the article.

Content

- Suspension shock absorbers, why are they needed

- The device and the principle of operation of the shock absorber

- Signs of fault of the front and rear shock absorbers

- Why shock absorbers better change in pairs

- Why new shock absorbers before installing need to pump

- How to pump a new shock absorber

- Tools, fixtures, consumables

- Safety in the replacement of shock absorbers

- How to replace the front shock absorber with your own hands (step by step)

- How to replace rear shock absorbers with your own hands (step by step)

- Why after replacing the shock absorbers it is necessary to make the wheel alignment

- Tips Prof.

Suspension shock absorbers, why are they needed

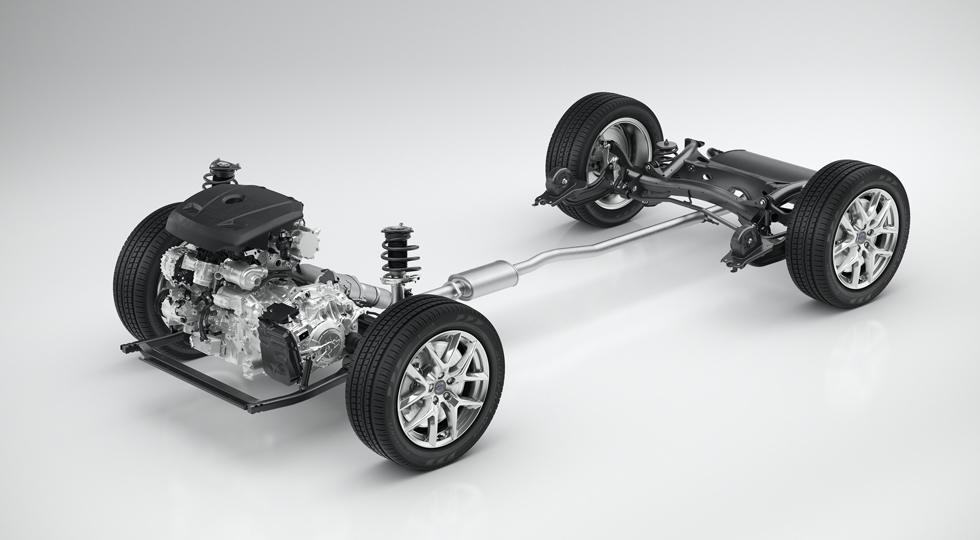

Even novice motorists know that there are springs and springs in the vehicle. It would seem that this is enough to level the oscillations when driving. But the design feature (work is only in one direction) does not allow the greatest smoothness. For this, shock absorbers are needed, which, thanks to its modern design, are effectively "quenched". The main task of the shock absorbers is due to hold the wheels of the vehicle in close contact with the road surface. In addition, they are needed to clean the jolts and shocks, which during the ride gets the vehicle body through the wheels.

The device and the principle of operation of the shock absorber

The most affordable and simple is two-pipe Shock absorber, which is 2 cylinders. One of these cylinders is placed inside the other. The working substance is a shock absorbing oil, which, with a piston located in the inner cylinder, is pumped by means of special holes from one cylinder to another. These holes are located both in piston and in the inner cylinder. So we have two working volumes where there is an alternate pumping oil depending on the stroke of the piston (down or up). During this pumping, the oscillation energy turns into heat. The piston is attached to the shock absorber. The working position for such shock absorbers is vertical.

The advantages of this type is its simplicity, maintainability, pricing accessibility. The disadvantages include the possibility of overheating and foaming the working substance in conditions of intensive work on a very uneven road floor when driving at high speed.

V one-rubles Designs, as a rule, applies gas under sufficiently high pressure to thirty atmospheres. It is separated from the piston and shock absorbing oil by another floating piston. Holes for pumping oil is exclusively in the working piston. As a result, weight and dimensions are reduced in such a design. It is better cooled due to the absence of an outer shirt. Better "keeps" the road, has excellent performance. The installation type for them does not matter. Can be mounted in stock down.

However, any outer damage to the cylinder is able to entail the piston enclosure and the yield of the shock absorber. In addition, they are sensitive to the ambient temperatures. High temperatures lead to an increase in gas pressure, which increases the stiffness of the stroke. Low temperatures, on the contrary, contribute to the increase in the softness of the stroke.

Signs of fault of the front and rear shock absorbers

Replacing shock absorbers are always necessary in the following cases:

- From the shock absorber oil leaks.

- On the supports of the springs Shock absorbers are expressive traces of corrosion.

- Piston rod corrosion The shock absorber is the direct cause of the deposit of the oil level, and, consequently, oil leaks.

- Corps deformation The shock absorber entails a slowdown or blocking the movement of the shock absorber piston.

There are a number of factors that determine the need for replacing shock absorbers:

- Accelerated tire wear.

- "Sat" a car in braking conditions with an increase in the brake path.

- The presence of uncharacteristic sounds when overcoming irregularities.

- Shake when driving.

- Large drifts when turning.

- Worsening manageability.

- "Shatting" of the vehicle.

- The expiration of the manufacturer of the service life.

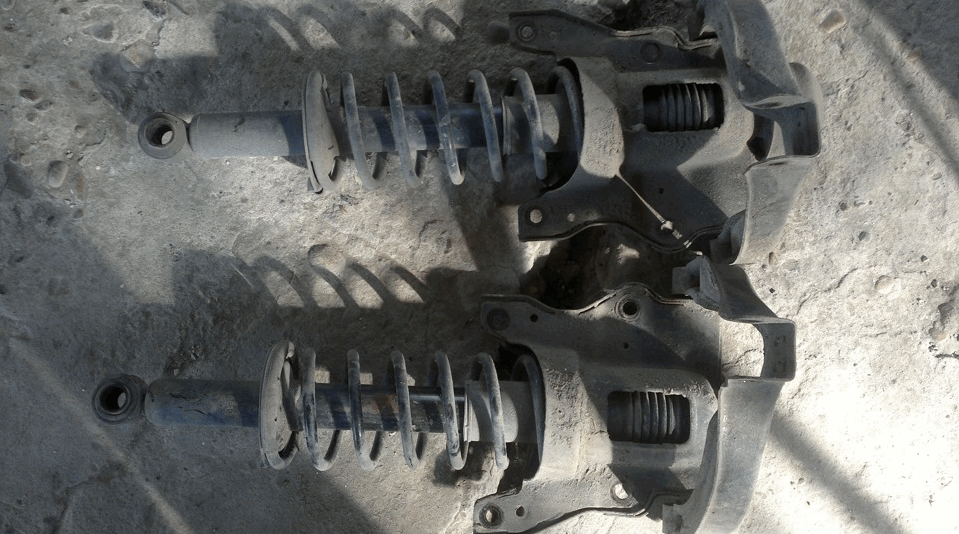

Why shock absorbers better change in pairs

Manufacturers of shock absorption racks and suspension elements advise changing shock absorbers only in pairs. None of the company for making shock absorbers will not give you any warranty on the rack if you have replaced only one shock absorber. This is due to the fact that if a worn old shock absorber installed on one side on one side, and on the other you installed a new one, the vehicle will become a roll, in fact all the load will have to the new shock absorber, which is why it will quickly fail. In addition, in conditions of such a replacement, the behavior of the car with a sharp braking and maneuvers becomes completely unpredictable.

Why new shock absorbers before installing need to pump

Since shock absorbers are stored in a horizontal position, gas in two-pipe shock absorbers falls from the external cylinder into the internal. This gas is not able to harm the rod or shock absorber during storage until the rack is installed on the vehicle. But if you do not drive it out before installing it from the inner cylinder, the shock absorber will not work correctly, it can also be caused by the jackets, failures in the shock absorber and exits of the valve valves. Therefore, two-pipe shock absorbers must be pumped before installing.

How to pump a new shock absorber

Two-pipe shock absorbers are pumped as follows:

- I turn down the shock absorber of the rod down, smoothly compress almost until the stop and fix it in this position for two to three seconds.

- Next, we turn the shock absorber in the compressed state back the stock up, keep in the compressed state three to five seconds and smoothly split the rod.

- Again, we turn down the shock absorber of the stock down, we wait for two to three seconds and repeat the previous operations three to five times.

- When pumping is finished, the shock absorber should be in a vertical position all the time (required to stock up) up to the installation on the vehicle, as well as during the installation.

Tools, fixtures, consumables

Most tools that will be required to replace shock absorbers will find in any car and garage: jack, screwdrivers, keys, mount and so on. From the specific - only the device for removing the springs of the suspension. It is a vertical axis with "hooks" to engage the powerful spring and carvings.

Safety in the replacement of shock absorbers

It is very important to securely fix the car before performing work on replacing shock absorbers, in order to avoid deposits.

How to replace the front shock absorber with your own hands (step by step)

- We post the wheel.

- We securely fix the vehicle.

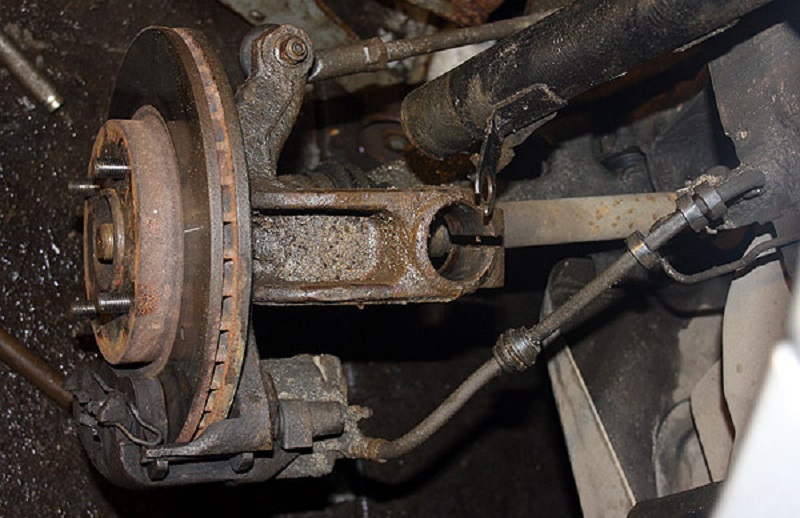

- We unscrew the bolts that the shock absorption rack is attached to the twilty fist.

- With mount or puller, remove the steering tip.

- Disconnect the brake hose.

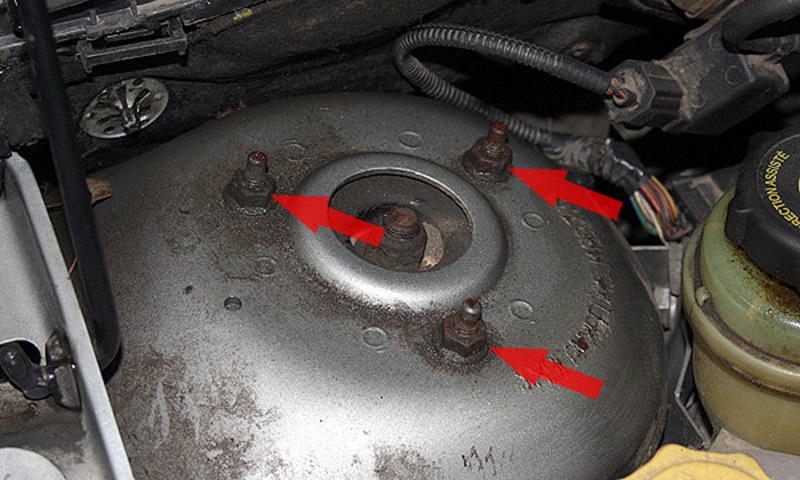

- We unscrew the fastening nuts of the depreciation pillow.

- Remove the rack assembly from the arch.

- With the help of a special device, we turn the spring until it release the supporting bowl.

- Remove the center nut of the shock absorber.

- We remove the dustproof and a rack with a spring, as well as a bump.

- Perform a replacement for a faulty shock absorber.

- Installing a new shock absorber on the car is performed in reverse order.

How to replace rear shock absorbers with your own hands (step by step)

Works on replacing shock absorbers on the rear axis are actually identical to the operations to replace the front shock absorbers. Differences are in the constructive features of the rear of the vehicle.

Before lifting the rear wheels, put the machine to the first speed and securely lock the stops. Wheels are hung off with jacks. Then you need to perform such operations:

- We unscrew the shock absorber fastening bolt to the bridge.

- Pull out the sleeve.

- We unscrew the nut, which extracts the shock absorber to the body from above.

- Remove the shock absorber.

The assembly is performed in reverse sequence:

- Breeping a new shock absorber.

- Adjust the height so that the bottom part is in the bracket on the bridge.

- Install the bushing and tighten the fastening bolt.

Why after replacing the shock absorbers it is necessary to make the wheel alignment

As you know, any interference in the driving part of the vehicle leads to a change in the angles of the installation of the wheels and, as a result, changing the behavior of the car on the road. To ensure good stability and transportability of the vehicle. The front wheels are set at a specific angle relative to body components and suspension.

So the score must be adjusted after each repair and / or replacement of the pendant components. And replacing shock absorbers is no exception.

Tips Prof.

It is worth saying that this technique describes only a general course of work on replacing shock absorbers. Each manufacturer in each model is trying to make constructive innovations in the pendant components and other nodes. Of course, they make their own adjustments and in the order of work. A detailed description of the measures to replace shock absorbers for a particular car can be found in the instructions for its use.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments