Not rare by car owners there is such a problem as chips, minor scratches and other external defects that occur on the paint-and-paint coating of the car. And this happens because the sand, gravel and small stones flying from under the wheels of other machines fall on the body of the vehicle and scratch it. In addition, there are other factors acting on the integrity of the paintwork - branches, bushes, all sorts of chemical reagents, high fences and curbs with careless parking, intruders who are able to scratch the body, random small collisions with other machines and so on. The car owner must pay attention to these defects in a timely manner in a timely manner, otherwise, with time, small damage will provoke large, which may further cause peeling and varnish peeling, as well as the development of metal corrosion. The best tool for protecting the car from such damage and to preserve its presentable appearance - the use of anti-agravine film. About this further in the article.

Content

- Anti-gravial film, review

- Car pasting with anti-growing film

- Cast polyurethane films how to choose a good quality film

- Anti-gravine pasting, the cost of work is approximate

- Valuable tips on the car's pasting of a good anti-growing film on their own

- Templates do it yourself on the details of the car, tips on the use

- Tools, Materials, Devices to help Master

- Film zm.

- Tips Profi, entrust to experts or do it yourself

Anti-gravial film, review

The most common in our time are vinyl and polyurethane anti-gravial films.

Vinyl anti-gravial films are used to complete the car body cover. They are more suitable for protecting the side of the vehicle from the stones that fall under an acute angle on the sidewalls.

Car pasting with anti-growing film

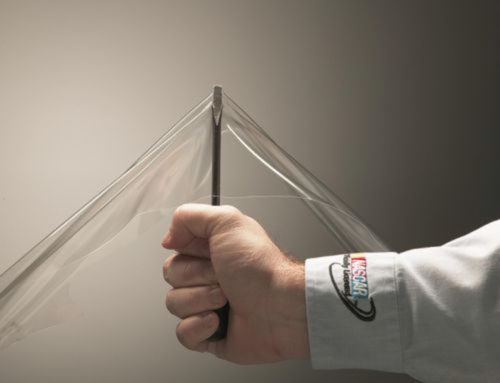

Strictly speaking, the vinyl films are more decorative function than protective against the influence of gravel, and better protect the body from ultraviolet, rather than from stones. Vinyl, unlike polyurethane, is very easy to break, polyurethane analogs are just stretched. This is a distinctive feature of the vinyl film, according to which it can be recognized. Example of vinyl film - KPMF series.

The advantages of vinyl:

- Vinyl film created by cast technology is highly flexible. Therefore, it is without any problems with even the coolest bends of the body surface.

- The additional property of the vinyl film is to protect the paint coating of the car from ultraviolet, whose influence can lead to the burnout of automotive paint.

- It is cheaper than polyurethane anti-gravial film.

Disadvantages of vinyl film:

- In winter, vinyl under the influence of cold becomes hard and partly loses elasticity.

- Vinyl films have a small thickness, as a result of which the polyurethane indicators do not reach strength.

The technology of protecting the car by a polyurethane film appeared in the US military-industrial complex and was inspected in Iraq at the Military Firm "Burya in the Desert". Then it was used to protect the rotating car blades from the sand. A strong polyurethane film, which received informal recognition of experts, has 100% permeability from the rays of ultraviolet, so the body will be uniformly fused under it evenly.

Polyurethane film is used to protect the frontal part of the hood, mirrors and bumper. The increased thickness of the film and the viscosity of polyurethane gives it an advantage in protective properties and strength, but this does not make it possible to apply it to absolute protecting surfaces that have a spherical shape and a large bend. Therefore, with all the efforts, such a film is not capable of closing the bumper completely. There is always about five percent of unprotected surface. In order for the film from the polyurethane normally to the convex paint and varnish coating, there are special cuts on it.

Cast polyurethane films how to choose a good quality film

The cast polyurethane films do not contain internal stresses and are more elastic, which makes it possible to accumulate the elements of the most complex configuration. They are ideal for the protection of the car.

The best polyurethane protection can be attributed to Xpel anti-growing film, Oracuard 280, Nano Fusion, Durashield +, Venture Shield. Unlike vinyl, polyurethane saves the desired form. In the bend place, where there is a strong tension of the material, there is a characteristic "cellulite" pattern, which spoils the aesthetic type of protection.

To avoid this, before use, they make a special cutting film from polyurethane for cooked templates, after which the cuts are glued to the desired surface without any tension.

For strength and thickness, polyurethane exceeds vinyl, but their service life is the same - five years. The lack of polyurethane anti-agviline film - over time it is capable of yellowing.

Anti-gravine pasting, the cost of work is approximate

To accumulate by anti-aggravine film the front of the car (bumper, hood, wings), on average will have to pay from 15,000 to 25,000 rubles. Although in some companies, the cost of this service exceeds 40,000 rubles. All this depends on the chosen company and material.

Valuable tips on the car's pasting of a good anti-growing film on their own

The main purpose of the anti-agviline film is to protect the headlights and the body from mechanical damage and scratches, the extension of their service life, as well as the preservation of the aesthetic type of body of the car. The use of anti-growing film in comparison with other protection methods has several advantages:

- Large service life.

- Invisible for the eye.

- Does not change the color of the paint coating body.

- If necessary, it is easily removed.

- I miss ultraviolet, as a result of which the car body burns uniformly.

- Does not change the initial form.

- It is firmly held on any body element.

- It has greater strength and viscosity.

- Easily polished when damaged.

- Scatters and amortizing the energy of the impact of solid particles.

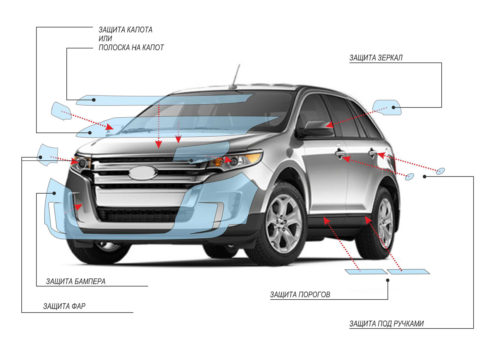

Protective anti-growing film is recommended to be installed on those parts of the vehicle that are most susceptible to foreign objects:

- Farmers and headlights.

- The back side of the side mirrors.

- The zone around the door handles, thresholds and doorways to protect against damage and scratches that occur when landing or disembarking passengers.

- Wings of the rear and front wheels.

- Front of the hood.

- Bumpers.

In the presence of desire and means, the protective film can be covered with absolutely all body of the vehicle, but it will require significant financial costs. Minimum protection involves the use of film on the most vulnerable areas of headlights, bumpers and hood.

Templates do it yourself on the details of the car, tips on the use

Recognized and safe film cutting method - the use of special automotive patterns. But many hundred in practice use the cutting film immediately on the car body. This method has several drawbacks:

- Pattern on the surface of the car body can not guarantee high accuracy. In this case, only his skills and experience can save from the master errors. Cut is made with a certain reserve. And if the material was purchased without an allowance, it may not be enough trite.

- In addition, the loose knife is able to leave small scratches on the body, where condensate falls and cracks occur in the place of scratches, and the metal corrosion appears under the paint coating. Even the most experienced masters cannot guarantee the complete absence of body damage with this method of cutting the film. In addition, the disadvantages of this method are manifested only when replacing the film when the old layer of film coating is removed. At this time, with surprise, it can be found that the paint or other disorders occur under the film.

When used, globes do not need to trigger the protective film on the body of the vehicle. They are able to provide high accuracy of cutting. With the help of special equipment, which is intended for the pattern of the film, it is cut into factory programs individually designed for each model of the car.

The plotter carries out high-quality film cutting for each individual body element, whether mirrors, doors, wings or headlights. The directory of the melted can be systematically improved and updated with the back of new models of machines.

The harvested patterns of the protective film are pasted on the appropriate body elements using a hot steam or a hair dryer, which heats the film and makes it soft and elastic, which makes it possible to stretch the anti-growing film and stick to the surface without leaving bubbles.

Tools, Materials, Devices to help Master

Application of anti-aggravine film on the car involves the use of the following tools and materials:

- Sealant.

- The sprayer in which you need to pour a soap solution in advance.

- Industrial dryer.

- Degreaser - White spirit or alcohol.

- Stationery knife.

- Raquel from felt, rubber or plastic.

- Dry clean rag.

- Painting sticky tape.

- Anti-agravine film.

Film zm.

Film 3M refers to polyurethane films. It is characterized by a multi-layer structure, the total thickness of which is 150-200 microns. The material under consideration was created taking into account all the factors that the machine is influenced during operation. In addition, the film was tested in different extreme conditions. According to the manufacturer, the film does not turn yellow during operation, does not change the shade of the paintwork and is distinguished by the presence of a glossy layer, which provides it with a shine, characteristic of the car paint, with which such a film merges with it, that is, such a film will not affect the appearance cars.

The considered film, except for other places, can be glued on the friction area and docking elements, for example, where the bumper adjacent to the body or on the edges of the doors. In addition, pasting such a film does not limit the maintenance of the machine. It can be polished and washed, and if necessary, remove the film.

Tips Profi, entrust to experts or do it yourself

It is not recommended to independently install the film, because for the unprofessional the pattern of the pattern is fraught with irreparable errors and is very complex. And air bubbles and dust between the surface of the part and the film will lead to the need for re-stickers. It is worth noting that the quality of pasting, from which the term and duration of its service depends, is largely determined by the skill and experience of the employee who has installed the film. No less important and guarantee on the work performed, which is issued by Social Specialists.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving a car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments