Car owners with manual transmission, know that for high-quality operation of a manual transmission, it is necessary that another important node continuously functioned - the clutch. When traveling drivers use it constantly when you need to switch the transmission.

Content

What is a grip?

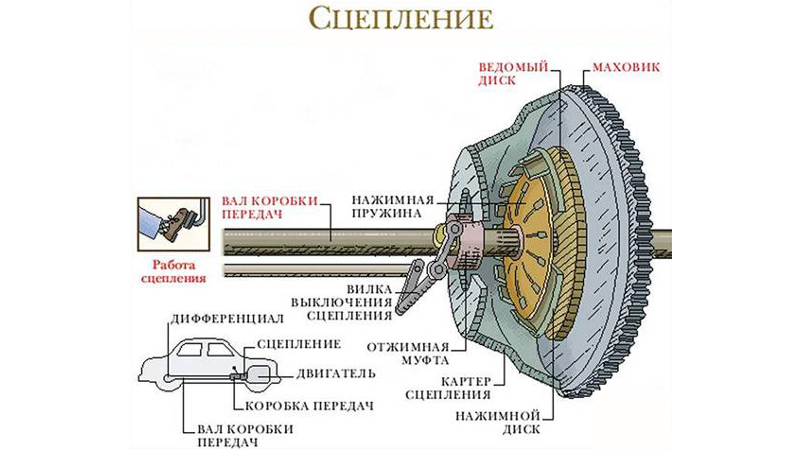

The clutch is one of the components of the automotive transmission. Thanks to him, a short-term disconnection of a working motor from transmissions drives is performed. After switching speed, the clutch smoothly includes this bundle back to operation.

Where is the clutch?

The schematic location of the clutch is the space between the power unit and the gearbox. This node makes it possible to avoid high power loads on transmission aggregates and suppresses appearing fluctuations.

Car clutch functions

Clutch coupling is one of the most loaded transmission elements. Its main functions are as follows:

- Smoothly disconnects and connects the engine and gearbox.

- Transmits torque without loss.

- Compensates loads and vibrations from uneven motors.

- Reduces the load on the elements of the power unit and the transmission.

Components of clutch coupling

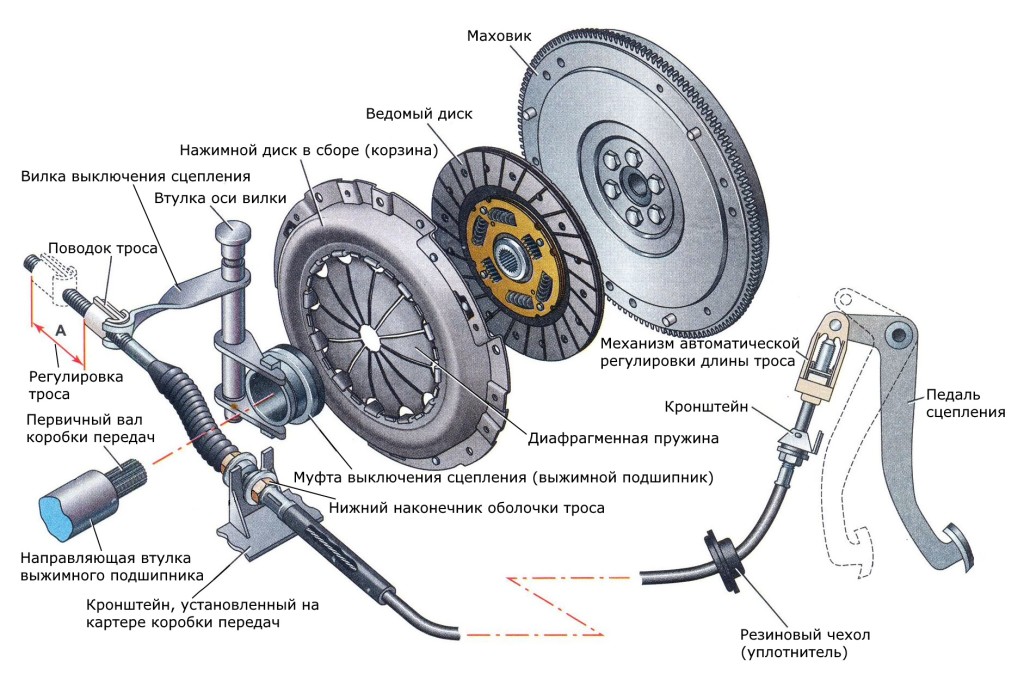

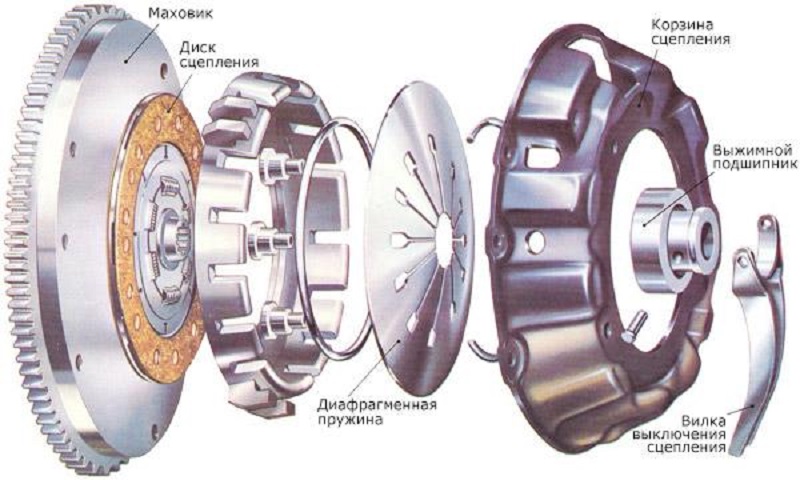

The design of the standard clutch of the clutch used on most cars with MCPP includes such basic elements:

- Fork clutch

- Clutch drive.

- Clutch outlet bearing.

- Motor flywheel (drive disc).

- Clutch basket (i.e. pressure disk).

- Clutch shutdown coupling.

- Slave clutch disc.

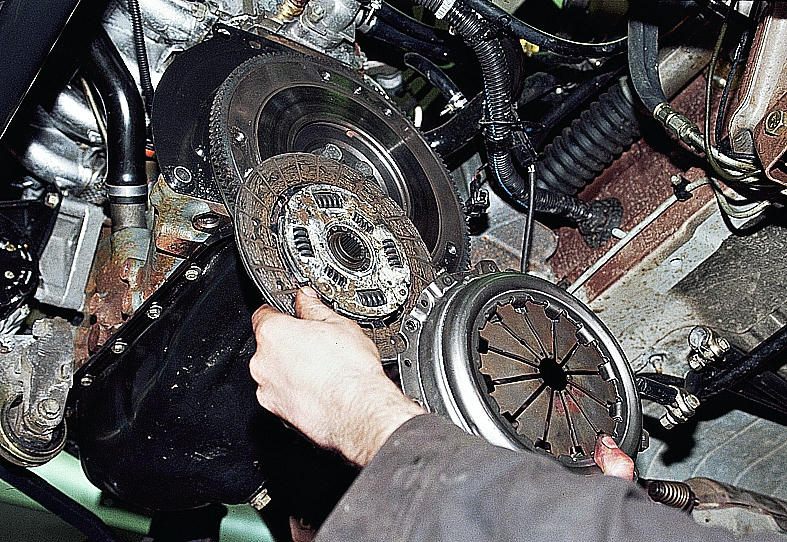

On the slave disk at both sides are friction lining. Its function is the transfer of torque using the friction force. The dramatic oscillation damper, which is embedded in the disk body, smoothes the connection with the flywheel, as well as extinguishes the load and vibration from the uneven operation of the motor.

The diaphragm spring and pressure disk are influenced by the slave disk, assemble is a single node called the "clutch basket". As for the slave clutch disk, it is located between the flywheel and the basket, and connects with the primary gearbox with the help of slots, it can move.

The diaphragm spring basket is either an exhaust, or pressure principle of action. The difference is based on the direction of the application of the effort from the clutch drive: from flywheel or to flywheel. The design of the exhaust spring makes it possible to apply the basket, the thickness of which is significantly less, which makes the node most compact.

The principle of clutch work

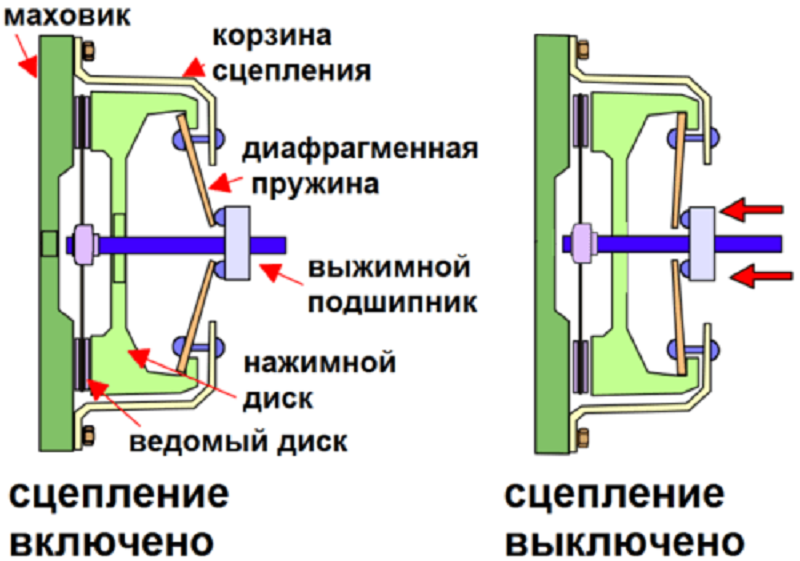

The principle of clutch operation is based on the hard connection of the motor flywheel and the slave disk of the clutch due to the appearing friction force from the efforts created by the diaphragm spring. The clutch has two modes: "off" and "enabled". The main operation of the flywheel is pressed against the slave disk. The flywheel transmits the torque to the driven disc, and it transmits it by means of a slotted connection to the primary shaft of the PPC.

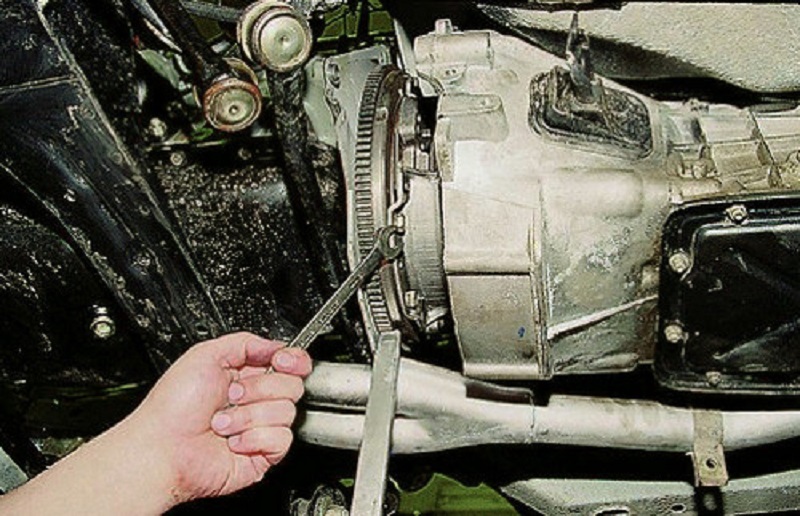

To turn off the coupling, the motorist presses a pedal connected to a hydraulic fork or a mechanical drive. The plug moves the release bearing, and it, by pressing the petals of the diaphragm spring, stops its pressure on the pressure disk, which frees the slave. At the moment, the motor is disconnected with transmission.

When the desired gear is included, the motorist releases the clutch pedal, the plug ceases to influence the release bearing, and it, in turn, on the spring. Next, the push drive presses to the flywheel slave. The power unit is connected to the transmission.

Varieties of clutch

From the moment of the emergence of motor transport and specialized engineering equipment, several options for this node were invented. These are mainly divided into friction and hydraulic. There are also electromagnetic, but in essence they are a type of friction type. Consider them in more detail.

hydraulic clutch

In such a clutch between the slave and the drives, which have a blade, circulates the liquid. The speed of the slave wheel depends on the amount of this fluid. If you delete it completely, the slave stop will stop. Such clutch significantly increases the smoothness of the vehicle's move, but complicates its design.

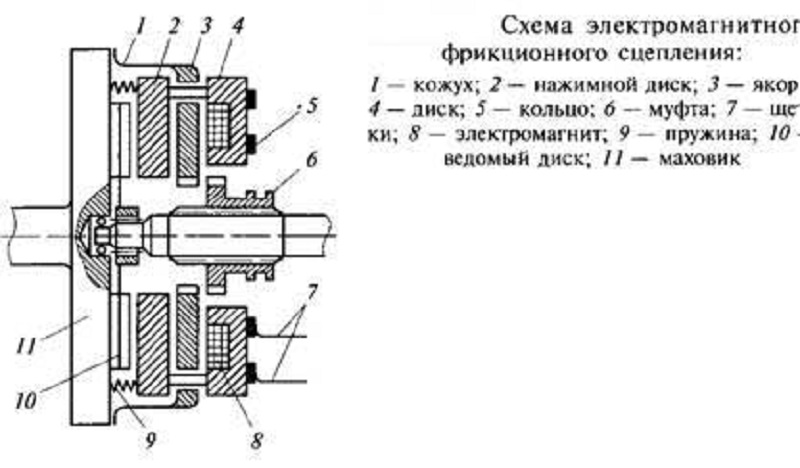

electromagnetic clutch

When the electromagnetic field appears, the driven and the leading portion of the electromagnetic type clutch are connected either directly or through a ferromagnetic powder that losing mobility under the influence of the electromagnetic field. Such clutches were used on vehicles that are intended for disabled. Nowadays, electromagnetic clutches are not rarely used in TC climatic installations.

friction clutch

Often, this type of clutch is used on cars. The torque in the friction clutch is transmitted using the friction force, which occurs between the slave and the drive parts of the clutch.

In transport you can meet both one-piece friction clutches and two-disc and multi-disc combines whose disks can function in liquid (so-called wet clutch) and without it (that is, dry clutch).

In general, friction clutches can be divided into the following criteria:

- By type drive (control).

- By the type of friction.

- By the number of slave disks.

- By the number of rotation transmission flows.

dry clutch

The principle of operation of such a clutch is based on the force of friction, which occurs in the interaction of dry surfaces: slave, pressure and drive discs, which ensures the rigid connection of the motor and gearbox. Dry one-piece clutch is the most common type that is used on vehicles with MCPP.

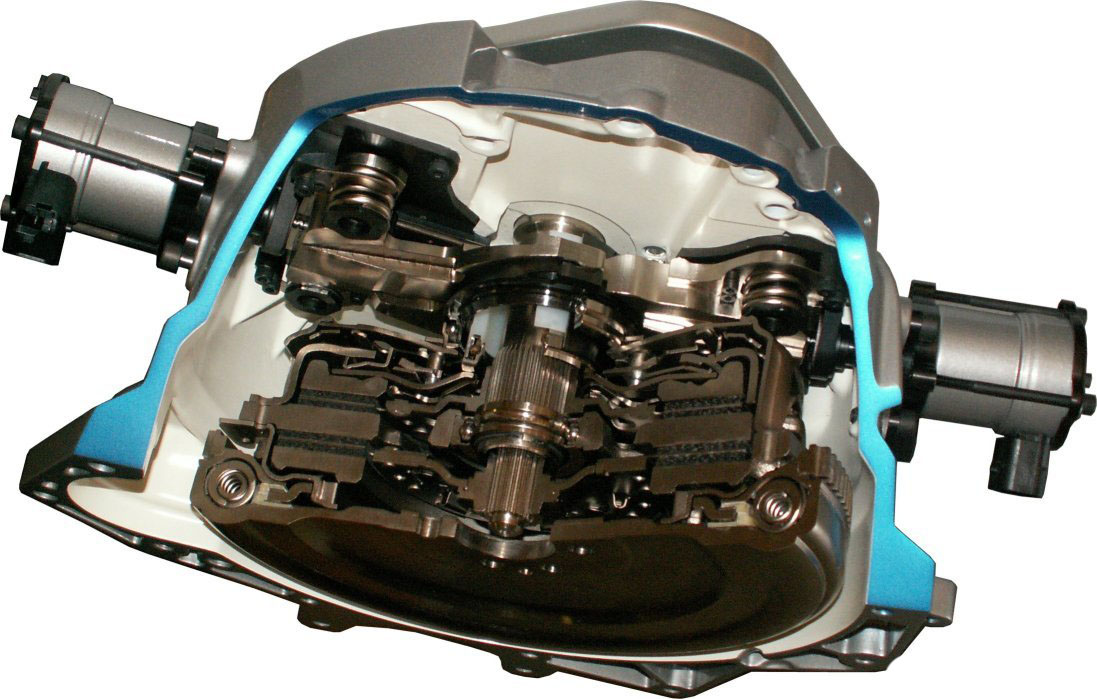

wet clutch

This type of clutch involves the functioning of rubbing elements in the oil bath. In comparison with dry clutch, such a scheme is capable of providing more smooth contacts of the disc, the node is cooled more efficiently due to the circulation of the liquid and transmits a greater torque to the transmission.

Wet clutch, as a rule, is used on modern robotic gearbox with double grip. A feature of the functioning of such a clutch is that the motor torque is supplied to the odd and even speed of the gearbox from different slave disks. As for the adhesion drive, here it is hydraulic and controlled by electronics. The transmissions are switched when the moment is constant to transmissions, without breaking the power flow. This design is more complex in production and expensive.

by the number of rotation transmission streams

On this system indicator can be divided into single-way and two-flow. As for single-threaded, in the first case, the rotation of the DVS is transmitted only to one element. Two-flow clutch is often used on the special equipment. Their difference from single-threaded lies in the fact that rotation is transmitted to two shafts, for this, the design includes two slave disks. Often the two-way clutch option is used on tractors. As for passenger transport, this type has found its use in cars with robotic checkpoint.

by the number of slave disks

Oneodyskaya Elements, as a rule, are mounted on cargo and passenger cars, where the transmitting torque is within 0.7-0.8 kNm. Exploitation Twochdiscovic Components are relevant in cars with high torque. Concerning multi-disc Systems, they are used in specialized mechanisms, for example in automatic boxes, safety clutches, etc.

by type of management

Types of drives are used to control the node:

- Hydraulic. In this case, the force is transmitted through two cylinders - the main and working, which are interconnected by the pipeline filled with liquid.

- Mechanical. The pedal force is transmitted to the bearing plug using the cable and lever system.

- Electric. Used in systems where the clutch control is automatic. In this case, the effect on the details of the clutch is conducted via electric motors with servo drives.

- Combined. Combines several of the types listed above, for example, hydromechanical.

Capture Requirements

The clutch must provide:

- Smooth and trouble-free inclusion, which makes it possible to reduce the level of load on the checkpoint and improve the dynamics.

- Comfort and convenience in the management plan.

- Wear resistance of surface components and long service life.

- Normal heat removal, to avoid problems with the overheating of the device.

- Reliable inclusion in the activated position, which reduces the risk of slipping.

- Full shutdown with deactivated position.

- Optimal weight and dimensions.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving a car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments