Automotive sensors carry a greater functional load, control the adequate operation and the operation of the engine, and also ensure the safety and comfort of all passengers when moving the car. Devices that perform diagnostics of all vehicle mechanisms are needed for a timely warning of a motorist about possible breakdowns. It greatly facilitates restoration work, as well as saves money and time.

Content

- Automotive sensors, as car sensors are divided by operating conditions

- Engine control sensors, which sensors are controlled by the engine (assignment and installation location)

- Pressure sensors, purpose and installation location

- Temperature sensors, assignment and installation location

- Fuel control sensors, purpose and installation location

- Comfort sensors, appointment and installation location

Automotive sensors, as car sensors are divided by operating conditions

Currently, the number of automotive helpers has been increased many times at the car market. All of them are distinguished by their characteristics, use features and direct appointment. Under the operating conditions and the following requirements, the sensors are divided into a number of classes:

- The first is sent to the diagnostic examination and control of the steering and brakes. Responsible for the safety of people in the cabin.

- The second class of devices monitors the integrity of the suspension, tires, transmission and power unit.

- The third provides protective functions for the vehicle and controls the comfort of movement.

Due to the modern development of electronics, tracking devices are made of high-tech materials and guarantee a high degree of reliability. Small dimensions make it possible to simultaneously apply several computer devices in one vehicle that can store and systematize information, adjust them, and also exclude possible errors.

There are two types of automotive sensors:

- Integral sensors that are endowed with intellectuality. Reduce the load on the control unit, even low intensity signals are processed, allow you to simultaneously use several embedded devices in one car, form flexible links.

- Fiber optic devices. May quickly fail, sensitive to pollution. Have low susceptibility to electromagnetic interference. Cannot tolerate pressure exposure. Sensors of this type are not used for all cars, since their work requires special couplelists and connecting connectors. The signal in external sensors appears outside the optical fibers, and in the internal - inside them.

Engine control sensors, which sensors are controlled by the engine (assignment and installation location)

The power unit control devices include:

- Temperature sensors.

- Air sensor.

- Content position and speed.

- Devices that provide pressure control.

- Sensors that determine the concentration of oxygen.

- Devices that control the operation of the motor and the fuel system and warn about possible detonation.

aerial sensor

Air sensor - a device that determines air flow is a reliable element that diagnoses a quantitative air indicator that is absorbed by the power unit. This indicator is measured in kg / hour. Moisture is the main destroyer. In case of failures, a twenty-percent overestimated error, which contradicts real data. The operation of the motor becomes unstable, "Troy" appears. It is also possible to increase fuel consumption. There is a sensor directly in front of the air filter.

lambda probe

Lambda probe (oxygen sensor) is part of the electronic engine control system. This sensor calculates the amount of oxygen, which is in the graduate manifold. The device malfunction may entail increased fuel fluid consumption. Due to the oxygen sensor, the fuel supply is adjusted. Lambda probe is located on the graduate manifold, near the steering rack.

exhaust control sensor

Controls the concentration of nitrogen oxide - determines the content of this gas in the neutralizer. In conditions of its contamination, excessive regenerative cycles occur. Location - throttle knot.

sensor valve Egrr.

A device showing the opening level of the EGR valve. This sensor is designed to reduce the degree of toxicity of exhaust gases in excessive warm-up modes and sharp acceleration of the power unit. Location - Motor Shield.

hall Sensor

Device - showing the angle of turning camshaft. Based on the Hall effect (in the conductor, which has a constant current and is in a magnetic field, the transverse difference of potentials occurs). This sensor is needed to measure the angle of the camshaft position or crankshaft. The device consists of plastic housing, output nodes, chips, rotor blades, magnetic pipelines and a permanent magnet. Signals that are transmitted by the device are the basis for changing the location of the pistons in the cylinders. The "Trojection" of the motor and the unevenness of his work may indicate the presence of sensor malfunctions. To check its functionality, the oscilloscope is used. There is a device on the rear cover of the camshaft.

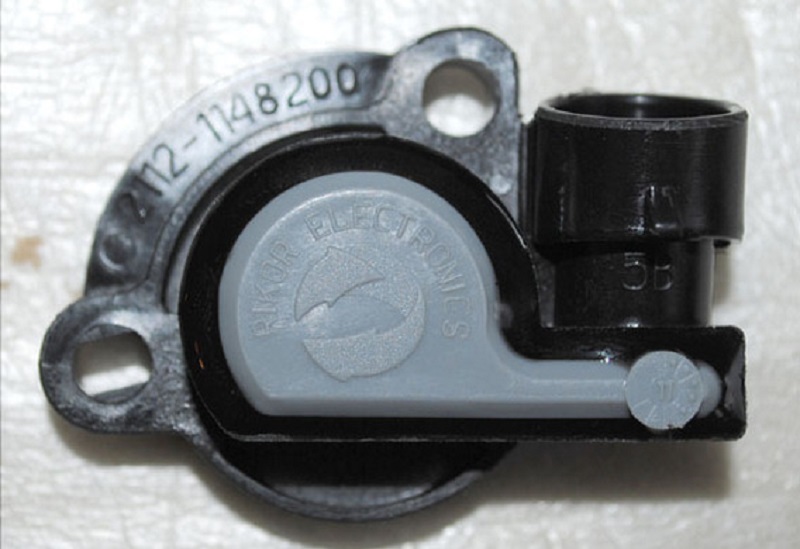

throttle sensor

The device fixing the position of the throttle valve. Indications that are read from gas pedals are considered defining. When purchasing, carefully refer to the issue of choosing a manufacturer of such equipment. It consists of a step motor and a temperature sensor that performs the role of a sensitive element. Based on the coolant temperature indicator, the device performs an adjustment of the position of the throttle. The higher the level of heating of the coolant, the higher the rotation frequency of the crankshaft. The device is closely interconnected with the axis of the throttle and is located on the side of the throttle.

crankshaft sensor

The device controlling the position of the crankshaft. With the help of its testimony, the time of supplying diesel fuel or gasoline, as well as the moment of sparking appearance is controlled. It is physically a piece of magnet and a thin wire coil. Extremely hardy device. If the device does not work, the launch of the power unit will be impossible. There is a sensor at the bottom of the cylindrical block.

Pressure sensors, purpose and installation location

To devices providing pressure control include:

- Pressure sensor inlet path.

- Tire pressure sensor.

- Oil pressure sensor.

- Fuel pressure sensor.

- Brake fluid pressure sensor.

- Passenger weight sensor.

inlet Press Pressure Sensor

Watching the pressure indicator in the inlet pipe of the power unit. Located in the engine compartment, in the field of electric heater fan. In the intake pipe, the pressure is regulated under the conditions of the slightest change in the rotational speed of the crankshaft and the level of load. The output voltage directly depends on these transformations. What they are more, the stress is higher.

tire pressure sensor

Built inside wheels. Controls the air temperature and normal tire pressure indicator in order to increase the safety level of the car.

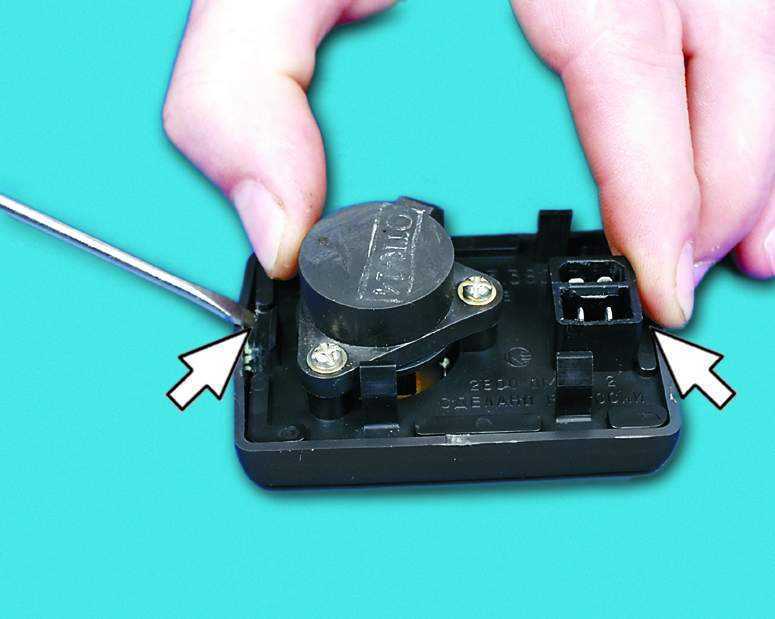

oil pressure sensor

Mounted on cars of Japanese manufacturers. The device includes a membrane type. Located on the cylindrical block of the power unit. The oil constantly puts pressure on the membrane, or rather, on its one side. The level of the membrane deflection is determined by the overall resistance of the sensor.

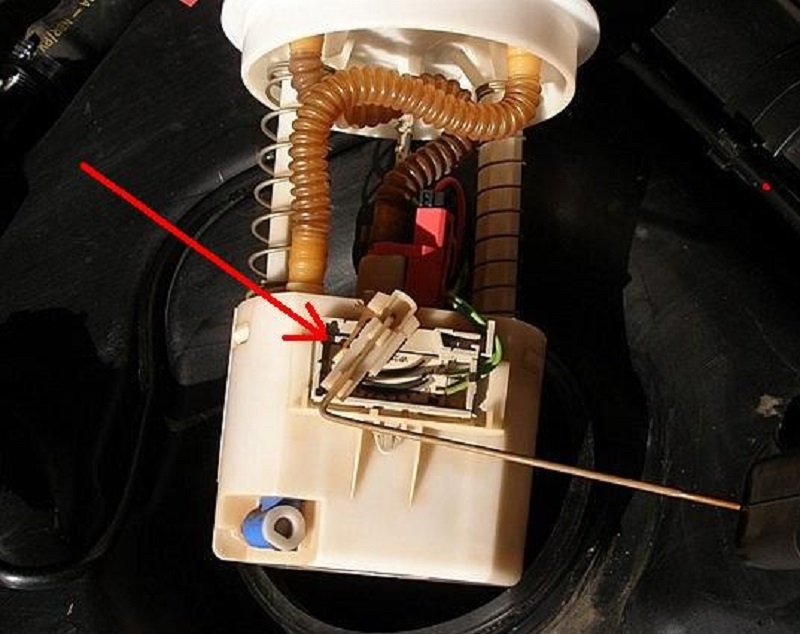

fuel pressure sensor

Device that determines the pressure of the fuel fluid. Mounted in the gas station housing.

brake fluid pressure sensor

Calculates the pressure of the brake fluid. Location - an anti-lock block unit.

passenger weight sensor

Devices that determine the pressure from the weight of the passenger. Located under the seats.

Temperature sensors, assignment and installation location

Temperature sensors are needed to ensure normal operation of many systems.

cooling fluid temperature sensor

Its work is to convert the input resistance during the slightest temperature fluctuations in the diagnosed medium. The DPE determines the time, as well as the submission of the command, after which the cooling fan is turned on. Different with the presence of a highly reliable sensor. Mounting place - GBC. The most commonly appears a malfunction of electrical contact, which is in the inside of the device. Violations in the insulation system also remove the device. A troubleshooting is evidenced by a burning coolant overheating lamp on the dashboard.

engine oil temperature sensor

Watch out the oil temperature. Need for correct operation and proper operation of the power unit. The installation site is the base of the oil filter.

outdoor air temperature sensor

The device determining the ambient temperature. Mounted not far from PTF, a little left of the ventilation grille.

salon air temperature sensor

Device measuring air temperature in the cabin. Mounting place - Torpeda.

Fuel control sensors, purpose and installation location

The devices controlling the operation of the fuel system include:

- Sensor for monitoring the amount of fuel in the tank.

- Fuel consumption sensor.

- Exhaust gases feed sensor from combustion chamber.

- Phase meter.

- Knock sensor.

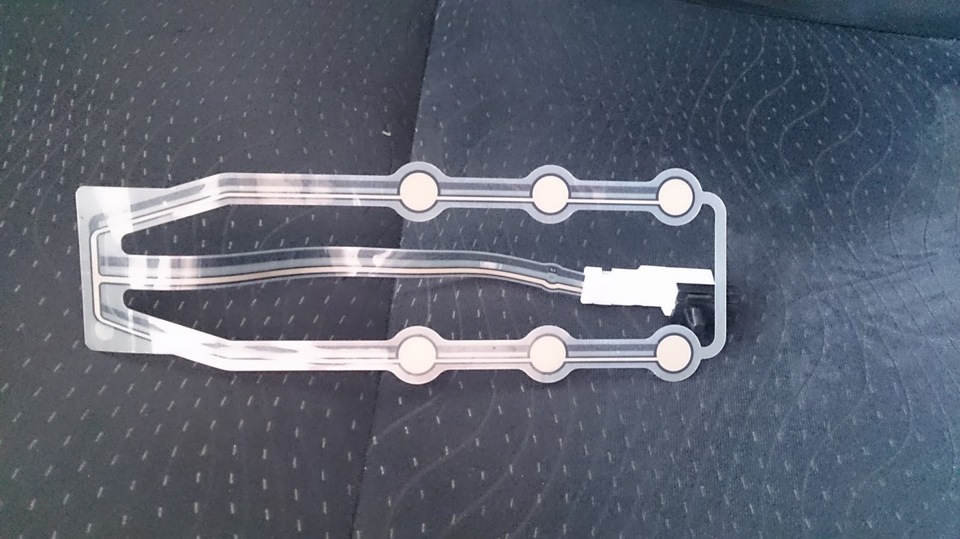

sensor for monitoring the amount of fuel in the tank

The device controlling the fuel level. Located in the fuel pump housing. The float has an impact on the sectorate of a rather long rod. As for the resistance of the sensor, it directly depends on the level of fuel in the gas tank. The device signals are displayed on an arrow or electronic pointer, which is on the instrument panel. Using an ohmmeter, you can check the correct operation of the device. To do this, measure the resistance between the contacts of the sensor.

fuel consumption sensor

Installed in the fuel system. The quantitative indicator of the fuel flowing through the device is converted to the pulses whose amount is determined by the flow rate for a particular time interval. Different with reliability and data accuracy.

exhaust gases feed sensor from combustion chamber

Located on the engine control unit. The signal notifies the control unit on atmospheric pressure. Depending on the resulting indicator, the waste gases are recycled and adjusting the pressure. The device malfunction says black smoke from the exhaust pipe.

phase meter

Controls the correct formation of fuel injection into a specific cylinder. The displacement of the device entails the transfer of fuel feed into the pairwise-parallel mode. The result is the enrichment of a combustible mixture. Mounted on the engine near the air filter, not far from the cylinder block.

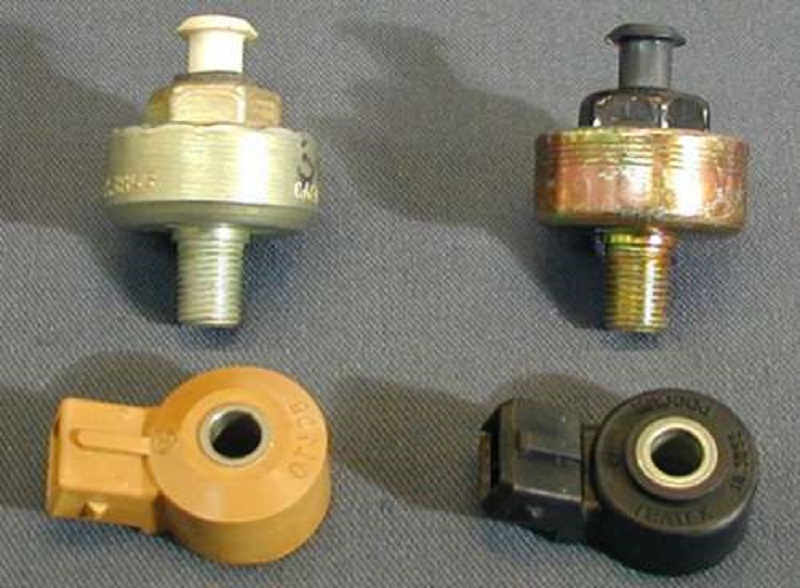

knock sensor

Element of increased reliability. Measures the ignition advance angle. If, when combustion of fuel, explosive processes appear and the risk of detonation appears, the device sends a specific signal, notifying the control system of the motor's need to reduce the ignition advance. Located between the third and second cylinder.

Comfort sensors, appointment and installation location

In addition to listed tracking devices, new sensors are being developed daily, which meet the modern requirements of motorists. Among them: Rain and ABC sensor.

rain sensors

Opticolocon type devices. Installed on windshield. Consist of a small infrared emitter and photodetector. React to the slightest occurrence of moisture, under the influence of which the refraction rate changes its path. This change instantly reacts the electronic system, activating the wiper and wipers. When the precipitates stop falling out, the work of the brushes stops.

aBC Sensor

Such devices are located on the car's wheelbase. Their main function is to determine the rotation of the wheels. The ABC breakdown is evidenced by the non-working lamp on the instrument panel when the motor is turned on.

conclusions

High-tech sensors and devices are responsible for the normal operation of many mechanisms, significantly facilitate car care and promptly notify the car owner on the need for a diagnostic study.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments