Petrol pump is the main unit in the fuel supply system into the engine. As it is clear from the title itself - the main task of the unit is to ensure the fuel supply of the carburetor or nozzles. Two types of fuel pumps are installed on modern cars: mechanical and electric. Mechanical fuel pumps are installed on cars with carburetor fuel supply. In such a system, the fuel for the formation of an aerosol mixture comes under low pressure. Electric fuel pumps are installed on modern vehicles equipped with injection fuel injector systems (the fuel mixture is sprayed by nozzles). In this case, the fuel is fed to the injector under high pressure.

Content

- Fuel pump, device and principle of operation, where the fuel pump is located

- How to find out which fuel pump is on your car

- Filter and grid of electrical spaces, why they are needed and how often change

- Fuel quality, as fuel affects the service life of the fuel pump

- Why drops fuel pump pressure, possible causes

- Diagnostics who can make the diagnosis of gas station work, advice pro

- Planned maintenance of fuel pumps, what works are made at this time

- Is it possible to repair the gas station with your hands

Fuel pump, device and principle of operation, where the fuel pump is located

Mechanical pumps are installed only on the fuel line, outside the tank. Some types of auto engines are equipped with two fuel pumps - one operates at high loads on the engine, pumps large volumes of fuel under low pressure, and the other, inside the tank, supplies the fuel with low high pressure volumes.

The mechanical pump sucks fuel from the tank and serves it in the carburetor through the fuel filter. The electric pump "pushes" fuel from the tank into the nozzles under greater pressure.

On vehicles equipped with a carburetor fuel supply system, the fuel pump is constantly and at the same speed, and in more modern injection systems, the unit felt fuel at that speed, which is specified by the electronic control unit.

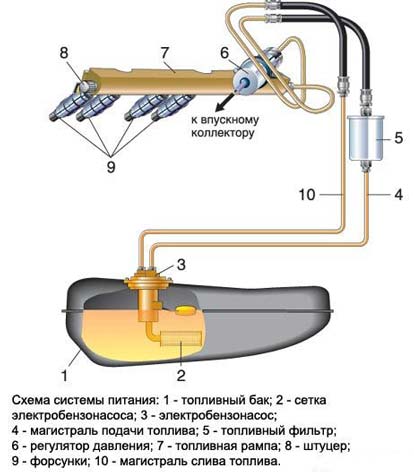

scheme of connecting gas station

Mechanical fuel pump is mounted very simply - in the provided place for fastening. After installing the pump, it remains only to connect the fuel supply hose to the inlet and outlet, after which the unit is fully ready for operation.

As for the electrical pumps, there are two circuits of their connection on modern cars: a long fuel supply ring is a refund of the unused fuel from the nozzles back to the tank. A short ring is the refund of the unused fuel in the tank right from the fuel pump.

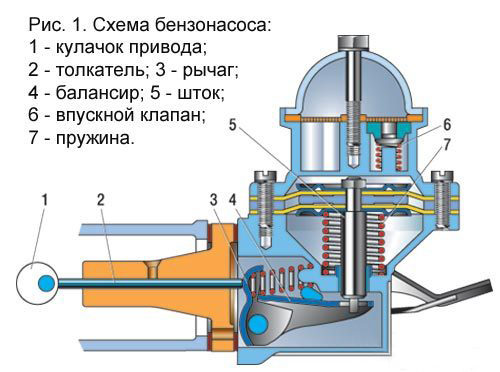

mechanical gas station

the device of this unit is quite simple:

• Lid.

• Mesh filter.

• Top of the housing.

• Top plate.

• Working diaphragms.

• Lower plate.

• rod.

• Return spring.

• Lower body.

• Manual fuel swap lever.

The whole design forms a chamber equipped with intake and exhaust valves, which are located in the upper part of the pump housing. Valves are simple washers from the textolite, which press the springs to the saddles of the valves.

The principle of operation of the pump is as follows: The aggregate drive lever moves up and down constantly, but the diaphragm shifts only at the moment when you need to fill the pump chamber with fuel. The initial position of the diaphragm is returned under the action of the return spring. Actually, thus, the fuel is flowing into the carburetor.

If we consider the functioning of a mechanical fuel pump in more detail, some differences are detected in operation on car engines with rear and front drive. If a car with rear-wheel drive, then an eccentric is installed on the drive shaft, which pushes the bodies of the fuel pump, ensuring this work.

Inside the front drive engines also have eccentric however it is installed on the camshaft. In the process of operation, the pusher tosses on the lever, which, in turn, affects the balancer at the bottom of the gas station housing. Balancer pursues the springs resistance and pulls down the rod with the pump diaphragms - the vacuum is obtained. The fuel is drawn through the fitting, the intake valve opens and passes it into the cavity above the diaphragm.

After that, the return spring pushes the rod with the diaphragm up - the pressure is created in the pump working chamber. Under the influence of pressure inlet valve closes and opens outwards. Fuel enters the graduation fitting, follows the hose and falls into the carburetor.

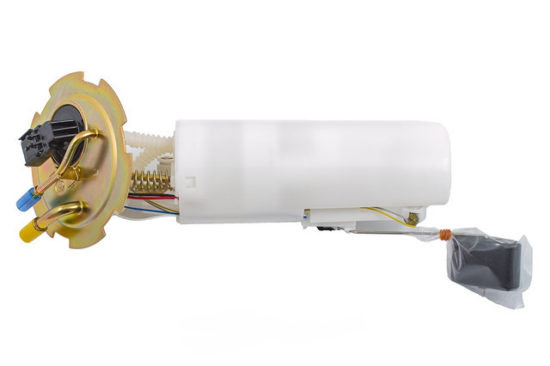

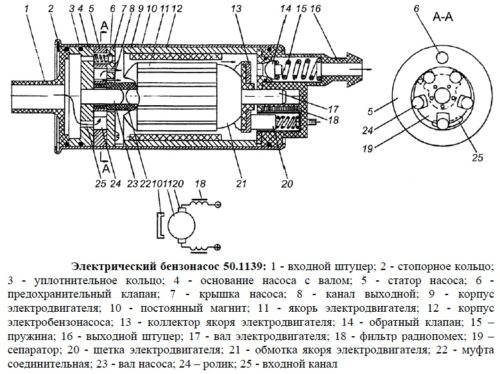

electric gas station

Structurally on a number of some parts the unit is similar to the mechanical pump. The principle of operation of the electric fuel pump is as follows: A special core is drawn into an electromagnetic valve, creating pressure until the voltage supply contacts are swollen. The code turns the key in the ignition lock, the fuel pump begins to work, lifting pressure in the system to the working level. Therefore, before starting the engine, it is strongly recommended to wait a few seconds in order not to expose the gas-pump of excess load.

In some models, gas station is launched at the time of opening the driver's door. The unit can create a working pressure of 0.3-0.4 MPa, in engines with direct fuel injection, this indicator can reach 0.7 MPa.

Inside the electric pump there is a diaphragm that moves up and down. When leaving the diaphragm down, a vacuum opens the intake valve of the pump is created. Gasoline enters through the filter into the chamber above the diaphragm. When moving up, it creates pressure covering the intake and opening exhaust valve - fuel moving on the line.

Electrical pump device as follows:

How to find out which fuel pump is on your car

Any more or less experienced driver is definitely aware of what type of gas is equipped with a fuel pump. As mentioned above, the carburetor engines put mechanical fuel pumps installed in a certain place. However, sometimes carburetor engines are equipped with electrical pumps - this moment you need to specify when buying a car, especially "from the hands".

On vehicles with an injection of fuel supply system, as well as with a system directly injection, exclusively electrical fuel pumps are installed, which are directly in the tank with flammable.

Filter and grid of electrical spaces, why they are needed and how often change

Fuel, with refueling, as a rule, needs additional cleaning. Especially sensitive to fuel quality Injector injection system. Fuel filters are used for additional cleaning. The cleaning process is in two stages: first coarse cleaning - through the gas station grid.

Large particles of rust and garbage are sifted here. The second stage is a fine cleaning that fuel filter performs. In different models of cars, fine cleaning filters are installed in different places. Most often it can be detected under the hood of the car.

The injector system requires a very thorough cleaning of fuel - from 5 micrometers. The pressure in such a system is quite high, so fuel filters are made of durable material or stainless steel.

replacing the fuel filter

In the engine manual, the engine must be specified how often it is necessary to change the fuel filter. Most often, this procedure is carried out once every two years or after a certain car run. However, given the quality of fuel on domestic gas stations, it is recommended to change the filter at least once a year. With intensive operation, the car is recommended to periodically check the fuel filter and, if necessary, immediately change it.

The filter replacement can be carried out at maintenance stations or independently - the procedure is simple. Before changing the fuel filter, you must reset the pressure in the ramp.

For this:

• Disconnect the "minus" terminal.

• Remove the fuel pump relay.

• Connect terminals to the battery.

• Run the engine, wait until it stalls.

Now you can dismantle the fuel filter. Press the fingers on both sides of the filter, and carefully remove it. Remember - about 100 grams of fuel remainion inside the filter and it can find out. Next, we produce actions in the reverse order - install a new filter, disconnect the terminals, put the relay on the place, connect the terminals, start the engine. We check whether there is no leakage in the connection places with fuel hoses.

It is very important to be able to determine when the filter is clogged. First of all, this can signal the bad start of the engine, the thrust drops significantly, during a sharp acceleration the engine "chips" can stumble. At idling, the engine works unevenly, during driving the engine lacks fuel, if the speed exceeds 100 km / h.

Fuel quality, as fuel affects the service life of the fuel pump

The reasons for which the fuel pump fails a few times, a little. Actually, there are only two of them: a dirty poor-quality fuel and a gross violation of the rules of operation of the aggregate.

Popular fuel can contain water and harmful additives. Water, when entering the pump, in the cold season, it can freeze and damage the unit. Additives are added unscrupulous fuel vendors to increase the octane number. These substances may contain various metals in high concentrations that increase the electrical conductivity of the fuel. Thus, gasoline can shorten the turns of the pump electric motor, which will fail.

Large mechanical particles in fuel can be caused by the breakdown of the benzonasos, especially the rust of the gas tank. This reason can be attributed to violation of the rules of operation - the car's tank must be maintained clean.

Why drops fuel pump pressure, possible causes

One of the most common causes is the lack of supply to the fuel pump. The gas station pressure may fall during the movement when the power supply unexpectedly stops, and the engine simply stalls. No less important indicator - the amount of fuel supply. That is, the fuel pump can buzz (food), but not to submit the necessary amount of fuel and not to create the desired pressure in the ramp. The pressure is gradually accumulated in the ramp and should have an indicator of about 300 kPa. To test the pressure in the fuel ramp use a pressure gauge. Pressure indicators must comply with a specific car brand. For example, for injection models of vases, when the ignition is turned on, the norm is 3 atmospheres, at idle - 2.5, when the gas pedal is pressed - 2.5-3 atmosphere.

Using a pressure gauge, it is possible to determine the nature of the malfunction: the failure of the pressure regulator in the ramp, the breakdown of the fuel pump, a decrease in its performance as a result of production, filter contamination (fuel filter, gas-pump mesh). For example, if the filter is contaminated, the pressure will grow very slowly or scaly.

When the gas station pressure is reduced below the norm, the engine may not start at all, or run hard, twitch, told, work unstable, with dips, etc. If the reason lies in the fuel pump and not in the fuel filter, then most likely, the pump mesh is simply clogged. In this case, it will be enough to clean it or replace.

If there is a suspicion in the breakdown of the benzonasos, it can be very easy to check. Just turn the ignition key and listen carefully - whether the pump is heard. If you do not hear the characteristic buzz of the working unit, it may have arisen with nutrition or wiring. It should be noted that in expensive brands a car, for example, a premium class, hear the sound of the working pump can not be due to high-quality sound insulation.

To the list of possible causes of non-working gas station, and, accordingly, the pressure drop can be attributed:

• Fuse failed.

• Belt breakdown of the gas station.

• failure of the pump motor.

• Oxidation of contacts, etc.

Diagnostics who can make the diagnosis of gas station work, advice pro

Of course, it is most accurate and efficient to diagnose the fuel pump, especially electrical, can only on a specialized service station. However, some manipulations, especially if the domestic production machine can be performed independently.

First of all, check the fuse of the gas station. Next, the check is subject to the fuel pump relay. To do this, check the presence of voltage on the control outputs, and the other end concerns the mass. The check is made using a multimeter or test lamp, with a current-consumed no more than 0.25 A. If the guard fuse, and the lamp does not burn, you should look for the cause in the wiring and control unit.

Electric fuel pumps are checked as follows: if the fuel pump is not removed, the voltage on its chip is measured. Shot of gas station is connected to a 12V source, for example, to a car battery.

Mechanical fuel pump check extremely simple: remove the hose from the outlet and press the manual swap lever several times. If the fuel goes - the pump is correct. In the case when the manual swap works, and when the engine running the engine is not served, the reason is likely to be in the formation of the rod. Due to permanent contact with the eccentric, the pump rod can over time "go round" and simply not to get to the lever. In this case, the detail needs to be replaced - the stock of the benzonasos is worth a penny and changes in 10-15 minutes.

Planned maintenance of fuel pumps, what works are made at this time

As you know, the best prevention is the careful attitude and proper operation of the unit.

And the following recommendations will be allowed to extend the life of the fuel pump:

With each scheduled repair, change the fuel filter and the benzone pump mesh.

Place high-quality fuel. Clean the fuel tank regularly - water and rust can accumulate in it, which can lead to a decrease in the performance of the pump and the fuel system. Water in the tank can lead to corrosion on the metal parts of the fuel pump.

Is it possible to repair the gas station with your hands

Mechanical fuel pumps, by virtue of its simple design, are subject to repair - actually nothing to break into them and there is nothing to break. Most often fails the membrane, sometimes rod. All this can be replaced, although most motorists prefers not to bother and buy a new pump - it is worth it inexpensively and changing literally in 10 minutes.

As for the electric fuel pump, it is not recommended to correct it. Theoretically, the device of electric benzone pump is not subject to repair - as provided by the manufacturer. In practice, some folk craftsmen open the body and feed on to repair or replace damaged or the details failed. Such amateurness is fraught with serious damage to the fuel system, so it is not worth experimenting, and it is better to purchase a new pump.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments