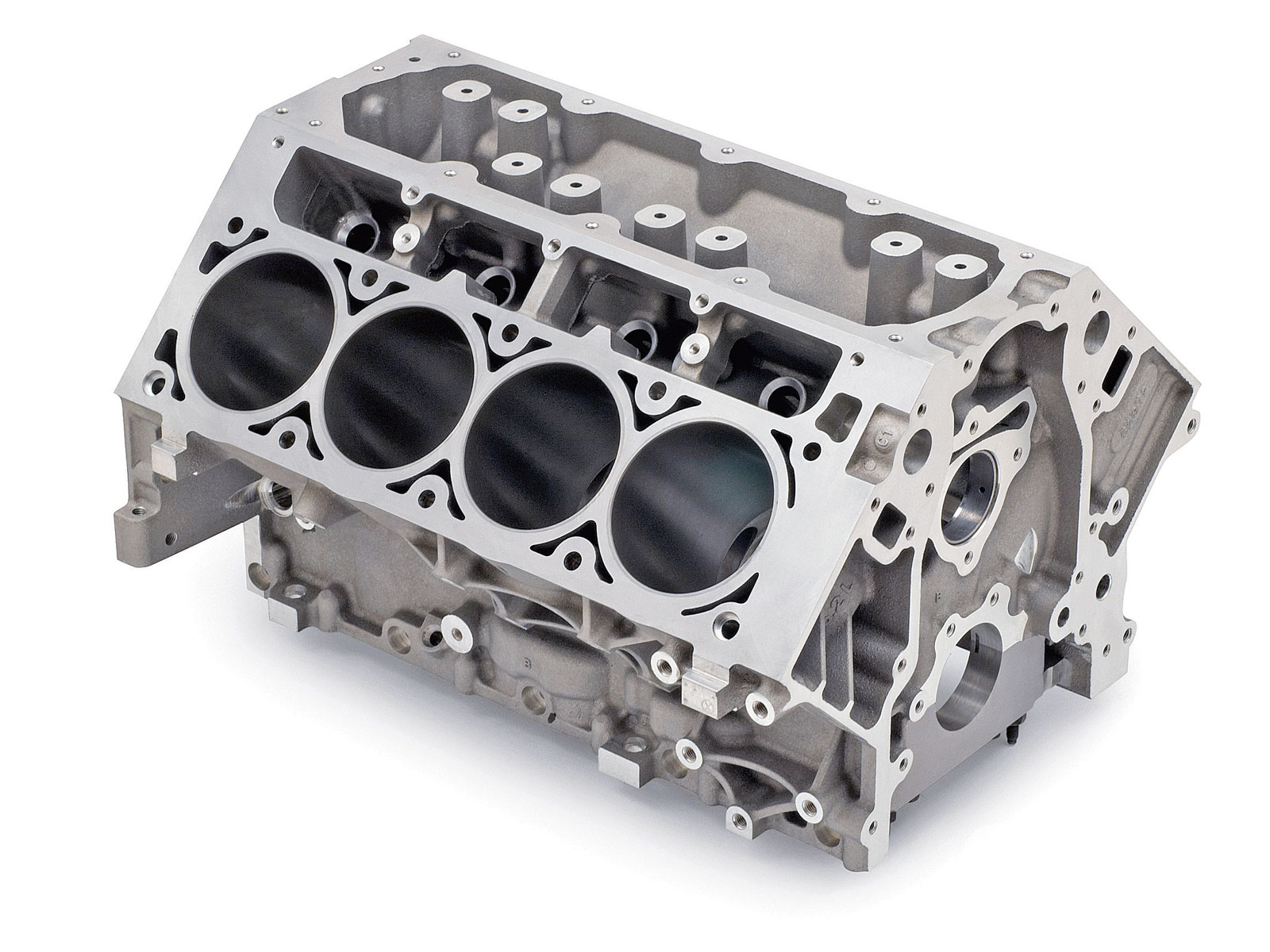

The cylinder block is the largest and most massive part of the internal combustion engine. It is made of aluminum, cast iron or their alloys. The main requirements for the cylinder block are good thermal conductivity, strength and durability.

Content

Engine Cylinder Block, Purpose of Cylinder Block

The cylinder block serves as container for the details of the cylindropore group.

Inside the block there is a crank engineering mechanism (CSM), consisting of: pistons, piston fingers, connecting rods and connecting rods, piston rings (compression and oiling), crankshaft, fasteners.

The crank-connecting mechanism is the main mechanism of the internal combustion engine, which ensures the conversion of the combustion energy of the fuel through the reciprocating movement of the piston in the rotational motion of the crankshaft.

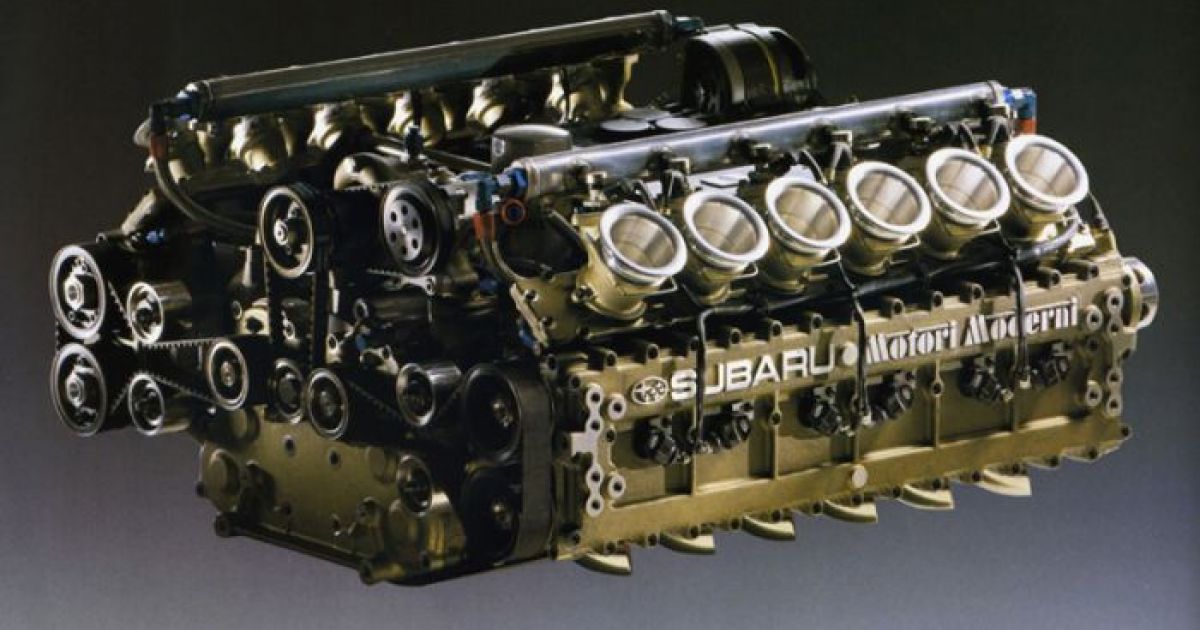

According to the constructive location of cylinders, the Cylinder blocks are:

- row

- V - figurative

- opposite

There are blocks of cylinders and other constructive species, but most often these three types are used on cars.

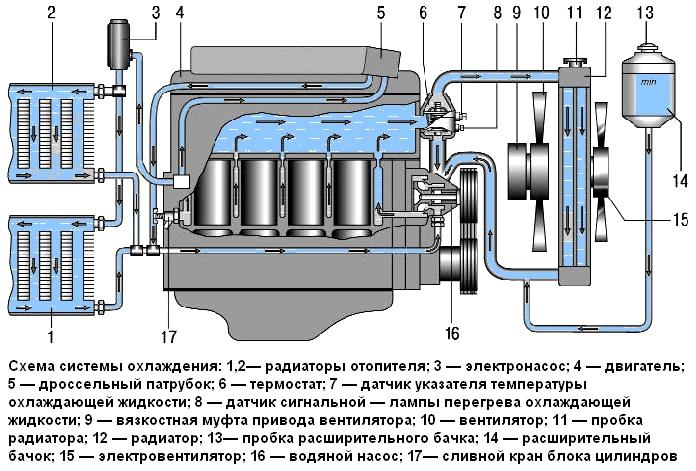

Cylinder Cylinder Cooling System

In addition to the crank-connecting mechanism, the cylinder block includes a cooling "shirt".

It serves to circulate the coolant, that is, the heat of thermal energy from the engine.

This ensures that the optimal work temperature is maintained. The cooling shirt is cut inside the cylinder block with a special tool.

In order to avoid clogging and blocking, a cooling fluid should be changed after a certain time, according to the regulatory and technical documentation for the operation of the car.

It is made up by the manufacturer.

Device block cylinders

The cylinders themselves are cut in the block using a lathe.

They must be smooth and resistant to wear and high temperature. Smoothness is attached using the homing procedure, strength - with the help of heat heat treatment.

On the engines of the old sample, the cylinders "guilized" - a sleeve was inserted inside the cylinder drilled hole, inside which the piston made reciprocating movements.

On modern cars, the cylinders "sleeve" only in critical cases of the overhaul of DVS.

Problems with the block are mainly associated with the action of the walls of the cylinders during the operation of the engine.

To avoid increased wear of the walls of the cylinder, as well as the details of the cylindrophone group, it is necessary to regularly change lubricants and filter materials.

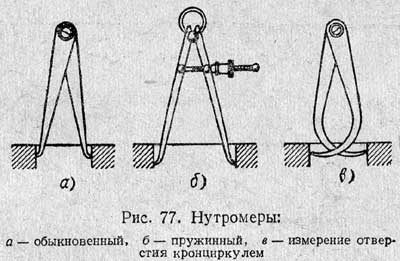

When determining the wear of the cylinder, the term "cylinder development" is used.

It is measured by a special instrument - a nutrometer that can be ...

If the generation exceeds the maximum allowable value, the cylinder block is sent to the boring until the next piston repair.

If the cylinders are worn so much that the boring does not help, they are driving them.

However, it is rarely resorted to this method, and the unit is completely replaced with a new one.

After the boring of the block, be sure to check with Tokary, under what size of the pistons are crushed cylinders (if you did not say about it) to acquire pistons of the desired repair size.

Otherwise, the block will not last for a long time, and after a couple of thousand kilometers, you will return it to turning on turning.

Remember that when repairing a block, an error of 0.1 mm may turn out to be fatal. Therefore, in advance, be patient and the necessary tool. It is especially important to have a micrometer at hand.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments