In the vehicle, the correct functioning of all nodes and parts is necessary, however, it should be taken into account that the brake system is one of the main. In the event of a motor breakdown or other important nodes, the car simply will not be able to move from the place, but the output of the brakes is in order to lead to very sad results. That is why each driver must constantly care for such important elements of the vehicle and regularly carry out prevention, which is not a complex process and is made independently. I propose to consider what characteristics should take into account when choosing a braking lubricant and what lubricant is the most suitable for calipers. Only when using high-quality materials, you can guarantee reliable operation and mounting brake pads.

Content

- Competitive brake system, safety and troublescence on the road

- Lubrication for guide caliper, which gives brake lubrication

- Technical characteristics of lubricants

- Copper brake lubricant

- High temperature lubricant

- Universal lubricant

- Best manufacturers and best lubricant for caliper

- Tips of professionals

Competitive brake system, safety and troublescence on the road

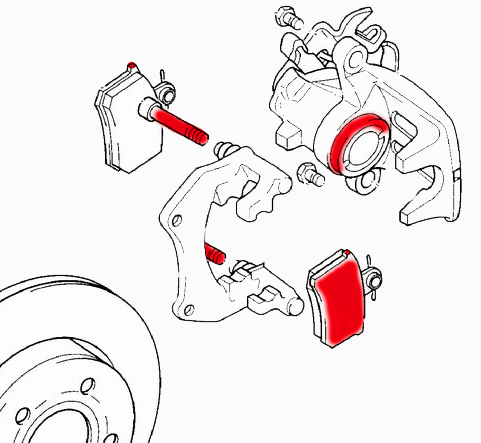

Brake caliper is one of the most important components of the brake system. It is from him that safety directly depends during the movement, as well as the life of passengers and the driver itself.

As a result of strong friction, the temperature of disc brakes is able to reach 500 degrees Celsius. If the vehicle is located in an aggressive environment, for example, when driving under the mountain, the details of the caliper are also impact. For this reason, only high-quality lubricants must be applied for guide calipers.

Lubrication for guide caliper, which gives brake lubrication

It's no secret that the brake system consists of pads, disk and calipers. Over time, the pads have the ability to wear, resulting in them to be changed. In addition, this node is also influenced by many other factors, such as: negative weather conditions, extreme ride or salt, which is sprinkled with garbage coatings.

However, the replacement of the pad is not able to solve all the problems. That the guide caliper functioned in the correct way, they need high-quality lubricant, which will fully provide trouble-free ride of the vehicle.

Technical characteristics of lubricants

Material manufacturers for lubricants are focused on certain conditions in which a particular node will work daily.

When taking into account a variety of parameters, in particular - the quality of the brake fluid, the operation of cars under different weather conditions or too high temperature during the friction of the brake pads, the lubricant for the brake caliper is needed with special characteristics:

1. Restable to the impact of various chemical compounds and to any water types - rain, fog, snow.

2. The lubricant must be high-temperature, that is, its operating temperature should be from 150 degrees Celsius and, if necessary, above.

3. It must be wake-up with elastomeric seals and plastic elements.

4. At high temperatures, the lubricant should remain as viscous to prevent its leakage.

Based on the parameters described above, and the lubricant should be selected for the brake calipers of your vehicle.

Copper brake lubricant

For brackets, anti-graded plates and metal coatings of the pads, and to be more accurate, then for their reverse side, high-temperature and anti-grade paste are used. This group includes copper lubricants with graphite and copper powder, with non-metallic filler, complex, that is, with different components and with Molybdenum disulfide.

Copper paste can provide protection and lubrication of components that are all the time under load, for example, fastening the parts of the suspension, the brake and intake system. In addition, they use copper paste and for lubricating spark plugs, as it is a resistant to high temperatures and they do not have the ability to influence it. Due to this, the paste is also used to lubricate compounds in the exhaust system.

To lubricate the desired element of copper paste, you should first clean it from corrosion. After that, we apply a paste with a brush or brush and distribute uniformly throughout the coating. The whole process takes only a few minutes.

Due to the wide temperature range in which the copper paste can be used, it is used in the energy, oil industry and in many diverse spheres.

In the vehicle there is another node in which you can use copper lubricant. When boiling or face the manual brake, the wheels are not capable of spinning. This can happen after visiting the car wash in the winter season or after a long standing of the car on the handbrake. In this case, the paste must be applied to the cables of the handbrake and the rear pads, which will bring the chances to zero to the fact that the handbrake does not want to move away.

High temperature lubricant

These pastes are used for pistons, sleeves, piston edges, and so on, however, they cannot be used with silicone components.

Universal lubricant

Universal lubricants are used for all moving caliper elements, including elastomeric and plastic.

Best manufacturers and best lubricant for caliper

If you are interested in finding out that paste for calipers is the most efficient and high-quality, I propose to revise the products of the manufacturers of narrow specialization:

Copper:

1. "Huskey341" from the manufacturer Husk-ITT Corp.

2. Kluber Lubricarion Munchen k from the manufacturer "Kluber".

3. "Loctite" 8012/8154/8155 from German manufacturers.

4. "Molykote".

5. "Liquima Moth" is high-temperature and one of the most effective.

High temperature:

1.ate Plastilube.

2. Loctite Teroson Plastilube.

Universal:

1. "MS 1600".

2. "Molykote" AS-880N GREASE.

3. "Slipkote" Disc Brake Caliper Grease.

For example, among the CIS countries, the Berdyan Plant "AMSOLOL" can be noted, which is located in Ukraine, however, it is very difficult to find their products in retail.

Tips of professionals

Clean and lubricate the caliper is necessary during each replacement of the pads. To do this, you need to clean all the accumulated dust and dirt. Then, you need to lubricate the guide pads, the guide fingers and their anthers inside. Whatever the caliper would hang on the hose, it is advisable to hang it on the wire. In addition, it is very good to clean it, whatever rust marks left anywhere. Next, the ends of the pads should be treated with a file and install all the details into place. To close the caliper, the brake cylinder needs to be deepened. Do not cost forget about the level of brake fluid. After assembly, pump brakes. After lubricating the guides, it is possible to accumulate a large amount of dirt, although it depends on the weather conditions.

There are lubricants for calipers who are not able to collect dust and dirt, such as LiquimolicUfperpaste.

It is worth saying that you do not need to save on the lubricant, since low-quality pastes are capable of crystallize and stick. It is unlikely, inexpensive lubricants from dubious producers will be able to guarantee the optimal, long-term and uninterrupted operation of the brake system. You must choose a lubricant for your car, respectively with the classification by groups.

Car and motorcycle manufacturers advise the use of silicone and high-temperature lubricants, as they are the best and guarantee the trouble-free operation of the brake system, reliably protecting it from aggressive environmental impacts - dirt, temperature drops, moisture and dust. Therefore, when choosing a lubricant, you need to pay attention to those materials that meet the requirements listed above and have a manufacturer's quality certificate.

The end itself, I would like to say about fairly common graphite lubricants, the so-called "graphs", which are strictly forbidden to use to lubricate brake calipers. They keep relatively low temperatures and can burn or flush.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments