In addition to the tools used to repair the vehicle, you also need tools for checking it. Among the diagnostic tools of this kind, the pneummeter is distinguished.

Content

Purpose Pneummeteter

The pneummexter allows you to determine the probability of leakage in the cylinders and the state of mechanics in the engine, especially the tightness of the camera, and also exclude this kind of breakage. The drop in the pressure falling into the cylinders through the candle holes is measured using a pneumatic) and, thus, malfunctions are detected.

When working with a pneummetter, you have the opportunity to determine the state of the cylindrophone group, the integrity of the gasket of the GBC and the density of the adjustment of the valves. Also, with the help of a pneummetter, you can estimate the tightness of the inner view of the motor cylinders.

Interestingly, it is possible to carry out work with a pneummexter at partly inoperative either dismantled motor, as well as on a non-working starter.

Device and principle of operation of the pneumatic

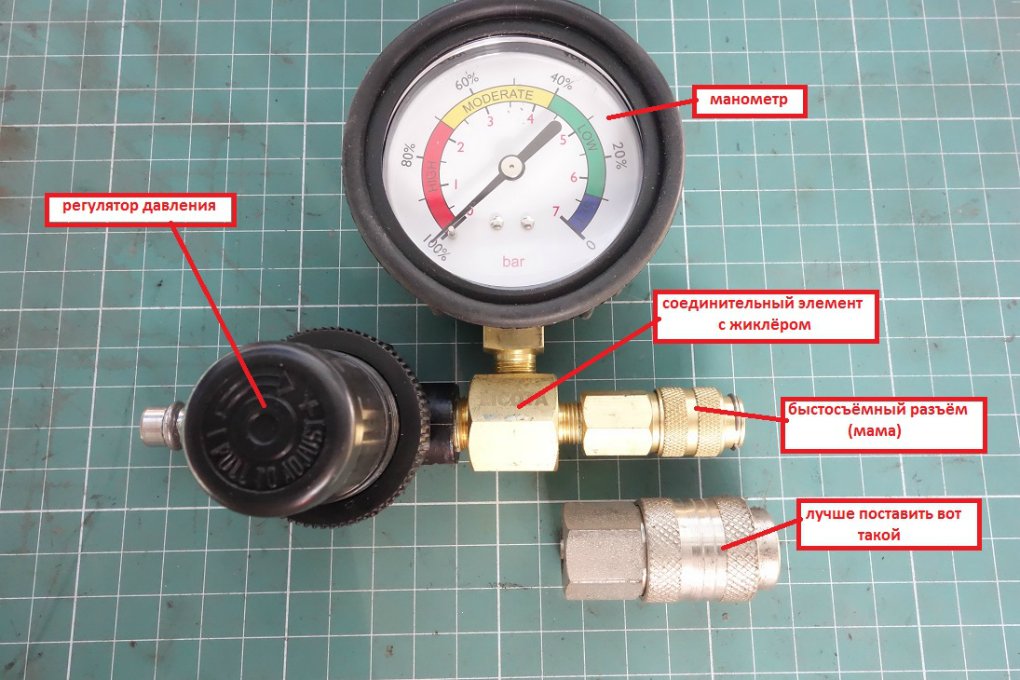

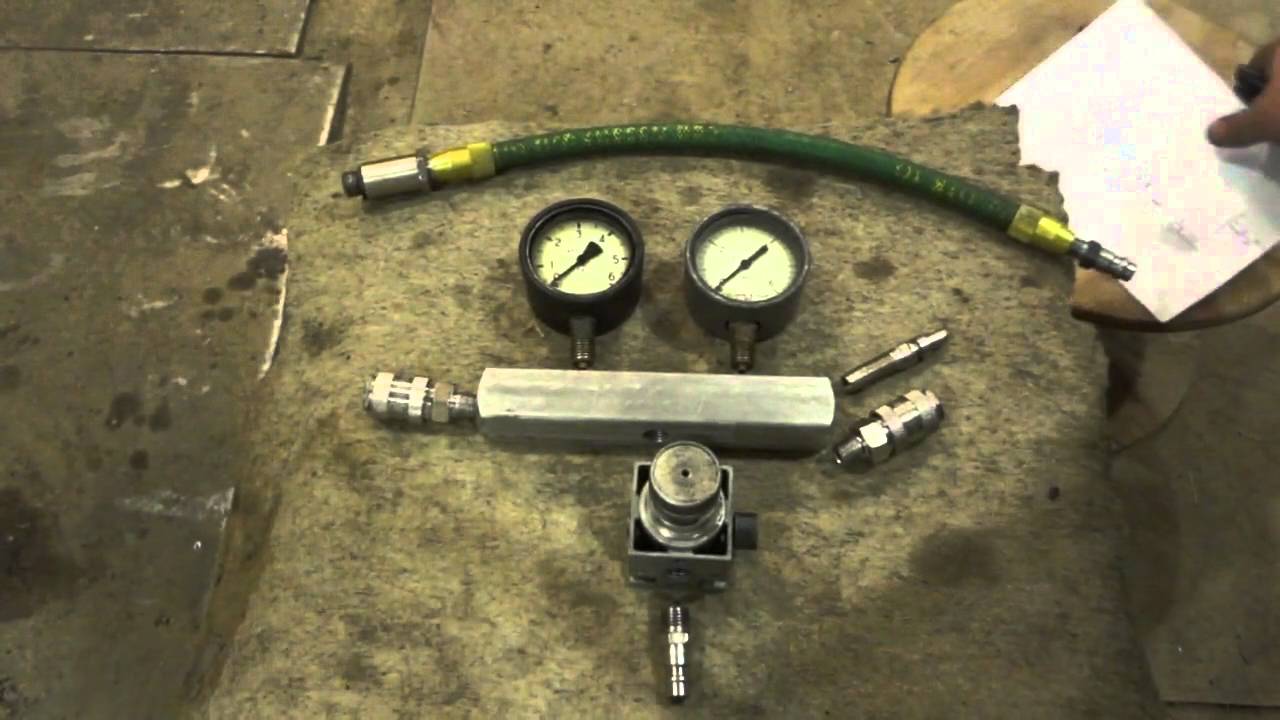

Pneummetter - pretty simple diagnostic equipment, but very useful. Its device is simple and comfortable. The pneummeter from the tube having two cameras between which the loaf is mounted. Pressure gauges are installed at the entrance and exit, and the pressure gauge, which is secured at the output, carries out pressure in percent.

As for the gibler, it is selected so that at a certain level of pressure, if the inlet is fully open, the pressure gauge shows a hundred percent leaks, and if completely closed - zero percent. In other words, in the conditions of a fully sealed surrounding space, the indicator of the pressure gauge will be zero percent.

The principle of operation of the pneummexter is to detect exemplary faults. Under the conditions of the fully open inlet, the indicator will be one hundred percent, and in the presence of depressurization there are the same values. This does not mean that there is no piston in the cylinder, it means that the level of looser and leakage in the epipal space is identical to the diameter of the inlet of the pneummeter.

Pneummetter from such components:

- Input fitting, compressed air is supplied to its sensor.

- Output fitting.

- Pressure pressure gauge.

- Manometer controlling air leakage. It carries out pressure in the epipal space of cylinders.

- Check valve.

- Air pressure regulator, which is served.

- Special adapter and hose connected to the candle hole.

How to use a pneummexter

Pneummexter is quite easy to use. It is important to know that before connecting it to the compressor or another compressed air supply device, it is necessary that the pressure regulator is in the leftmost position. How is the leak test?

- First, warm the motor up to a comfortable temperature, then drain it and turn off the ignition.

- Unscrew the candles.

- Install the cylinder piston in the upper point of the compression tact.

- Lock the crankshaft. For MCPP - turn on the highest transmission and tighten the parking brake. For automatic transmission - hold the crankshaft of the motor with a lock or a special key.

- Check if you need an adapter to connect the pneummex hose and connect it to the screw hole of the required cylinder, if the motor is gasoline, or in a diesel engine - to the nozzle, but until you connect this hose to the pneummetelate.

- Next on the left pressure gauge, install the pressure regulator of the air supplied to the minimum level, which will protect the pressure gauge during the cutting air supply.

- Then you can connect the pneummetexter to the pneumatic network or compressor, exposing the pressure of 6-10 atm.

- Applying the pressure regulator, smoothly increase the pressure. If operating pressure is set to the device, as a rule, 2-6 atm, we set the required.

- We attach to the pneummetelater the pneumatic hose connected to the required cylinder. We remove the results from another pressure gauge, whose indicators can be measured both in atm and in percentage of leakage depending on the pressure value, which is supplied. Color indicators are not rarely found, denoting "good", "critical" and "satisfactory" leakage state.

- When detecting critical leaks, perform additional research.

- Before disconnecting the pneummexter from the cylinder or compressor, reduce the adjustable air regulator to the minimum value.

- Disconnecting the pneummeter from the cylinder or the nozzle, repeat this procedure for each of the data of the engine elements.

We estimate the testimony of the pneummeter

Even a new car will not give one hundred percent tightness, because in the motor, in any case, there are constructive gaps that allow the level of leakage of 15-20 percent. During the operation of the car, these indicators increase to 30-40 percent. This table will allow you to navigate in the testimony of the pneummexter.

| Indicator | The magnitude of the leakage% | Meaning of indicators |

| Green | 40% | Minimal leakage corresponding to a new motor or motor with normal technical characteristics |

| Yellow | 70% | Satisfactory condition of leakage level. However, the leak is quite large and requires detailed detection of location. Requirements are recommended. |

| Red | 100% | Critical leakage level. It is necessary to overhaul, because in the cylinder there is definitions. |

| Red | Full leak condition: 1. Most likely, the pneummexter is not connected to the motor. 2. Elements acting on the tightness of the thrown valve, or part of them are destroyed. |

If the leak indicator flashes red, you need to figure out the reason for such indicators in more detail and determine the leakage place. To do this, do the following:

- Remove the lid of the radiator, the expansion tank, open the oil-tapping lid and use the oil probe. And if you have a carburetor, remove the air filter cover.

- We install 2-6 atm pressure at the input pressure gauge.

- Now you can visually determine the places through which the air leaves, or by noise, which air creates when you exit:

If it comes out of the oil hole or the nests of the oil probe, this indicates the depressurization of the pair of a piston-cylinder, any problems with piston rings or about the destruction of the piston.

The air from the inlet system comes out - this indicates that the pair of the "intake valve - the valve saddle" is depolent. Most likely, failed in the work of the valve mechanism.

The air from the muffler leaves - this indicates the leakage of the "Saddle of the Valve - Exhaust Valve" pair. Most likely, failed in the work of the valve mechanism.

The air leaves the adjacent candle hole - the crack in the cylinder or depressurize the gasket of the GBC.

A sharp increase in the level of fluid in the radiator or an expansion tank (the air bubbles can be noted) indicates the start of the gasket of the GBC, the crack to the GBC, or there are such damage to the block itself.

Also, you can also exclude a combination of all these types of damage.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments