A good brake system is one of the important components of the safety when driving. In order for the vehicle to suddenly not lost the brakes, you need to constantly control the wear of the brake pads - the key working component of the entire system. About this further in the article.

Content

- Brake shoe wear sensor, where installed, why it is needed

- Brake shoe sensor, how many sensors are installed on the machine

- Mechanical Brake Shoe Ware Sensor

- Advantages and disadvantages of mechanical sensors

- Electronic Brake Pad Wear Sensor

- Advantages and disadvantages of electronic sensors

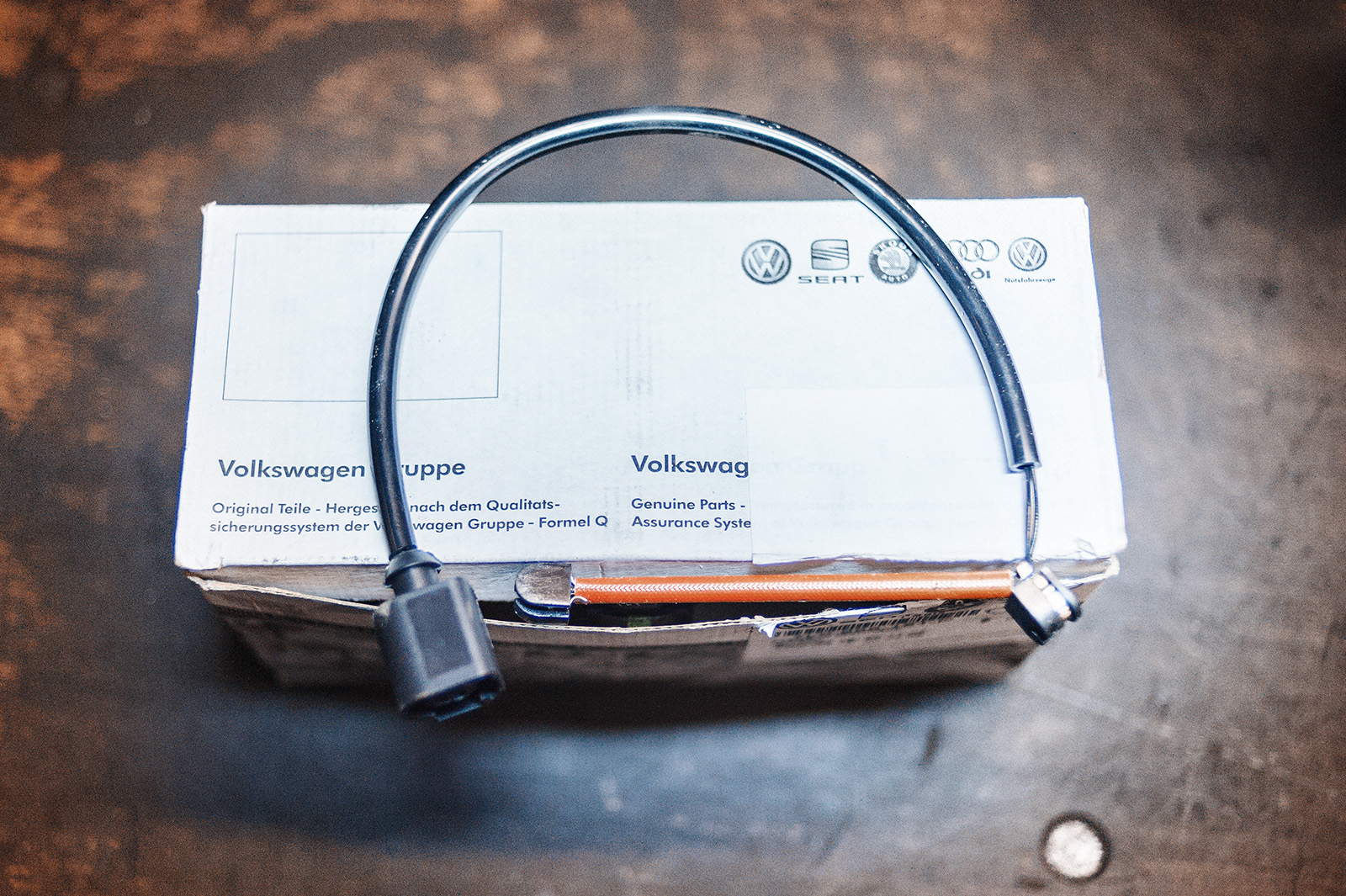

- Tools, fixtures, consumables

- Replacing electronic brake pad wear sensor (step-by-step instruction)

- Council Prof.

- As on Aliexpress, find and order the necessary sensors and other auto parts and parts at a reasonable price and free shipping

Brake shoe wear sensor, where installed, why it is needed

In modern cars today, friction-type brakes are used, which are triggered as a result of friction force. The interaction between the pads and the disk through their contact and entails braking. The most extended component of the brake mechanism is a friction layer of brake slap.

Even until recently, the car owner had to control the residual thickness of the pad. Nowadays, many cars, or rather, brake pads are installed, brake pads are installed, which significantly simplify such controls. Such alarms installed on the bar or inside it, in conditions of achieving a frictional layer of serious wear, inform about the need to replace them.

Brake shoe sensor, how many sensors are installed on the machine

In cars, a different number of brake pad wear sensors can be used - from one mounted on a block of one of the front wheels, and up to four, mounted on all wheels (the sensors are installed only on the external blocks). The optimal solution is two sensors, one of which is mounted on any of the front wheels, and the other on any of the rear.

Mechanical Brake Shoe Ware Sensor

A few decades for monitoring brake slap control is used, however, an effective solution is a mechanical sensor. Its design consists of a U-shaped spring steel plate, fixed by one end on the block. Another end is perpendicular to the brake disc at the distance of the limit wear of the friction layer.

The principle of this sensor is quite simple:

- When the frictional material is erased to the minimum allowable values, the plate comes into contact with the disk, making a specific rattling sound.

- The appearance of this sound warns the car owner on the need to replace brake slats.

The constructive solution of such alarms makes it possible to install them only on disk braking systems.

Advantages and disadvantages of mechanical sensors

Some manufacturers do not glue mechanical signaling devices to the metal area of \u200b\u200bthe plank, and fasten with different fasteners. And considering our roads, such a fastener contributes to his loss while driving.

The second problem, independent of the alarm, is small gravel and dust, falling between the disk and the lining. The resulting sound is sometimes perceived as the triggering of the sensor.

Electronic Brake Pad Wear Sensor

Such sensors manufacturers equip all modern cars, considering them more reliable. After all, with the help of such alarms, it is possible to control not only over the total wear of the brake pad, and above the degree of depreciation of the friction material. Electronic sensors are two types:

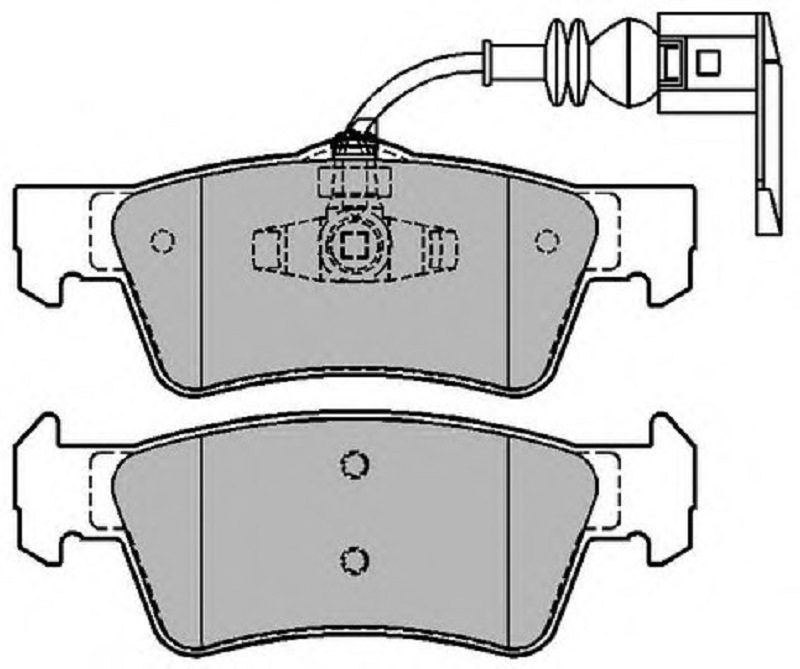

- External alarms are fixed either on the side of the brake slap, or in a specially intended remission, which makes it possible to replace them when breakdown.

- Integrated sensors - in the production of slats they will be pressed into the friction material. In this case, their replacement is impossible.

Such sensors are pretty simple: a core is located in the plastic case. In order not to damage the brake disc, it is made of soft metal varieties. From the rear side of the sensor there is a connector with a tap wire.

The principle of operation of such alarms is based on the processes that occur in the electrical circuit under the conditions of its closure. When the core, during the wear of the slats and the destruction of the front of the case, begins to touch the disk, the same processes occur. The contact chain and the lighting of the indicator on the instrument panel occurs.

The result of the operation of integrated and external alarms is slightly different in the signal appearing on the dashboard:

- During the response of the external sensor, the light indicator lights up when the thickness of the friction material reaches the critical mark. The indicator at the same time will constantly burn in one color.

- When the integrated signaling device is triggered, the indicator lamp will be changed color depending on the wear of the brake pads. If the thickness of the friction layer approaches critical indicators, the light bulb will burn yellow. In case the frictional material is worn completely, the lamp lights up in red.

Advantages and disadvantages of electronic sensors

Like any signaling device, the sensor controlling wear has certain disadvantages:

- Wire connectors are not protected from dirt and moisture from entering them, which does not rarely lead to the closure of contacts or their oxidation.

- The wires that they are equipped are quite subtle and are not rarely robbed and shared.

- If the weather is rainy, moisture that falls on the friction layer is capable of changing his resistance, which entails the false indicator triggering.

It is worth noting that even in the conditions of cliff wire, electronic sensors will still point to wear of the lining. In this case, they will work as mechanical alarms - when the sensor rod will be close to the brake disc, the specific sining sound will occur.

Tools, fixtures, consumables

Replacing electronic brake pad wear sensor (step-by-step instruction)

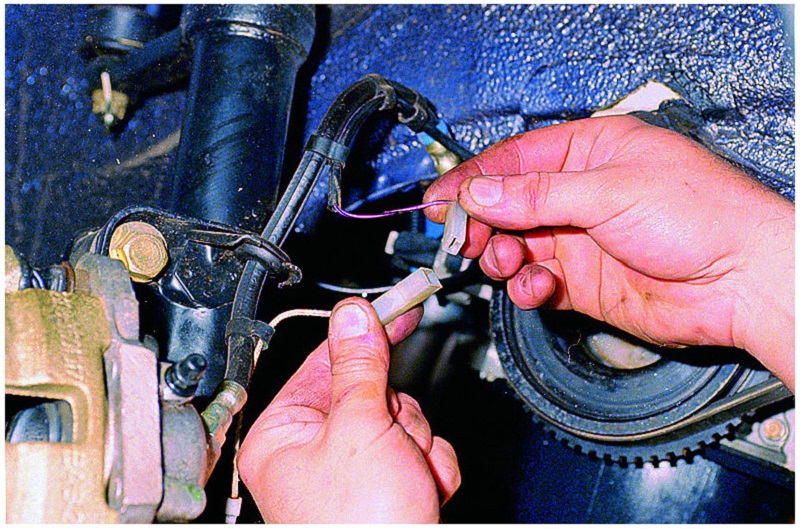

- We raise the vehicle using a jack for five centimeters.

- We unscrew the wheel.

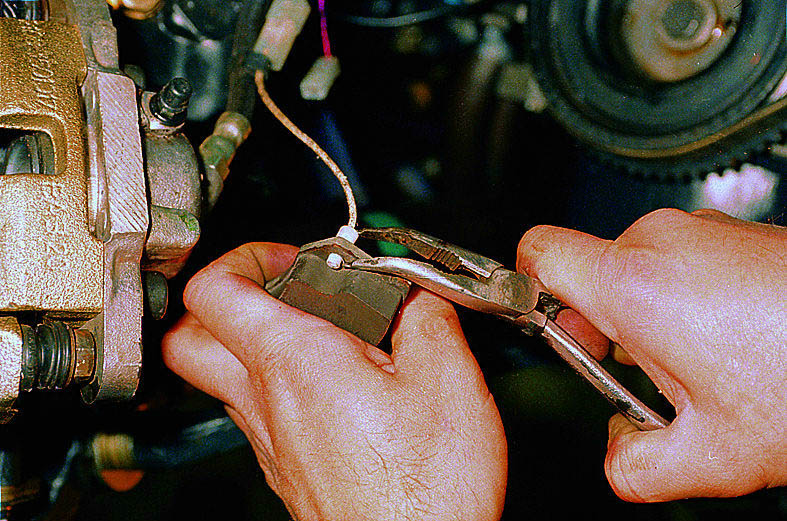

- The integrated sensor is mounted into the body of the shoe, and the external alarm is located on the side of the hub. The fixing system of the device is based on clamps or spring clamps, which makes it possible to quickly replace it.

- We dismantle the old sensor.

- Carefully clean all contacts.

- Install a new alarm.

- To reset the indicators on the onboard computer, turn on the ignition and hold the reset button of the kilometer for a few seconds pressed.

Council Prof.

If the sensor signals the wear of the brake pads, the car owner should replace them as quickly as possible, otherwise the consequences can be quite sad, since safety on the road directly depends on the health of the brake system.

As on Aliexpress, find and order the necessary sensors and other auto parts and parts at a reasonable price and free shipping

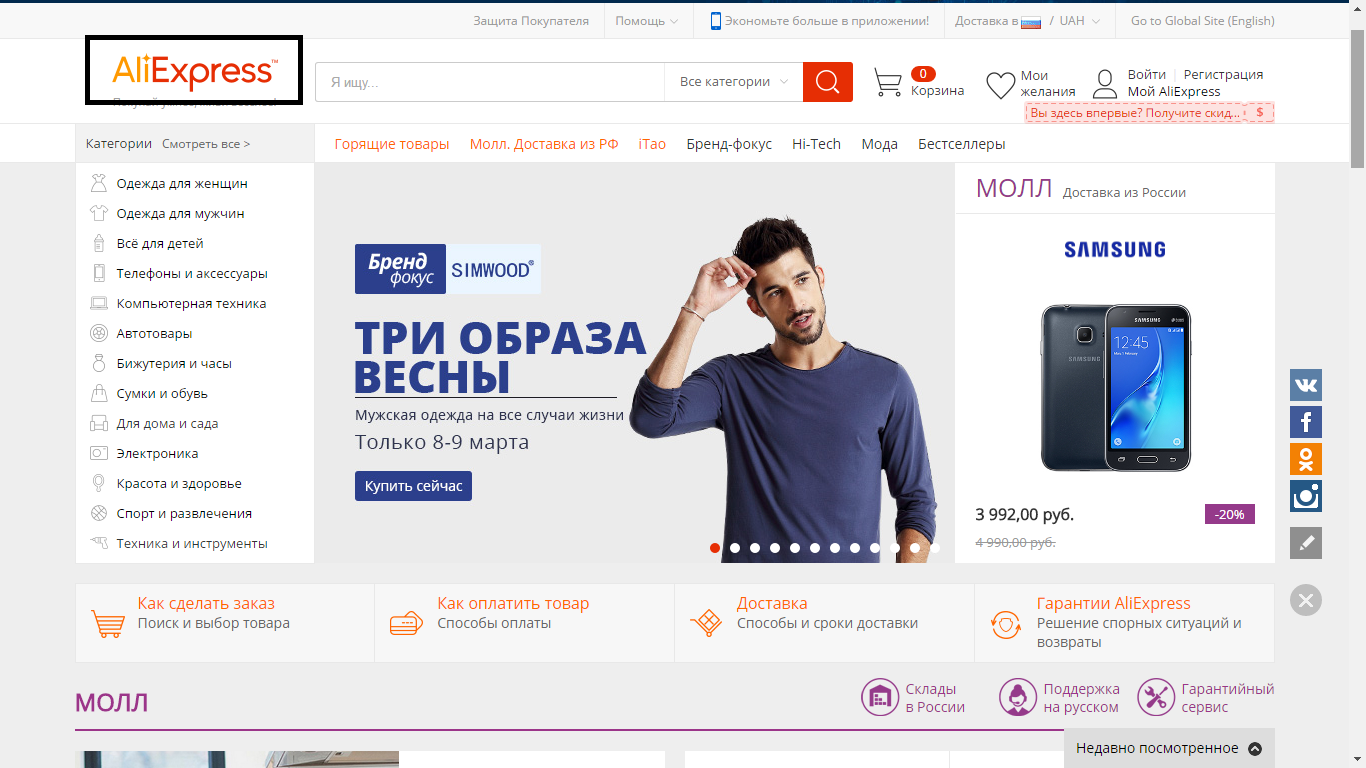

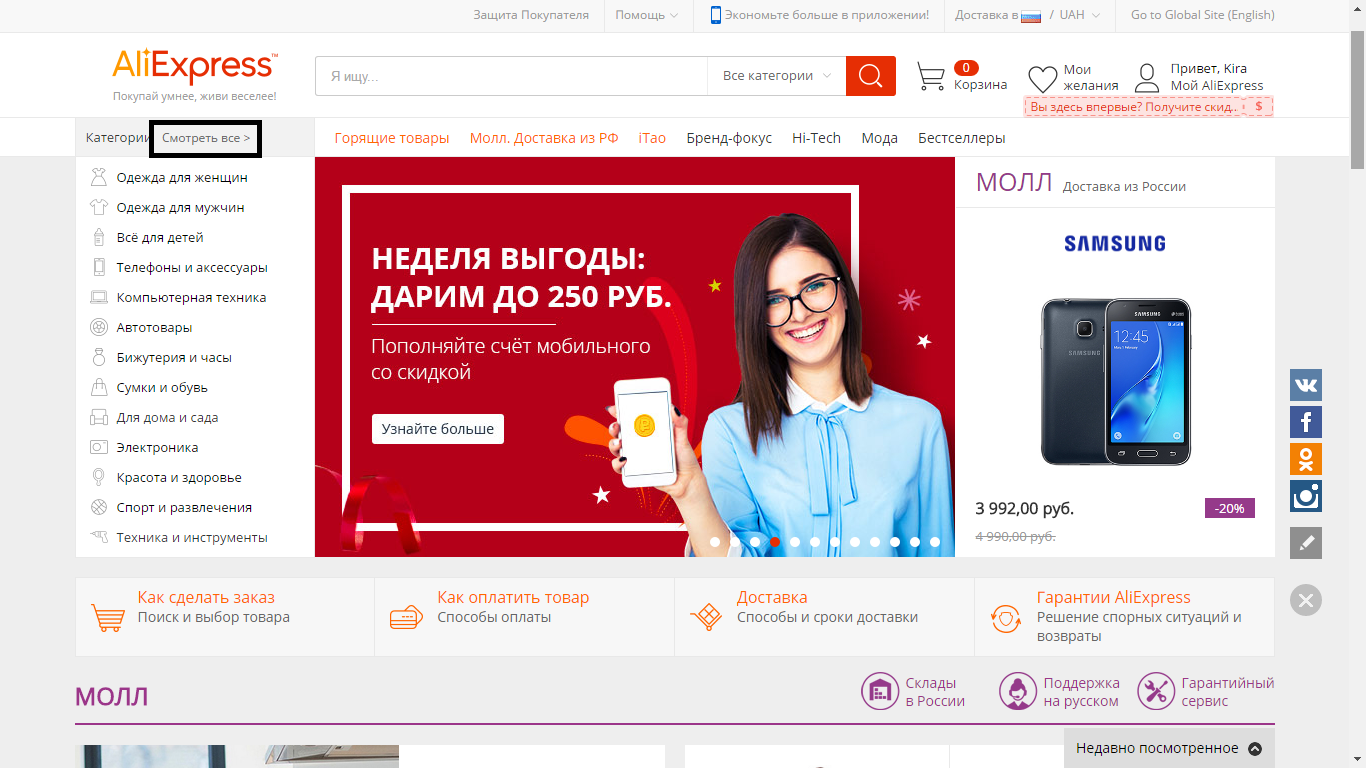

- Go to the site Aliexpress.

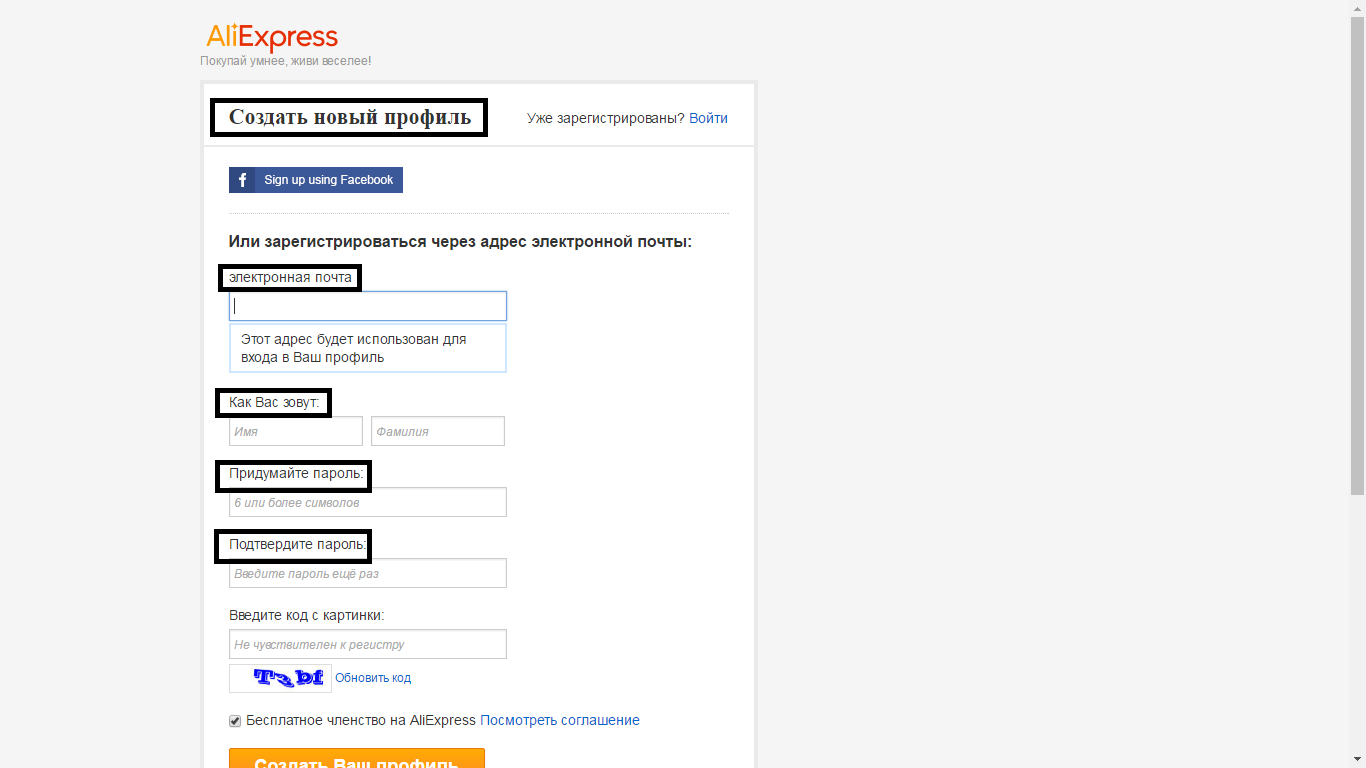

- We register for which it is necessary to enter your email address, name and surname to the special registration form, and then come up with and confirm the password.

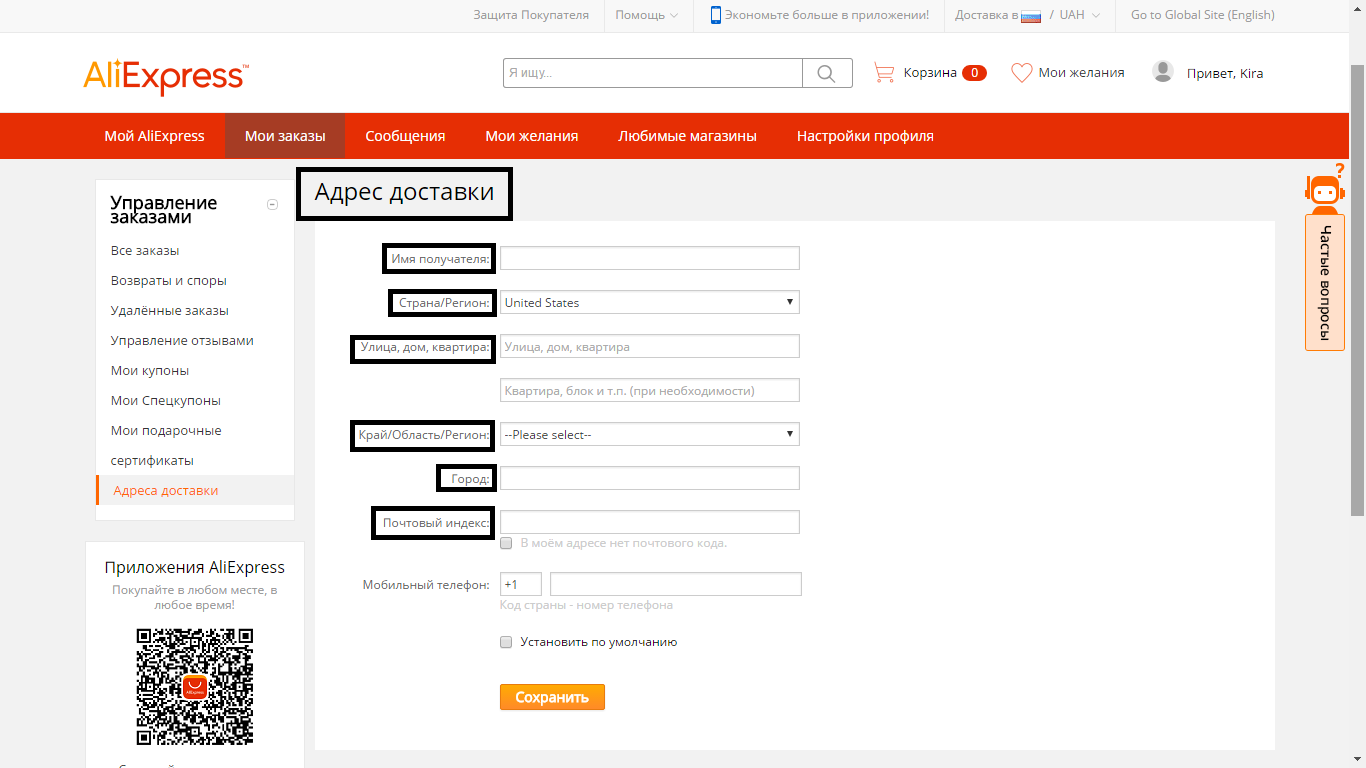

- Next, go to your profile and fill in the shipping address. This is done only by English characters.

- Near the category line in the left part of the site, click on the "Watch all" link.

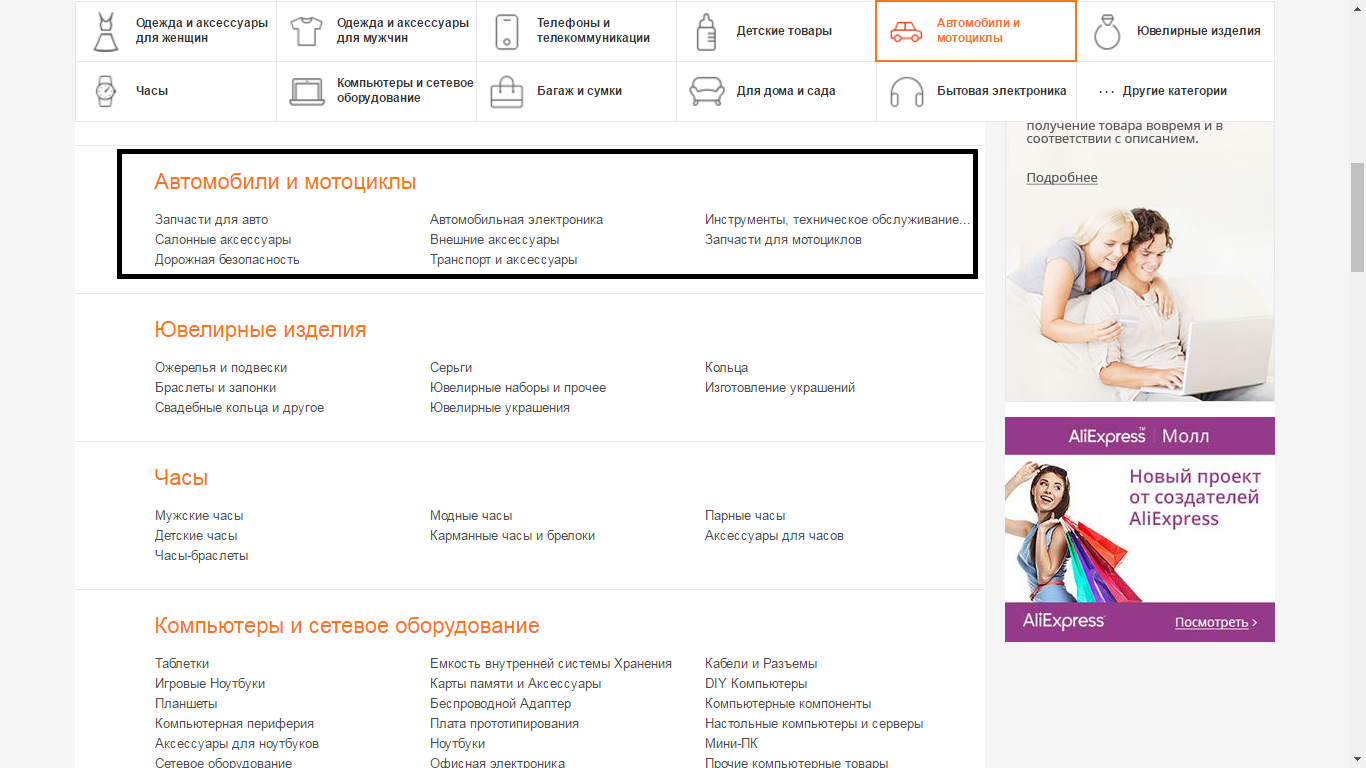

- Select the category "Cars and Motorcycles".

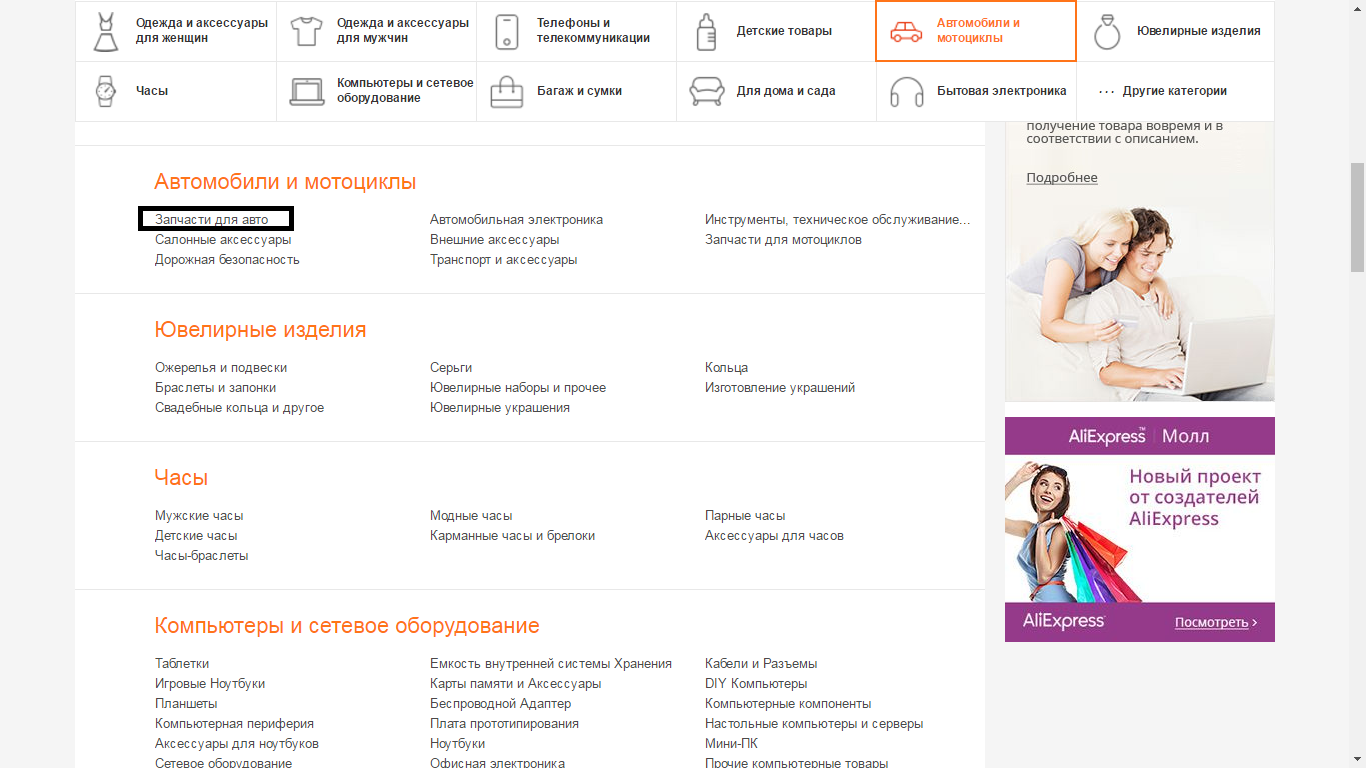

- Click on the "Auto Spare Parts" link.

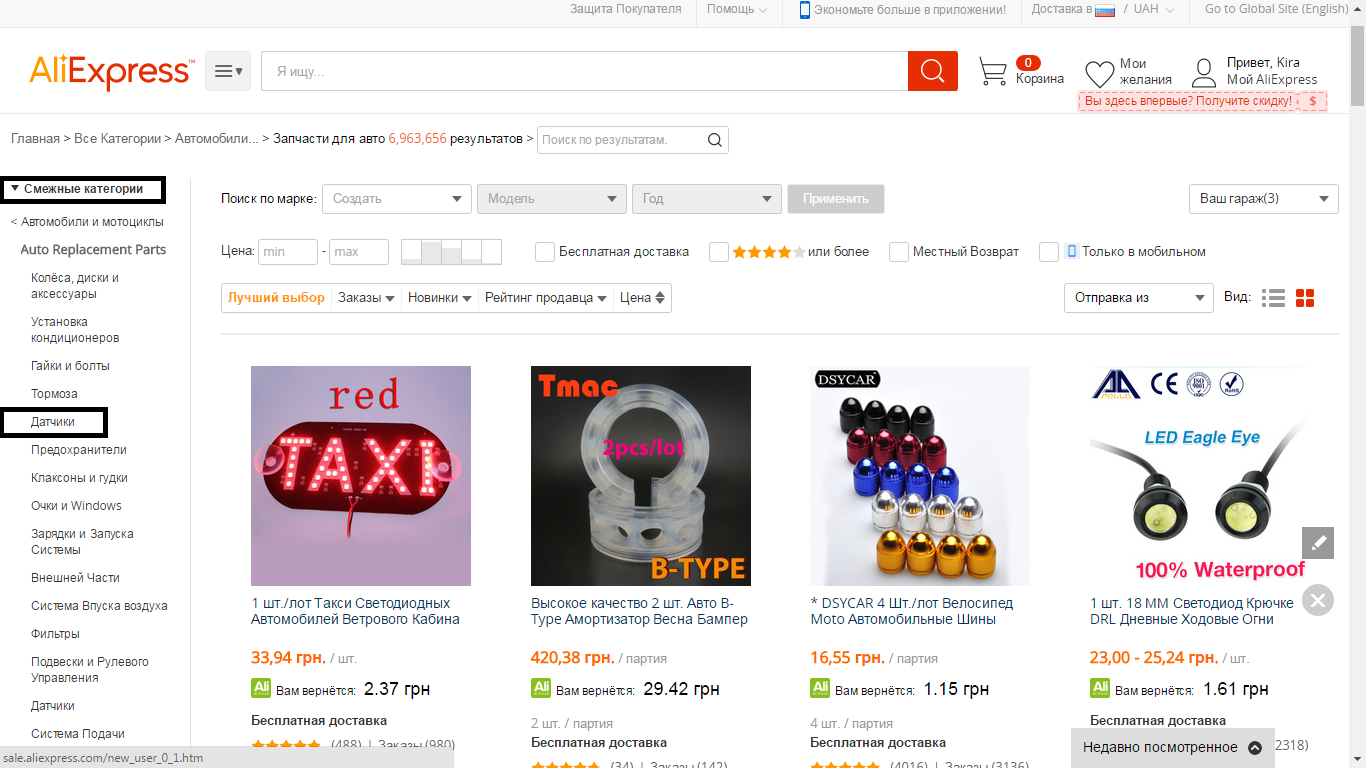

- In the left side of the page under the inscription category list, select the "Sensors" category.

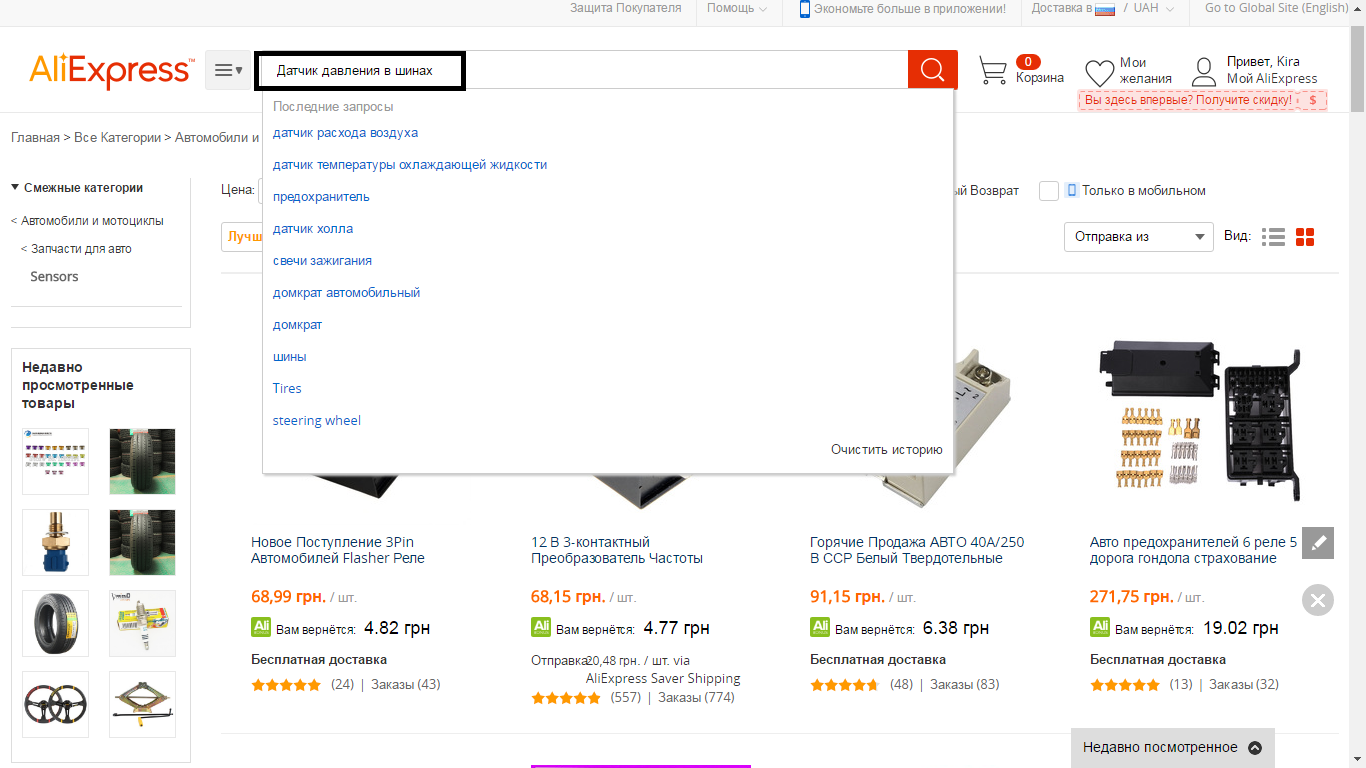

- We drive into the search string the name of the desired sensor, for example, tire pressure sensor.

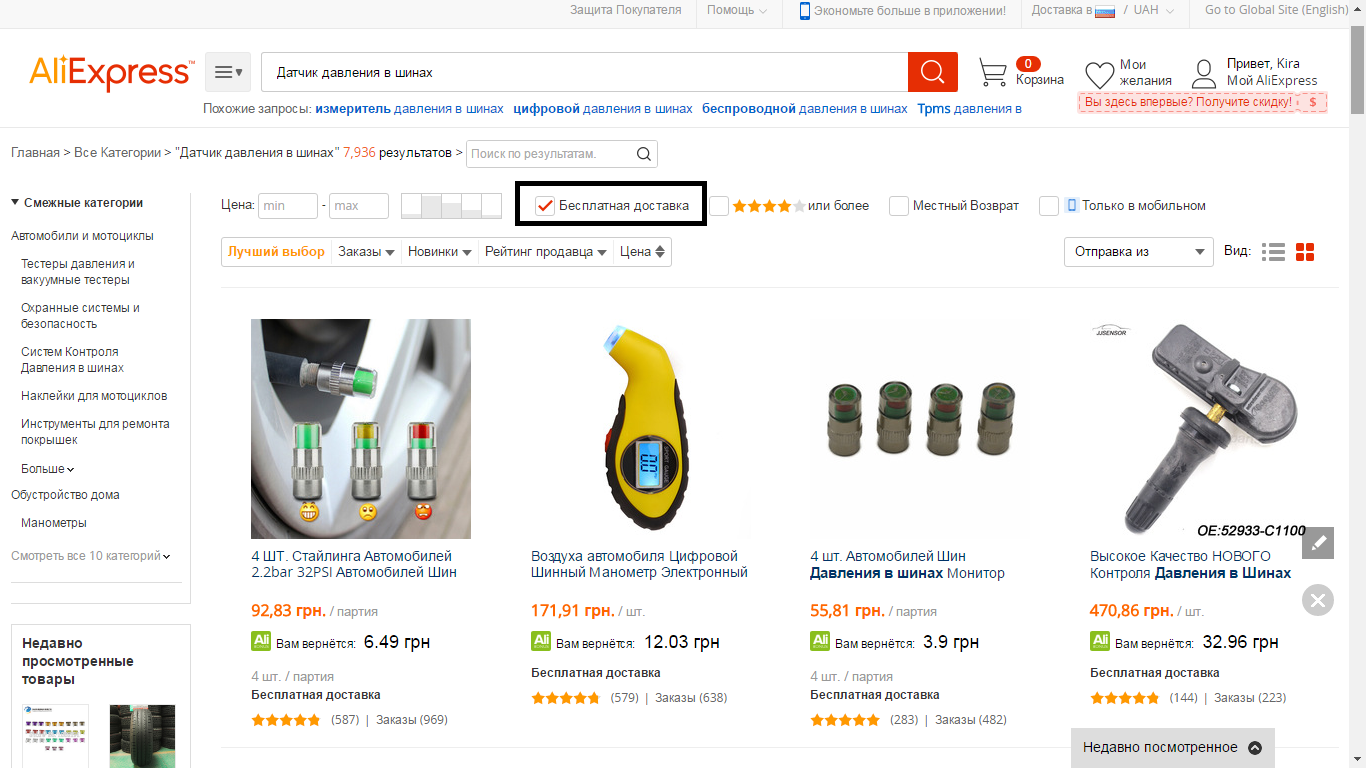

- Choose goods with free shipping.

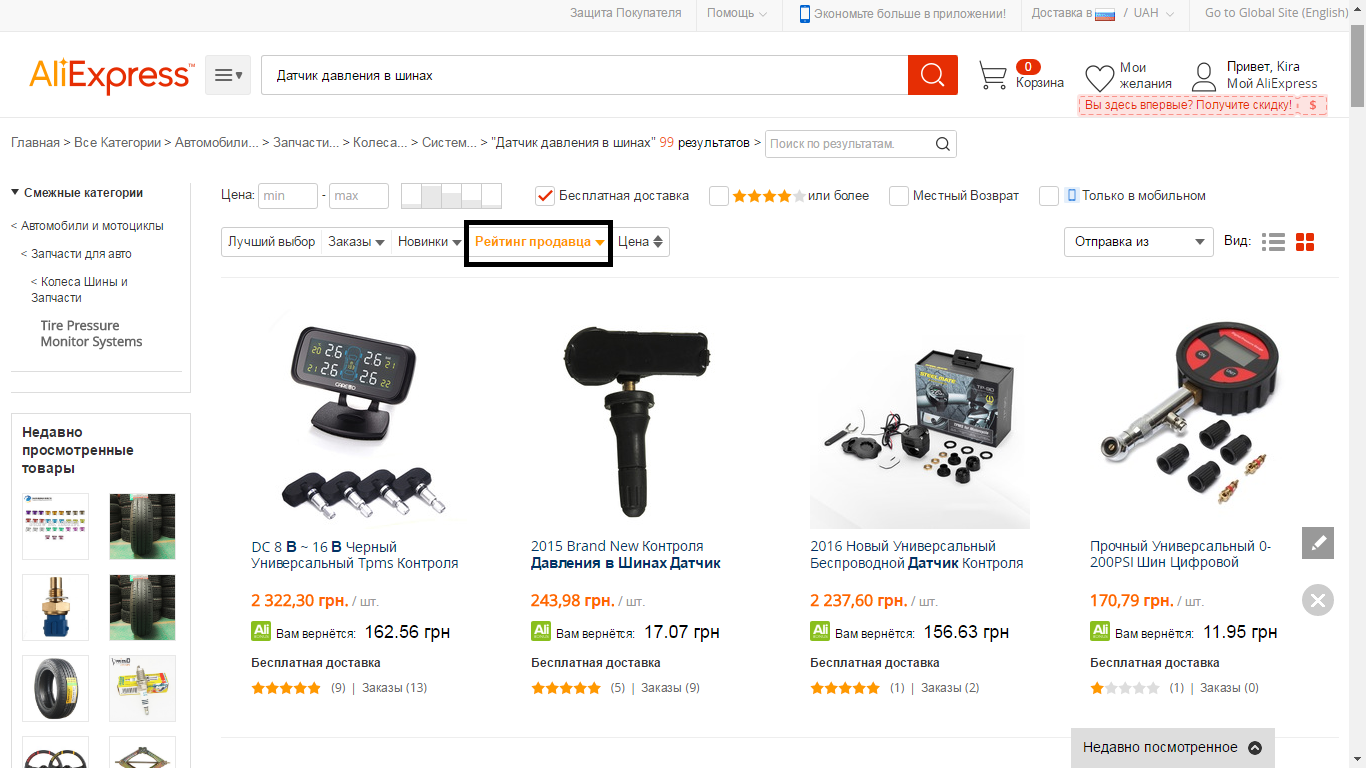

- We choose sorting results by the seller rating.

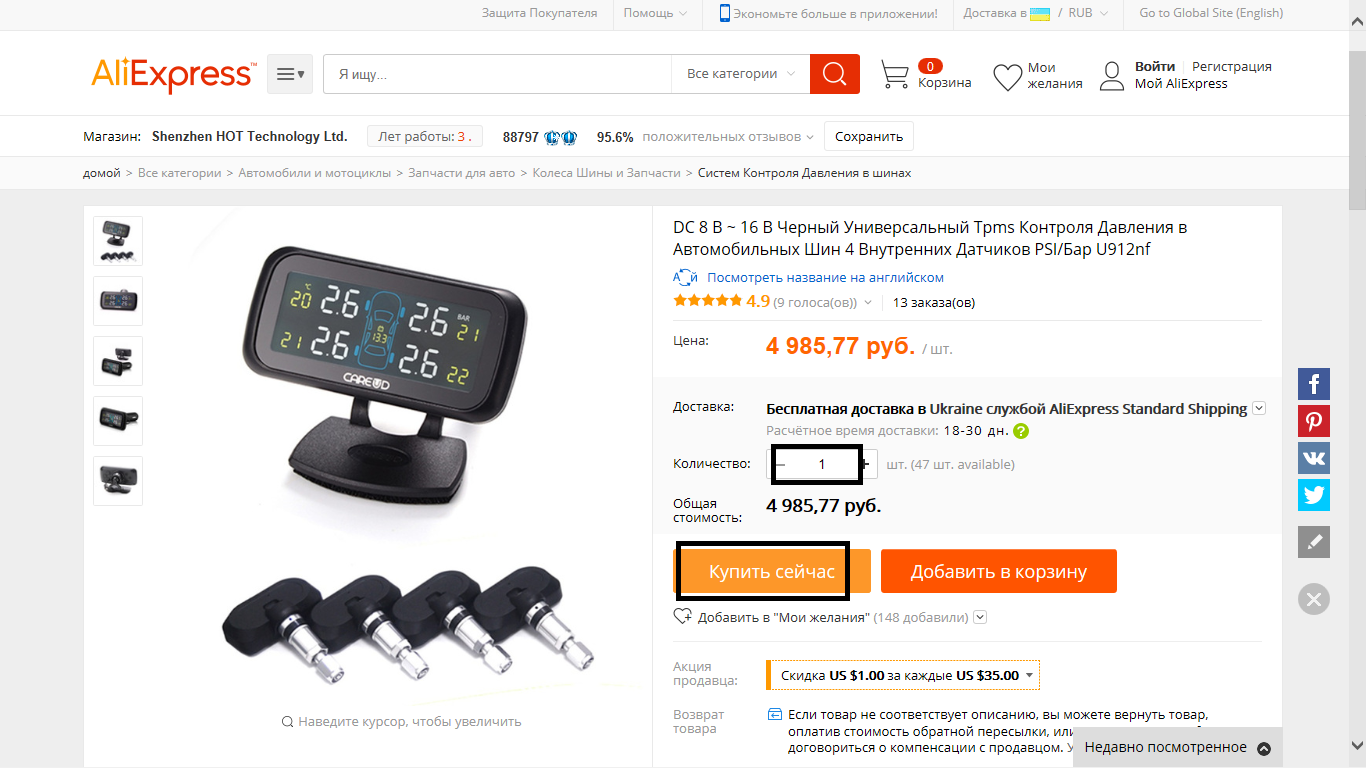

- On the description page of the desired sensor, choose the number and click "Buy Now".

- We pay for the order.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments