Modern "dozens" are equipped with a mass of various nodes and devices that perform a variety of functions. The crankshaft sensor on the VAZ 2110 is one of the most important elements in the car and directly affects its performance. Where is this sensor? What are the signs of its malfunction? How to replace DPKV yourself? About this further in the article.

Content

- Crankshaft sensor, device and principle of operation

- Sensor location location

- Signs of sensor malfunction

- Ommeter for diagnostics, diagnostic process, which criteria is determined by the failure of the sensor

- Tools for repair

- Safety to prevent short circuit

- Replacing the sensor DPKV, step-by-step instruction

- Council Profi, cleanliness Pledge of car health

Crankshaft sensor, device and principle of operation

On an 8- or 16-valve motor, the DPKV performs non-controlling functions, but performs the phase injection phase synchronization. In addition, the crankshaft sensor transmits the pulse to ignite the air-fuel mixture in the engine combustion chamber, so the controller failure is capable of entrusted with the coherent and incorrect operation of various vehicle systems, therefore, the normal robot of the motor will be impossible.

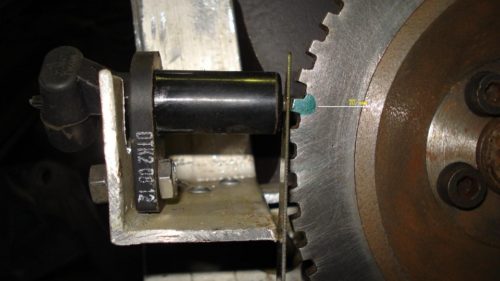

The DPKV itself is an inductive type device. This controller responds to the passage of the teeth on the specifying disk, which is installed on the pulley of the generator drive, and the controller itself is mounted near it. It is worth noting that 58 teeth are located on the pulley, between which there is a flow of two teeth. It makes it possible to synchronize with the upper so-called "dead point" of the piston of the power unit. When the catch runs near the controller, the corresponding signal comes to the motor control unit.

The designs of the devices of this type are quite a lot, and their principle of operation is based on the Hall sensor. In the latter case, in addition to the other, the regulator reacts to the rotating shaft, but its triggering is made due to the passage of a permanent magnet.

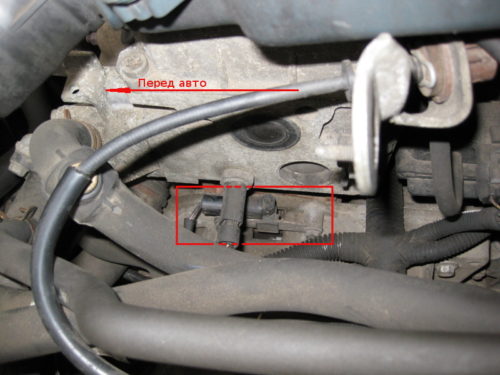

Sensor location location

If you have noticed the malfunction of the power unit, then before proceeding to detect breakage and malfunction symptoms, you should find out where the regulator is. Open the hood and pay attention to the lid of the oil pump. If you have an 8- or 16-valve "dozen", then the crankshaft sensor will be located directly on it (the oil pump lid). As you can see, the location of the regulator is not particularly comfortable. VAZ developers thought out and for the convenience of replacing the controller equipped the crankshaft sensor with a long wire for eighty centimeters.

Signs of sensor malfunction

If the controller located on the oil pump fails, the car owner will not be able to start the motor. When breakdown, solve the problem of the impossibility of starting the engine will allow only the regulator replacement. It is worth noting that on the VAZ 2110 the controller is not so often fails. As practice shows, in most part cases, problems are gradually accumulated.

So, what signs of a malfunction of this sensor:

- Reducing the power of the motor when driving. When the motorist presses sharply on the gas pedal, power failures can be observed. It is worth noting that in carburetor engines this can occur with incorrect operation of the accelerator pump.

- Possible difficult motor start.

- Sometimes the detonation of the power unit can occur, especially when it works at high speeds. In some cases, this situation may be due to the use of low-quality fuel.

- Another feature of a malfunction, the elimination of which requires the replacement of the crankshaft sensor is an increased gasoline consumption.

Basically, the failure of this controller may entail an unstable operation of the power unit. Causes of breakage, as a rule, are caused by the factory marriage. Sometimes the regulator breaks as a result of contaminants at the installation site.

Ommeter for diagnostics, diagnostic process, which criteria is determined by the failure of the sensor

The process of diagnosing the device is based on checking the resistance parameters of the crankshaft sensor windings, for which an ohmmeter is used. If the tester showed the values \u200b\u200bthat differ from 550 to 570 ohms, which means the controller failed. In order to avoid damage to the sensor, the place of its installation should always be clean. In addition, checking the integrity of the wiring will not be superfluous. The quality of the connection also plays an important role. If we talk about repair, then the crankshaft sensor cannot be repaired - it can only be replaced with a workable.

Tools for repair

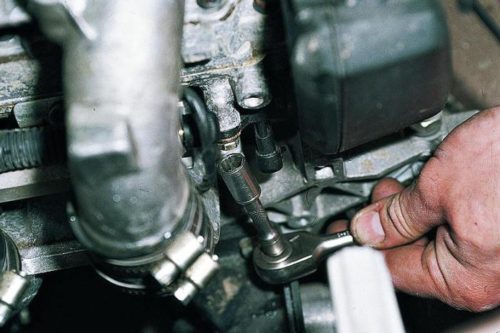

To execute this event, you will need only a wrench to "10".

Safety to prevent short circuit

To prevent possible closures on the onboard network of the car, disconnect a minus terminal from the battery from the battery.

Replacing the sensor DPKV, step-by-step instruction

- First, turn off the ignition.

- Next, open the hood and find the location of the controller.

- Then disconnect the connector from the regulator.

- Using a wrench, we unscrew the bolt that fixes the device.

- We dismantle the crankshaft sensor from the place of installation on the oil pump lid.

- Install a new device.

Council Profi, cleanliness Pledge of car health

Before installing, make sure that the problems with the operation of the power unit are not caused by poor-quality wiring. Otherwise, the replacement will not give the desired result. In addition, it is necessary to clean the connector from pollution and dust and the installation site of the device, which will give the opportunity to avoid failures in its work.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving a car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments