The crankshaft rotation sensor provides synchronization of the engine of the internal combustion engine and the ignition system. This is due to the transfer of data on the position of the crankshaft, directly into the engine control unit. Which in turn determines the operation of the ignition system. Violations in its work lead to a complete stop of the power unit of the car.

Content

Where is the crankshaft sensor how it works

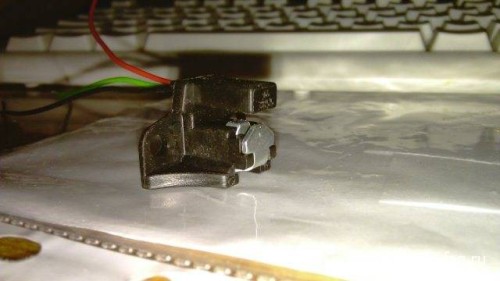

The location of the crankshaft rotation sensor may vary depending on the type of engine. It is usually located close to the pulley of the generator drive.

The crankshaft sensor is externally, almost identical to the camshaft sensor, with the difference only. It has a long wire with a connector for connecting to the engine control unit. The crankshaft sensor wire can reach the length of 60-70 cm.

The principle of operation of the crankshaft rotation sensor may vary depending on its type. Total are used three types of crankshaft sensors.

Interesting! The crankshaft rotation sensor in different literature is called differently. So, for example, the abbreviation of DPKV is found. Which is decrypted as a "crankshaft position sensor".

crankshaft induction sensor

The induction sensor of the crankshaft revolutions is an autonomous device that does not require the power supply. The signal fed to the control unit is formed by electromagnetic induction at the time of the synchronization tooth through the magnetic field. In addition to the data on the position of the crankshaft, the induction sensor also transmits the velocity of the vehicle.

optical type crankshaft sensor

The optical crankshaft rotation sensor runs through light threads. The principle of operation of such a sensor is next. The synchronization disk is made with holes, it interrupts the light stream between the light source (LED) and the photocell. When you turn the synchronization disc, the light stream passes through the hole and enters the photocell, at this point the optical sensor produces an electrical pulse and gives it to the electronic motor control unit.

hall type crankshaft sensor

The operation of this sensor is based on the Hall effect. The pulse is supplied from this sensor at the moment the effect on the electromagnetic field. It affects it in a specific position of the synchronization disk. This type sensor also acts as a ignition distributor sensor.

Crankshaft sensor faults, fault signs

About the malfunction in the work sensor position of the crankshaft say:

- Taped on the car dashboard indicator "Check Engine";

- A significant reduction in the dynamics in the engine operation during movement;

- Unstable speed at idle;

- Spontaneous decrease and increase in engine speed;

- Detonation arising in the engine during movement;

- The engine does not start.

Checking the crankshaft speed sensor

Checking the crankshaft speed sensor is performed in three different ways. Two of which can be used independently in the presence of certain devices. The third is only available in specialized auto repair shops.

Important! Before starting checking the crankshaft rotation sensor, it is extremely recommended to explore the instruction attached to the car.

Consider more details of checking the crankshaft rotation sensor:

checking the crankshaft sensor, check synchronizer and electrical system

Check is carried out using a special device of an ohmmeter or multimeter.

Sequence of actions when checking the crankshaft rotation sensor:

- Set the sensor position labels;

- Dismantle directly the sensor itself;

- Make a visual inspection for mechanical damage;

- When detected contaminated contacts, clean them with alcohol;

- Establish the distance from the crankshaft sensor core to synchronization disk. The distance must be 1.0 mm + -0.4 mm;

- Turn on the mulitimeter the function "Resistance Measurement";

- With the help of the multimeter probe, measure resistance at the output;

- The resistance of the working sensor of the crankshaft should be 550-750 ohms.

Important! This check does not guarantee 100% of the likelihood that its results are correct.

instruments for checking how to make a deep sensor check with your own hands using measuring instruments

This method of checking the crankshaft rotor sensor is more complex and efficient.

To verify the sensor in these methods, you will need:

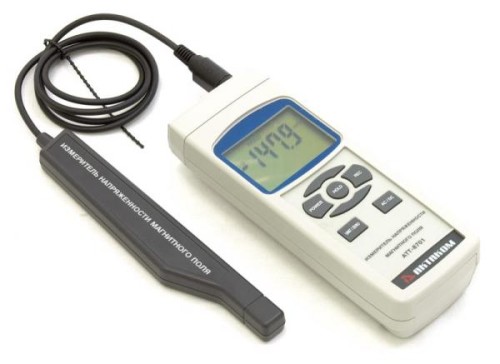

- Megommeter;

- Magnetic induction meter.

Prepare instruments need, you can proceed directly to verification:

- Set the sensor position labels;

- Dismantle directly the sensor itself;

- Make a visual inspection for mechanical damage;

- When detected contaminated contacts, clean them with alcohol;

- Establish the distance from the crankshaft sensor core to synchronization disk. The distance must be 1.0 mm + -0.4 mm;

- Turn on the megommeter in the position of 500 volts;

- Turn on the magnetic induction meter;

- We measure the insulation resistance to the megommeter and electromagnetic induction;

- The resistance of the sensor should be more than 20 MΩ, and the induction induction is 200-400 MHz.

The above data will talk about the health of the crankshaft sensor.

checking the crankshaft sensor to a hundred

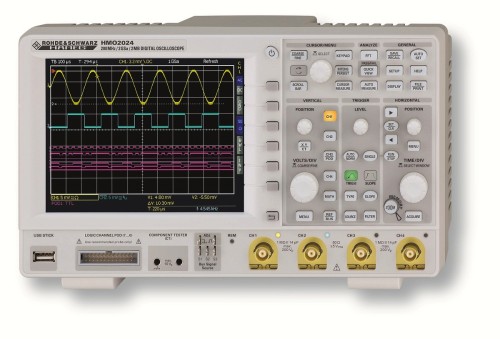

The most accurate and qualitative way to check the crankshaft rotation sensor. Is his check in a specialized maintenance station (service station). At the service station, the sensor is carried out using an oscilloscope.

Interesting! Oscilloscope - a device for measuring electrical pulses (signals) at a certain period of time.

Checking the oscilloscope is carried out without removing the crankshaft rotation sensor and allows you to effectively determine the presence of problems in the ignition system.

Tips of professionals

- The most efficient way to check the crankshaft rotation sensor is to check it with an oscilloscope in a specialized auto repair shop.

- It is recommended to carry a spare crankshaft sensor with you, in trunk. Its price is not large, and the value for normal operation of the engine is difficult to overestimate.

- When removing the crankshaft sensor, the labels of its initial position should be set. To bring the sensor correctly when installing.

- The distance from the sensor core to the synchronization disk should be 1.0 mm + -0.4 mm.

- When dismantling the sensor, the ignition should be turned off.

- In no case should not check the operation of the crankshaft sensor with a lamp. This is a sure way to bring the sensor into a non-working condition.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments