Air flow sensor, it is also a mass flow sensor (DMR) installed in the car, to determine the exact amount of air required by the car engine, to give a car of the desired power. So, in the problem of the air flow sensor, control of the fuel mixture of the engine cylinders (gasoline + air or solar + air). Since the correct ratio of air and fuel in the injection system occupies an important place in providing a power machine, the air flow sensor quickly received an introduction to a car. The air flow sensor is located between the inlet and air filter (air filter).

Content

How the air flow sensor works

To ensure the operation of the engine in the right mode, the correct ratio of the mass of gasoline to the mass of air should be created in one clock - the ratio of 1:14.

In case of non-compliance with this proportion, the optimal engine operation is disturbed (the engine can reduce the power or increase the fuel consumption).

The task is set before the air flow sensor, measure the volume of the air received and transfer the information received, onto the computer.

On-board computer, adopting information about the air received, will make an instant calculation of the required amount of fuel that the engine needs to efficiently work.

The driver, using the gas pedal, can adjust the air supply by clicking on the gas pedal, you increase the air supply and if the air flow sensor works correctly, more fuel will be served into the engine.

Experienced motorists know that riding without jerks, reduces gasoline consumption, i.e. If you do not "break" the gas pedal, you do not increase the amount of air, and that, accordingly, reduces gasoline consumption.

Consider the design of air flow sensor

The air flow sensor is the measuring tube, in which the finest platinum wire is located, it is throttle to it.

The operation of this device is on the principle of constancy of temperature.

The modifications of air flow sensors have a lot and determines the amount of air each sensor in its method.

But to prevent the platinum wire pollution, designers, developed the installation in the electronic control unit to support the incandescent function of the wire.

In one second, after turning off the engine, the surface of the platinum wire, it gets the heating to 1000 * C, it allows the platinum wire to be cleaned and removed all the dirt.

When breakdown, air flow sensor, it is very difficult to fix it, most likely you have to replace it with a new one, but the craftsmen will always find a way out.

How to define a malfunction

On the control board, faults light up and if you follow, then you can understand that the car has problems:

- if Check Engaie caught fire on the instrument panel, the car warns about breakage and it is possible that this is faulty air flow sensor;

- if you do not feel the speed of changes in the movement of the car;

- if fuel consumption increases;

- if the engine power is lost;

- if problems appear in the engine operation.

In addition to the above, the driver should pay attention to the operation of the air flow sensor and clean the sensor, as the surface of the air filter, through the ventilation of the motor crankcase, can enter the machine oil, this leads to the improper operation of the sensor.

Sensor developers, constantly invent new, to ensure the sustainable operation of the sensor, with different temperature differences.

The car market offers about 50 varieties of air flow sensors.

Blank air flow sensors

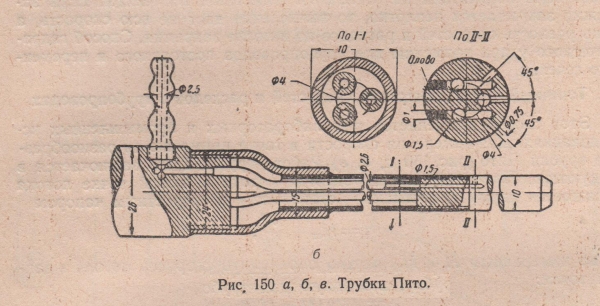

Pito tube is the basis of this flow meter, in the middle of the tube there is a thin plate.

Fastening the plate is not rigid, but soft.

Air flow is capable of bending a plate.

The potentiometer maintains permanent registration of the bending of the plate and changes the resistance indicators.

All information on the bending plate, enters the control unit, based on this information, the fuel supply changes.

Air flow sensor with thermoelectric meter

The most common option of sensors.

Thermomemometric film fleet HFM 6

1 - electronic unit; 2- part of the stream; 3 - protective grille; 4 - suction air; 5 - measuring tube; 6 - sensitive element

In the design of the heat exchanger, there are two platinum plates through which the current is carried out.

One plate is a worker, the other is backup.

Since the principle of operation of the sensor is concluded in the reduction of both temperatures of the plates in an equal state, the air flow cools a hotter plate, tries to compare both plates at a temperature.

The non-working plate falls under the larger current, this indicator affects the amount of gasoline supply.

If a multimeter is checked, and it shows a low signal, then the sensor works faulty.

Verification of air flow sensor

In order to check the sensor and find a fault, you must make the following actions:

- turn off the car engine;

- disconnect the sensor connection connector to the onboard system;

- turn on the engine, while the system will work in emergency mode. Now it does not matter how much air is served, the main thing is how the throttle valve behaves;

- try to drive by car, if with the sensor is turned off, an improvement in the dynamics of the machine has occurred - the sensor may be faulty.

Air flow sensor can be viewed visually.

There should be no signs of dirt or dried oil on the surface of the sensor.

If you find signs of contamination - clean all surfaces and eliminate the cause.

To diagnose, purchase a multimeter, measurements, with a constant voltage in 2 V. Multimeter, connect to the first and third connectors.

When the motor is turned off and when the ignition is turned on, the voltage on the sensor must be in the range of 0.996 - 1, 01 volts.

If the voltage is higher (above 1.05V.) You can throw away your air flow sensor - no resuscitation will save it.

If the sensor can be restored, depending on the readings of the multimeter, let's try to restore it.

We repair, clean and collect air flow sensor

On the issue of repair there are two opposite opinions.

But, if you do everything according to the instructions and carefully, we hope that you will succeed.

Purchase carburetors or WD40 cleaning fluid. Before proceeding with work, remember that in no case the following materials cannot be applied:

- no cotton sticks;

- no acetone and acetone-containing agent;

- do not attract compressor and compressed air to help;

- do not use the ether.

Everybody has done, and now we work:

- unscrew all bolts, screws;

- we remove the sensor nozzle;

- the sensor can be contaminated with a large amount of oil, with a liquid for cleaning carburetors or WD40, sprinkle on the contents of the sensor and wait until it dries;

- you can repeat the action

- after cleaning the sensor, clean the grid and the inner surface of the nozzle;

- replace the air filter;

- collect all that disassembled and install in place.

We hope that your problem is solved and you know how to make the sensor flushing.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving a car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments