The design of the internal combustion engine includes a special temperature sensor, showing to what extent heated coolant. It is from its temperature that the optimality and quality of the fuel mixture depends. The coolant thermal sensor is one of the very important elements in the vehicle design, which is monitored by the motor temperature and informs the driver about all the changes that occur. If the device has failed or began to give inaccurate readings, it is necessary to replace the part. I propose to discuss this topic in the most detailed way.

Content

- Where is the coolant thermal sensor

- Signs of malfunction in the operation of the thermal sensor of the coolant

- Checking the working state of the thermal sensor of the coolant, the course of the work has phased

- How to remove the cooling fluid temperature sensor with your own hands, the course of work is styled

- Replacing fluid temperature sensor with their own hands, detailed

Where is the coolant thermal sensor

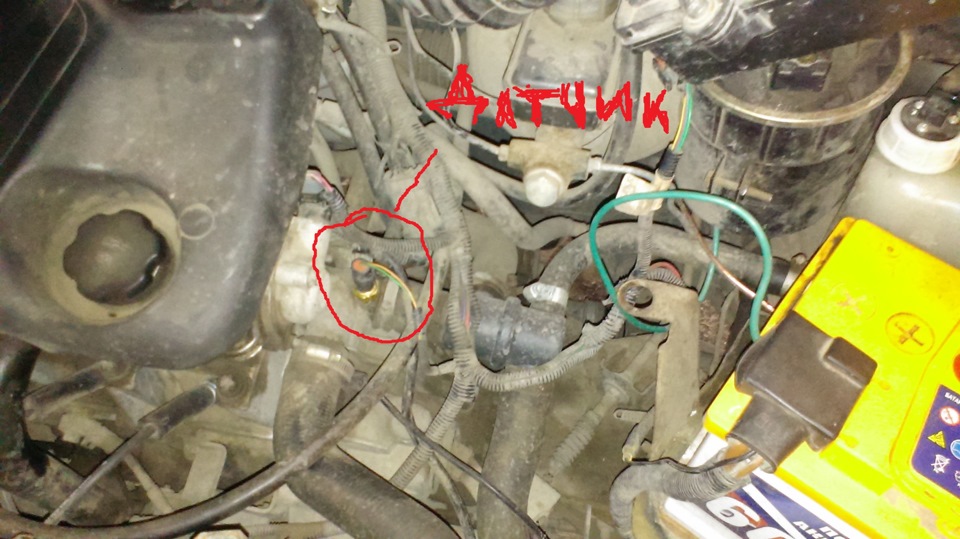

This sensor is located near the thermostat housing and install it in such a way that there were direct contact with the coolant, otherwise it makes no sense to talk about the quality and reliability of the signal.

When operating the motor, the temperature of its main nodes is increased. To pick up the heat concentrating in the cylinders and the cooling fluid is necessary. When the heat fence, the temperature of the block and cylinders is changing, the coolant thermal sensor fixes these oscillations followed by their transmission to the electric vehicle control unit. After receiving the signal, the state of the engine becomes clear - heated it or cold, how he warms and works at the necessary temperature.

Thanks to this, the facts are particularly important for the motor system, the main engine performance indicators can be corrected. If the temperature of the engine is known, the electronic control unit can select the desired operation mode, which has a positive effect on the car handling. With the help of Dzh, the system performs the following functions:

1. The possession of the delay or the ignition advance. With a properly exhibited ignition coal, the number of exhaust gases will significantly decrease, the car will use less fuel, and the operation of the motor will be more appropriate.

2. If the car is equipped with fuel injection system, gasoline is able to enriched. Upon receipt by the signal control unit for too low motor temperature, it immediately lifts the duration of the pulse transmitted to the nozzles, which makes it possible to exclude fluctuations when warming the motor and ensure the optimality of its operation at idle. When the temperature rises, the fuel mixture is shifted by a block, which allows the machine to produce a smaller exhaust and reduce the fuel consumption. With a faulty thermal sensor electrical block

The control does not control the processes in the engine, which makes the mixture of excessively enriched, contaminated and it is consumed in more.

In addition, the temperature sensor controls the rotation of the crankshaft and increases the revolutions in the case of idling.

Signs of malfunction in the operation of the thermal sensor

Coolant

Determine the malfunction of the coolant thermal sensor, you can look at its appearance. The first signs of malfunction of this sensor are cracks, strong corrosion or leakage of the cooling substance. However, sometimes the appearance of the sensor can be quite normal. There are several more factors indicating faults in the coolant temperature sensor:

1. If gasoline consumption increased.

2. If the electronic control unit shows

This problem code.

3. If the test lamp on the dashboard signals the overheating of the motor.

4. If the engine stopped or unstable.

5. If it is difficult to start the motor at idle.

Checking the working state of the thermal sensor of the coolant, the course of the work has phased

To check the thermal sensor of the coolant, it is necessary to consider more and more detail. The main indicators for which the sensor malfunction is checked is voltage and resistance. For proper check, it is necessary to arm a multimeter or an ohmmeter, a thermometer having a measurement limit to one hundred degrees and a heat-resistant capacity, which has a volume of more than O.5 liters.

Then, measure the resistance of the coolant thermal sensor

Liquids with a variety of temperatures. To make such a procedure, it is necessary to lower the sensor in the tank

With coolant and warm it. In the measure of how the water will cool, it is necessary to make a measurement of resistance every 20 minutes. The information obtained must be as close as possible in comparison with the data from the table, which can be quite easy to find on the Internet.

The principle of operation of the device is quite simple - the smaller the temperature of the motor, the greater the electrical resistance of the thermal sensor or the greater the temperature, the less resistance. Before checking the coolant thermal sensor

Fluids, make sure that the engine cooling system is proper. Check the correctness of the filling of the system is the cooling system, radiator, shelf life and composition of the coolant. Often, the cooler includes antifreeze and water in the same proportions, however, the manufacturer may slightly change the composition. In addition, pay attention to the operation of the fan, which is able to significantly reduce the risk of engine overheating.

How to remove the cooling fluid temperature sensor with your own hands, the course of work is styled

1. It is necessary to merge the cooling fluid. In principle, you can not merge not all, but only a certain part. It is important here that her level was not above the thermal sensor

Coolant. To do this, it is necessary to find the plug of the drain hole of the cylinder block, usually it is located under the ignition block module. The cork needs to be unscrewed by the Cauldron and wait a few minutes until the required amount of fluid is found.

2. Next, you need to remove the air filter to work it is more convenient. To do this, you need to remove its cover and weaken the clamp, fixing the air duct. We unscrew all the screws on which the air duct cover is attached. Then remove the filtering device.

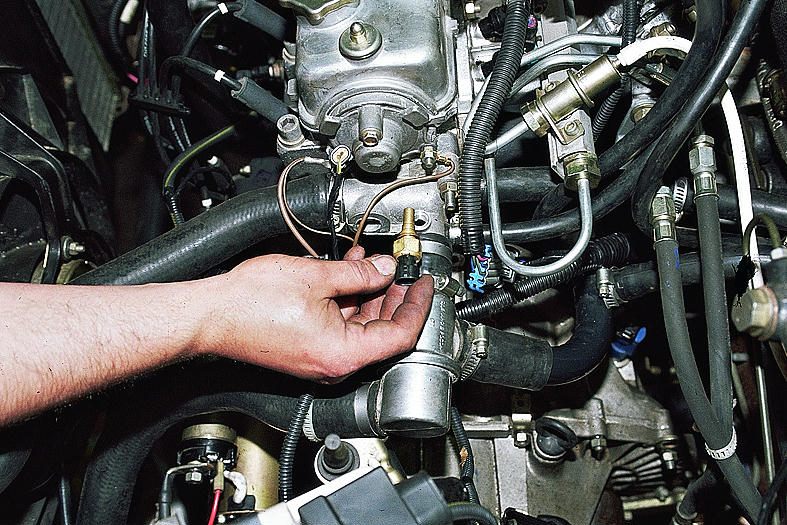

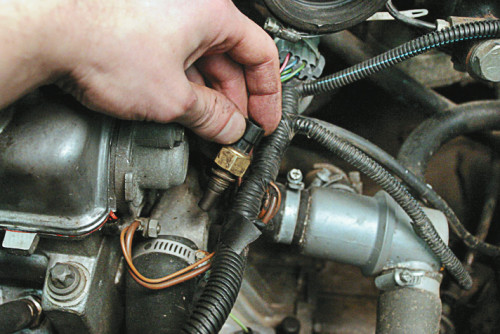

3. Then, you need to remove the rubber case from the device, but be sure to remember in what position the sensor marking is located.

4. Now we unscrew the instrument with the key to 21.

Replacing fluid temperature sensor with their own hands, detailed

1. Minding the thermal sensor of the coolant, not forgetting how the marking of the thermal sensor was located.

2. Install the air filter back.

3. Pour a new cooling fluid.

By the way, there are two types of thermal sensors

Coolant - bimetallic and magnetic. Each driver can independently determine which sensor is in your vehicle. Whatever it is to understand, get the car and look at the zak arrow of the pointer. If your bimetallic sensor is mounted, the arrow will move gradually, and in the case of a magnetic - bouncing to display data.

There are also thermal sensors of an old sample or capillary, which work as follows - the liquid that is contained in the sensor has a low boiling point, and when the device is heated, it is capable of evaporated and boiled. Thus, the pressure in the flask increases and the indicator arrow moves.

The broken thermal sensor of the coolant is capable of leading to high fuel consumption and to violate the engine operation. Knowledge of self-replacement of the temperature sensor will never be superfluous, on the contrary, they will help you to maintain your financial resources and allow you not to worry about the engine and about its long and uninterrupted operation. The motor in all weather conditions will quickly warm up, and even in the most rigid frost, and the temperature of the coolant will always be optimal with the most different modes of the engine of your car.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments