When the fuel ends, the choice of a small car owner - or recover the car again, and today it is the cheapest pleasure, or walk. Naturally, all drivers tend to choose the first option, however, probably should not be made to such situations when you have to make a decision immediately. To avoid such problems and a fuel level sensor has been created.

Content

Fuel Level Sensor - Device (Dut)

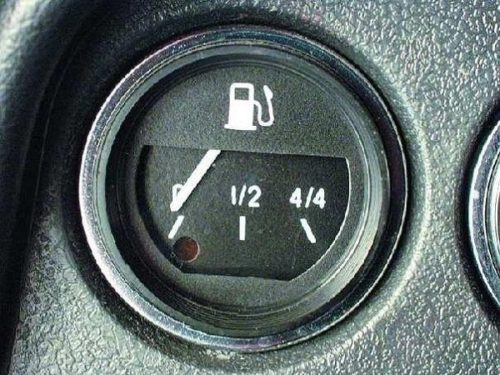

In this article, our attention will be focused on vehicles, where it is used to indicate the fuel level, converting this level into the volume and transmission of the resulting values \u200b\u200bwith a digital or analog path.

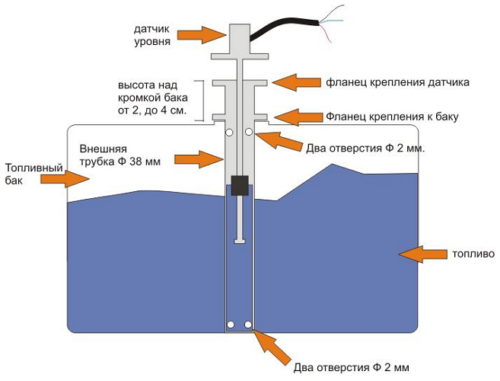

This device consists of a metal rod mounted into the fuel tank by means of a standard opening or a specially made hole suitable for diameter. The sensor is connected to the monitoring system of the car, where the required data is transmitted.

Often they are high-precision universal devices, which makes it possible to use them not only in transport, and at other techniques, and even in stationary facilities - plants, warehouses. This unit is closely interconnected with a fuel level pointer placed on the instrument panel.

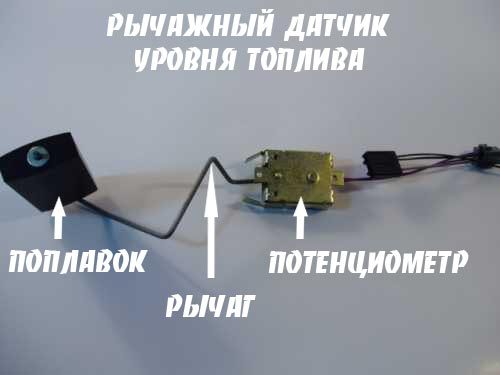

To date, there are a series of variations of the Dut - universal, ultrasound, float, digital, electronic, but their common goal is one - the correct definition of the fuel tank consumption so that each driver has the ability to control the fuel costs. In addition, the device makes it possible to monitor the amount of plum (the most useful option for taxi services, managers of enterprises and other organizations in which employees are able to merge a bit fuel) and fuel gas stations (in which volume when and where they were carried out).

For the possibility of more detailed control of the level of fuel, it is necessary to mount the corresponding device with a minimum error and increased sensitivity to the car, which will ensure the most accurate indicators.

connecting the fuel level sensor

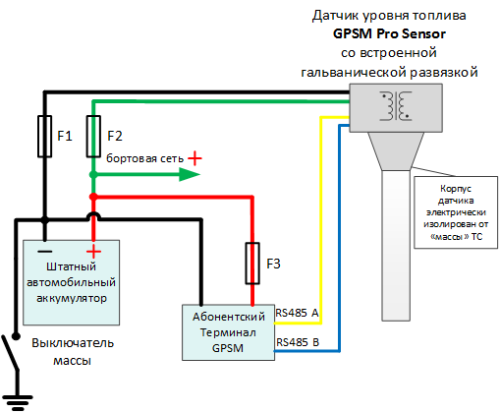

There are two methods of connecting to the onboard vehicle network, the design of which includes the mass switch:

- Connecting to the onboard network after the mass switch. The sensor, at the same time, will be de-energized immediately after turning off the mass of the car. In this case, you will be impossible to find out the drain time when the parking lot will be - the sensor will be turned off. This connection method is recommended for cheap sensors where there is no galvanic junction.

- Connecting the sensor to the battery directly. This connection method is ideal from a practical and functional point of view. In addition, the connection is duting directly to the battery is safe, since the consumption of the sensor current is only 10-48 mA. Connect the Pro Sensor sensors directly to the battery, since they are distinguished by the presence of built-in galvanic junction to 3000 V. In addition, the polymer body of this sensor is an insulator, as a result of which all electrical circuits are securely protected from electrical breakdown. To connect other sensors directly to the battery, you will have to mount an additional galvanic junction.

Fuel level sensor does not work

Dut, like any other elements of the car, can systematically fail, resulting in a need for repair work. Now we will consider in detail the most frequent causes of this phenomenon:

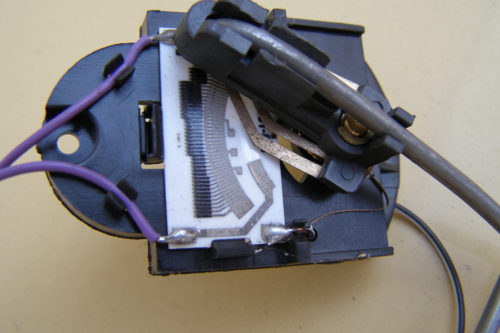

- If the readings are constantly changing ("download"), the contact tracks were worn on the board, which are influenced by the time as a result of the fact that the device's runner is constantly moving. If the erased area is not big, try to get the slider so that it is located above the erased place, however, with a large deposit area, it will be possible to solve the problem only by replacing the sensor.

- It happens that with full fuel tank, the sensor index arrow returns to zero value. Possible cause of this phenomenon is incorrectly placed location stop limiter.

- With the engine running and the ignition turned on, the index arrow remains fixed. As a rule, the reason lies in damage to the connecting wires, the oxidation of their tips, the malfunction of the pointer receiver or in the fuse brave.

- If the fuel level index arrow constantly drops to zero value and, while also twitching, the current collector should be checked, it is probably not enough for the sensor resistor, or the resistor winding was cut.

- In addition, the minimum fuel level warning lamp in the tank may stop working or work incorrectly, with interruptions. In this case, most likely the problem lies in the resistor and may have to be replaced.

The most common problem of potentiometric sensors is the rapid wear, as well as the oxidation of the tracks than and is determined by the appearance of the problems described above.

Check the fuel sensor VAZ

First of all, you should check the resistance of the sensor, for which it is necessary to do the following manipulations:

- Remove the rear seat.

- We unscrew the protective cover that the VAZ is located under the rear seat.

- We unscrew the dip and gently take it from the gas tank.

- Next, we switch the multimeter to the ohmmeter mode and measure the resistance of the sensor in the conditions of different positions of the float: if the float hangs under its own weight, the resistance should be from 280 to 330 ohms; When lifting the float upwards, the resistance must be from 7 to 20 ohms. It is worth noting that these values \u200b\u200bare given for a low dashboard (the instrument panel is also high - the numbers for low and high dashboards are slightly different).

- If, when moving the float, the resistance of the sensor does not change or significantly differs from the desired, this sensor should be replaced.

- With a good sensor, it should be carefully examined by its connector and a wire for a mass that comes from the sensor. Rust and oxide should be absent because they interfere with its correct and proper work.

If the sensor is working, and the fuel level index does not work exactly, we do the following:

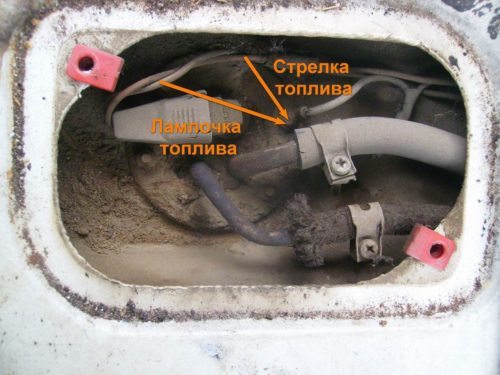

- The fuel sensor connector is characterized by the presence of two wires - pink and blue. A low fuel lamp is running blue in the tank, from pink - level indicator arrow.

- Armed with a jumper (part of a conventional wire) and with its help with the ignition turned on closing the pink wire for mass. In this case, the fuel level arrow should show the full fuel tank.

- Next, with the help of jumpers, we connect with a mass of the blue wire - a lamp of a low fuel in the tank should turn around.

- If during a closure to the mass, the pointer will not work, then the reason or in the pointer itself, or in one of the wires from the fuel sensor to the dashboard.

Replacing the fuel level sensor

If the fuel level sensor shows incorrectly, it should be replaced. To do this, you will need:

- New sensor.

- Crosshead screwdriver.

- Rozhkov's caps or heads.

- Screwdrivers.

- Ommeter.

It is worth considering that the sensor is in direct contact with the fuel, so it is necessary to adhere to certain safety rules. First, turn off the battery. It is not necessary to completely remove the battery, just disconnect the minus wire from the terminal. Then dismantle the sensor (how to do it, we will look below). Installation of the new Duts produce in the reverse order. When assembling it is desirable to further process the place of the jack of gasket and the pressure ring using a gas-resistant sealant.

how to remove the fuel level sensor

To remove the best, do the following:

- Raise the seat of the second row.

- Next, it is necessary to clean the area of \u200b\u200bthe technical hatch from the accumulated dirt and dust.

- Using the cross screwdriver, turn the screws that hold the hatch.

- Disconnect the wiring harness from the connector.

- Then we turn the key to "17" and we unscrew the fuel tubes to the side so that they do not interfere with the dismantling of the gas station body.

- With the help of a cape head on "7" we turn the fastening nuts that fix the pressure ring.

- If nuts zakisli, use WD-40 or other similar means.

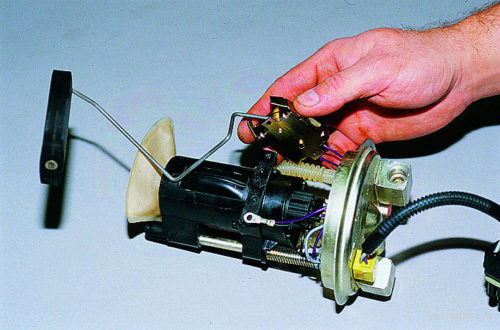

- Removing all attachments and pushing the ring, gently remove the entire node from the gas tank, together with the lever and float.

- The next step is unscrewed using a crust screwdriver two screws that hold the sensor and the release of the electrical connector of the pump.

- Next, we take out the guides from the pump housing (the clamps need to be renewed with a screwdriver).

- On the pump lid, we unscrew the bolts, holding nuts using the key to "5".

- Removing the lid, get access to the sensor.

Repair of the fuel level sensor

As mentioned above, the most frequent cause of failure or incorrect work is found - wear of the contact track of the sensor. In this case, you can move the runner to the working (unsteady) part of the track, a little sparking the runner mount. In addition, check the "mass" swirling under the "handler" for corrosion. Also, the repair may need to be destroyed sensor contacts.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving a car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments