Most of the modern car manufacturers, the usual cable mechanisms are replaced by electric. In this situation, there are many issues related to the principle of its action, the advantages of cable brakes that cause faults and how to eliminate them. These questions are more than relevant.

Content

Principle of the electronic pedal of gas

Models of modernity more and more simplify the life of a person, freeing more time.

Of course, there is nothing bad in this, but the role of man is gradually decreasing, which leads to the delegation of powers and important electronics solutions.

And the pedal having such an origin, confirms the above. This is a minus for those who understand their cars.

For not interested in the structure and operation of the mechanisms, such systems are really useful.

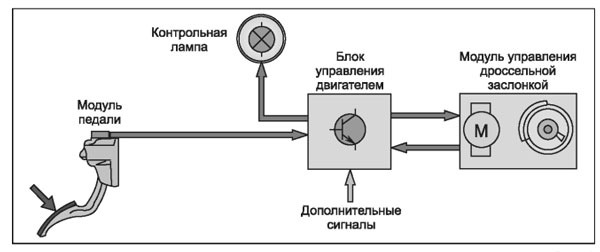

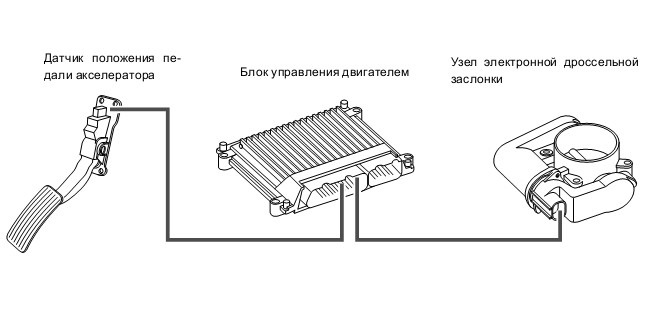

Electronics works on the following principle.

As a result of pressing the gas pedal, information about the angle of inclination by means of electrical signals is transmitted to the operation unit.

The electronic control unit defines the desired opening angle of the throttle.

The opening of the drive is also carried out according to the specified indicators, under the same angle.

If you need to change the angle, the control unit performs this process independently.

In this case, the driver adjustment is completely impossible.

Malfunctions of electronic pedal gas

Basically, all problems are associated with electrical circuits.

The support part of the pedal is equipped with a pair of sensors.

Their task is to transmit signals to change the position of the accelerator.

The panel has an indicator that will signal the system malfunction.

When a single engine turnover sensor is rapidly increasing at low speed. If both devices break, the emergency mode is activated, the engine functions in idle.

As a result, the breakdown is required to replace the pedal, as the sensors are not subject to recovery.

The loss of wiring integrity leads to a collection of throttle.

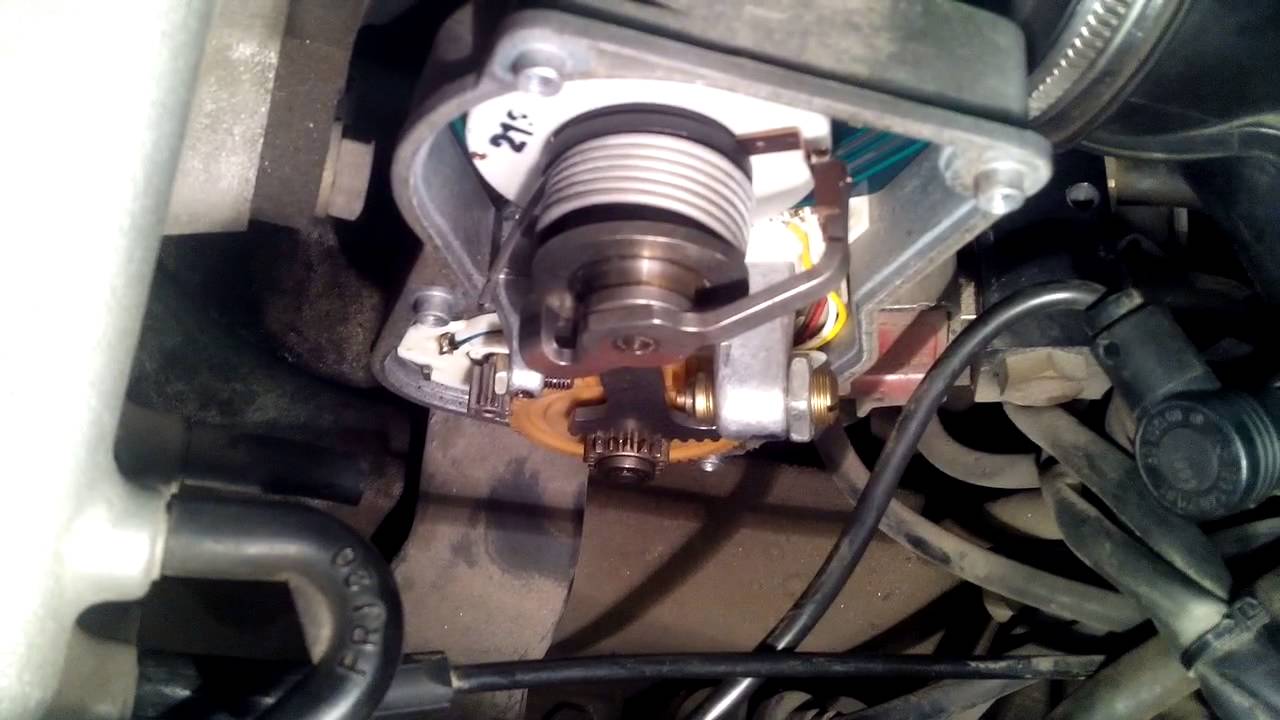

If an electric motor comes into disrepair, the information on the monitor will reflect an error indicating the accident.

These problems are simply solved. The electronic pedal accelerator, when it breaks, is replaced by a new one.

Repair of electronic pedal gas

Often, independent repair implies the replacement of the entire system.

But it is first recommended to determine the grounds, the result of which was a breakdown.

To check the pedal, technical documentation is previously studied. To remove it, you need to turn off the sensors and the block, weaken the fastening nuts and remove them.

Multimeter is needed to determine the indicators.

It is fixed at different conclusions.

In the process, its activity is controlled, i.e. resistance is determined. Normally there is a slow down.

In the situation with jumps, it follows: the detail failed.

If the wiring is damaged, then the repair is fully implemented.

By setting the wire defects associated with its breakdown or loss of insulation integrity, the following measures are carried out.

Removed harness.

For this, the bracket is released by the means of shifting wires.

After that, the process of pulling the cable is passed.

Wires are replaced with new, the location of the connector is displeasted under the pedal. After the damper is restored and the car is ready for operation.

The electronic corrector is applied with the coincidence of the time to use the gas and the engine action.

Simply put, the action takes place later.

The so-called spur, allows you to maximize the lapse of the opening and pressing the damper.

This sensor conducts signal processing, followed by their conversion.

If the experience of independent work does not allow repair independently, you can always use the services of maintenance stations.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments