The output of the clutch is one of the most annoying vehicle breakdowns. With such a problem, you need or catch a fellow way to tow the car, or call the tow truck if the vehicle is equipped with an automatic transmission.

Very few motorists know that the improper clutch work is usually caused by the fact that the air is inserted into the hydraulic part. To revitalize the vehicle, you should perform a fairly simple and fast procedure - to pump the clutch, which we will talk about now.

Content

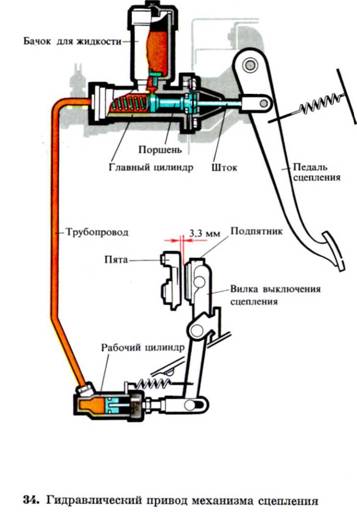

Device and appointment of clutch hydraulic

It is no secret that almost all cars have a hydraulic clutch drive, that is, the brake fluid acts as a brake mechanism. Back from the course of physics, which was studied at school, we know that the liquid is not compressed, because of which it transfers effort from the pedal to the main and working cylinder. However, the situation is radically changing the situation of even an insignificant amount of air.

This is due to the fact that the air is capable of compressing, which means in the clutch system during compression of air, the share of efforts from the pedal evaporates, which leads to incorrect turning on or turning off the transmission. As a rule, the procedure for pumping the clutch is performed by two people.

clutch hydraulic elements

- Return spring.

- Cylinder case.

- Internal sealing cuff.

- Rod (piston).

- Outdoor cuff.

- Rod pusher.

- Protective case.

- Bypass fitting.

- Tank.

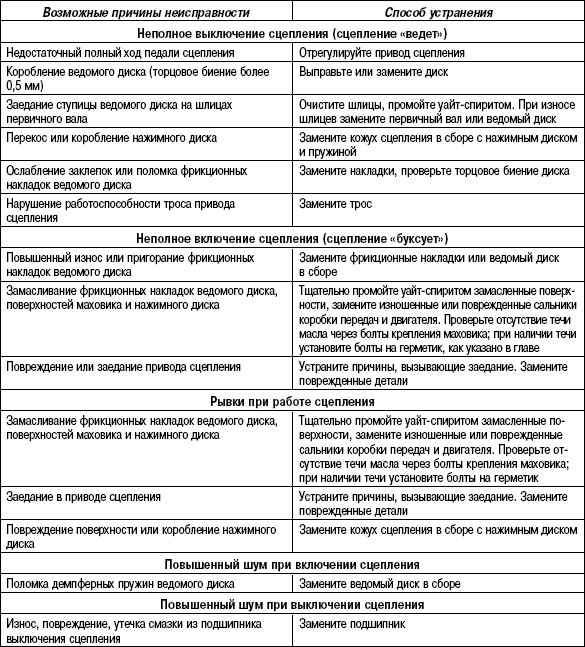

Possible clutch hydraulic malfunctions

In the hydraulic drive may be such malfunctions:

- The failure of the working cylinder is a crawling cuff.

- Violation of the system tightness - the presence in the air system or the leakage of the working fluid.

- Floating hydraulic drive.

The breakdown and wear of the constructive components of the clutch occurs, as a rule, as a result of the violation of the rules of operation of the vehicle - a foot on the adhesion when driving or sharp touching. One of the causes of breakdown or wear can be the deadline for the operation of the clutch components.

The reason for the release of the clutch may also be the low quality components. While buying spare items, it is advisable to prefer original spare parts.

In addition, the clutch malfunction is easy to diagnose by external symptoms. However, any particular feature may indicate several clutch faults. Therefore, the specific coupling breakdown is usually set when it is disassembered.

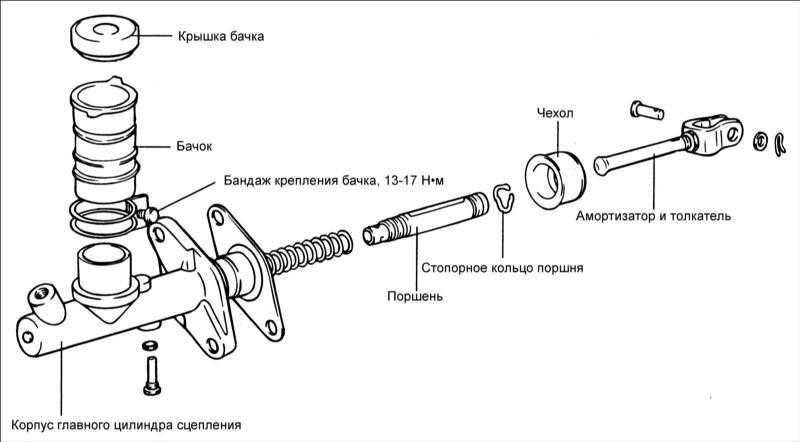

chief Cylinder Clutch, Fault

- If the clutch is significantly reduced in the clutch tank, it means somewhere a brake fluid leakage occurs (in the connecting tubes of worn cuffs or by malfunction of the main cylinder piston).

- If you have detected a leakage at visual inspection.

- If, when pressed to the pedal, periodic failures occur, which signals the presence of air in the clutch drive.

- If during the shift of the gear you hear the characteristic sound in the box, which resembles a crunch. The reason for this is either a breakdown of the spring of the main cylinder, or the failure of the piston.

In the presence of the signs described above, you should not delay, you need to more carefully check all the elements that are responsible for the work of the clutch hydraulic plant.

working cylinder

The malfunction of the working cylinder indicates such symptoms:

- A visual decrease in the level of the brake fluid, which indicates a leakage, the causes of which is the wear of the working cylinder cuff or impaired the wholeness of the hose, which will be well noticeable on the spots under the vehicle.

- Periodic failures of the pedal or too soft stroke, which signals the air in the system.

- If the clutch pedal is lowered and there are problems with gear shift, and the pedal height setting does not result in the result, it means the spring is broken in the operating cylinder and it is necessary to replace it.

Pumping clutch

If briefly get acquainted with the algorithm of clutch pumping, then it happens as follows:

- Preparation of a system for work.

- Connect to the jubular hose fitting.

- Pressing the clutch and drain of the liquid to the full air outlet.

For pumping hydraulic clutch, you will need such tools:

- Tool for fixing the clutch pedal.

- Canister for draining brake fluid.

- Rubber hose, which we will connect to the drain fitter.

- New brake fluid.

- Standard tool kit.

Before pumping the clutch, it should be adjusted, because it is impossible to effectively pump the clutch system if the piston pusher does not move freely. In this situation, the air will not work.

replacing clutch fluid

To begin with, a liquid should be added to the cylinder tank. Its level should not be below two centimeters from the highest edge. At the same time, it is necessary to try that the garbage does not get into the system, different foreign impurities and so on.

Remove the rubber cap in the upper body of the case, after which they put the hose. Through it, the system will pass the brake fluid. About two hundred milliliters of brake fluid is poured into the container.

clutch pumping fitting

Open the bandwidth and click several times on the clutch pedal.

Watch out for air bubbles, it is now that the entire system is cleaned. In addition, make sure that the level of brake fluid does not fall below three centimeters from the edge. After the pedal is lowered as much as possible, it is necessary to finish the bypass valve until the end. The process is made several times.

Now remove the rubber hose from the fitting and wear a safety cap. Next, pour fluid into the tank.

Tips for the experienced motorist

At the end of the procedure, the clutch pedal should work normally, there should also be problems with pistons. It is extremely important, since in some cases the swelling of various rubber elements can occur, which is very dangerous, because it leads to the failure of the entire system.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving a car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments