The brake system in the automotive transport is the most important body, resulting in any, even minimal manifestations of its incorrect work, such as whistle, squeak, creak and others, should be diagnosed in a timely manner and eliminated. What these sounds indicate and how to eliminate the brake creaking - read further in the article.

Content

- New brake pads, reasons for screenshots

- Creak brake pads after some exploitation, why they squeezed

- Creak brake pads due to vibration, reasons for vibration, how to eliminate

- Lubrication for brakes, what a lubricant is needed and how to use it

- Vibration and creaking brake pads due to poor-quality assembly, to pay attention when attaching wheels, in which the danger

- Brake discs are warm, the consequences of the operation of the car with a faulty brake system

- How to check discs when buying, to pay attention, the minimum tolerance for the deviation of the disk thickness over the surface

- Tips Pros: how to save life to the driver and car

New brake pads, reasons for screenshots

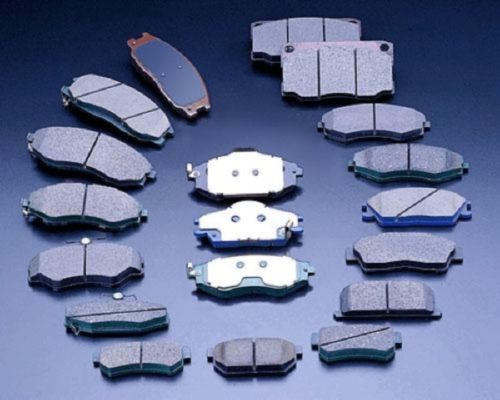

Skipping pads is the result of its oscillations in the process of friction on the brake disc, which is the main resonator. Many different factors affect this process. To eliminate noise, the pipe manufacturers use special anti-graded plates, but they are mounted only on "conveyor shoes" - for the purpose of saving for sale in the secondary market they are not installed.

The most common cause of the screenshot is poor-quality material pads. Any friction pad pad is a polymer composition of the mass of elements. Cheap Product Manufacturers save and use an inexpensive composition for creating pads. However, not all creaking pads are bad. Another possible cause of their violin is incompatibility with brake discs. Therefore, it is necessary to buy brake pads and disks of one manufacturer.

If new, only installed brake pads, most likely, they need some time to work. Wait a little, perhaps unpleasant noise will pass. And this happens because the top on the block is a special layer with an admixture that causes the opposite sound. Over time, he must disappear (with full abrasion of this layer). To quickly get rid of the screenshot, make some intense braking.

If after a certain run of the pads continue to whistle and creak, you need to replace them. Also, the creak in the brakes appears as a result of their pollution or ingress of water. In this case, it is necessary or clean the pads, or wait for a while.

Creak brake pads after some exploitation, why they squeezed

Any brake pads are equipped with a special wear indicator (t. N. "Piskuna"), which looks like a metal plate. With a strong wear of the pad, this plate is in contact with the brake disc, which is why creak or screech occurs. This signals the urgent replacement of the brake pads.

This creak can also manifest itself on new pads, which occurs as a result of poor-quality fastening of the plate, which is why it is prematurely in contact with the disk and makes an unpleasant sound.

In addition, the brakes are able to creak from the heat. This creak is not strong, but, nevertheless, it is present. With intensive movement around the city, alternating overclocking and braking, even the original pads can creak a little. This occurs in cars, on which ventilated brake discs are not mounted. Consequently, the pads are rarely and published creak, but it is insignificant and quickly eliminated when the pad is cooled.

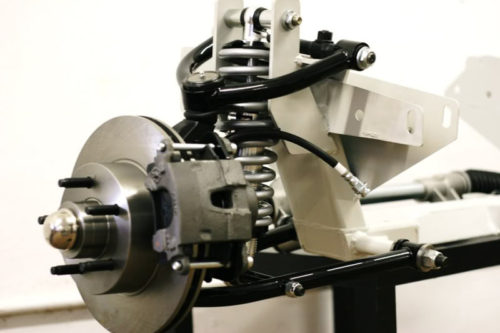

In the process of replacing the pads, it is recommended to lubricate guide calipers using a special lubricant, since it is another cause of the brake screen.

The occurrence of a violep undoubtedly causes unpleasant sensations, but does not affect the efficiency of braking. If you are confident that the creak is caused by non-brake pads, inspect and clean the brake system using special means. It is possible that assembly-disassembly, as well as the lubricant of all moving elements will help get rid of the screens.

Creak brake pads due to vibration, reasons for vibration, how to eliminate

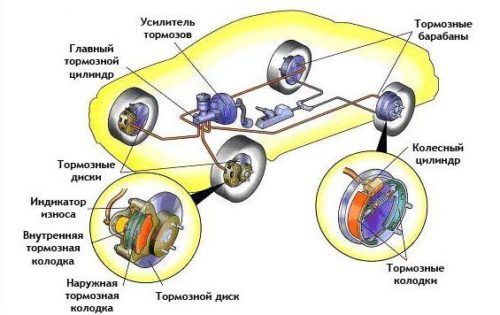

Auto-oscillation proceeds not from brake caliper or disc, but from brake pads. Although the vibration is formed all the elements of the brake system, discs and the caliper are fixed very hard, resulting in absorption of vibration, however, the pad and then remains in low-amplitude movement, so the driver and hears this braking creaking and squeak. In this case, you should not blame all the pads in all, it is necessary to distribute the entire system and detect the cause of the data of the oscillations. Actually, there are several such reasons:

- Low-quality brake pads. That is, for overlapping, the lining took a bad adhesive mixture, the lining are inhomogeneous in composition and so on.

- The piston is not entirely correctly moving in the caliper mine, as a result of which ambiguities appear in the brakes.

- Guides "dry" caliper, which is why brakes are slightly twisted.

- The brake discs simply wear out, as a result of which the "bin" was formed along the outer disk diameter.

Solve problems due to which brake pads vibrate is quite simple:

- We remove the discharge on the disk using its groove, but only when the thickness of the repair layer makes it possible to perform such work. Either you will have to replace the brake discs, because when installing even the most fashionable and steep brake pads, the crop and creak will not pass in any case.

- Before installing new pads, check the caliper for the presence of problems, in particular, check the operation of the guides and pistons. Guides compulsory lubricate with a special material that reduces friction.

- In addition, before installing new brake pads, they should smear their ends, as well as the rear wall of the lining with the help of a special anti-graded paste. Naturally, it is forbidden to touch the working surface of the shoe.

Lubrication for brakes, what a lubricant is needed and how to use it

There are two varieties of brake lubricants - ceramic and heat-resistant.

Ceramic lubricants for calipers are distinguished by containing microscopic ceramic particles in their composition, with which high brake efficiency in different conditions are ensured. If you correctly pick up the brake fluid, it is possible to avoid not only zaking and jamming the components of the caliper, but also to completely eliminate any crushing or screech. Elements will be most securely protected from the dangerous effect of dirt, dust and moisture, as well as all sorts of temperature drops.

In addition, ceramic pastes are distinguished by high corrosion resistance and are not crowded from the deposits throughout the service life. Perfectly combined in fact with any pad materials. The paste is not applied to the surface of the pad or disk. It is used to lubricate disk brake caliper elements. Good selection - ceramic lubricants from Liqui Moly, Permatex, Presto, Bardahl.

The use of heat-resistant pastes - anti-slip plates, surface pads and brackets. An excellent choice for most models is a high-temperature paste for brakes Liqui Moly and Molykote CU-7439 Plus. These past types have proven themselves with quite high pressure and temperatures, as well as in places where rust is expected.

When choosing a brake paste, it should be noted that it must necessarily meet the following requirements:

- Resistance to various chemical impacts.

- Water resistance.

- Good thermal resistance.

- Compatibility with plastic.

- Under conditions of high temperatures should not manifest itself. "Capple effect".

Vibration and creaking brake pads due to poor-quality assembly, to pay attention when attaching wheels, in which the danger

Due to the jacket of friction material or incorrect assembly, defects may occur on the working surface of the disc, which, in turn, entails the creak and vibration. To resolve the problem, you should soak the surface of the disk or carry out measures to ensure the flatness of the brake disc, for which we dismantle the disk, carefully clean the surface of the hub from contamination and rust, and then re-install the brake disc. On the peripheral part of the disc, we check the beyon with the micrometer, which is fixed on the magnetic base. If the value of the beating exceeds 0.1 mm, try reinstalling the brake disc, turning it to 180 or 90 degrees relative to the hub if it allows you to make the configuration of the holes. If the problem remains, change the brake disc.

Not rare car owners make mistakes with independent installation pads, which are intended for a specific side, and also incorrectly place anti-shifted devices (lining), which can lead to not only creak, but also other, more serious problems. Therefore, when installing the brake pads to this should pay special attention.

Brake discs are warm, the consequences of the operation of the car with a faulty brake system

Naturally, the main reason that brake discs are braking - braking, which is carried out by interacting the brake disc with the block. It is at the moment that the disk is heated. It is worth noting that it occurs instantly, but it does not have time to cool the brake disc, especially if we talk about ride in urban mode.

The second, no less important cause of the heating of the discs - driving style. Each driver is individual and, probably, it is not necessary to explain that with an aggressive manner of driving in urban conditions, that is, extreme braking and sharp acceleration, brake discs will be heated continuously.

And finally, there are a malfunction of the brake system. More precisely its individual parts or nodes. Consider them in more detail:

- Non-quality brake pads (lining).

- The thickness of the brake pads and the thickness of the brake disc is less than the minimum-dimensional manufacturer.

- Breeding brake disc.

- The use of a mixed brake mechanism system. Rear brakes - drum, front brakes - disk. This is a weighty cause of heating the front brake discs, since the main load during braking falls on the front axle.

Permanent intense heating pads and disks are able to entail a change in the properties of the material from which they are made. At the same time, a malignant film is formed between brake discs and pads, which has the ability to significantly reduce the coefficient of friction of the brake pads about the surface of the disk. As a result, the efficiency of the entire brake system is significantly reduced. And even if the driver somehow adapts to weakened braking, solve the problem with boiling brake fluid in any case, it will not be possible.

This may entail a breakdown of the entire braking system. In most cases, strong overheating leads to a breakdown of brake caliper and pads. If brake discs are warm after replacing the pads, it is possible that corrosion near the brake cylinder gum is a source of subflinking.

How to check discs when buying, to pay attention, the minimum tolerance for the deviation of the disk thickness over the surface

When purchasing a used brake disc, first of all, it should be checked using a dial thickness in several places. Why? Yes, because there is a phenomenon as an uneven disk wear, which occurs for various reasons. Also draw a visual inspection of the brake disc for deep scratches, colors and other mechanical damage to the working surface of the disk.

If you buy new brake discs, pay attention to their value. As you know, the better quality product, the more expensive it is. It is better to give preference to famous brands, since large companies take care of their reputation and, as a rule, offer customers only high-quality products.

The admission to the deviation of the disk thickness over the entire working surface is 0.0035 millimeters. If you found the non-uniformity of the brake disc thickness outside the tolerance, it is necessary to replace it, including the pair brake disc on the axis. If the disk thickness has changed within the tolerance, try to eliminate the problem of re-acquisition.

However, if the repetition does not lead to success, the disc can be soaked using a special device. But, at the same time, make sure that the residual thickness of the brake disk makes it possible to do this, and the battery of the hub part of the mounted disk does not exceed 0.05 millimeters. Now the friction surface must be smoothed, ensuring the required roughness - 3.2. Well, it is advisable to replace the pads. If the disc cannot be soaked, it will have to be changed.

Tips Pros: how to save life to the driver and car

First of all, it is necessary to diagnose, repair and change the elements of the brake system. Do not forget that the brakes are one of the most important knots of the car and even insignificant problems at first glance are capable of leading to fatal consequences. Wrap discs from artificial deformation. In hot time it is forbidden to wash the vehicle immediately after movement. It is necessary to give brake discs to cool, otherwise your own actions you will threaten the part of the brake mechanism.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments