One of the key components of the car suspension car is a ball support - a product that is responsible for fastening the levers to the wheel hub. Due to this, the components are securely connected to each other without losing mobility in the desired plane. However, over time, the product is able to wear out and require replacement. About this further in the article.

Content

- Ball support, device and principle

- Ball support faulty, fault signs

- Causes of failure

- How to check the condition of the ball support

- Rules for buying a new ball support, to pay attention to

- Tools, fixtures, consumables

- How to remove the ball vaz 2110 if there is no puller

- Dismantling ball support step by step

- Revision shot of a ball support

- Installing a new ball support (step by step)

- Council Pro: What lubricant is better to use

Ball support, device and principle

When driving, the drive wheels of the vehicle perform two functions. The first - ensure the movement of the car along the road. The second - make it possible to make maneuvers, that is, turn to the left or right. To ensure ride and maneuvering to the wheel position relative to the road, a number of requirements are presented: the wheels must be securely attached, easy to operate, stand smoothly and roll back or forward. Compliance with these conditions provides suspension where the ball support takes an important place.

The ball support device is sufficient. This includes the following structural elements:

- Metal rod either "finger", on the one hand there is a spherical tip, and on the other - thread.

- Bellow - an elastic rubber element that makes the work of the rod hermetic.

- Purpose washer fixing the polymer liner.

- The polymer liner, which, as a rule, consists of two parts - the upper (stop) and the bottom (cup).

- The cylindrical body from the metal, on the one hand there is a wide opening, and on the other - narrow.

- Rolling Clad of washers is the bottom of the ball support.

Ball support faulty, fault signs

About the malfunction of the ballproof testify the following signs:

- Tires wear unevenly.

- When moving in direct front wheels wicked.

- When turning the steering wheel, you have to make great efforts.

- When turning in the front of the car, the creaking is heard.

- Even with a slow movement along the uneven road, the wheels begin to pound suspiciously.

Causes of failure

During the operation of the car, the ball support is subjected to large loads. Especially quickly support will wear out with a long movement on uneven surfaces. The most common breakdown is the wear of contacting elements. During operation, the gap between the body and the finger is constantly expanding. The finger in good condition should simply rotate, and when wear, it moves from the side to the side. If you do not solve the problem, after a while, the ball support may simply fall out of the housing, it will stop holding the wheels and the vehicle will fall on the asphalt bottom.

How to check the condition of the ball support

The easiest way to detect a malfunction is to appeal to the car service. If you do not have such an opportunity, you can conduct diagnostics yourself. This requires a source of intensive lighting, as well as a lift or observation pit.

- Swing the car and listen. Determine where the knock comes from. If the sound comes from the wheels, then the supports are very worn.

- Hall the brake pedal until you stop - you can avoid the bearing backup. Swing the wheel with my hands, taking it behind the lower and upper points. The presence of a backlash indicates the appearance of a gap between the case and support, which means it is necessary to change the product.

- In VAZ cars, the test is performed by means of a control opening located in the lower support. To diagnose, you will need a depthine meter or a caliper, which you need to measure the distance between the end of the support finger and the outer part of the case. The indicator should not be more than 11.8 millimeters. This method works only if you have not previously performed the replacement of the ball support.

- To check the back of the top product, you will need a hopmetometer with an indicator. The normal indicator is not more than 0.8 millimeters.

- Diagnostics can also be carried out without tools, but you will need an assistant. It is necessary to place the palm on the body of the ball support, while touching the finger and the housing. Assistant at this time should rock the wheel. If there is a backlash, you will feel it.

Rules for buying a new ball support, to pay attention to

There are two varieties of these products: with metal-ceramic bearings and fuel. For car VAZ with front-wheel drive, fastening options are better suited, since they withstand heavy compression loads. As for metal-ceramic products, they are mounted on the rear wheels and are high-strength on stretching.

The most common manufacturers of supports for VAZ are: "Belmag", "Track", "Cedar", "behind the wheel". Trust deserve: Fenox, Moog, Hi-Drive, Hola and some other manufacturers.

Tools, fixtures, consumables

How to remove the ball vaz 2110 if there is no puller

During the operation of the machine, the supports of the support are affected by corrosion, high temperatures and friction. As a result, the composite parts are tightly dragged to each other. Especially often this happens to the nest and cone. Previously, the problem was solved simply - gas torch and sledgehammer. However, it is not recommended to use such a way, because you can damage steering thrust. In order to avoid problems, it is recommended to apply a special puller ball support.

Dismantling ball support step by step

- Raise the jack of the front of the car.

- Remove the wheel followed by the desired ball support.

- Apply penetrating lubrication on bolts and fastening nuts.

- Using the key to "19", unscrew the bottom fastening nut of the finger.

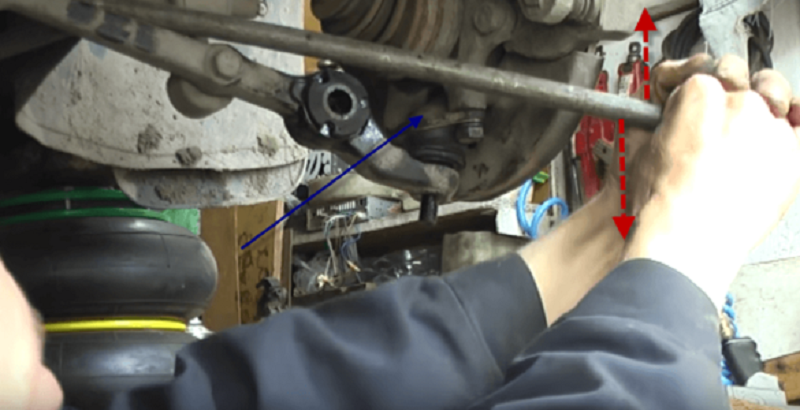

- Install the puller and squeeze the ball finger.

- Remove the two bolts that fix the ball support. One of them is located in front, and the other - on the reverse side.

- Press the lever and remove the support.

Revision shot of a ball support

- We carry out the last check of the ball support, shaking the ball itself in the clip. The greatest backlash should be no more than 0.7 millimeters.

- If your finger is free to dangle freely - uniquely replaced.

- If the support is in order, but there are visible defects on the grease cover, the lubricant should be replaced, as well as the case itself. If you get inside the support of dirt or water, it is advisable to completely replace the element.

Installing a new ball support (step by step)

- Install the expansion sleeve.

- Half will score a new cap.

- Treat sealant Place planting cap on support.

- Collect everything in reverse sequence.

- Do not forget to perform a control tightening of threaded connections on a loaded car.

Council Pro: What lubricant is better to use

The modern market offers many different lubricants for ball supports. The most common among car owners: Litol-24, Slsus-4, SRB-4.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments