The idling sensor in the car is responsible for stabilizing the rotor of the motor at idle. A question may appear why this device is important, it is possible to do without it, how to diagnose the problem, and what to do in the event of a malfunction. The bottom line is that the regulator breakdown affects the operation of the motor as a whole. To understand why you need to constantly monitor its correct adjustment, we will analyze the features of the engine.

Content

- Idling regulator, what role plays in stable engine operation

- Engine operation mode on low revs

- What problems and difficulties arise at low revs

- Signs of idle regulator fault

- Causes of possible malfunctions of the idle regulator

- Methods for detecting faults

- Safety technique

- Tools, fixtures, consumables

- Dismantling of a faulty idling regulator (step by step)

- Installation of a new idle regulator

- Tips Pros: Features of mounting and adjusting the idle regulator

Idling regulator, what role plays in stable engine operation

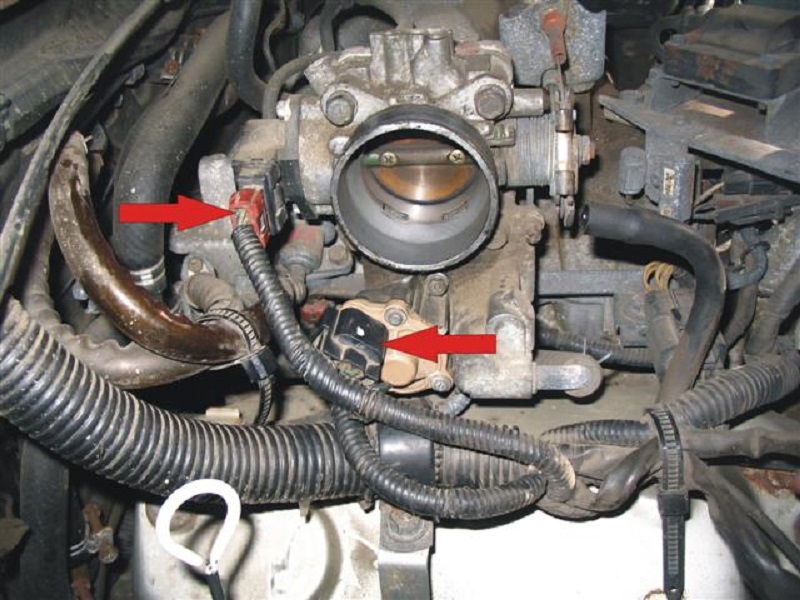

For stable operation of the power unit, there is a strictly dosed combination of air and fuel, otherwise "burning" will not occur, and even if it is, it is incorrect. So this regulator is responsible for the supply of air under idling conditions, bypassing the throttle, which begins to open only when the gas pedal is pressed.

In principle, this stepper electric motor equipped with a conical needle with a spring performs the adjustment of the amount of air to a smaller or most side. It works along with DMRV and depending on the receipt of the required data regulates the process.

Engine operation mode on low revs

No matter how strange it sounded, however, for the motor, the most "tedious" and heavy is the mode of operation on low revs. This happens for several reasons:

- Fuel is cold and power units you need to warm up for normal functioning.

- The pressure difference between intake and exhaust manifiers entails throwing the combustion products back to cylinders. As a result, there is a significant reduction in the "efficiency" of the motor. Details are stronger and faster wear out. In addition, the exhaust increases the percentage of carbon dioxide.

What problems and difficulties arise at low revs

All this is due to the fact that at this stage the air-fuel mixture into the release system is served very slowly. As a result, it is poorly mixed, which reduces its effectiveness.

Quite often, it is possible to hear such an opinion that designers when creating vehicles make such calculations and develops so that the idle sensor worked during the entire period of "life" of the force aggregate. But the realities are such that the regulator fails quite often. As a rule, this is due to malfunctions that are associated with wiring.

To avoid problems and to ensure optimal engine operation at idle, different devices are used, as an option - the mechanical idle regulator is used, which makes it possible to significantly reduce the toxicity of exhaust.

Signs of idle regulator fault

Let's wonder what deviations of the motor work are forced to think. But it must be borne in mind that some of them are characteristic of other problems, for example, poor quality of the fuel used or failure of the throttle sensor. However, there are specific features.

- The revs are unstable (arbitrarily rises or declined). There are "dancing" sounds.

- When you turn off the transfer, the engine completely stalls. This problem is especially noticeable at the traffic light.

- At idle engine runs unstable. This is great: become explicit revolutions. In addition, the vibration of the power unit may appear, which is extremely negatively affecting its work. As a result, the time resource of its service is reduced.

- After starting the engine refuses to function at elevated circulation (you click on the gas pedal, and there is no reaction).

- When some electrical appliances are turned on: air conditioning, stoves, fog headlamps or long-range headlights, there is a decreased engine revolutions.

These problems in the complex appear if the situation is running. Even when one of the listed, you need to take action.

Causes of possible malfunctions of the idle regulator

Regardless of what was the reason for the breakdown, it is not necessary to pull with the diagnosis and replacement, since this type of malfunction significantly affects the operation of the power unit, which is not for nothing that the vehicle is considered the "iron heart" of the vehicle. So, the reasons may be two:

- The wire exploded inside the sensor.

- Eutiles erased.

Methods for detecting faults

When the problems listed above appear, first of all, it is necessary to put the correct "diagnosis", as some deviations of the power unit can also be characterized to break the throttle sensor. That is why the symptoms should be considered comprehensively and cut off the symptoms for this species. At the same time there are two methods that we consider:

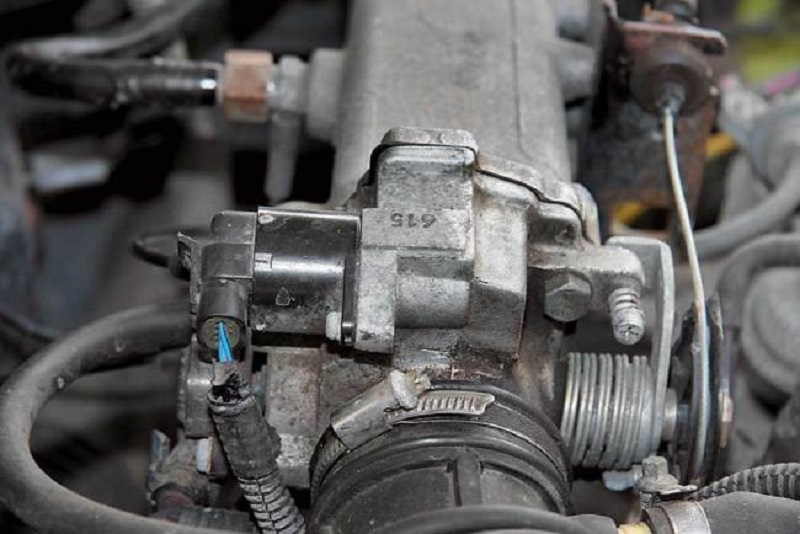

- First option. Here you will need an assistant. It is necessary to dismantle the sensor (how to do it, read below). However, after the removal, connect the four-pin connector again. Next, put a finger at the end of the needle of the regulator, without doing any effort. Then it is necessary that your assistant turns on the ignition. At this time, the regulator must push the needle. If this did not happen, the problem in the idle sensor. If the sensor put forward the needle, it means everything is fine with him. In this case, it is recommended to check the throttle position sensor, since signs of faults are sufficiently similar.

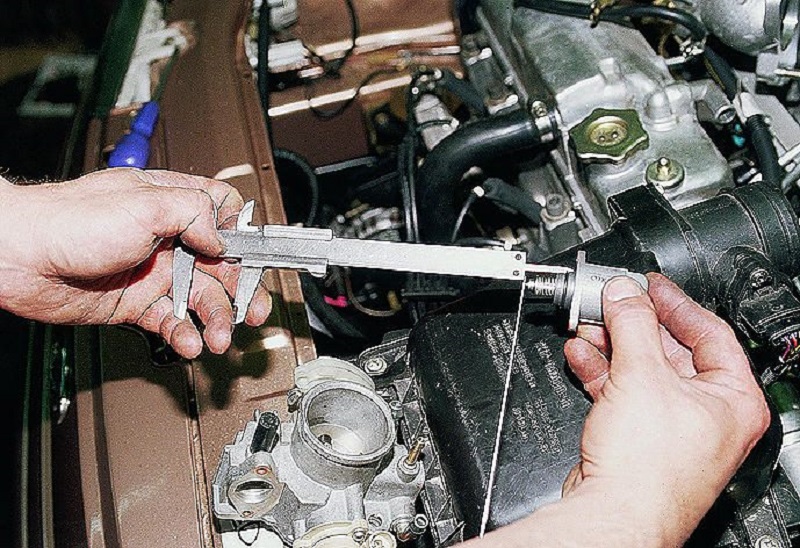

- Second option. We dismantle the sensor and using the multimeter measure the magnitude of the resistance of the regulator windings. Between the contacts A-B and C-D, the indicator should be located in the range of 40-80 ohms. If everything is fine, perform additional cross-dimensions between B-C and A-D. If the device shows an infinity sign (chain rupture), there are no problems with it.

Safety technique

Previously, the idling in carburetor vehicles was done manually, for which special carburetor adjustment screws were provided. This event is complex and demanded certain skills, additional devices still needed: a gas analyzer and a tachometer. However, such cars are becoming increasingly rare on the roads.

Today, the process of replacing the regulator of great difficulties does not represent. However, it is necessary to comply with the correct and most appropriate sequence of work. It is worth noting that all the work can be carried out only on the power off - this is a security requirement.

Tools, fixtures, consumables

- New idle sensor.

- Rag.

- Key to 13.

- Universal crosshead screwdriver.

- WD-40.

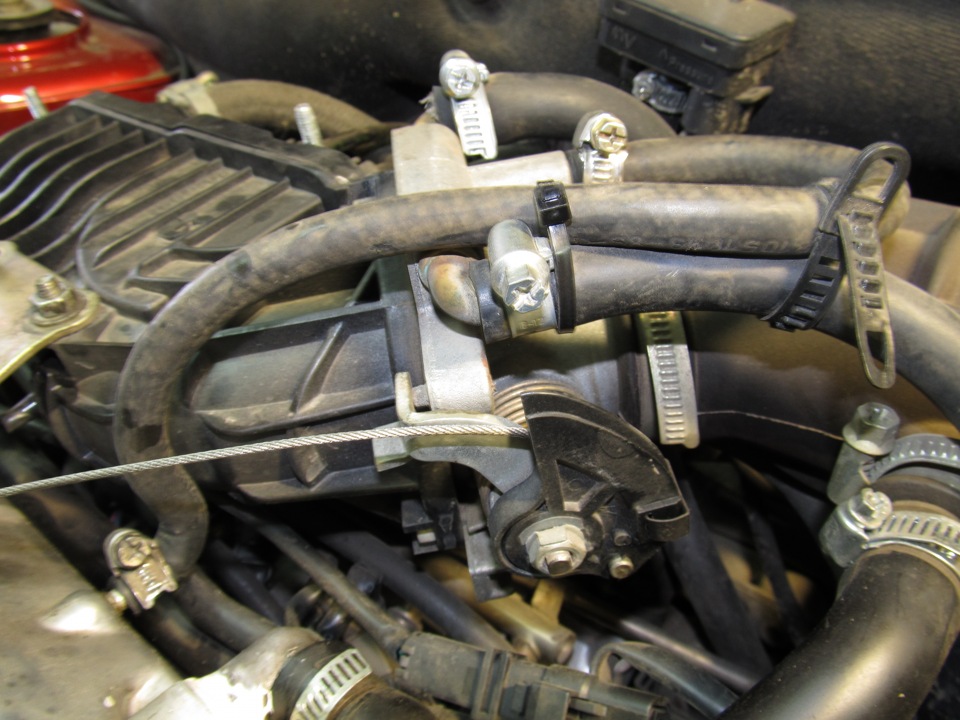

Dismantling of a faulty idling regulator (step by step)

- Remove the terminal from the battery.

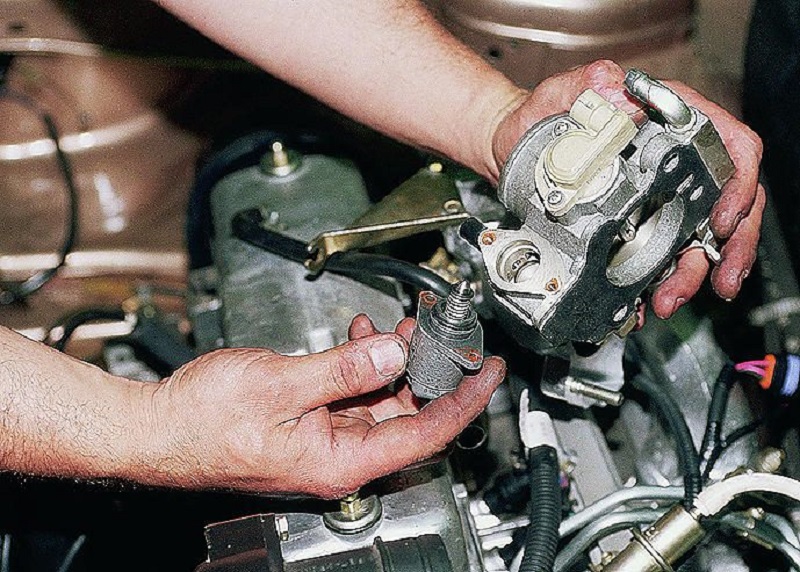

- Disconnect the four-pin sensor connector.

- We unscrew the mounting bolts (2 pieces).

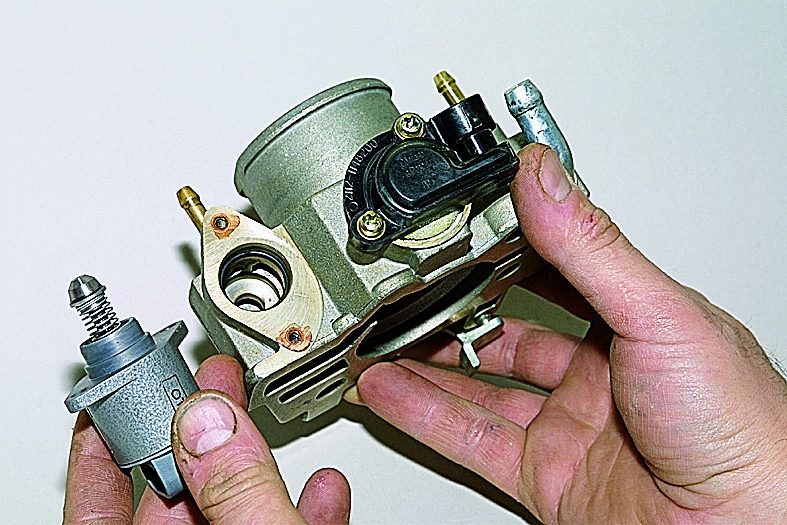

- We dismantle the old idle sensor.

Installation of a new idle regulator

Installing a new regulator is made in the reverse order:

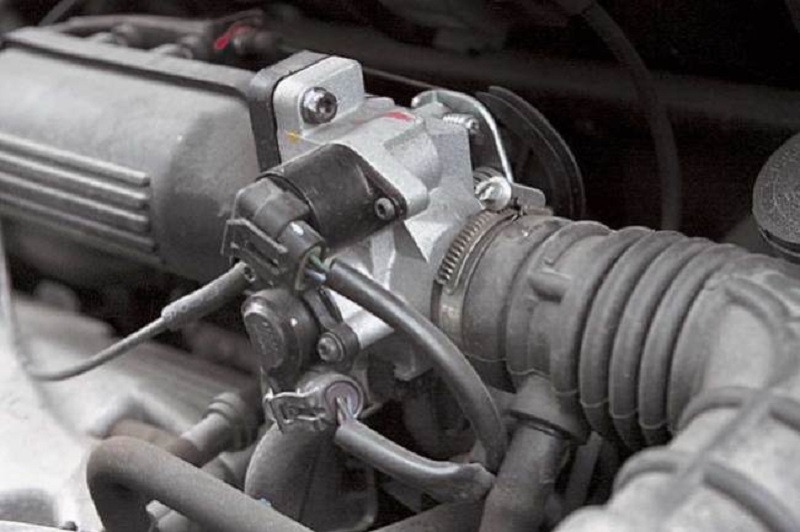

- We put the regulator in place.

- Carefully tighten the bolts. The sensor must be fixed tightly and should not "hang out." Note that the distance between the sensor and the mounting flange should not exceed 23 millimeters.

- Connect the four-pin connector.

- Turn the ignition for ten seconds, but the motor does not need to start. At this time, the electronic control unit performs the calibration of the idle regulator.

- Now you can start the power unit and calmly exploit it.

Tips Pros: Features of mounting and adjusting the idle regulator

It is worth noting that the idling sensor is a one-piece node that cannot be repaired. However, in some cases, its external cleaning will help with a special means of WD-40 or chemistry intended for cleaning the carburetor. In this case, it is necessary after removing the regulator one of the funds proposed above using a cotton stick. It is forbidden to pour its chemistry either to rub much, as this is a high-precision device.

If you have noticed that the engine idling is unstable, with jerks, it is not necessary to hope that everything will be held in itself. You need to carefully study the symptoms of breakage. As you can see, it is not difficult to make the diagnosis and replacement of the idling sensor, and the time does not occupy a lot. But you will provide a power unit proper feeding during the most difficult mode of operation.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments