To date, very few drivers know how to check the ignition coil independently, although this knowledge every day get up more and more urgent. After all, due to incorrect or improper operation of this device on the road may occur undesired and unexpected stops. Timer and the ignition coil are the most important nodes because provide a full and uninterrupted operation of the vehicle. Various defects in the device or its breakage can lead to serious disruptions in operation of the vehicle, but sometimes also to absolute engine stop operation.

Content

- Tools assistants to verify the ignition coil

- Ignition system, how it works

- Faults in the ignition system, what are the causes, how do you know

- The ignition coil device and its

- By operation and ignition coil with a multimeter tramblera

- Electronic ignition principle and dignity

- Electronic Ignition System Diagnosis

Tools assistants to verify the ignition coil

To check the ignition coil, you need to equip a multimeter, which has two operating modes - checks for ohms and volts. In addition, the test can be done the old, but rather a common way. To do this, you must identify the spark between the vehicle body and a candle. However, it is not always safe and can lead to the absolute output of the mechanism of action.

Ignition system, how it works

Well, let's see why the ignition system and where it is located in the car. Timer is at the top of the motor, and it receives a low-voltage current. It passes from the battery via the onboard network and transformed into a high-voltage, when placed on the ignition coil. It is in the timer high-voltage current is discharged to the primary wire which is on the spark plug. This happens with the help of contacts and slider on the device cover.

Further, the candle that screwed into all cylinders of the engine, a spark is supplied to the combustion chamber of the fuel composition, and wherein the produced inflammation. In such a situation, the power and quality of the current very much depends. For example, the inflammation does not happen, if the current is not filed on time, and the ignition coil should be responsible for the optimum strength of the current.

If the coil or the entire ignition system is not working properly or is ineffective, the current will not be properly fed. As a result, the engine starts, will not happen, even though the starter is rapidly rotate the crankshaft. Also, in this case, the muffler can be a smell of gasoline, which indicates a problem with the ignition of the air-fuel composition.

Faults in the ignition system, what are the causes, how do you know

Yield element failure may occur for several reasons, however, the main options are the following motifs:

1.Starenie specific node or all elements of the ignition coil.

2.Povrezhdenie device during ignition of a spark at admission to the desired destination.

3.Takzhe, problems can occur if the installed candles or substandard wiring slaughtered.

Check the ignition coil and diagnose problems can be well-known and quite popular method:

1.Neobhodimo reverse voltage wire and one of the candles.

2. After you need to miss a candle in the wiring, which would analyze the spark.

3.Odnovremenno the preceding paragraph is required to start the engine if the spark between the body and slipped a spark - which means that the device is working properly. If the spark is absent, the coil current and does not need to repair or to replace it.

Ordinary drivers who are not really aware of all the details of the ignition system, the engine and other mechanisms, often used by the method described above. However, not everyone knows that you can not check them every tramblernuyu ignition system. There are vehicles that at such a verification fails even working coil. For example, Honda's 2001 issue.

Furthermore, the engine may stall and for other reasons. Therefore, before testing the coil, it is necessary to pay attention to the wires, which can have breakdowns or spark plugs.

Very often, the 'green' motorists because of their inexperience and forgetfulness, check out the candles on the performance or try to replace the coil, although, in fact, the reason that the vehicle will not start, it may be very simple, such as the lack of fuel in the tank. It is said that to carry out such checks in the field is not highly recommended, it is better to do it in his garage.

The ignition coil device and its

If you carefully checked all the elements that are responsible for the power supply, but the result remained the same, it is necessary to inspect the coil. However, for starters, let's look at the details of what it is. Undoubtedly, each unit consisting of housing, not capable of transmitting current. In this situation, it is made of hard rubber - material which is a good electrical insulator, it consists of high - vulcanized rubber with 50% of the sulfur content, it has excellent color and black to machine.

On top of the coil should be cover, wherein the central terminal is located. Another design is within the core, the central spring terminals, the insulating material, screws and so on. Often, the mechanism can be damaged due to any internal damage anything, but there are situations where current can break into the housing.

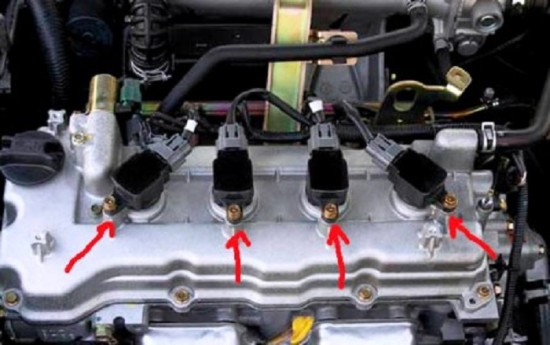

By operation and ignition coil with a multimeter tramblera

For the competent inspection work of this part, unscrew the clamp and detach the connector harness from tramblera. Next, we take the meter and tune it to the voltmeter mode. After that, it is necessary to connect one end to the vehicle body, that is, to the mass, and the other - at the conclusion of the coil. However, it should be twelve volt voltage. If the voltage is not at all, then breaking in the engine control system or the electrical circuit tramblera.

Next to be checked for open coil primary winding. To do this, you must switch the multimeter in ohmmeter mode and put the reel-to-conclusions: first, A - B, then B - C. As in the first and in the second case, it is not necessary that the resistance would have sunk lower than two ohms. However, if this should happen, then there is a break and have to replace the device.

With regard to the secondary winding of the coil, then it must be checked in the same way as the primary. They differ only in that the ohmmeter reading should not be less than five ohms.

In the end, it is required to check the timer on the closure of the two windings. It is necessary again to an ohmmeter connected mode terminal leads in coil A and to one of the high-voltage outputs. The circuit will be opened in case of resistance to infinity.

Electronic ignition principle and dignity

The principle of operation of this system is the rotation of the magnet, in which the number of poles must match the number of the number of cylinders. Upon rotation of the magnet, an alternating current in the coil a special controller.

This type of ignition system is capable of operating at different temperatures - from -40 to +80 degrees Celsius. On this correctly positioning it in the engine compartment. Installation of the ignition coil and the sensor must be done in the field for a conventional (standard) ignition system. It is said that electronic ignition system is much more efficient than conventional, and their service life is much higher.

Electronic Ignition System Diagnosis

To diagnose the ignition system must be checked breaks in the wires, which are located between the switch and the sensor. Scheme electronic ignition system is arranged so that breakage can also be associated with breakage of wires that connect the coil itself with the switch or circuit breaker.

It is said that the smell of burnt coil may, without any checks indicate to you that it is worthless. A electronic ignition system does not need adjustment and securely perform their duties for a long time.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments