Hinge of equal angular velocities (i.e. Solus) is one of the main nodes of the transmission of a passenger vehicle. In the people, it is also referred to as "grenade". It is very important to monitor the state of this item and, if necessary, repair it or replace it, in order to avoid unexpected breakdowns that can be very dangerous. In addition, problems with this node can negatively affect the controllability of the vehicle. About this further in the article.

Content

- What is the Sls where is it, why do you need

- Internal Slusa Device and Purpose

- Internal shrus and external shrus, what is the difference

- Causes of a shrus

- Signs of malfunction of an internal shrus

- Diagnostics of internal shrus faults (detail)

- Lubrication for a shruss, what tasks it should perform

- Types of lubricants for a shrus

- Lubricants that can not be used for a shruss

- Tools, fixtures, consumables

- Choosing a workplace

- Replacing an internal shruss with your own hands

- Tips Prof.

What is the Sls where is it, why do you need

As a rule, shruses are located on the front of the vehicle. Often, they are installed four, two units on the side, but it happens two, one by one to the side, depending on the design of the car. The role that this device performs is the transmission of torque from the gearbox to controlled wheels of the car. It is thanks to this mechanism that turning rotation to the front wheels when turning. Many modern vehicles are equipped with such a node.

Internal Slusa Device and Purpose

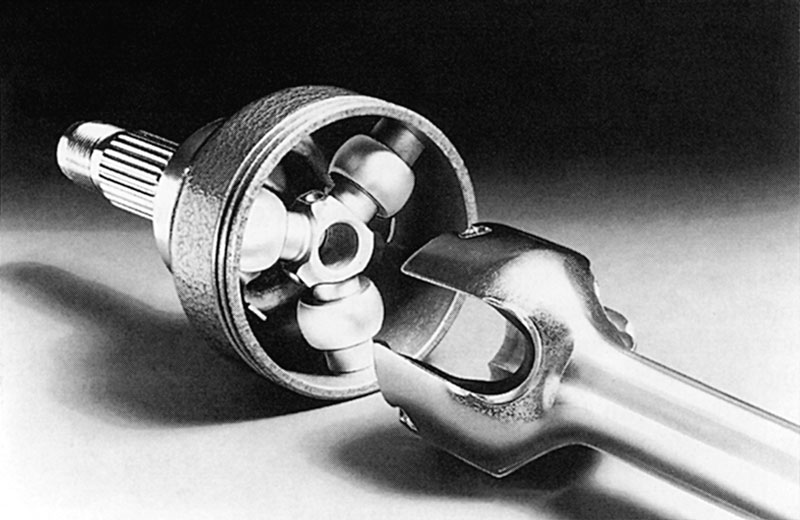

The design of the inner screw, as a rule, includes such components:

- Housing, it looks like a spherical bowl, in which the slave shaft is mounted.

- The inner clip, which is a spherical fist with the leading shaft.

- The separator made in the form of a ring with holes in which the balls are located and hold.

- Metal balls (six pieces).

Internal shrus and external shrus, what is the difference

It turns out that there is little to have a car for the movement one shruh on the wheel. To the drive function, their steam is needed. The inner is called Sls, transmitting rotation from the checkpoint to the shaft. It is much larger in size. As for the external shrus, it rotates the wheel hub and has planting slots for her. As a result of the lack of a sufficient number of free space, it is done smaller in the dimensions.

Causes of a shrus

Sls are made of durable metal, since a large load is assumed to this part. As manufacturers assure, the service life of the shrus is quite large, but in reality it is not always the case. There are several reasons for the accelerated release of "grenades" in order:

- Aggressive driving style.

- Bad roads.

- The abrasive garbage falls into it as a result of damage to the anther.

- Bad lubricant.

- Defective details or fakes.

Signs of malfunction of an internal shrus

The breakdown of the screw can be detected by characteristic features in the work of the node:

- Schedule in Hinge.

- Rods during acceleration.

- Crunch when starting.

- Crunch when turning.

Diagnostics of internal shrus faults (detail)

In order to avoid problems with the survivors when driving a screen, you need to perform diagnostic work in a timely manner. Detection of breakage is performed in this way:

- Remove the wheels and touch the scene. The presence of a characteristic crunch will indicate problems with shurts.

- Raise the wheel with a jack or use the lift. Then inspect the Sls for visible damage. They should not be. After that, move the wheel. The hinge should not have the backlash.

- Post the front of the vehicle. If you have a manual box, turn on the first transmission, and if automatic, select D mode. Then run the motor and listen. Wheels should not make a crunch.

Lubrication for a shruss, what tasks it should perform

Each motorist knows that lubricants that are used in the vehicle nodes are intended not only to reduce friction and prevent premature wear of metal elements. They also have to reduce the load, which falls on the details in order to ensure their free rotation. As for the lubricants for a shrus, then, except for protection against friction, they also reduce transmission losses of the vehicle and fuel costs.

The second, no less important, the lubricant is based on preventing the spread of corrosion. As is known, most of the breakdowns of metal elements becomes the result of a considerable corrosion, which is also called cracking corrosion or pitting. In this case, cavities appear in the shurts, which are called sinks - the effectiveness of the torque transmission is lost and an unpleasant knock occurs, which becomes most noticeable when the steering wheel is rotated. Lubrication is designed to prevent the proliferation of corrosion processes in the shrusses to ensure their durability.

In addition, it is important that lubricants are gentle by synthetic and organic polymers. To protect the Sls, plastic or rubber anthers are always used, which prevent contaminating substances from entering the outside. Lubricants should not dissolve the material from which they are produced.

Types of lubricants for a shrus

Over the years of the existence of all-wheel drive and front-wheel drive cars, many varieties for shruses were created. In fact, they are all capable of effectively cope with friction, as well as lower loads that fall on the transmission elements. But many of them can show aggressive properties in relation to polymer compounds or are not able to fight pitting.

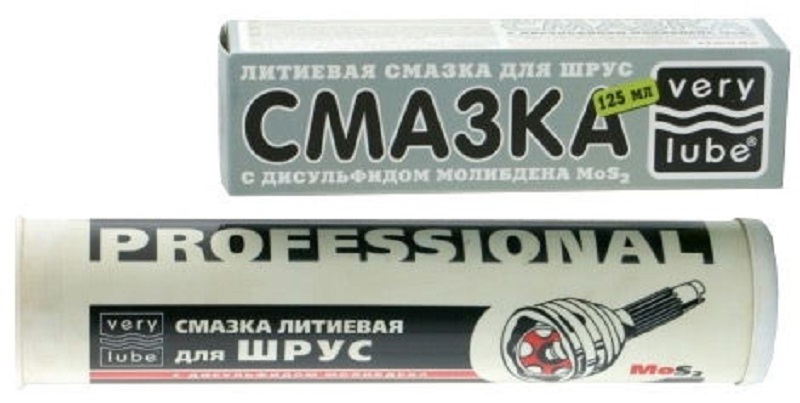

Lithium lubricants

The most common grease for transmission and other elements that are exposed to very high loads. It is made on the basis of foamed lithium solution in organic acid. It is a consistent yellowish composition of high viscosity, becoming even more dense at low temperatures. Lithium compositions are perfectly coping with friction and can reduce the loads per items to the elements of the drive mechanism.

It should also be distinguished by their conservation properties - they protect the metal elements from moisture, neutralize the dust and other pollutants that fell inside. But not all lithium lubricants are able to fight with heavy corrosion of shruses, therefore experts are advised to check the knotting of the drive system after 50-60 thousand km. Run. The exception is Litol-24 lubricant - Russian manufacturers of cars allow its replacement after one hundred thousand kilometers.

Lithium-based compositions are resistant to most of the types of polymer coatings, which are used in the manufacture of shrusov antics. But some vehicle manufacturers are used to create such protective components Modern high-strength plastics on an organic basis - Litol and its analogues can dissolve them. In this case, read the TC instruction manual - it should be said, which lubricants are better to use to protect the scrub.

To date, domestic manufacturers retain world leadership for the release of lithium-based shoes. Most foreign companies refuse them as a result of new technologies that are capable of providing transmission elements with better protection. But the market still meets lubricant for shruses on a lithium-based basis of the following brands:

- Renolit.

- Very Lube.

- Hado.

Lubricants on disulfide - molybdenum basis

Despite the fact that lithium products for shruses are highly efficient, experts searched for a new solution that would be perfect for all cars. The result of this was new lubricants in which the Molybdenum disulfide was added. The main difference between such compositions is high corrosion resistance. According to the reports of specialists who conducted tests, even after one hundred thousand km. The grenade runs do not show symptoms of serious wear. But such a lubricant is not eternal - even under ideal conditions of use, it needs to be changed every one hundred thousand km. Or five years after the initial packing of the node.

These lubricants are also effectively struggling with friction, as well as lithium-based analogues. In addition, the decrease in the content of organic acids replaced by the metal salt, led to a decrease in aggressiveness against any polymer surfaces. Disulfide molybdenum lubricants for shruses can be applied in fact in all vehicles - this recommendation is given by manufacturers.

But such funds have one significant disadvantage - they are afraid of moisture ingress in the conditions of a disruption of the tightness of the anther. The consequence of this non-essential damage may be the absolute loss of lubricant properties, which will cause the destruction of the node. Some of the best are the lubricants of the following manufacturers:

- Shrew-4.

- ESSO.

- Mobil.

- Texaco.

- Liqui Moly.

- BP.

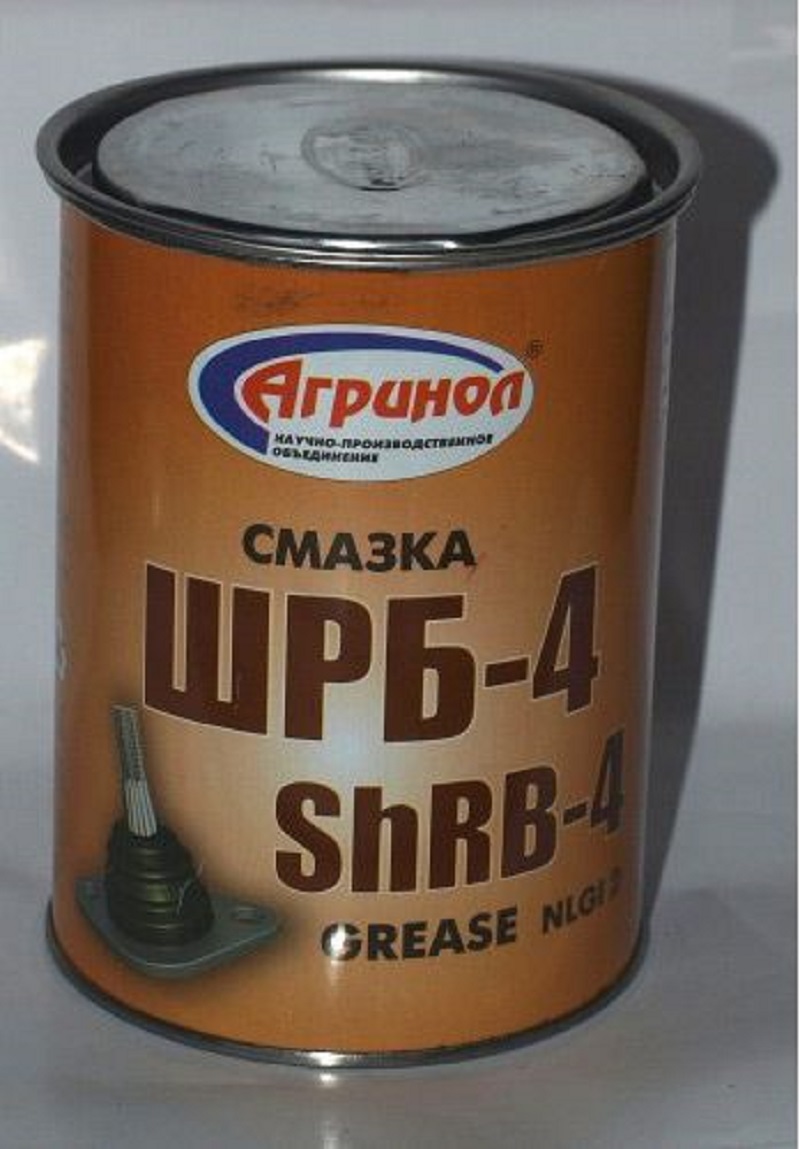

Barium lubricants

The main advantage of barium-based funds is increased resistance to moisture. For example, after breaking the anther, it is not necessary to change the barium lubricant if, of course, it did not accumulate a huge number of polluting materials. In addition, the barium composition can fight all types of corrosion, thereby preventing the premature yield of shruses in order, even during the operation of the vehicle in particularly aggressive conditions. The advantages of barium compositions can also include a neutral chemical composition in relation to any polymers. But such funds are still weakly distributed due to their complexity of manufacture and high cost. Another significant disadvantage is a weak resistance to low temperatures. The only domestic product on a barius basis is the SRB-4.

Lubricants that can not be used for a shruss

Not rare car owners become the victim of various marketing moves of vendor vendors - they claim that their products are a guarantee of the safety and reliability of the car, although in practice there is an absolutely opposite situation. For example, it is not necessary to apply graphite lubricant to protect the shruses, as its purpose is to protect bearings and other electromotor moving connections. Before acquiring graphite lubricant, it is important to understand that it will be no more than 25 thousand km from it. It should be particularly attentive when replacing lubricant in the garage service - it is not rarely practiced by the use of poor-quality or inappropriate materials.

In addition, it is not worth buying hydrocarbons, in particular technical vaseline, although their packaging may contain information about the possibility of processing shruses. The reason for this is based on the conservation nature of such compositions. They strongly withstand the influence of moisture, do not allow for damage to outsiders and corrosion, but begin to collapse after reaching the temperature of 45 degrees. Of course, there will be a much greater temperature in the shurts, which will entail a full washout of lubricant after a few kilometers of driving. The use of technical pumpeline and other hydrocarbons to protect the fuses of technical pumpeline and other hydrocarbon means after a small time interval.

The rapid destruction of the shruses can also contribute to different consistant compilations made on the basis of calcium or sodium. They are used when assembling different parts of cars, including drive cables, moving connections, bearings, but are absolutely not suitable for shruses. The worst consequence of their use is the accelerated distribution of corrosion - after 15-30 thousand km. Shrusi will be unsuitable for operation. Among the lubricants prohibited for use in automotive transmission and containing mineral components are compositions based on zinc and iron.

Tools, fixtures, consumables

To replace the inner scrape, such tools and materials will be required:

- A new internal shrus that includes clamp and lubrication.

- Set of standard tools, in particular jack, mount, pliers, screwdrivers, keys and so on.

Choosing a workplace

Works on the replacement of the inner screw are performed on the observation pit or the lift, which is due to the location of the "grenades" at the bottom of the car (access to the shruss is possible only in this position).

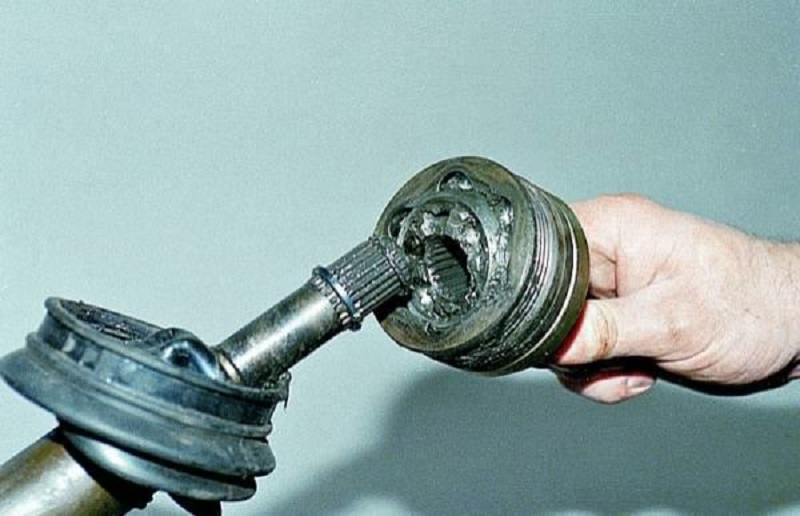

Replacing an internal shruss with your own hands

As an example, a VAZ 2110 car is taken. Procedure for work:

- First of all, it is necessary to fix the car by tightly tightening the parking brake and turn on the fourth transmission.

- Then set the anti-tart wedges for the rear wheels of the vehicle.

- Next, remove the protective cap of the unit and unscrew the nave nut with the help of the mount.

- After removing the hub nut, we start unscrewed the fastening elements of the car wheel.

- With the help of a jack, we hang the wheel on which the need for a screw is replaced.

- We unscrew six bolts, as a result of which the shrus will hold only the flange.

- We unscrew the two bolts of filling the bottom of the fist.

- Turn the steering mechanism to the extreme position, after which the unit will automatically fall.

- Now it remains only to install a new silver.

Tips Prof.

When installing a new scrape, it is important to remember:

- Before installing the unit, provide styling the required amount of lubrication.

- At the end of the shaft you need to install a plastic plug.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments