Corrosion, in prosecudio - rust - the enemy of any metal, and since the car mainly consists of metal, with corrosion it is necessary to fight. In this article. Tell motorists how to make anti-corrosion protection with your own hands.

Content

- Why do you need to make anti-corrosion car protection

- What materials are used with anti-corrosion processing

- Than protect the bottom of the car

- What to protect the arches of the wheels

- What to protect the hidden cavities of the car

- Anticorrosive processing stages

- Making anti-corrosion processing with your own hands

Why do you need to make anti-corrosion car protection

If you want to save your iron friend for a long time in good condition - periodically perform additional anti-corrosion processing.

Manufacturers when assembling a car produce primer and body color, the bottom is covered with mastic, and protective compositions cover hidden cavities.

Responsible manufacturers can establish a warranty period to complete end-to-end body damage.

But all sorts of factory anti-corrosion treatments are capable of maintaining metal only from mechanical damage, it is desirable after purchasing a car to consult in the anti-corrosion center, and if you purchased a used machine - make a complete anti-corrosion processing, and then after a year or two again.

Of course, the entire volume of work depends on the conditions of operation of the machine, from the quality of factory protection, on the quality of the applied anti-corrosion preparations, etc.

And if the accident and replace or repair the body - you need to make a complete anti-corrosion protection of the car to avoid repairs.

What materials are used with anti-corrosion processing

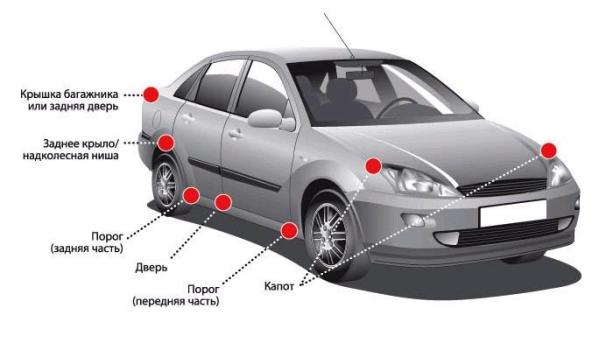

Since the appointment of anti-corrosion materials is to prevent the appearance of rust on metal parts of the body, except for primers, varnish and enamel, it is necessary to use anti-growing coatings of the bottom and body, to preserve hidden cavities, use anti-corrosion processing for the inner surfaces of the wings of the car and the arches of the wheels.

By purchasing anti-corrosion coatings, it is necessary to pay attention to the operation of this material in a wide range of outdoor air temperature, humidity, for resistance to aggressive medium, etc.

When protecting your iron friend from corrosion, it is necessary to pay attention to the welds - they are also reliably and efficiently need to be treated with anti-corrosion protection.

Than protect the bottom of the car

There is a very high impact on the bottom of the car, aggressive reagents, abrasive effects and therefore anti-corrosion protection should create a protective film that should be thick, durable and elastic.

The protection is applied to the purified and pre-primed bottom surface, the composition of anti-corrosion protection often includes fine-dried aluminum powder and necessarily chemical corrosion retarders.

The protection of the bottom can be easily made in the conditions of the garage, in the presence of a viewing pit, you can protect with a simple brush.

The bituminous domestic MASTAST BPM was greater popularity - with a filling of rubber crumbs.

What to protect the arches of the wheels

Since the surface of the arches of the wheels is susceptible to a very strong abrasive wear - the arches of the wheels must be protected with high-quality anti-corrosion material.

Modern manufacturers have adjusted the release of a durable elastic material in the form of a liquid locker.

When applying a liquid locker on the arches of the wheels, a thick layer is created from this material, which is capable of protecting from the flow of wet mud, ice and stones.

You can insert plastic flaps in the arches of the wheels, they are called lockers or shoes.

But the "liquid locker" and plastic sneakers will reliably protect the arches of the wheels.

You can handle the arches of the wheels and the composition for the bottom, but it is necessary to apply it in two layers, also brush.

What to protect the hidden cavities of the car

Thresholds, racks, langers, all sorts of floor amplifiers and trunk lids, are hidden cavities.

And in these cavities can only be accessed through special holes, and sometimes you have to drill these holes themselves.

Since the holes, through which you can protect small, it requires a liquid consistency with corrosion inhibitors.

After applying liquid low-viscosity materials, and they have a high penetrating ability and are able to get into all the slots and joints, a half-having film is formed on the walls of the hidden cavities - it protects the surface from water.

To protect hidden cavities, Movil is widely used, it is produced in aerosol packages.

Anticorrosive processing stages

1. Produce car wash from below with hot water under water pressure to 100thm.

2. Automobile is dried within 15-30 minutes by blowing hot (up to 80 * C0 air.

3. Produce the inspection of the bottom of the car when the wheels shot.

4. Defects.

5. In hidden cavities, in the production of work in anti-corrosion centers,

the method of air spraying is supplied to the material in the mixture with air under pressure to 8thm. The protective dried film must have a thickness of 40 to 60 md.

6.Dine and wheeled arches are processed by airlessly, the dried protective film must have a thickness of 250 to 300 μR.

7.After processing, it is not recommended to use a car during the day, since anti-corrosion protection must be captured.

Making anti-corrosion processing with your own hands

If you have new parts on your car and there are welded seams, the welds are shut off with a sealant for welded seams.

The cheapest sealant is Body 999 - it perfectly sticks to the metal, is able to quickly dry even in the cold and does not miss moisture.

A mastic is applied on the sealant from above.

Thresholds, langers and racks are processed by a preservative Movil.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments