From the time of purchase a brand new car some time has passed. And you already notice that the sun's rays reflected from the windshield does not create such an effect lights. The reason for that is not your negligence - is the result of the impact of the environment and avoid the appearance of negative points can be only one way - by refusing to travel.

This variant is unacceptable for car owners, so it makes sense to consider how to learn how to eliminate scratches on their own - in fact a systematic appeal to the masters of the service center will serve the cause of another expense item in the family budget.

Content

- Scratches on the windshield as they appear

- Classification of the depth of scratches

- How to remove a small scuff on the windshield

- Preparatory work of cleaning the surface

- Materials, appliances, tools

- Abrasive materials such as abrasives to choose, so as not to harm the glass

- How to remove scratches polishing machine, works technology (detail)

- What is important in the polishing work

- The main error in polishing

- How to clean the windshield surface from the remaining abrasive particles

- Tips Pros: it does not hurt

Scratches on the windshield as they appear

Are subject to aging effects, even the most solid metal parts that really there to talk about the car windows. Moreover, it windshield while driving meets rushing towards the air that contains dust, small and large grains, these impurities act as abrasive element.

Falling under the brush avtodvornikov particles of dust and sand also cause scratches across his path. Many surfaces can cause harm himself motorist: when rubbed dry dusty glass cloth having microscopic scratches, surface acquires haze.

Do not pay attention to the changes impossible. Scratches - this is not a cosmetic defect that affects the aesthetic appearance of the vehicle.

An increase in their number with time will cause problems with travel in the dark - defects give rise to glare, the road pattern is distorted, it leads to an increase in the driver's eye fatigue.

Create problems entering the windshield stones that emerge from under the wheels of other cars. In such cases, there is an option scratching and chipping, remove them on their own problematic.

Classification of the depth of scratches

Depending on the severity of the defects they are separated by type.

minor scratches

This category includes subtle scratches. They are difficult to see with the naked eye, but in bright light they reflect the sun's rays, thus creating serious problems for the driver.

The appearance of such defects cause:

- dust and sand falling on the surface

- use wipes for cleaning hard

- carelessness when removing snow

This kind of damage to give the glass dimness.

To resolve this problem, we recommend treating the surface with abrasives. Polishing procedure is considered effective if required to remove small defects during operation is permissible to remove a layer, whose thickness does not exceed 1 micron.

medium scratches

The depth of such lesions can be up to 300 microns, to determine a degree of damage very easily - during a fingernail across the surface will be felt for obstructions.

To eliminate the damage of this kind need to be applied as a fine-grain abrasive nazhdachku after treatment need polishing.

Polishing surface makes sense if needed removal of a thin layer within 1 micron.

deep scratches

To this species belong noticeable to the naked eye defects. To eliminate use special photopolymer formulations, they are colorless, designed to fill deep scratches.

If in the process of work is used abrasive materials, then these are coarse-grained pastes. Work is performed manually, the finishing processing is made by a fine-grained polyrolol, or by products that do not contain abrasives.

When grinding uses a large-grained paste, the thickness of the removable layer can reach 200 microns and more.

How to remove small blasting on the windshield

To eliminate small defects, the surface is recommended to be polished. But before proceeding with work, you should carefully prepare.

First, inspect the entire surface, to find and mark all the sections that will need to pay special attention. Experts are not recommended with the same thoroughness to process the entire surface - unique areas should not be polished.

When serious chips, leading to the destruction of the upper protective layer, will be needed to eliminate them. If there is no independent experience of doing this kind of work - it is better to turn to car service masters.

There is a threat that in the process of polishing in such places there may be overheating, and consequently - and cracking at the point of the chip.

Preparatory work on surface cleaning

Preparatory work will be as follows:

- detection and repair of large chips

- studying the surface, detecting and applying labels to the most affected areas

- preparation of tools for work

- buying and preparing polishing mixtures

The preparation process also includes careful cleaning of glass from contamination, using special detergents. Also, after washing, it will be necessary to ensure that there are no abrasive elements on the surface, which can cause re-damage during polishing.

In order to obtain the desired result, it will be necessary to comply with a certain priority of work.

Materials, devices, work tools

Glass processing manually involves using:

- high-quality polyroli capable of eliminating defects, give water-repellent properties and create a protective film on the surface, it can be powder or pasta

- polishing machine or drill

- felt circle for polishing, with a fastening or velcro nozzle

When performing polishing, there is a threat of pollution of the entire body. If you plan to do without car wash, you will need to prepare a film that can be covered by the body.

In the process of the final stage of work, you will need to use:

- cleansing Liquid for Glass

- napkins

- scotch and Marker

- sprayer for water

Tip: The polishing machine can serve or a polishing machine or drill, but in no case Bulgarian.

The optimal number of revolutions supported by a polishing device - from 1200 to 1700 per minute, the high speed of rotation can lead to a negative phenomenon - excessive heat heating.

Abrasive materials, how to choose abrasive materials so as not to harm glass

In order to properly choose abrasive materials, we should not forget that it will initially need to apply a coarse-grained polishing paste for grinding glass, for finishing polishing - fine-grained paste.

If the damage is serious - the grinding will be required, it is produced using the emery circle, this work requires special attention and professional skills. If there are doubts that we successfully handle the task - better contact the masters for help.

Small damage can be removed by polishing by applying special pastes. Mechanical impact on the glass will be minimal. To eliminate the threat of glass damage, it is recommended to stop the choice on fine-grained abrasive.

Consider the 3M 60150 paste for processing silicate glass.

The instructions indicate that the tool is intended for:

- polishing minor scratches

- removal of acid spots and plated

It is made of water based paste, it does not include silicone and ammonium. Cerium oxide is included as an abrasive component. If earlier it was not necessary to use this means, it is desirable to test it on any surface suitable before you begin to polish the automotive glass.

Diamond pastes are no less popular, they are produced with different graininess, in accordance with GOST, are divided into the following types:

- coarse-grained - red

- medium grain - green

- fine-grained - blue

- thin - yellow

- finish - the smallest, white

Diamond pastes are produced in solid and pasty form.

Apply the paste with the help of a felt circle or a napkin from felt tissue, for each type of paste it is recommended to use a new napkin, and the pastes themselves apply in order to reduce graininess.

Poly rates are also used for polishing work, which, depending on the basis of the manufacture, are divided into wax and teflon, they differ in terms of service and resistance to moisture.

The advantages of teflon polyters should be noted, they are slower to wash off, for a long time provide protection against the appearance of scratches.

The best and longer effect is obtained in the case of polishing after pre-grinding glass.

Polyrol is applied with a grinding machine or drill, or manually.

Among the most popular brands:

- Turtle WaxUsing the products of this company is completely easy to maintain the appearance of the car in perfect condition. Turtle Wax polishes are well coped with minor scratches, removing even the slightest traces of damage on the glasses.

- Remove microscopic cracks and scratches will help funds from DOCTOR WAX.Polyrols perfectly remove the residues of the composition used earlier for processing, traces of dust and dirt, the remains of insects. The presence in the compositions of DOCTOR WAX thin abrasives allows for one-time application to get complete cleaning and excellent glass polishing, to provide ideal transparency.

- Products Firm Sonax It has a fairly high cost, refers to professional. The results of its use are distinguished by high quality, it allows to eliminate faded eroded spots, small and medium scratches scratches, eliminates rubbing, significantly increases the transparency of the glasses.

- Moderate cost of polishing from the manufacturer Yacco. It should not give reason to doubt the high quality of polyrollas, they can eliminate small and medium glass damage and give them a high degree of transparency.

- Tools OT Hi-Gear. Cool with minor defects on the surface of the glass, but you cannot recommend them to eliminate serious damage.

For manual polishing, a versatile agent, pasta gays also apply. Its base serve chromium oxide. The paste 4 species is available, the products at number 4 and 3 are designed to remove small scratches and pronounced losses, NO2 and NO1 are designed to impart jewelry.

The processing process of pasta is to apply it to a soft felt napkin and further polishing the glass surface. To improve the result, it is recommended to drop on a napkin a couple of drops of a mixture of gasoline and oil.

How to remove scratches by polishing machine, work technology (detail)

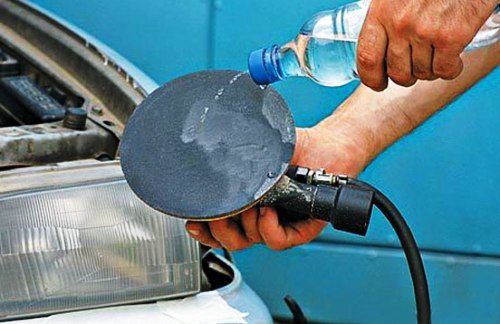

For polishing, you can use or grinding machine or drill. It uses nozzle-circle and velcro for fastening and tool for polishing.

We celebrate the felt-tip pen on the back of the glass of the contours of all problem areas.

Plots of the body that can be contaminated close by film, fix it with a tape. Next, we produce the processing of the wiper.

Then you can apply a paste on a polishing circle, pre-wilted with water, and proceed to applying it to the glass. Recommended speed of rotation - 1200 revolutions per minute. The recommended tool inclination angle is about 5 degrees.

If you feel that the circle began to move harder - sprinkle on the processed section with water from the sprayer. This will lead to the softening of frozen paste and reduce the glass temperature.

Working with a drill should be very careful, too active pressure on it can lead to overheating of glass.

Specialists are recommended to perform polishing on sites, and not to this area of \u200b\u200bglass at once. For example, you can select a plot of 0.4 x 0.4 m and polishing it make sure that you perform the work efficiently.

If the result is satisfactory - continue processing on sites, overlapping the transition lines.

The use of polishing devices allows you to simplify the process and reduce the cost of time, but it should not be forgotten:

- pressure force on the grinding machine should be constant, with an increase in it there is a risk of overheating of glass, with a decrease - vibration can occur, which will have a negative impact on the result of the work

- it is impossible to allow the polishing circle small fractions of foreign substances

- work is performed by uniform circular movements, stop the typewriter on one site.

- the machine must move smoothly, gently, without passing plots

What is the main thing in polishing work

The quality of polishing is determined by several factors that affect the result equally, here:

- careful preparation for work and surface cleaning

- determining the severity of damage

- selection of processing option, i.e. It will take a grinding, or you can do with one polishing

- choosing a polyrolol

- competent treatment of polishing fixtures

It is the last items that are the main - a mistake when choosing an abrasive material and its improper application may damage the glass, a negligent approach - and your actions will turn into the process of applying scratches.

Then it will be possible to correct the situation only by replacing the glass to the new, or a serious restoration of its car service masters. The most important thing is not to harm!

Main mistakes for polishing

Motorists of beginners should not be engaged in experiments and believing recommendations from insufficiently reliable sources. At least for the reason that the correction of harm applied by its own hands will cost considerable money.

It is impractical to save on polishing and use the inappropriate products as it, for example - tooth powder. If it is recommended, then exclusively for treating thick glass headlights. The windshield, which also has a much smaller thickness, a real result that will turn out - an increase in the number of scratches.

If you like the option using the GOA paste, then you should buy only the most subtle types of it, the use of coarse paste will cause the appearance of microhanins that negatively affect the quality of visibility and increase the fatigue of the driver's eye. The maximum allowable layer for removal during polishing is 1 micron thick.

Even subject to the choice of the right fund, it is not recommended with force to pressed on glass, unevenly attached great efforts will lead to the formation of lenses.

When working, you will need to track the heating of the treated surface - high temperatures may cause cracking.

How to clean the surface of the windshield from the remaining abrasive particles

Upon completion of work, it will be necessary with the help of cold water gently remove all residues of abrasive substances. Permanently performed carefully, it is impossible to allow sediment fragments from abrasives to remain on the glasses.

Then you can remove the protective film from the hood. Glass is recommended to wipe in a wet, then a dry napkin, carefully inspect it and evaluate the condition of the restored sections.

When identifying shortcomings - note the place of their location and repeat the polishing procedure.

Tips Pros: how not to harm

Before making an independent removal of scratches, it is advisable to still consult the master and clarify whether your desired effect will give your actions. Perhaps a more rational option will be the complete replacement of glass or appealing for help to professionals.

It is not recommended to grind on your own machine, complex defects can hardly be eliminated, and the lens effect is very simple. It is better to apply polishing.

It is recommended to pre-get the experience of polishing on an unnecessary piece of material suitable on the texture of the material, and only stinging the hand to start working on the windshield of the car.

It should not be independently attempts to correct the defects of moderate severity, or eliminate deep cracks and serious chips - there is a risk of aggravation of the problem.

It is not recommended to save on the purchase of high-quality polyteroli, special napkins are also recommended for work.

Since the car accumulates a certain amount of dust, it is recommended to periodically clean and polish not only the outer, but also the inner side of the glass.

With apparent simplicity, polishing the automotive glass is still a procedure for consideration, requiring accuracy and professional skills

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments