Perform the replacement of the clutch fork (hereinafter the car) of the car is quite rare. But, if this, it would seem, a completely insignificant element fails, the movement of the vehicle is literally paralyzed. After all, the aircraft is one of the important components of the transmission. And if the item is not capable of performing the functions assigned to it, the engine will not transmit torque to the drive wheels and, as a result, the machine will not go. As a result, even such a non-essential breakdown has to be eliminated operational. Fortunately, this can be done without the help of specialists and at home.

Content

Coupling plug VAZ, device, appointment, principle of operation

The main role of the clutch is to ensure short-term disconnection of the transmission and the engine, as well as their subsequent connection after switching transmission. However, in addition to the clutch, another important task is entrusted - to provide smoothness to the transmission elements and protect them from unnecessary loads and oscillations. All clutch components are between the gearbox and the motor.

Nowadays, there are several types of clutch, which arose and modified together with the development of the car industry: electromagnetic, friction and hydraulic. Friction grip, in turn, is one-, two- and multidisci.

Most modern cars are equipped with one-piece clutch, the design of which includes such elements:

- Coupling plug.

- Diaphragm spring.

- Release bearing.

- Clutch clutch.

- Slave disk.

- Lead (push) disk.

- Flywheel.

The principle of operation of this mechanism is:

- When the driver is pressed on the clutch pedal, it acts on the clutch drive, moving the plug of this mechanism.

- Next, the plug has an effect on the release bearing, so that the bearing shifts and affects the petals of the diaphragm spring spring.

- As a result, the petals of the spring bend to the flywheel, and its outer edge departs from the leading disk, giving him freedom. At the same time, the "pressing" of the drive disk occurs at the expense of tangential springs.

- As a result, the transmission of torque stops.

- When the driver releases the clutch pedal, the leading and driven discs are closed again with a diaphragm spring, and the springs contact with the flywheel is set again. The transmission of torque on the checkpoint is restored.

From the described process, the principle of operation of the fork of clutch and other elements becomes quite understandable. This item is playing an important role when you turn off and turn on the clutch between the transmission and the engine, that is, forms free space between the slave and pressure disks. It is necessary to completely disable the transmission from the motor.

If we talk about the manual transmission, then its work is generally impossible without a good clutch plug. Thanks to her:

- Increases car maneuverability when moving at low speeds.

- The TC may remain fixed even with the engine running and without activation of the neutral transmission.

- The multi-line mechanism for switching vehicle speeds is launched.

In addition, without a plug, the clutch cannot work, since this element is a switch and switch. With it, the motorist can control the operation of the motor and provide him with normal operation modes.

Signs of malfunction fork clutch VAZ

If the clutch works unsatisfactitably and poorly responded to pressing the pedal, most likely, one of his mechanisms broke and, most likely, this is a plug. To eliminate such a malfunction, some motorists perform the so-called setting of the free move. Due to this, a normal clutch work is resumed for some time, however, such a procedure, as a rule, is not enough for a long time, and malfunctions in the functioning of the clutch and are further manifested.

If no extraneous sounds comes from clutch, most likely, the culprit of the situation appeared is fork. During intensive operation, a crack may appear on it, which may result in its additional deformation. As a result, the free course of the pedal increases, the transmission is badly included. It happens that the clutch pedal literally falls into the floor, without affecting the clutch drive.

Diagnosis of malfunction

To check whether the malfunctions and interruptions in the clutch were caused by a breakdown of a fork, you need to carefully inspect this mechanism, for what follows:

- Drive cars to the observation pit.

- Next, slide from under the Niza vehicle a protective boot that closes the clutch fork.

- With the help of a flashlight, carefully inspect the plug for cracks. If they are, to see them will be easy. Most often cracks arise on the part of the element where it goes into a flat plane.

But cracks are not the only reason for the exit of the clutch fork. It will not rarely happen due to the presence of a factory marriage, but if the installation of the previous fork you performed yourself, the cause of the fault may be different. Often this is a banal wear, occurring and with all other elements of the vehicle and the clutch mechanism.

When operating a car with a clutch fork, another series of breakdowns may occur:

- This element may simply be broken. It can happen and because of the fact that first the cracks arose on it, which the car owner did not notice and did not replace the item on time. If the plug really broke, the clutch pedal in this case will fall abruptly, and the vehicle will not be able to continue to continue.

- The paws were worn out. With this situation, those drivers, a clutch plug, which have been installed for quite a long time, may be encountered. It is worth noting that due to the paths of the paws and the clutch is shutdown. In addition, they are constantly in contact with other components of this mechanism, so their wear is an absolutely normal phenomenon.

- The plug bent. This rarely occurs, because to get a metal element, it takes a rather large mechanical impact. Most likely, together with the fork, other elements of the clutch were faced, the result of the incorrect functioning of which is the deformation of the part.

- Defect on the legs of the element, located in the place where they are in contact with the coupling. Prevent the manifestation of this actually impossible. Because of this, it is necessary to pay attention to the presence / absence of marriage while buying a fork.

Unfortunately, as a result of the nonsense of the primary symptoms of the clutch plug breakage, it is in fact it impossible to prevent its final failure. Therefore, if during the inspection you really found a crack or other serious fork defects, without replacing this item, it is not necessary to do.

Choosing a workplace

Work on the replacement of the clutch plug must be performed on the overpack or the observation pit, as it takes access to the bottom of the car.

Tools, fixtures, consumables

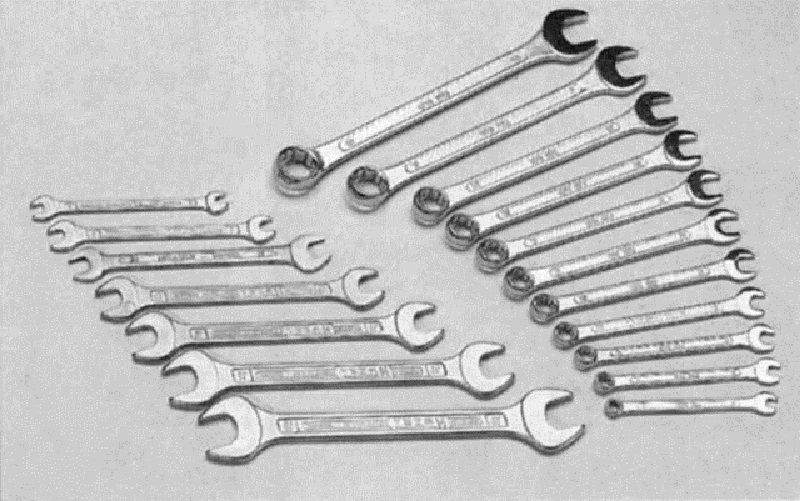

To work, you will need materials:

How to replace VAZ clutch fork with their own hands (step by step)

Consider the option of replacing the fork without removing the gearbox. The new element will have to be processed by a special way. Paws forks, that is, its ends, you need to sharpen with a special grinding stone, holding the element itself at an angle of 45 degrees. Due to this, the new plug will be easily accommodated under the clamping spring located on the hub of the release bearing.

To install the plug as simple as possible and quickly, you should make a special hook under the spring, with which you raise it and essay the plug. So, to remove the old plug, you need to do the following:

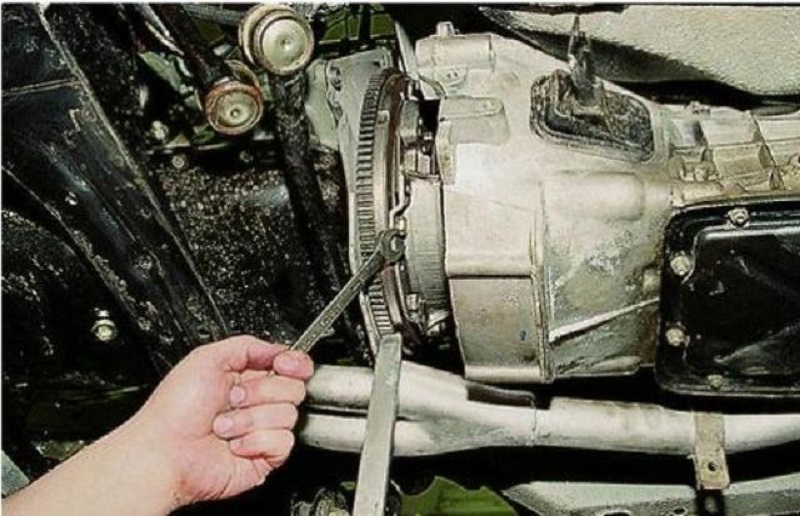

- Remove the clutch working cylinder. It can be dismantled only with the rod. Then take to the side of the cylinder together with the hose that crepts it.

- Remove the protective cover of the plug and carefully inspect it. If there is no hope that the plug will be able to work further, get it out of the casing.

- Inspect the housing itself. If there are any additional items in it or if it is badly polluted, ensure that it is maximum clean.

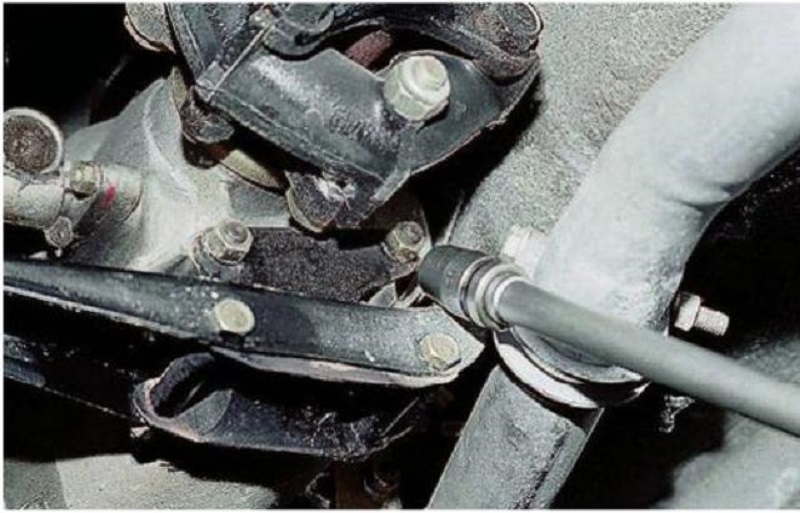

- Now go to the installation of a new clutch plug. In the clutch casing there is a special spherical finger, impose under it the petals of the plug fixer.

- Then concentrate your attention on the wire spring and the hub of the frost bearing. Under this spring, the sharpened ends of the fork should be fork (in order to pull the spring, you can use a pre-prepared crochet). It is necessary that the plug is in the end between the hub bearing and the spring. But you should not change this stage of working with the previous one, as it will not give any result.

- We perform the reverse assembly of all parts and elements.

Tips Prof.

On this work ends. It remains only to check the adhesion performance. When replacing the plug, it is recommended to pay attention to the release bearing. Most often, these two elements simultaneously fail, or rather, the breakdown of one can cause premature wear of the second.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments