As a result of an inefficient or defective motor ignition coil on the road, unforeseen stops may occur. It is on this, today, information about an independent check of the ignition coil is becoming increasingly relevant. The rubber with the coil is one of the most important nodes that ensures the full functioning of the car.

To check the ignition coil, you should use a multimeter that has two modes of operation - on ohms and volts. There is another old method of checking the coil - a way to identify the spark between the vehicle hull and candles.

Content

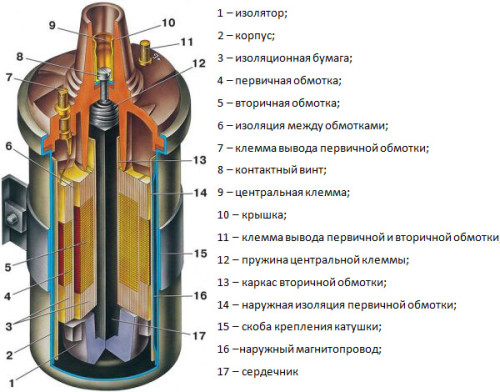

Device of the ignition coil

The ignition coil is an increase in the transformer converting a voltage that comes from the generator or battery, to the high-voltage used for the ignition of the air-fuel mixture. The current from the battery or the generator enters the main (primary) winding of the coil, which, usually, folds out of 100-150 turns of the copper wire of a rather large diameter, isolated by a special composition. The ends of the winding are summarized to low-voltage contacts, which are located on the coil cap with a voltage of twelve volts. The winding of the secondary contour consists of 15-30 thousand turns of thin copper wire.

Due to the difference in the number of turns, as well as, in the wire thickness, high pulse voltage occurs in the secondary winding. The secondary winding is located inside the winding of the main (primary) circuit. The first contact of the secondary circuit is derived for minus contact of the main circuit, and the second is connected to the central terminal in the coil lid. This compound is necessary to transmit high voltage current, the high-voltage wire is derived to it, the second end of which is connected to the central contact in the distributor lid.

To increase the power of the magnetic field, both windings are installed around the iron core placed in a special case. To optimize the work and prevent excess heating, the coil is filled with transformer oil.

Injector ignition coil

In the injector electronic ignition system, the method of static placement of high voltage is used, in other words, there are no movable elements in the system. On injector vehicles from the ignition coil, the high voltage is transmitted to two cylinders, and their pistons are currently moving to the upper point. In one cylinder, the mixture compression period occurs, and in the second - the release period.

A similar principle of high voltage is called "idle caviar". On modern injector motors on each cylinder, individual ignition coils are mounted.

Work, Ignition Coil Scheme

The principle of operation of the coil lies in the occurrence of high voltage current in the secondary winding during the passage of the low voltage current in the primary winding.

Using the emerging magnetic field, a high voltage pulse is formed in the secondary winding. When the spark is needed, contacts are blocked in the ignition distributor. In this instant, the primary winding circuit is broken.

The high voltage current is transmitted to the central contact of the ignition coil and goes to contact on the lid, opposite which, at this point, the electrode runner is located. Now the chain closes, and the pulse is supplied with a candle of one of the cylinders.

As a result of the unreliability of ignition distributors, mechanisms with individual coils are used on modern vehicles for each specific ignition candle. Due to this, the energy of sparking increases and the level of radio domain created by the ignition system is reduced. In addition, the system with individual coils makes it possible to get rid of the use of unreliable high-voltage wires.

Faults of the ignition coil

There are several reasons for the failure of the ignition coil, however, the most common - wear of the unit and all the elements of the coil or the diagram disruption during the implementation of the ignition and admission to the desired point of the spark. In addition, the reason for the breakdown may well be in punched wires or non-accurate candles.

How to check the ignition coil

For a competent check of the ignition coil, the retainer should be bent, and to disconnect the wiring harness block from the traver.

Then you need to configure the multimeter to the voltmeter mode and put to the output of the coil with one end, and the second to the mass, that is, to the vehicle body. Voltage, at the same time, should be twelve volts.

If the voltages are not at all, in this case the electric circuit of the traver or the ECM has failed.

Next, we check the primary coil winding on the opening, for which we switch the multimeter to the module mode, and the coils put to the outputs - first of all A / B, and then b / c. Resistance, in both cases, should not be lower than 2 ohms. Otherwise, there is a break and the device must be replaced.

In the same way, check and secondary winding, however, the emmeter readings, in this case, should not be below 5 ohms.

Now check the rubber on the closure of two windings. Multimeter (in Ommeter mode) connect to high-voltage output and the output of the A-coil. Evidence that the chain open will be the desire of resistance to infinity.

Tools assistants

Multimeter with two modes of operation - a voltmeter and an ohmmeter.

Tips for the experienced motorist

Quite often, drivers of old vehicles notice that from the driver's door or other body component to which they relate during the entry or exit from the cabin can "beat the current". This occurs as a result of microcracks in the housing of the ignition coil through which the high-voltage current leak occurs.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving a car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments