The most effective and common method of checking the cylinder-piston group is considered to be the diagnosis of motor compression. As a rule, it is performed under 2, however, in some cases, it is made unscheduled. In fact, this check is not able to give an unequivocal response about the malfunction of the cylinder-piston group, but it allows you to detect negative changes in its state, based on which, make a decision on more intensive diagnostics, which implies other equipment and complete or partial disassembly of the motor.

Usually, an unscheduled compression test is produced in such situations:

- If fuel consumption and engine oil rose.

- If one of the cylinders turned off and stopped participating in the motor operation.

- If the engine at one point lost power.

Content

- Engine compression that this is what it affects

- What compression should be

- Compressometer, instrument for measuring compression, types of compressometers

- Preparatory work, what needs to be done before checking engine compression

- Engine compression, compression check, work stages

- Analysis of the data obtained

- Tips of professionals

Engine compression that this is what it affects

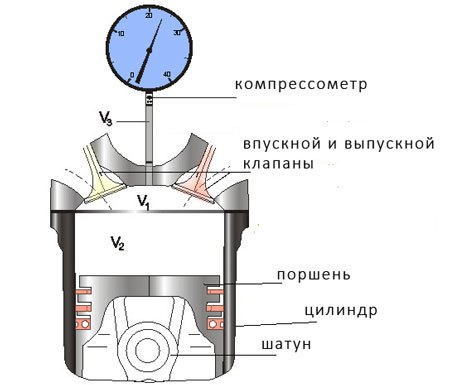

Compression is the maximum pressure index in the cylinder. It is measured at idle, however, at the same time, the air mixture should not be supplied to the motor. The rotation of the crankshaft is carried out using the starter, the installation of the engine to the rolling stand or scrolling the drive wheel during the transfer is enabled. The device measuring compression is called compressometer.

Compression has its impact on many parameters, the main of which are the launchers of the engine, especially at low temperatures. Initially, this applies to diesel engines, where the temperature and pressure of the end of the compression depends, whether fuel flashes in the cylinder. However, the gasoline motors in the cold state are also sensitive to the change of compression - it has its effect on the evaporation of the fuel, which is only theoretically in the cold start on the road to the cylinder should evaporate. In reality, it enters the cylinder in the form of liquid non-combustible drops.

Reduced compression is capable of increasing the pressure of crankcase gases. In this case, a lot of oil vapor flies through the ventilation system. This is pretty unpleasant, as it grows toxicity and the rate of contamination of the combustion chamber increases sharply. The compression unevenly in cylinders is capable of causing vibrations of the motor, which are especially noticeable with small speeds or idling, which, accordingly, harms engine suspension, transmission and car owner itself. In a word, the role of compression as a diagnostic attribute, which largely characterizes the state of the motor, is large enough.

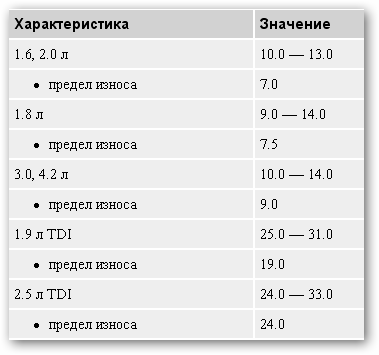

What compression should be

It turns out that compression in the cylinder depends on the level of its compression, and this dependence is determined by a specific coefficient. It is believed that such a coefficient is 1.2 - 1.3 for gasoline four-stroke engines. In other words, if you know the level of compression of your engine, then find the engine compression will be easy (this information can be seen in the official documentation for the vehicle much more often than information about compression).

Undoubtedly, in practice, these compression officials will differ from the officially declared manufacturer, at least because this compression depends on the procedure of natural wear of the piston group, and than this wear is larger, the compression will be less. However, what is the face when compression is the maximum low and engine elements can be considered overly worn out? It is believed that this criterion is about ten or twelve percent of the level of the coprecination, which is declared the manufacturer or obtained by calculations. In other words, if the documentation of the compression rate is 12 kg / cm 2, it is not difficult to calculate that the motor with a compression is considered to be faulty less than 10.56 to 10.8 kg / cm 2.

Compressometer, instrument for measuring compression, types of compressometers

To check the compression, you will need a compressometer - this device is not expensive and is a manometer having a check valve, with which it fixes the maximum compression in the cylinder. There are such compressometers on constructive execution:

- With a threaded tip, which screws up instead of a candle.

- With a conventional rubber tip that you need to insert the candle to the hole and hold at the time of the check.

Preparatory work, what needs to be done before checking engine compression

Before measuring compression in motor cylinders, such conditions should be performed:

- To get real indicators, you need to charge a battery well, and the starter must turn the motor with a frequency of at least 200 revolutions per minute.

- Before the start of measurement of the compression, you need to warm up the motor to the operating temperature of 90 elders.

Engine compression, compression check, work stages

- First of all, you should remove all the candle wires.

- Then you need to unscrew all the candles, remembering which candle from what cylinder. Some car owners unscrew only one candle in the cylinder in which the compression is currently carried out. However, this is an incorrect idea of \u200b\u200bthe measurement, since eventually erroneous, indexes of compression will be obtained.

- Next, you need to disconnect low-voltage wires from coils, as they can be poured.

- After that, it is necessary to prevent fuel to cylinders. In the presence of a mechanical fuel pump, disconnect the fuel hose. If the pump is electrical, remove the power wires from all the nozzles, pull out the fuse or the pump relay.

- In the presence of a compressometer with a rubber tip, you need to insert it into the candle hole and grip tightly. Your assistant must get behind the wheel and open the throttle, squeezing the gas pedal. Then he should rotate the engine with the stoker until the readings on the device will stop growing.

- The readings in this cylinder should be recorded, after which we reset the information on the instrument and carry out this procedure in the remaining cylinders.

- After measuring compression in the motor, you must collect everything back.

Analysis of the data obtained

On your motor excellent compression, if:

- Compression in the cylinders is about 11 - 15.

- The pressure difference between the cylinders is not more than one.

To more accurately determine the limits of the compression rate for a particular motor, pay attention to the technical documents of your vehicle.

If the pressure in some cylinders is an order of magnitude lower, then certain malfunctions exist. To pre-reveal the breakdown in the cylinder, add ten milliliters of pure engine oil to it and make me out again.

If the compression has risen or exceeded the testimony in other cylinders, this indicates a strong wear or rings.

If the compression has not changed, there may be a problem in a loose fit of the exhaust or inlet valve, the crack in the piston, block or head, the test of the cylinder gasket.

Tips of professionals

It is not necessary to make final conclusions, based only on the measurement of compression. Pay attention to many other, equally important factors.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments