On vehicles of the VAZ 2110 model, a five-speed gearbox is mounted, consisting of two shafts. It is distinguished by the presence of 5 front gears, one rear and equipped with synchronizers to move from one transmission to another. Constructive MCPP combined with the main transmission and differential.

Content

- Gearbox 2110, device, principle of operation

- Tools assistants, fixtures and consumables

- Gearbox 2110, Disassembly, Step-by-step instruction

- Repair box VAZ, what defects pay special attention

- Repair the gearbox with hands, how to bring parts in the desired view

- Remover for reprinting bearing, if not, what to replace

- Roller bearings, which radial clearance to be sufficient

- Gloves in which they should be condition

- The advice of the pros, which sealant lubricate the touching surfaces

Gearbox 2110, device, principle of operation

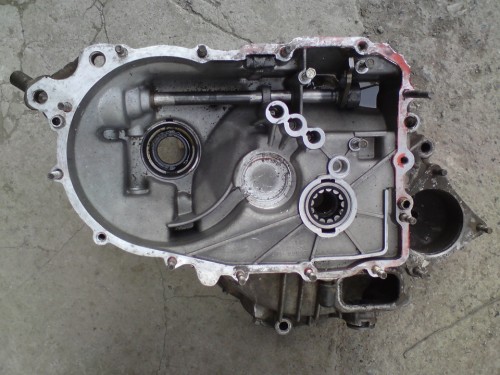

The MCPP housing consists of three elements (clutch crankcase, gearbox crankcase and the back cover of the CATRP) and is formed from aluminum alloy. Between elements is a benzon-abrupt gasket-sealant. Carter's nest is equipped with a special magnet where the metal balance is assembled. The primary shaft is a block that has drive gears constantly lurked with slaves.

Hollow secondary shaft is equipped with a removable leading gear gear. On this shaft there are driven forward gears and corresponding synchronizers. The front roller bearings are mounted on the shafts, as well as rear balls. Under the front bearing on the secondary shaft there is an oil separator, which is designed to direct the flow of oil to the slave gears inside the shaft.

Differential is a two-calves. On the flange of his box is attached by a leading gear gear. The design of the MCPP control drive consists of a PP lever, thrust, ball support, stock PP, as well as selection and speeding systems. Screws, with which the hinge and lever fastening is made, have different lengths, coating and tightening torque.

In the case of axial movement of the power apparatus, when driving a transport, spontaneous shutdown is possible. In order to avoid such situations, the drive control of the PPC VAZ 2110 is equipped with a reactive burden. One of her end is associated with the power apparatus, and the clip of the spare arm of the PP lever is attached to another.

All elements of the PPC VAZ 2110 in the process should be lubricated, therefore, the transmission fluid is poured into it, the level of which is controlled by the help of the probe and should all the time are located within the minimum and maximum.

Tools assistants, fixtures and consumables

For disassembling and repairing gearbox, you will need such tools and consumables:

- Spanners.

- Screwdriwer set.

- Clean rag.

- Hammer.

- Wooden timber.

- Special puller for bearings.

- Glue TB-1324.

- Grinding skin.

Gearbox 2110, Disassembly, Step-by-step instruction

To disassemble the manual transmission, it is necessary to follow the instructions below described below:

- We remove the gearbox from the car, clean it from different contaminants and mine from the outside.

- Pointer showing the oil level, remove from the gearbox.

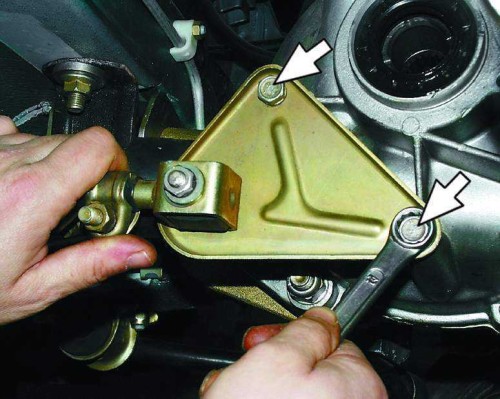

- Next, we put the checkpoint in the vertical position on the clutch crankcase, after which we unscrew the bolt with a flat washer and two nuts with a spring washer fixing the clutch cable bracket. By reloading all the bolts, remove this bracket from the checkpoint.

- On the cover, located behind, we unscrew all other fastening bolts (four pieces).

- Remove this cover, for which it is necessary to lift the tide with a screwdriver, which is located on the lid.

- Then we unscrew the bolt with a spring washer that holds the fifth transmission plug.

- Now it is necessary to prevent from scrolling the gearboxes from scrolling, for which they should be fixed - on the transfer of the plug and the clutch of the synchronizer, move down to connect the clutch and gear slots, then turn on the fourth or third gear, moving the gear selection rod.

- Next, you need to open and unscrew the primary shaft fastening nut. Here you need to try, as the nut is very tightly spinning.

- Then we do the same manipulation with the secondary shaft as the primary.

- We raise in the fifth gear using a screwdriver a driven gear (we compress the synchronizer hub from the tree). Together with the gear, remove the fork of the secondary shaft and the synchronizer. Make sure that the synchronizer clutch does not move, since the balls fixing the synchronizer are capable of crumbling.

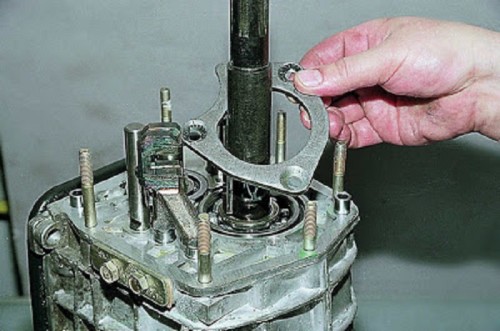

- In the synchronizer, we remove the stubborn plate on top, and then in the synchronizer itself, we carry the plug in the groove of the coupling.

- Also from the synchronizer should be removed the blocking ring and the gear of the fifth gear. Name the coupling and blocking ring, then remove it. It must be done to set the ring to the same position as it was, because when the rings and the clutch's teeth were working on each other.

- Remove the sleeve on the secondary shaft.

- On the secondary shaft is the main gear of the fifth speed. Remove it and remember, in what position it stood.

- Remove the bearings plate. Take a shock screwdriver and unscrew the bearing plate four bolts with spring washers. On the secondary shaft, remove the stubborn puck.

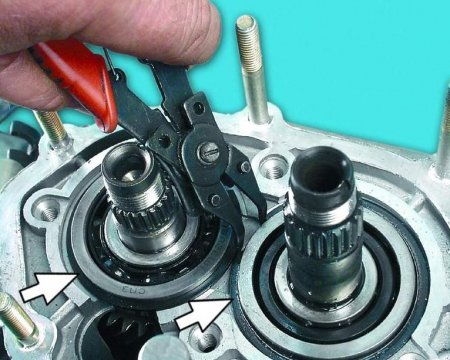

- Next, lift two shaft with your hand and remove the lock rings from them.

- Unscrew the locks and get balls from there with springs.

- Then unscrew the reverse lock, remove the sealing ring, then remove the spider of the retainer.

- Tilting the box, get the bulb of the lock.

- On the attachment of the CPP Carter, unscrew 12 nuts and a bolt with spring washers. Do not forget to remove the technological cap.

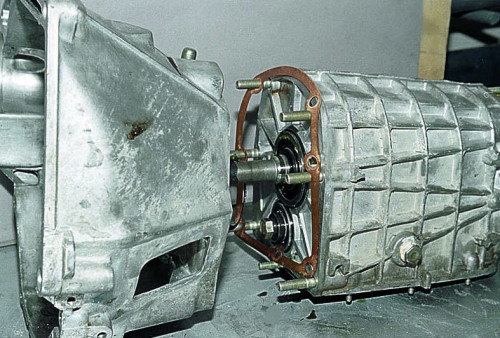

- Along the carts are three special grooves. Insert a screwdriver there and disconnect the CAPTER CARTER CARTER.

- Rimming Carter PPCs, turn it left so that Carter leaves from under the gear. Next, remove the CTP Carter from the clutch crankcase.

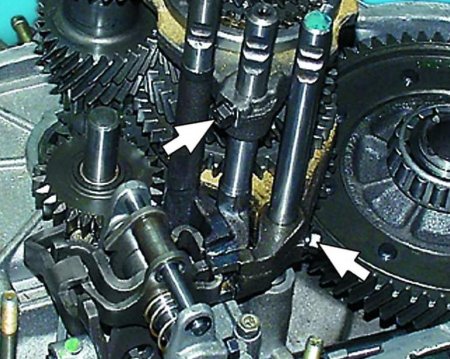

- Unscrew the bolts on the mounting of the forks 1st - 4th gear.

- Lift the switching stock of the first and second gear and make sure that it leaves the support. Then turn it left so that the head stop cling to the blocking bracket. Remove the rod with a fork - remove from the groove of the clutch of the synchronizer rod fork.

- Turning the rod, the head of the switching range of the 3rd and 4th velocities, we disconnect from the velocity selection lever. Next, we raise the rod and remove it along with the fork, pulling them from the groove of the clutch of the synchronizer.

- Then we remove the inclusion of the 5th speed from the support of the 5th speed, for which turn it and get the head connected to the locking bracket.

- Remove the axis of the intermediate reversing gears.

- Remove the intermediate gear, for which we shift it to the mechanism of selection of speeds, turn on forty degrees and remove the shaft from under the gear.

- At the same time, we remove the primary and secondary trees, swaying them.

- Remove the differential in the clutch crankcase.

- On the mounting of the speed selection mechanism, we unscrew three bolts with spring washers, after which we remove this mechanism.

- We take out the magnet in the clutch crankcase.

- We unscrew the nut of the speedometer drive body with the driven gear and remove the housing itself. If the sealing ring of the housing is torn or there is no elasticity, it must be replaced.

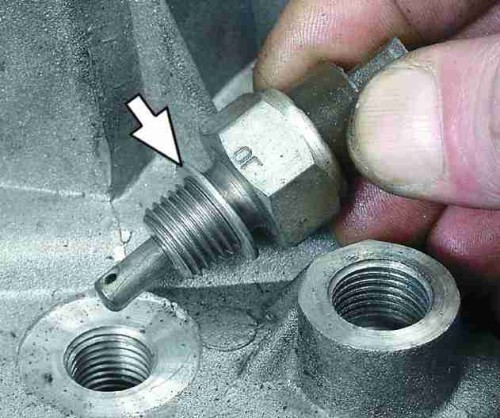

- We unscrew the reverse light switch, as there is a place for the sealing metal ring. It is located in the CPP Carter.

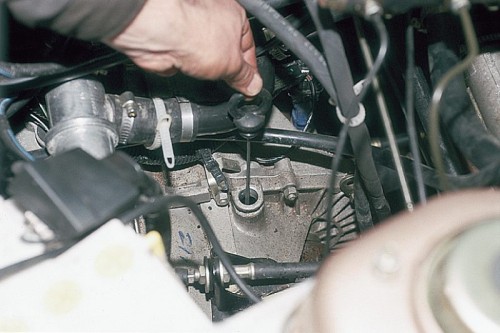

- Next, we write with a special puller or screwdriver the bearing of the secondary shaft.

- Remove the oil collector, which is located under the bearing.

- Special puller press the primary shaft bearing.

- Taking a suitable mandrel, we will prescribe new front bearings in the clutch crankcase.

- In a protective cover of the gear selection rod using a screwdriver, we move the edge with the stem reference sleeve.

- Weching the stock by reloading a bolt on the mounting of the speed selection lever, after which we remove this lever.

- Next, in the clutch crankcase, we take out the speed selection rod.

Repair box VAZ, what defects pay special attention

- Check the gearbox and clutch crankcase on their integrity. If there are any defects, the crankcase must be replaced. To do this, you need to remove the bearing from the crankcase and the clutch shutdown plug. Then they write the glands.

- In the checkpoint and the clutch crankcase should be checked all surfaces and rear lid. If there are small damage, it is possible to clean them with a grinding skirt. If there are significant damage, in particular the chip, dents, cracks, it is necessary to replace it.

- Check gear shifts. If they are bent, there are jackets or bursavires, various irregularities were either holes under the clamps, replace them.

- Also pay attention to forks. If there are worn paws, bent forks or other defects, replace them with new ones.

Repair the gearbox with hands, how to bring parts in the desired view

- If you need to replace the rod hinge, it is necessary to push the protective case on it, then unscrew the bolt on the hinge attachment. For strength to the bolt, a special glue TB - 1324 was applied. Therefore, it is necessary to clean the bolt before assembly and apply this glue to the surface.

- Check the magnet if it is integer, just clean it from pollution. If small cracks are detected or if it is bad magnetic, it should be replaced.

- Paint from the sealant surface of the CAT cartridges, clutch and rear lid.

- With the help of transmission oil, lubricate all rotated items.

Remover for reprinting bearing, if not, what to replace

If it is missing, bend the wire in the form of a hook, insert it into the groove of the crankcase and put the hook under the bearing. A screwdriver is scored from the crankcase bearing, putting a wooden timber under a screwdriver, and knocking the hammer on it, rearranged the hook in the grooves.

Roller bearings, which radial clearance to be sufficient

If the rollers, separator or rolling track are damaged, replace them and place them on the shaft, taking into account the measurement of the radial gap, the value of which should not be greater than 0.07 millimeters. If there is a backlash in the bearing, it is also necessary to replace it.

Gloves in which they should be condition

In addition to all above, it is necessary to pay attention to the glands of the semi-axle. If there is a handover, stretched or broken spring, an uneven edge with elbow elements or sparkles of rubber, the glands must be changed.

The advice of the pros, which sealant lubricate the touching surfaces

When installing the CATRP CTP on the clutch crankcase, it is necessary to lubricate all contacting surfaces with a special sealant for a better connection.

Also lubricate sealant in contact with the surface when connecting the back cover with the CAT Carter.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments