The exhaust system of the car and the lambda probe are closely interconnected. It should be understood that the presence of this device in the car is not accidental, in principle, like other high-tech sensors. Yes, it is the sensors, since the lambda probe is still called a different oxygen sensor (O 2-sensor), which is fully justified. The serviceability of this sensor strongly affects the operation of the car's fuel system as a whole, so the check of the lambda probe must be carried out at least every ten thousand kilometers of the mileage. Many motorists believe that about a 2-sensor and catalyst are closely interrelated in work, but this is not quite the right opinion. As a rule, the catalyst is mounted after the lambda probe and does not affect its operation. However, the presence of an oxygen sensor significantly extends the operation of the catalyst, since its service life directly depends on the quality of the combustible mixture. About this further in the article.

Content

- Lambda Probe device

- Work lambda probe

- Lambda oxygen sensor probe, as it affects the composition of the fuel mixture

- Lambda Probe, types of devices

- Sensor of the oxygen lambda probe, causes damage and that threatens the car during operation

- Lambda probe, checking the health of the sensor with a visual way, causes and consequences: dirt, soot and greed on the sensor

- Oxygen sensor Lambda probe, checking service with appliances, detailed operation when checking a voltmeter for a depleted fuel mixture

- Oscilloscope check, decrypt reading graphs

- Tips Pros: how to correctly check

- Conclusions and recommendations

Lambda Probe device

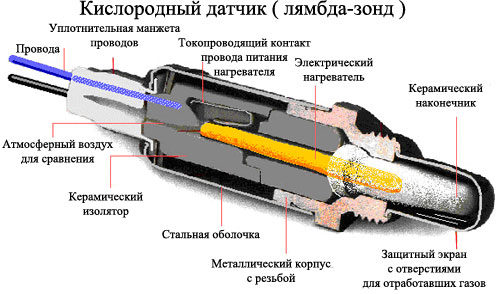

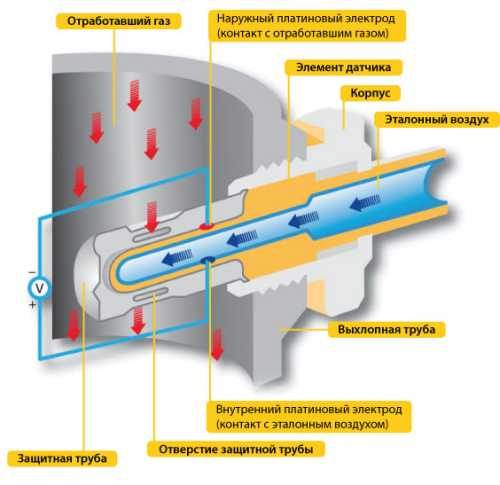

In the design of the oxygen sensor includes such components:

- Protective shield with a special hole for the release of gases.

- Spiral located in a special reservoir.

- Ceramic tip.

- Conductive contact.

- The protective housing in which the hole is drilled, which provides ventilation.

- Wiring with special cuffs for sealing.

- Seal (ring).

- Ceramic insulator.

- Metal case with chopped carvings.

The peculiarity of these sensors - exclusively heat-resistant materials are used for their production, since they have to function at high temperatures.

Work lambda probe

The basis of the lambda probe is based on the phenomenon of the electroplating effect. The meaning of this phenomenon is based on the fact that, when comparing exhaust gases and pure atmospheric air on the elements of the sensor, voltage occurs. This happens with the help of complex physical processes, which makes no sense to consider here.

The current from the oxygen sensor enters the computer, which changes the composition of the combustible mixture depending on the voltage indicator. The lambda probe works only at high temperatures (300-400 degrees Celsius), since only under such conditions, an electric current is produced in the sensor and a galvanic element works.

On the cold motor, the combustible mixture is formed on the testimony of other sensors, and the lambda probe begins its work automaticly when driving the motor. Some transport are mounted on 2-sensors with built-in heated, which is still at an early stage of operation of the motor ensures the last supply of high-quality combustible mixture.

If the standard o 2-sensor operates 40-70 thousand mileage kilometers, the lambda probe resource with heating is significantly larger.

Lambda oxygen sensor probe, as it affects the composition of the fuel mixture

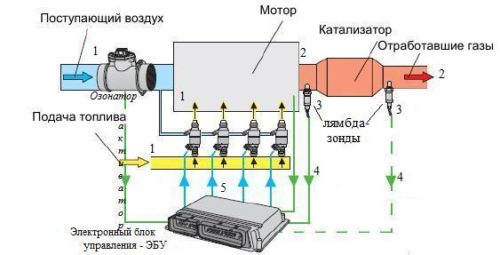

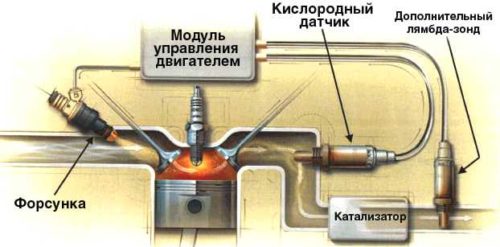

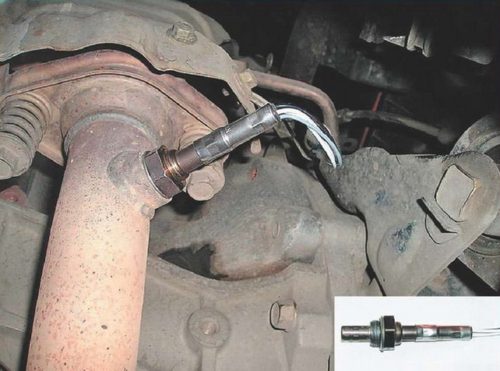

After the combustion of gasoline, the gases fall into the exhaust collector, where the oxygen sensor is in front of the gas catalyst. It removes the information of the qualitative characteristics of the exhaust, in particular the amount of residual oxygen in it compared with the content of 2 in atmospheric air.

This indicator is extremely important because with its help the computer calculates the optimal ratio of fuel and oxygen to form a combustible mixture with current loads, for the highest efficiency of the motor.

Installation of the second lambda probe after a catalyst allows a computer with more accurate calculations, but in our time it is a rarity.

It is worth noting that all calculations are based on one important indicator - the effective combustion of one part of the fuel is capable of providing 14.7 parts of the oxygen.

Lambda Probe, types of devices

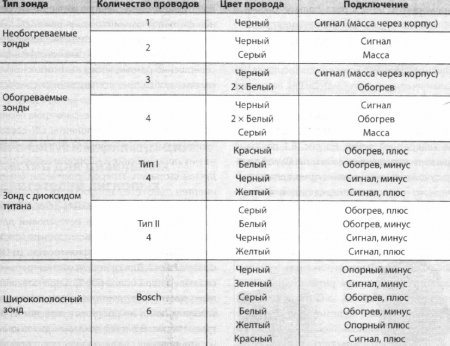

Depending on the number of wires, with which the oxygen sensor is connected to the system, there are four types of these devices:

- Four-wire.

- Three-wire.

- Two-wire.

- Single-wire.

Sensor of the oxygen lambda probe, causes damage and that threatens the car during operation

To reasons, the breakdown of the oxygen sensor can be attributed:

- Fit into the housing of different technological fluids and dirt.

- Increased lead content in combustion.

- The use of fuel with a high octane number, which does not rarely lead to overheating of the components of the lambda probe.

- Poor-quality fuel.

This can lead to unpleasant consequences, namely:

- Reduced power.

- Rods in motion.

- Motor floating turnover.

- The appearance of excessively contaminated exhaust gases.

- Incorrect catalyst operation.

- Incorrect operation of the injector.

- Great fuel consumption.

- On cars with automatic transmission, switching gear occurs with tapping and jerking the car.

Lambda Probe, checking the sensor's health by visual method, causes and consequences:

dirt, soot and harness on the sensor

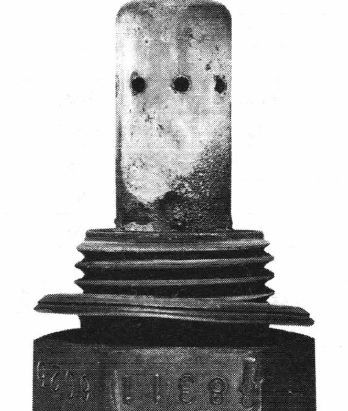

Before checking the oxygen sensor with the help of devices, it is recommended to first produce its visual inspection for the presence of dirt, soot and gar on the sensor.

The reasons are the overheating of the lambda probe, the combustion of the re-entered combustible mixture.

The consequences - the inhibited response of the oxygen sensor, the late issuance of these to the computer and late voltage switching.

sERO-white deposition on the sensor

Causes - the use of additives of different types in fuel and oils.

Consequences - the incorrect operation of the fuel system, the device is required.

on the sensor brilliant deposits

The reason is a lot of lead in fuel.

Consequences - the incorrect operation of the fuel system, the device is required.

Oxygen sensor Lambda probe, checking service with appliances, detailed operation when checking a voltmeter for a depleted fuel mixture

Checking the oxygen sensor using instruments only in the event that the above defects were not detected during visual inspection. Otherwise, the lambda probe simply change to a new one.

To diagnose the lambda probe using instruments apply:

- Experienced drivers - oscilloscope.

- For standard checks - a voltmeter, better - digital.

- Well, naturally, knowledge.

Next, we act in this way:

- Disconnect the lambda probe from the pads with wires.

- Connect it to the voltmeter.

- We start and warm up the motor.

- We increase engine speeds up to 2000-2600, after which we sharply throw the gas pedal.

- From the vacuum pressure regulator, remove the tube.

- We measure the voltage, which should be 0.45-0.8 watts.

With the help of the tube removed from the vacuum regulator, we create an artificial air drier. When the output voltage is less than 0.2 W, then the sensor is working.

As an option, to check the performance of the oxygen sensor, rearrange it to another vehicle, provided that the connectors are suitable. Not rare this test method is applied where there are two cars in the family.

Oscilloscope check, decrypt reading graphs

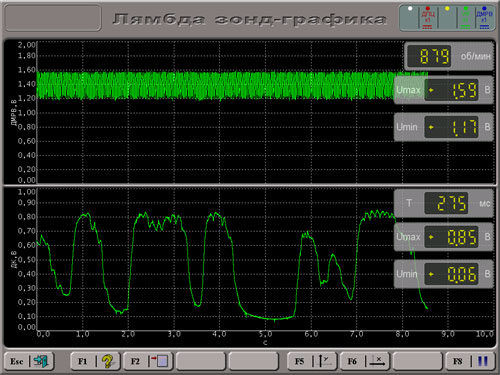

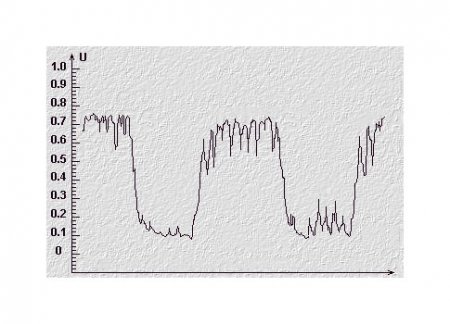

The main advantage of this check is the ability to fix the time for which the output voltage is changed. This important indicator is fixed only by the oscilloscope and should not exceed more than 120 ms. Figure below indicates the correct operation of the oxygen sensor.

As you see, the voltage varies smoothly in the range of 0.1-0.75 W. The time in the picture is not visible, however, as it was already above, it should not exceed 120 ms. Figure below, there is a completely different picture.

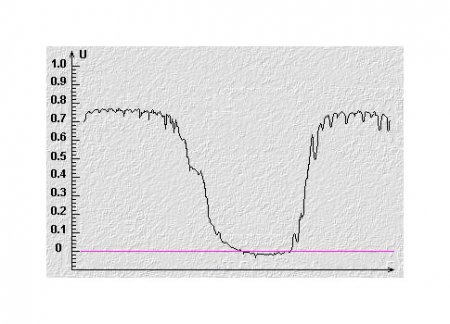

Here it is seen that the output voltage dropped below 0-1 W. This suggests that the lambda probe is faulty and should be replaced. With such a breakdown of the oxygen sensor, on the dashboard, as a rule, "Check Engine" lights up.

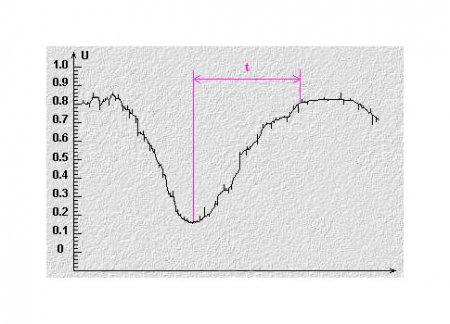

In this figure, a slow motion reaction of the lambda-probe on the change in the amount of oxygen in the exhaust is indicated by the oscilloscope. It clearly exceeds 120 ms. The car control system is not capable of determining this malfunction, and the Check Engine error does not appear on the dashboard. The main consequences of this malfunction is to reduce the power of the motor and increased fuel consumption.

Tips Pros: how to correctly check

All checks are made only on a heated motor with revolutions 2000-2600. Unlike checking with a voltmeter, where the lambda probe should be turned off from the controller, when checking the oscilloscope, the oxygen sensor from the network is not necessary.

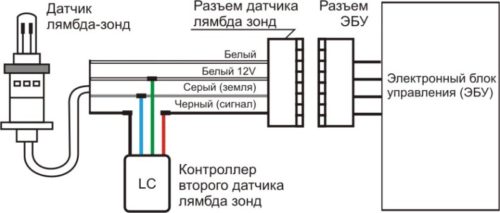

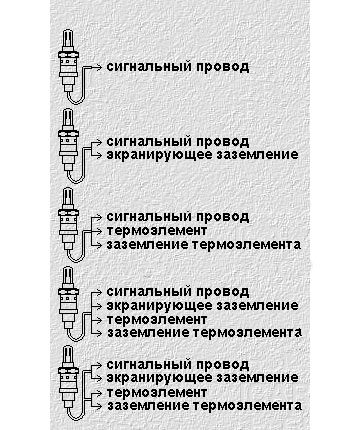

The oscilloscope probe is connected to a 2-sensor warning wire and readings are removed. The location of the connectors can be viewed in the figure below.

In the following figure you can get acquainted with the connectors of oxygen sensors, wiring colors and their connection.

Conclusions and recommendations

It is necessary to check the oxygen sensor, since the consequences of its malfunction can be critical, as well as completely stopping the vehicle. When replacing this device, it is better to use a new analogue, since the computer of your machine is already adjusted to receive a signal from this model.

Although it is worth noting that some car owners are still risking and assemble instead of faulty expensive oxygen sensors cheap analogues. For example, for cars Moskvich, Vaz about 2-sensors produces BOSH. She also produces them for Ford cars, so European quality standard. Consequently, for the vehicle Ford you can buy an analogue of a device made for VAZ cars. The most important thing is that the number of contacts is the same.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments