Any motor vibrates in the process of work. This is explained by the design of the engine, which, depending on the number of cylinders, is able to be balanced to one extent, but it is virtually impossible to achieve full balance. Vibration and noise are transferred to the body either in the vehicle salon, causing a sensation of discomfort from the driver. To combat this phenomenon, a motor suspension system was developed. Its key elements are supports, often called "engine pillows". The support is a buffer installed in the fastening points between the motor and the subframe, the frame or body of the vehicle. They are able to absorb the vibration of the engine and hold it in a relatively static position. The motor is thus protected from sharp blows and jolts.

Content

- Engine Support, Support Design

- Engine fastening wear, which leads to a late replacement of supports

- Engine Support Signs

- Tools assistants, consumables

- How to check engine pillows

- Engine cushion, to pay attention to when inspection

- Safety at work

- Engine Pillows, Replacing the right cushion Step-by-step instructions

- Engine Pillows, Replacement Left Pillows, Step-by-step instructions

- Engine cushion, replacement rear pillow, step by step

- Engine pillows, replacement front cushion, step by step

- Tips of professionals

Engine Support, Support Design

The number of reference points is due to the direction of the motor of the motor inside the body and the calculation of the team of engineers of a particular manufacturer, so the pillows can be four or more.

The main criterion when choosing points is the reliability of the attachment and a slight probability of a motor displacement to the side. As a rule, a motor assembled with a gearbox in a common unit is attached in two or three places at the top and in three or four places below. In modern transport, cushions of two main types are used - hydraulic and rubberometallic.

The design of rubberometallic support is simple. The lower supports are metal plates, between which a rubber pillow is located. The upper supports are created as a short suspension lever with silent blocks, the first side of which is attached to the body bracket with a through bolt, and the second to the bracket that is attached to the cylinder block. This type of supports found the most extent as a result of cheapness in production and reliability.

Some designs of the lower support pillows, to increase elasticity and giving hardness, reinforced with springs. Some manufacturers instead of rubber are used polyurethane - as a more wear-resistant material. Pillows with polyurethane are also not rarely used on sports cars, to increase rigidity.

As a result of the appearance of fashion for tuning, some companies have settled the manufacture of polyurethane supports for the most relevant models of transport. Also, polyurethane and rubberometallic supports are classified in unimprovable and collapsible design.

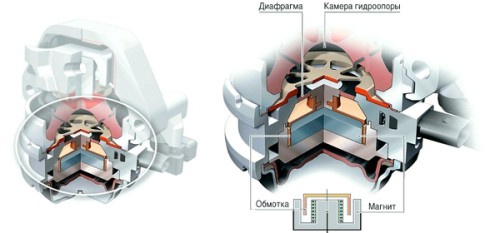

Hydraulic supports are a more progressive mechanism. Such supports are able to adapt to various rotation of the motor and effectively suppress vibrations at any speed. Supports consist of cameras, between which the membrane is located. The data of the chambers are filled with a special hydraulic fluid or propylene glycol (antifreeze).

The movable membrane is capable of extinguishing oscillations at idle motor. When driving around an uneven road or at high speed, hydraulic fluid starts working. Through special channels under pressure, it makes the support with a rigid, flowing from one camera to another. Hard support is able to extinguish strong vibrations.

Hydroporas are:

- Mechanical control. Such a design is calculated individually for each model of a car. At the stage of development of a certain model of transport, it is decided which the purpose for the support will be key - effective damping at rapid ride or comfortable noise insulation during the operation of the "Freshoye" motor.

- Electronic control. Such supports react to changing the motor vibration mode in broader borders. The stiffness of the cushion changes with the help of electronics depending on the situation on the road. The hydrophopores of this type are supports of a new generation that provide optimal comfort when working in various modes.

Engine fastening wear, which leads to a late replacement of supports

The main purpose of the DVS support is to provide an elastic reliable engine mount to the body. From this depends on the level of body vibration and, accordingly, noise insulation of the entire car. On severe wear indicates excessive strangers and noise when moving through poor road surface. You should not bring so important elements of the car to such a state, as it can lead to the following:

- As a result of an inefficient engine mount, an air filter will be fought about the hood.

- The cooling fan will contact the radiator grille, which can be able to drive its blades and weaken the mount.

As a rule, the power units of cars are equipped with three pillows, but there are also such models for which five such elements are assembled. Professionals are advised to replace all the supports at once, and not separately.

Engine Support Signs

When operating transport, the engine support breaks for a variety of reasons. The most frequent defect is a breakdown of the pillow. And at least these parts serve sufficiently long, as a result of high load, the rubber does not endure and breaks. The largest loads occur when driving transport from place and during braking. If the auto owner prefers a high-speed movement with a sharp start, then he will not serve the motor cushions for a long time.

Rubber on the pillow is able to lose its elasticity and dismiss. Sometimes an aluminum bracket is rocked at the obstacle. If the oil from the gearbox is either from the motor hits the rubber block of support, the rubber is exhausted with oil, and the support fails earlier than necessary. Also adversely affects the brake fluid and toosol. In any situation, the operation of the car with a faulty motor cushion will be uncomfortable, and, sometimes, and unsafe.

The following features indicate the pillow fault:

- When driving around the uneven road, there is a return on the gear lever.

- The appearance of vibration.

- The movement along the uneven road surface is accompanied by blows in the front body.

- During braking and starting from the scenes there are knocks and clicks ahead of the car.

Tools assistants, consumables

To replace the motor pillows, you will need the following materials and tools:

- Scrap.

- New pillows.

- Small cellophane packages.

- Thread glue.

- Marker.

- Wrench kit.

- Several repair stands.

- Two jacks.

How to check engine pillows

To check the motor supports, you need to put a car on a flat surface, lift it with a jack, install a log or other support under the engine and remove the jack. Then you should climb under the vehicle and inspect the pillows, as well as the space around them.

Engine cushion, to pay attention to when inspection

In case of inspection, pay attention to the presence of impulses and cracks, solidification of rubber and bundle of support - the disconnection of its rubber part from the metal. All this will indicate the need to replace the pillow.

Safety at work

To ensure safety, before starting work, disconnect the terminals of the battery and put the vehicle to special repair stands.

Engine Pillows, Replacing the right cushion Step-by-step instructions

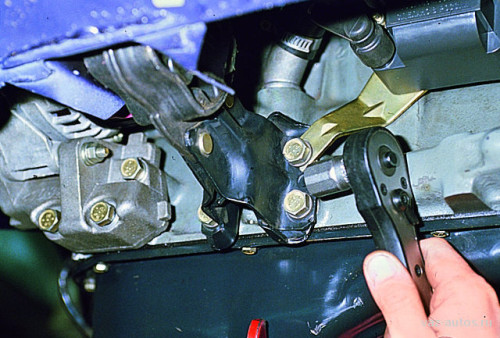

The replacement of the right pillow must be produced in such a way that the motor is located in a raised form on the right. This condition is easily done with the help of a jack. Then it is necessary to unscrew the nut that fastens the detail, after which they are two bolts that fix on the bracket with a support, and three more bolts that are fixing on the right side member bracket. Now remove the bracket, unscrew the nut and put a new product instead of the old one.

Engine Pillows, Replacement Left Pillows, Step-by-step instructions

In this case, the jack must be placed under the gear or left. Then we do the following:

- Disconnect the engine left airbag. When it is lowered to stop the gearbox should be supported.

- We remove the top limiter given details.

- Remove two bolts that fasten the product to the body.

- Remove the old element and mount a new one.

Engine cushion, replacement rear pillow, step by step

When replacing the rear support you need:

- Remove the two nuts that fasten the back support to the body.

- Unscrew two bolts that fasten the device to the gearbox.

- To disconnect the rear cushion bracket, you must hold it into vice, then unscrew the bolt.

- We change the pillow to the new one.

Engine pillows, replacement front cushion, step by step

The replacement of the front support is actually not different from replacing the back. In this case, it is necessary to dismantle the mudguard of the power unit, then unscrew the bolt, which is attached to the crossbar of the front suspension of the front support bar. Then disconnect from the bracket to the bar, remove the worn item, we mount the new and reverse assembly.

Tips of professionals

Specialists are recommended when replacing pillows apply a thin layer of glue to the bolt thread, which will ensure more reliable fixation of this device.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments