Vehicle suspension elements include a lot of different parts - brackets, levers, springs, shock absorbers, bearings, and so on. Each of them has its own purpose, but only a good condition of all elements and suspension nodes forms conditions for the safe driving of the car. With strong wear, they can serve as sources of foreign sounds - squeaks, knocks and so on. One of these components directly affecting the rotation of the vehicle (the indicator indicating the behavior of the car in turn, the turning is neutral, redundant and insufficient) is the reference shock absorber bearing. About this further in the article.

Content

- MacPherson suspension, device and purpose

- Bearing of the shock absorber rack, device and principle of operation

- Signs of bearing fault

- Diagnosis of bearings

- Tools, fixtures, consumables

- How to change the support of the front rack with the bearing (phased job)

- How to replace the support bearing, step by step

- Repair of the support bearing, does it make sense to repair or better put a new bearing

- Reference bearing, change both or one

- Front shock absorber pillar support if the bearing is in good condition, is it possible to make renovation of the support of the shock absorber rack

- Tips Prof.

MacPherson suspension, device and purpose

MacPherson suspension is one of the most common types of automotive suspension. The main design element of the suspension is a shock absorption rack, as a result of which the suspension also gained the name "swinging candle". Mostly "candle suspension" is used for the front wheels. The use of MacPherson suspension made it possible to cross the gearbox and the motor in the rotor space and led its broader use in modern automotive industry.

MacPherson suspension consists of:

- Stabilizer transverse stability.

- Depreciation rack.

- Swivel fist.

- Transverse lever.

- Subframe.

In MacPherson suspension, support bearings play a key role. It is they who are the so-called link between the body of the car and the front suspension. The quality of the data management, comfort and ride safety depends on the status of the data of the elements.

Bearing of the shock absorber rack, device and principle of operation

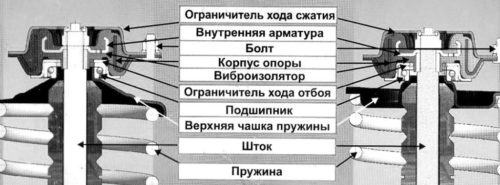

Support bearing, unlike the usual rolling bearing, has a large thickness of the outer ring. In this bearing, cylindrical rollers play the role of rolling. Each such roller is perpendicular to the previous one and in order to protect separated from it using the separator. This design gives a separate bearing the opportunity to take over loads from any directions.

Basic variations of support bearings used in modern cars:

- Single-separated type of reference bearing. In such a bearing, the outer ring is divided in one place, with which the rigidity increases. This bearing is used to rotate the external ring with great accuracy.

- Bearing with a separated outer ring to rotate internal. In this bearing, the inner ring is connected to the housing, in the external - separated. This model is used where the accuracy of the inner ring is required.

- Bearing in which the inner ring is separated to rotate external. In this model, the inner ring is separated, and the outer is connected to the housing. This type of support bearings is used where the accuracy of the rotation of the external rings is needed.

- Bearing with built-in outer or inner ring. In this model, the clamping flanges are not required, as a result of the presence of mounting holes. In addition, the design of the support bearing with an inserted ring provides gaskets, which is capable of providing constant rotation accuracy and eliminate the influence of the installation. This type of bearing can be applied to rotate both an internal and outer ring.

Signs of bearing fault

- As a result of the presence of a mechanical connection of bearing and supporting cups of racks, even the slightest backlash will immediately give in the body with specific knocks.

- When turning in the area of \u200b\u200bsupport cups, creak is heard.

- The rotation of the steering column becomes difficult, especially this is noticeable on vehicles without an amplifier steering wheel.

Diagnosis of bearings

More detailed diagnostics can be made using assistant:

- First of all, you need to turn the hood and ask for an assistant to rotate the steering column (if there is an amplifier steering wheel, you need to start the motor). Next, put your hand on the support, after which you will feel the click and punches. More accurate malfunction can be determined using a car stethoscope. In the absence of such, the ordinary medical is suitable.

- With the help of a partner, we swing the vehicle from one side to another. If the support is defective, the stuffs will be heard.

Tools, fixtures, consumables

- Caid-key (handle must be curved).

- Special head designed to disassemble racks.

- Screed springs.

- Dynamometric key.

- Ratchet with a set of heads.

- Key for rod.

- Long head (candle).

How to change the support of the front rack with the bearing (phased job)

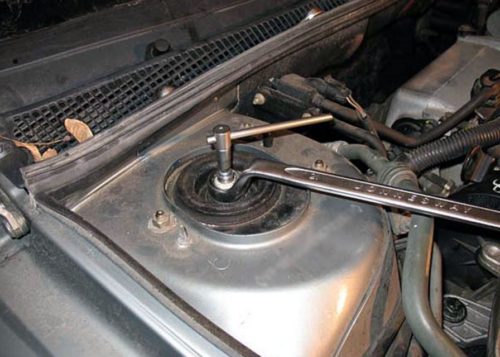

- First of all, we completely dismantle the rack. To begin with, you should unscrew using two keys upper shock absorber.

- The lower part of the rack is removed by the traditional method or simply derogate with the pile of support, for which the vehicle is lifted by the jack. Next is removed support.

- If the reference bearing is faulty, it makes sense to check the entire shock absorber node.

- After removing the rack with a support, you should carefully clean the planting place from dirt and check the mechanism for corrosion damage. Next, we clean the metal from corrosion, if any, we proceed with rust converter and paint.

- The old support, especially with damage, is not subject to repair, so it must be changed on a new one.

- Then the rack must be assembled without dismantling the springs screed, and install an updated node in place. Do not forget to relieve marker the position of the rod and all fastening nuts to save the Castor angle.

- The rack must be fixed on the lower lever of the suspension, and then carefully raise the node using a jack. It is advisable to perform this operation with the assistant. The first mechanic raises the jack, the second - controls the alignment of the planting spree.

- But, you can do on the contrary - raise the car body, leaving the pendant with the wheel on the ground. Then mount and fix the support. Next, slowly lower the jack, at the same time aligning the shock absorber in the support point of the support. This installation makes it possible to more naturally place the element in the planting socket.

- After shrinking rod into the hole of the support, tighten the fastening nuts.

- Do not forget to dismantle the snug of the springs of the rack after fixing all the details. At the end of repair, you should carry out a test trip to check the performance of the steering and the absence of extraneous noise.

How to replace the support bearing, step by step

If everything is fine with a support, and the fault lies only in the bearing, it is possible to separately replace it, for which we dismantle the stand with the support (the procedure is described above) and disassemble the latter (the design of all different, but the principle is about the same), after which we produce an audit of the bearing. Typically, the balls are unevenly worn, the glands are destroyed, there are jackets on the clip. Next, change the reference bearing and set everything in the reverse order.

Repair of the support bearing, does it make sense to repair or better put a new bearing

Despite the fact that bearings, most often, we can also access individual components, it does not make sense to repair them. First, the cost of the bearing is small, and, secondly, this is a sufficiently responsible node, as a result of which the replacement of the glands or balls with a handicraft method will not lead to anything good. Therefore, - unambiguous replacement.

Reference bearing, change both or one

One change the bearing or immediately both - there is no one opinion. As a rule, the steam replacement is carried out more due to reinsurance. Workers STRs diagnose this need, based on the state of the automotive suspension as a whole. It also happens that it is impractical to replace the second bearing - why throw out a well-working part?

Front shock absorber pillar support if the bearing is in good condition, is it possible to make renovation of the support of the shock absorber rack

If the bearing is normal, and the cause of the knock is the wear of the damper or another element that is not a responsible design unit, then the support can be repaired. For example, if the rubber pillow is good, but during operation, it has changed the size, you can compensate for the shrinkage by mouncing the gasket made on the machine. Of course, it will not be possible to return to the support of 100 percentage of performance, but it is possible to provide mileage a couple of thousand kilometers, and without explicit safety and comfort problems.

Tips Prof.

Although the support of the shock absorber rack is a responsible node, it is possible to restore its performance without contacting the service. Depending on the severity of damage, it is necessary to choose between the repair, replacing the worn items or installing the new node. The solution depends on the cost of components and your qualifications.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments