Replacing the brake pads - the inevitable thing for any car owner. For most car enthusiasts, this happens at a planner, for some - completely unexpected. Anyway, the question is serious and directly affecting safety, so it is necessary to approach the choice of brake pads responsibly and carefully. About this further in the article.

Content

- Brake pads, principle of operation

- How often do you need to change brake pads

- Symptoms talking about the need to replace brake pads

- Brake pads and their types

- Original shoes series "O.E.", pads for car manufacturers (for conveyor), pros and cons

- Brake pads for retail spare parts, pros and cons

- Brake pads for export, for developing countries, pros and cons

- What to pay attention to when choosing a pad:

- Overview of brake pads of famous manufacturers, pros and cons of each brand

- Tips Prof.

Brake pads, principle of operation

Previously, two variants of friction materials were used for drum and disc brake systems - asbestos and semi-metallic. Manufacturers quite rarely offered to ordinary consumers materials that are fundamentally different from specifications and cost.

Currently, asbestos is actually not applied in production. This material does not comply with the standards of modern cars. In addition, working with asbestos dust is dangerous to health. Suppliers of automakers developed new materials, and at present the market presents a huge number of components for brake systems under different trademarks.

A brake plug is made of friction material molded on a metal plate, which is attached to the caliper. Today's brake calipers are made so that in the measure of erasing the friction layer, the pads are automatically pressed to the disk. This provides the same time interval from the moment of pressing the brake pedal before the start of efficient braking.

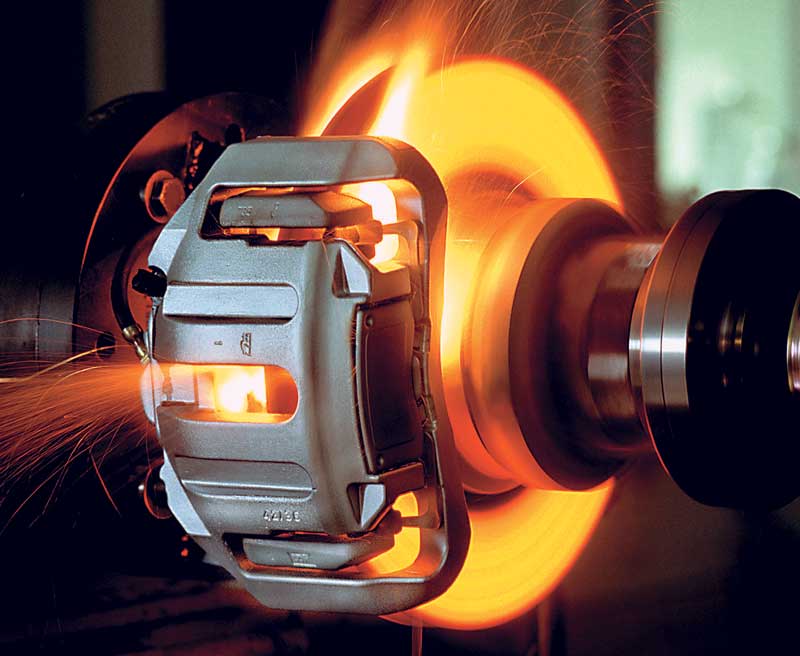

In the process of friction, the particles of the friction material of the brake pad are settled and a certain time is held on the surface of the disk, which ensures the optimal coefficient of friction and protects the disk from erasing. Both pads and discs must have good thermal conductivity, withstand strong heating and high temperature differences. In this case, the wear of the friction lining should be uniform, contrary to uneven heating when braking, it should also not crumble.

The principle of operation of any brake system is quite simple: the driver, having an impact on the braking pedal, transmits an effort through a series of devices to brake wheels, which have an impact on brake discs by pressing the pads to them and, thus, stop their rotation A, therefore, and Vehicle as a whole.

How often do you need to change brake pads

The brake block is replaced if its working surface was worn out. For the convenience of car owners, the TC instruction manual contains information about the permissible thickness of the friction layer of the pad. For most TC, the control value is two millimeters without base and 6-7 millimeters with a base.

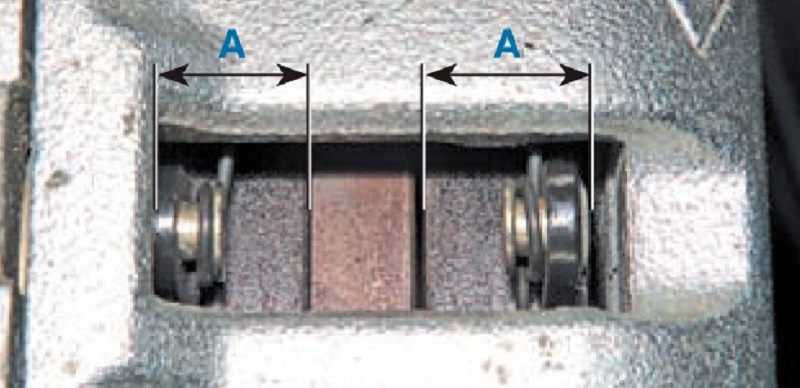

Most pads have electrical or mechanical wear indicators that signal the need for replacement. However, wear can be checked. To do this, it is better to use a caliper, although experts are able to evaluate him to the eye. Using the caliper, you can also measure the thickness of the brake disc.

It is worth noting that if the control value is achieved only on a single block, everything is smoothly necessary to replace all the pads on the front or rear axle. If you install brake pads of different manufacturers or different batches of manufacture on the car, or it is not all replaced, then during braking the vehicle can "take away" to the right or left as a result of differences in frictional properties.

Symptoms talking about the need to replace brake pads

As a rule, the first sign of strong wear of the working surface of the block is a squeezing sound. This sound is published by the soft metal of the wear indicator, rubbing about the brake rotor in order to prevent the driver about the need for replacement. Among other symptoms can be noted: when braking, the vehicle pulls in one direction, pressure on the brake pedal becomes softer, and the brakes are vibrated. The crushes indicates that the replacement of the pads need to be carried out as quickly as possible, as they are able to damage the brake discs.

Brake pads and their types

Currently, there are four main variants of brake pads for cargo and passenger cars:

- Semi-metallic. As a rule, this formula that contains 30-65% of the metal, includes a chopped with steel wire or a wash of iron powder, graphite either, mixed with fillers of inorganic type, as well as friction modifiers, which connects all the ingredients together. These pads are more durable and distinguished by excellent heat transfer, but it is much faster, it can be noisy and cannot work optimally under conditions of low temperatures.

- NonasBestOS (NAO or Organic). This type is made of fibers, which contains materials such as high-temperature resin, kevlar, carbon, rubber and glass. These pads are soft and create little noise, but they wear out faster and create a lot of dust.

- Low-metal NAO. They are made according to the same formula as organic NAO, only with the addition of steel or copper (10-20%) to improve heat exchange and ensure better braking. With the addition of metal there are more brake dust, the pads of this type are more noisy in operation.

- Ceramic - most progressive. Consist of fillers of non-ferrous metals, ceramic fibers binding and, in some cases, a small amount of metal. When using ceramic pads, brake discs are wearing less, since it is the abrasive dust that is the main factor of disks. In addition, such pads work significantly quieter than classic.

All brake pads are conditionally divided into three categories:

- For delivery to the conveyor (O.E.)

- For delivery to the auto parts market (aftermarket).

- For delivery to export.

Original shoes series "O.E.", pads for car manufacturers (for conveyor), pros and cons

Pads that are delivered to the conveyor of motor assembled plants are manufactured according to the manufacturer's requirements. A part of the pad coming into a free sale is also performed with the corresponding quality. These parts are packaged or in the corporate packaging of the car, or in the packaging of the manufacturer of the pad. On the market it will be the most expensive consumables. The seller calls them the "original".

Brake pads for retail spare parts, pros and cons

Brake pads made for supplies to the car market of spare parts will be a little cheaper - about 30-70 percent of the cost of the original. However, to reduce the cost, they can make small changes in the quality and composition of the mixture that allow you to reduce the price. In addition, one concern can immediately have several divisions that occupy a different position in the market and in the inner hierarchy. For example, Textar and Pagid belong to one concern. However, in the second case, the pads are made on the premium level, as evidenced by PAGID supplies for conveyors of models such as VW Golf R32, Porsche Cayenne, Audi Q7 and others, while Tekstar initially produces products for the auto parts market, but its quality also supposedly corresponds Premium segment. You can find Textar and from the factory - for example, on Renault Logan.

Brake pads for export, for developing countries, pros and cons

The most modest in terms of cost will be export pads that are intended for sales in developing countries, and were initially developed on the basis of standards and conditions operating in the markets where they will be sold. The lowest cost of these pads (20-30 percent of the price of original products) is due to the simple mixtures used when creating.

What to pay attention to when choosing a pad:

There are a number of factors for which you need to pay attention when choosing a brake pads:

appearance packaging

First of all, the label should be a quality certificate. As for new cars, there are certain standards to which pads must match. In this case, this is the smallest brake path in different situations according to the specified effort on the pedal. If you need more productive pads, you should give preference to products of well-known manufacturers, however, such pads may not be a quality certificate, as it is very expensive. Manufacturers must check only standard lines for a specific vehicle model. It is advisable to look for manufacturers that regularly test their product line.

exterior Brake Shoe

Obviously, high-quality pads will be the corresponding packaging. The marking should include an ECE R90 conformity mark (in some cases 90R or R-90) - this indicates that these blocks have been certified in Europe.

There should be larger cracks on the product itself (shallow cracks are allowed a couple of millimeters). It is important that the metal base is not bent, and the frictional material did not get away from it. In addition, the structure of the lining should not contain foreign bodies (for quality, small barely noticeable droplets of paint or chips along the edges).

brake pads design features

You can not save on the brake system, give preference only to high-quality items that are suitable for your car. It is not enough to take some abrasive bar and glue with instant glue to the steel plate. This imitation of the pads will fall apart at first emergency braking. Produce brake pads that have predictable and constant friction characteristics, it is very difficult. It is advisable to refrain from the purchase of pads, the cost of which is significantly lower than the average price in automotive stores. Low cost suggests that the friction mixture during the production of the pads were used cheap components that do not ensure efficient operation.

what material made brake pads from

As mentioned above, the brake pads are made from different materials, in particular from ceramic fibers, a powder of graphite, iron, copper and others (see "brake pads and their kinds").

friction coefficient which it should be

Standard pads have a friction coefficient 0.3-0.5 units (depending on the manufacturer and the pad itself), 0.25-0.35 - Conventional shoes aftermarket, 0.35-0.5 - Premium Poles O.E. The higher the value, the more efficient braking.

sports blocks, can I put them on a regular car

For slow ride in urban environments and even for rapid movement, there will be quite enough pads, the temperature of which is up to + 300-350 degrees Celsius. Sports pads are capable of working at a temperature of + 800-900 degrees Celsius, but they will function normally after + 100-200 degrees. This means that in the conditions of the city they are actually useless. On the family car to install racing pads, everything is exactly what to throw money on the garbage, since their friction coefficient at high temperature exceeds 0.5 units, and at work 150 degrees it is barely reaching 0.2.

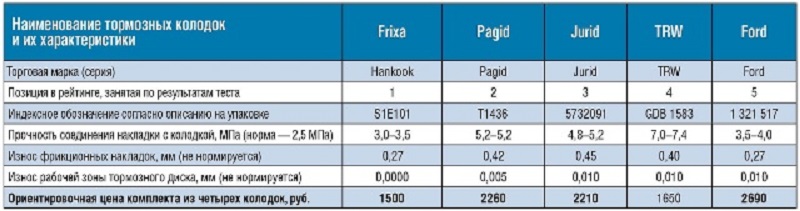

Overview of brake pads of famous manufacturers, pros and cons of each brand

- Brake shoes ABS. All Brake System was based on almost forty years ago and is considered one of the leading specialists in the production of brake parts. The company's range represents more than 1,500 items of goods covering the full range of light freight and passenger cars of American, Korean, Japanese and European industries. All company products meet the requirements of TUV / ISO, which is confirmed by the relevant European certificates.

- Brake pads Allied Nippon. In 2016, these pads were recognized as one of the best. The ruler was developed specifically for complex operating conditions in the city cycle of motion associated with constant braking and overclocking. Priority data The brake pads are designed to use in the brake mechanisms of SUVs and heavy vehicles. The main tasks are to increase the friction coefficient and depreciation - were solved by using Ferro Carbon technology (Mineral Metallic).

- Brake pads ATE. ATE CERAMIC pads are designed to increase the operational period of the pads, the exclusion of dust, which arises during the work of the pads, and reduce noise. Numerous tests of the company showed that the product meets all the requirements and standards for the original products for any operational modes. These pads are certified for use in original automotive brake systems. It is believed that ceramic brake pads are effectively inhibited only in a heated state, but ATE CERAMIC is designed to use on common roads in conventional brake systems, therefore, they are equally efficiently functioning at any temperatures.

Tips Prof.

Finally, I would like to note that you need to pick up brake pads, taking into account the driving manners and the operating conditions of the vehicle. To avoid possible negative consequences (creak, mediocre braking speaker), it is advisable to buy original pads. Integet to test pads, as well as read forums and reviews.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments