If the load is missing, the throttle in the vehicle motor is completely closed. But the engine continues its work and constantly supports the revolutions, which provides the ability to not start it again at each stop. This is due to the idling regulator, since it allows enough air to the intake path. The breakdown of such a small element is able to significantly complicate the use of the vehicle, according to this, every car enthusiast should know the principles of the idle regulator, where it is located and how to identify the causes of its failure. Information on the methods of restoring the idle regulator will be quite interesting and useful for each driver, which is independently repaired by its vehicle.

Content

What machines brand have idle problems

Vehicle owners of AvtoVAZ vehicles need to be able to check the idle regulator, because its failure does not entail the "Check Engine" indicator on the dashboard.

It is for this reason that the owners of domestic cars often start checking the car from other nodes, in particular, the intake system, and only then go to the idle sensor, although in fact it is from it that should begin to start it. For owners of foreign cars or modern vase models, such a problem is not relevant, since the failure of the idle controller is easily diagnosed using a special scanner and is displayed on the instrument panel.

Why idle speed swim

The idle regulator is often referred to as the XX sensor. It is so small, which is placed on the palm of an adult. The idling sensor consists of three main parts - a conical needle that is intended to change the bandwidth of the nozzle, the spring and the stepping electromotor with the rod.

Such a device is able to change the cross section of the passage channel, which is responsible for the arrival of the air to the motor during the closed throttle valve. When the ignition is turned on, the idling regulator pulls the rod automatically until the needle falls into the calibration hole. During the engine launch, the idling sensor automatically opens the passage, which allows the engine to obtain a sufficient amount of air for stable operation. In the case of a too low temperature of the coolant, the XX regulator is able to supply more air, providing an increase in engine revolutions to speed up heating. Thus, the vehicle can immediately start, not having warmed the engine, without risk to stall.

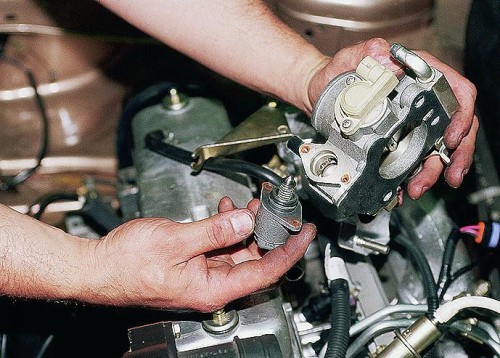

The idling regulator is always located near the throttle position sensor. It can be recognized by a typical plastic cover of an electric motor that strongly performs above the surface of the unit. It lasts a wire that connects to the connector nearby or branches from a joint harness associated with the control unit. Here it is necessary to be more close, since on modern cars, the idling regulator can often be located under a common casing that protects the throttle assembly.

No matter how strange it sounded, but the engine is most difficult to work on small speeds. This happens for several reasons:

1. Cold and the motor must warm up to function normally.

2. Between the intake and exhaust manifiers, there is a pressure difference, which leads to throwing the combustion products back to the cylinders. This reduces the efficiency of the motor, which provokes the rapid wear of the parts and increases the percentage in carbon dioxide exhaust.

All this is due to the slow supply of the air-fuel mixture to the exhaust system at this stage. Subsequently, it is mixed worse, which reduces its effectiveness.

Motor speed at idle can swim for many reasons, but you can select the most common of them:

1. If the guide needles erased.

2. If the wire explodes inside the sensor.

How to find out the cause of breakage

There are two methods that will help diagnose the cause of the fault:

1. Demonstant the sensor and connect the four-pin connector again. Leading finger at the end of the needle of the idle regulator. You will need an assistant who will turn on the ignition. If the XX sensor has advanced to the needle, it means it is working and the reason you need to search in the position of the throttle position, since the symptoms of the breakage are very similar.

2. We dismantle the regulator and using the multimeter measure the resistance value in the sensor windings. Between the contacts A - B and the coefficient should be located in the range of 40-80 Ohm. If everything is fine, it is necessary to further produce cross-measurements - between B - C and A - D. The device should show the sign of infinity - the chain break.

No idling sensor does not work how to eliminate breakdown

Very often the cause of the failure of the idle regulator is its strong pollution. To eliminate breakdown, you need to clean it:

1. Connect the wires and unscrew the screws. If the idling sensor is fixed with varnish, you will have to dismiss the entire throttle node.

2. Wash your cotton wand in a special tool or alcohol and carefully wipe the contacts.

3. In the case of strong contaminants of the conical needle, springs or rod, the WD-40 means should be applied to remove deposits.

4. We check the condition of the throttle and clean it if necessary.

5. Mount the idle regulator back and check its performance.

In addition, the causes of the sensor breakdown can be a torn wire. In this situation, it is necessary to clean the platforms of contacts, they solder and cover with varnish this place that corrosion would have had an impact on the reliability of the node. However, not all malfunctions of the XX sensor can be solved simple cleaning. For example, the rod production, the belief of the conical needle or the destruction of the engine is solved only by the complete replacement of the sensor.

Cleaning throttle valve

1. Demonstrate the device. For this, we free the hull of the throttle from the air corrugation. Separate the coolant hoses and check that all fluid flows.

2. Remove the throttle gasket and the damper itself.

3. Clean the base of the intake manifold in the presence of contaminants.

4. After cleaning, it is desirable to purchase a new gasket.

5. To clean the throttle, there will be enough aerosols and an ordinary cloth.

6. Aerosol must be applied to the surface and leave for 15 minutes.

The throttle sensor does not work how to change

1. Consider a minus terminal with a rechargeable battery.

2. Press the plastic latch on the throttle sensor and disconnect the wires.

3. Remove the sensor by unscrewing the fastening screws.

4. Install a new throttle sensor in reverse order.

How to clean the carburetor or injector, the course of work is styled

Clean the injector:

1. In the working condition of the motor, we remove the fuse that is responsible for its operation.

2. Separate the terminals of the nozzles, pumping and reversible fueling hoses and unscrew the rail with nozzles.

3. Remove the nozzles rings.

4. We take the wires with terminals and connect to the power source.

5. Find a five-pharmaceutical syringe to the wide side of the nozzle to ensure a dense fit to the basis of the nozzle.

6. Imitate the operation of the valve by pushing and release the switch button.

7. After the fluid was passed through the nozzle several times, it is necessary to leave it for a while and repeat the procedure.

8. We produce assembly in the reverse order.

Clean the carburetor:

1. Drive the carburetor, following the safety rules.

2. We put all metal parts into the pre-prepared container.

3. Pour a cleaning agent there and wait for a while.

4. We rinse all parts under the jet of water, removing all pollution.

5. We are all elements and produce back assembly.

Collect the carburetor is actually very difficult. For this, be patient and collect everything according to the instructions.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments