No detail, whether it is made of high quality and durable metal, will not be able to serve the ever-different kind of physical activity, sooner or later, the cause of destructive processes will be caused. So wondering why during the operation of the car on his front beam becomes noticeable, defective places - do not have to.

Content

- Front beam VAZ 2107, where it is and how it works

- Why cracks appear in the front beam housing, in which the danger

- Choosing a workplace

- Tools, fixtures, consumables

- Dismantling the front beam VAZ 2107, stepdown

- Professional advice on relief dismantling work

- Installation of the front beam VAZ 2107 (in detail)

- Safety technique

- Installing a new front beam, as it facilitates the car work

- Professional Tips for Survey Ball Support and Silent Blocks

- Why after replacing the front beam need to make the wheel alignment

- Tips Prof.

Front beam VAZ 2107, where it is and how it works

The front beam of the VAZ 2107 is a bulk design, the technological process of its manufacturer includes stamping operations and welding. The material of its manufacture is a steel sheet.

It is located in the engine compartment, in cross position. For this reason, it is often called transverse. It combines the front spars, its ends serve as a platform for attaching the axes of the lower pendants. In addition, the transverse beam is a support for a car motor.

Why cracks appear in the front beam housing, in which the danger

Since the transverse beam is the part of all-metal, it serves for many years. Special maintenance does not require. But when conducting that-2, a visual inspection of the part is required to identify deformations and cracks. The same checks require the details having direct contact with the beam.

Of common faults that are detected with such inspections are deformations, they occur as a result:

- increased static or shock loads

- fatigue stresses of metal causing cracks

- wear fastening elements

What is the danger:

- the accuracy of installing the front wheels is disturbed

- reduced car sensitivity to control

- safety of car movement is reduced on the road

- there is a threat to complete destruction of the part

Naturally, the elimination of such a problem must be fulfilled in the shortest possible time. If minor deformations are detected, you can try to correct the beams in a special machine.

Choosing a workplace

If the detected deformations are serious - the optimal option is a complete substitution of the part.

The replacement procedure is a rather laborious process, it includes:

- dismantling

- installing a new beam

- checking the accuracy of adjustments of suspension elements

To perform work, you will need to suspend the engine onto the hoist or traverse, the process should be performed or on the lift, or on the pit, i.e. The optimal place to work will be equipped with a properly boxing.

The best option is to enlist the support and help of a partner friend.

Tools, fixtures, consumables

Of the tools and spare parts, it is advisable to stock:

- spanner keys, complete with extension and gate

- jack with the necessary load capacity

- talu with fastening construction

- montiva

- carrying - to highlight the workplace

- tie springs

- new front beam

- new fasteners

Dismantling the front beam VAZ 2107, stepdown

If you need to replace the beam, lifting devices and plumbing tools are used. First, the car is drunk on the observation pit, put it on the handbrake. Under the wheels it is recommended to install anti-tart stops.

First remove the shock absorbers, for which we turn over the upper first, then the bottom nuts. To warn the scrolling of the rod at the same time you can keep it with a horn key.

Actions are performed in such a sequence:

- the front of the car is highlighted, the front wheels are removed, reliable supports are accurately installed under the body.

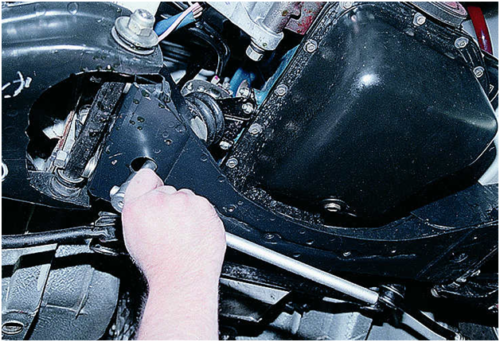

- steel sheet is removed, employee to protect the engine and mudguards

- to accidentally damage the hood - it is also recommended to remove it

- engine disassembly is performed, but it is necessary to strengthen it. It is necessary to strengthen it onto the hoists, for this use the eye on the head of the cylinder block located between the tee and the carburetor

- disassembled on both sides front suspension, disassembling springs and lower levers with axes

- reveal fastening elements and engine cushions themselves are removed

- having used tools, it is desirable to stop the beam - after we unscrew the spars it should stay in place

- now it remains to remove the fastening of the beam and move it to the side

Professional advice on relief dismantling work

If there are no special lifting mechanisms - you can put a solid support for the engine crankcase, but it is recommended to put a piece of the board under it - it is necessary to follow the possibility of deformation of the part.

In order not to damage the air filter, it is also recommended to dismantle it.

When performing dismantling work, you should remember the order of removal of parts - when assembling it will be necessary to repeat all your actions, only in reverse order.

Installation of the front beam VAZ 2107 (in detail)

It is easy to guess that the order of installation work will be reverse than the one that was used when dismantling. Initially, check the pillings of pillows - when installing, they must enter the mounting holes.

If there are no screeds for springs - they are replaced with wire, the jack is also used, which is commonly used when performing repair work on "Zhiguli" or "Muscovites".

The procedure itself must be performed with extreme caution - the wire break can cause a spring firing.

If you speak in detail, then:

- the jack plank raise up, to the height, which will allow insert a spring

- multiple wire loops are attracted to the jack, it will avoid wrapping the wire or popping it in the compression process.

- by smooth lowering the jack plank, it is required to achieve a springs compression

- compressed spring will need to firmly fix with wire twists

Removal of wire twists produced after installing the spring in place. Remove them with special accuracy.

All work performed in the sequence, reverse dismantling.

As a fastener, it is recommended to use exceptionally new items. All those having defects and damage nodes should also be replaced with new ones, especially the ball supports and silent blocks.

Such an approach is considered more rational, because it will eliminate the need to perform repairs in the near future.

Safety technique

Performance of dismantling and installation is associated with safety requirements.

When removing the engine, it will be necessary to securely strengthen it on the waist, make sure that the fastening is strong enough.

Experts are recommended when installing a new beam for fixing springs to use special ties, to use wires and jacks to resort only in extreme cases.

Spring compression should be done exactly how much so that it is possible to install it, but not more. Otherwise, problems may occur during the removal of twists.

Installing a new front beam, as it facilitates the car work

By installing a new beam, you can get rid of such phenomena:

- ringing the car on the highway

- uncontrollability cars

- arbitrary deviation from the specified direction

The car body becomes more resistant to twisting loads, it has a positive effect on the overall state of the car.

Professional Tips for Survey Ball Support and Silent Blocks

It is necessary to replace the stabilizer pillows if they have cracking, broken holes.

Mandatory replacement is the silent blocks that have a gap or worn on one side. The issue with the wear of these parts is sufficiently important, because It can act as a reason for the hinders of the wheel of the collapse of the wheel.

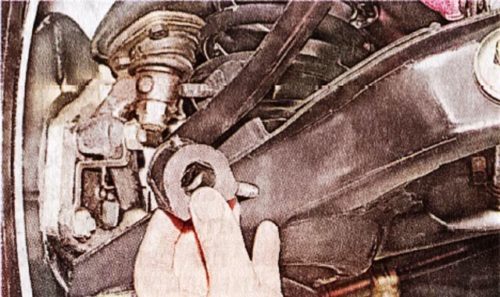

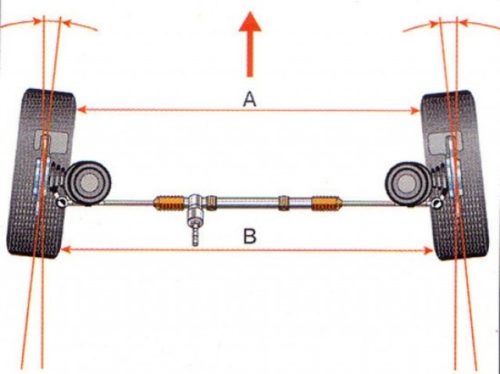

To make sure in good condition of the silent block, you will need to measure the radial displacement of the stubborn washer relative to the end of the sleeve and determine the distance between the inner end of the stubborn washer and the outer sleeve.

The optimal radial displacement rate is in the range of 2.5 mm for the front suspension levers, with the distance indicators between the sleeves (ends) can be 3-7.5 mm (for the lower front suspension lever), from 1.5 to 5 mm (for top lever front suspension).

The inconsistency of the second parameters recommended means that it is necessary to make sure that the silent block is correcting in the front suspension lever.

Create replacement ball supports - if torn protective covers are detected.

To make sure the fitness of the upper ball support should be:

With the help of a mounting blade to shift the top lever of the front suspension, in the vertical direction. At the same time, attention should be paid to whether there is a backlash between the ball support housing and a finger. If it is present - the ball support should be replaced.

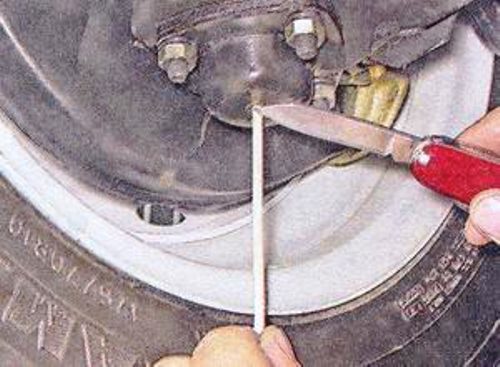

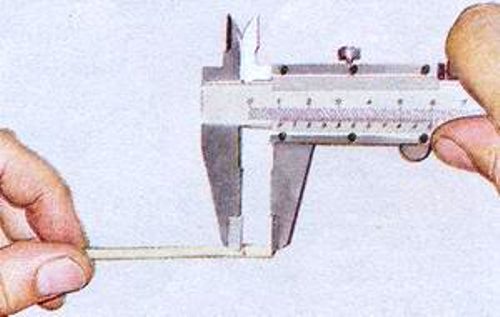

If the car on the observation pit is to determine the state of the lower ball support, you can use the depthine meter of the calipers, while measuring the distance between the spherical surface of the ball rings and the lower end of the ball support.

If the car is on the site, then a piece of wire can be used as a measuring instrument. It should be inserted into the ball support after turning through the plug.

On level fork ball support on wire apply bright mark.

Further would need measure length named cut.

The maximum allowable value is less than 11.8 mm, exceeding the indicator means that the ball support should be replaced.

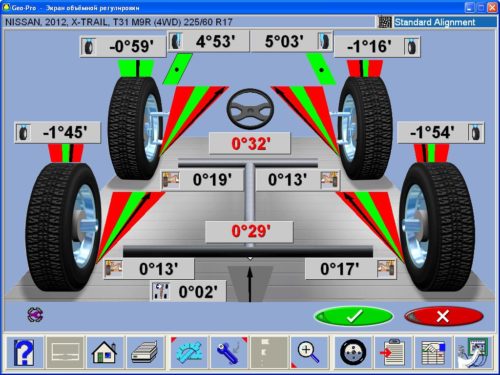

Why after replacing the front beam need to make the wheel alignment

If the work on replacing the front beam is quite actually done with their own hands, then on the issue of adjusting the collapse of the convergence, it is recommended to contact the service center. The fact is that when replacing the carrier elements of the body, or any manipulations with steering mechanisms, the settling unit will necessarily break.

Timely appeal over the adjustment of the collapse of the convergence will preserve the premature wear of the tires and will guarantee the correctness of the behavior of the car in the conditions of slippery road.

To determine with the accuracy of the violation in the setup parameters, you can only apply the computer diagnostics, but the following symptoms may indicate the need to visit the car service:

- steering wheel rotation performed with variable effort

- the car in the process of movement "takes"

- non-uniformity of tread wear on tires

- enhance the noise level created by wheels

Tips Prof.

If you decide to get savings on repair and restoration work, you can perform the replacement of the front beam with your own hands. But experts do not recommend save on the adjustment of the collapse of convergence.

It is impossible to perform this procedure qualitatively independently, moreover, without the appropriate equipment, in the conditions of the garage, folk crafts will be able to cope with such work. Modern requirements for a qualitative result suggest that when adjusting, not only whole degrees will be taken into account, but also the tenths and hundredths of the unit.

Moreover, in order to maximize the degree of secure yourself on the track, experienced drivers recommend visiting the computer diagnostics of the adjustment of the collapse of the convergence every 10-15 thousand km of run.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments