As a rule, piston rings must be changed depending on the mileage of the vehicle. In fact, this procedure depends on the quality of the oil poured into the engine, its timely replacement and so on. However, today, the cost of such works for a hundred unreasonably overestimated, and paying repairing on the service, you do not always have a certain one hundred percent that the work is done really qualitatively. This is exactly what forces many drivers, even those who have never been repaired before, producing these operations on their own. Our article will make practical help for drivers who decided to replace the piston rings of the motor on their own.

Content

Set of piston rings

When replacing the piston rings, first of all, it is necessary to purchase a new set of piston rings. When buying, you should definitely pay attention to the rings themselves and on the appearance of the packaging. Usually, the quality product should look attractive, be competently painted and do not imply any flashes. The marking must be observed with accuracy and indicate the bottom and top of the ring, and the packaging must be directly framed, with an excellent design. When buying poor-quality rings, the entire replacement procedure will be useless.

Types of piston rings

Piston rings are open rings with a minimal gap, which is mounted in a special piston planting groove. First, the piston rings in the internal combustion engines were made from the ductile cast iron, because it combined with the cast-iron cylinder block. With the help of its porous structure, the lubricant on the forged cast iron was well held out, which further reduced wear. Then they began to produce rings from plastic cast iron. Such rings, besides all the advantages of the previous species, are distinguished by the presence of elastic deformation, which has a positive effect during their installation in the cylinder block sleeve.

There are also piston rings from chromium, molybdenum and stainless steel. However, they are all actually applied together with the cast-iron base or other metals. Today, molybdenum rings are widely used due to their reliability and durability.

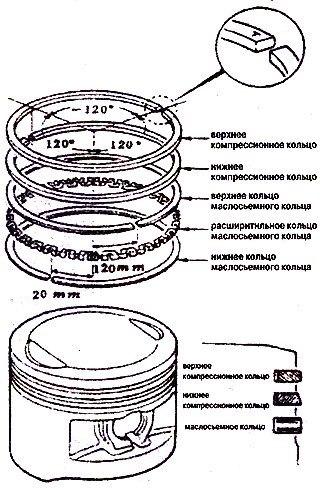

Piston rings are two types - oil surfactant and compression.

compression rings

In fact, compression rings are a kind of barrier for gases between the crankcase and the combustion chamber. The ring in the free state has dimensions that exceed the inner diameter of the cylinder. To set the ring inside the cylinder, make a cut, which is called the lock.

The upper compression ring is able to differ from the lower. Its surface can be inclined or in contact with the bottom or top with the cylinder. As a rule, the compression ring is flat or twisted with L - shaped department. This department, depending on the pressure in the cylinder, makes it possible to change the force that is applied to the cylinder walls. As a result, you can achieve the maximum efficiency of the motor. The second compression ring is an additional seal, after the top oilmage. In addition, it plays the role of an assistant to the oil-chain rings - scraps from the cylinder excess oil and prevents the detonation of the motor.

masonry rings

The oil rings remove the excess lubricant from the cylinder, and also prevent its burning into the combustion chamber. As a rule, they are mounted below the compression rings, however, they are distinguished by the presence of end-to-end slopes. The operation of the internal combustion motor is completely and completely depends on the state of the oilmaging and compression rings. Over time, the materials and design of piston rings change, but the appointment remains unchanged.

Replacing piston rings, step-by-step instructions

Most novice motorists fear to replace the piston rings on their own, as it is necessary to remove the motor.

In addition, the procedure itself, at first glance, is complex and requires highly specialized knowledge and skills.

However, it is not. Replace the rings on new may well, and one person who does not particularly know all the specifics. In most cases, you do not even need to remove the engine, it will be enough to arma with certain tools.

tools assistants

- Hex keys.

- Crimple for rings, which can be made with your own hands.

- Dynamometric key.

- A set of keys.

- Set of heads with a rattling.

- Set of piston rings.

remove piston rings

- With a battery remove a positive terminal.

- Tosol merge.

- We remove the decorative lining of the motor, for which we unscrew the four nuts.

- Remove the intake manifold, for which it is necessary to display the throttle drive cable. Next, we disconnect the throttle assembly itself, dismantle the ignition coil, after which all the armor guns. Remove all hoses that are located at the top of the collector. Weakening the clamp that connect the lower nozzles with the upper. It is very important to remember or record the process of disconnecting the hoses, so that it would not be confused when assembling.

- We dismantle the valve cover, twisting all the bolts and disconnect all the hoses.

- Remove with motor attachments.

- I carry the fuel hoses and disconnect the contact, which goes to the fan power sensor.

- We unscrew two bolts, which fix the thermostat. We remove either we move all the hoses.

- We dismantle the generator roller.

- Remove the timing belt cover.

- We dismantle the tension roller of this belt. Remove the camshaft belt. Carefully, do not lose the knaps. We dismantle the second part of plastic casing. That in the process of work the camshaft did not scroll, fix it with a fine montage.

- We dismantle the casing of the exhaust manifold and the collector itself.

- From all engine sensors, remove the connectors.

- Let us dismantle the harness of the wires, which goes on the nozzles.

- Now remove the GBC, for which you unscrew ten bolts in the desired order.

- Remove the pallet.

- We turn the crankshaft, which would be the necessary piston in the lower dead point.

- We dismantle the connecting rod, after which they push the pistons of all cylinders upstairs.

installing piston rings

- We believes from the pistons of the Nagar.

- After removing the old rings, mount the new ones.

- First install the oil surcharge ring.

- Be sure to tighten the rings with a special mandrel.

- Collect all the details back.

Tips for the experienced motorist

After replacing the piston rings, make sure how to work and check the internal state of the unit.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst for the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving a car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments