With a breakdown of the belt of the gas distribution mechanism, actually all drivers face, but not every car owner knows about the consequences of such a breakdown. The belt of the gas distribution mechanism is an important element of the vehicle, the discontinuity of which is capable of increasing the power unit. How to prevent the belt break and what to do if the breakdown still happened? About this further in the article.

Content

- Timing belt device, work principle

- What is made, or types of timing belt, dignity and disadvantages of each type of timing belt

- The main causes of breakdowns

- Consequences of the timing belt

- Signs of timing belt

- Who must change the timing belt

- How to follow the timing belt

- How often do you need to change the timing belt

- Tips Prof.

Timing belt device, work principle

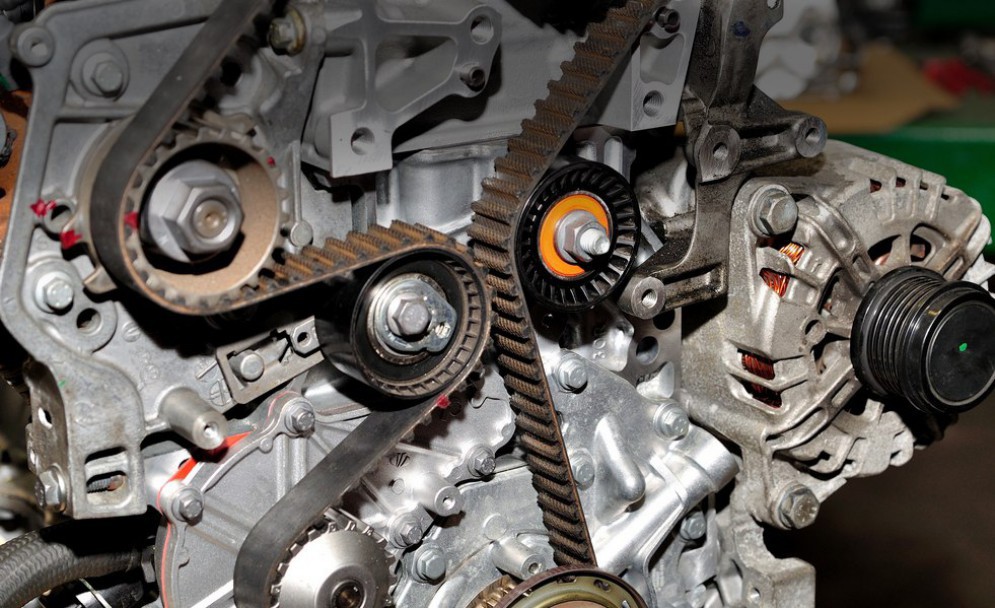

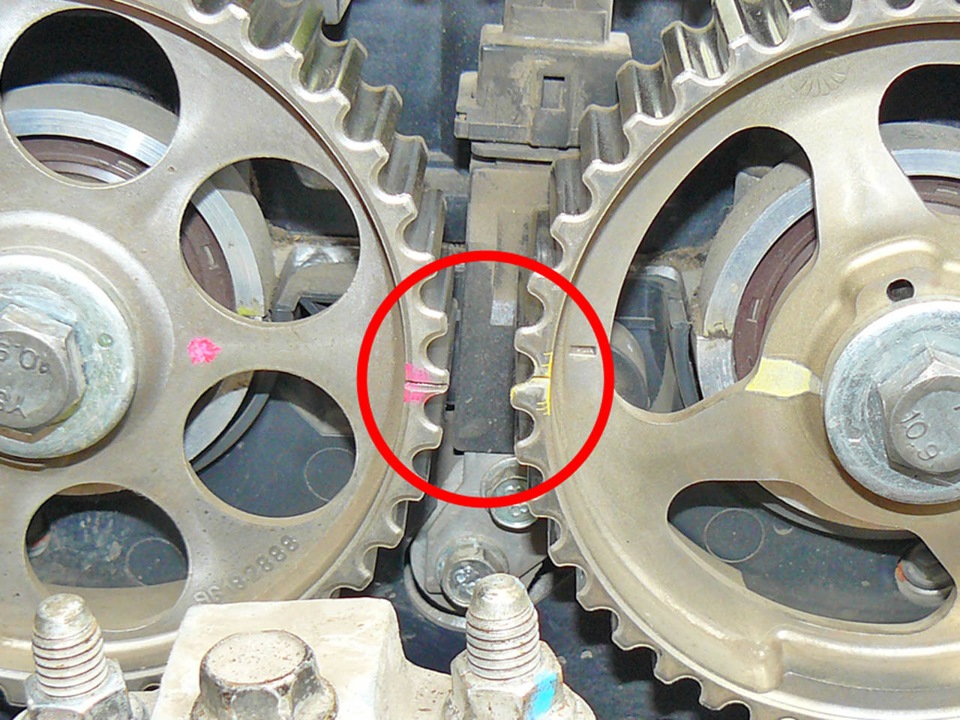

The belt of the gas distribution mechanism is closed, most often a rubber ring, the diameter of which directly depends on the model and the type of power unit. The inner side of the belt is equipped with special notches located throughout the perimeter. Despite the simplicity of its design, without it the movement of the vehicle is impossible. Belle's task - tie a crankshaft with distribution and synchronize the movement of the pistons with valves.

Since this part, as a rule, is made of rubber, it is not corrosion and is actually silent in operation. However, the device of the gas distribution mechanism is distinguished by constant friction between pulleys and a belt, as a result of which it is able to wear and require periodic replacement.

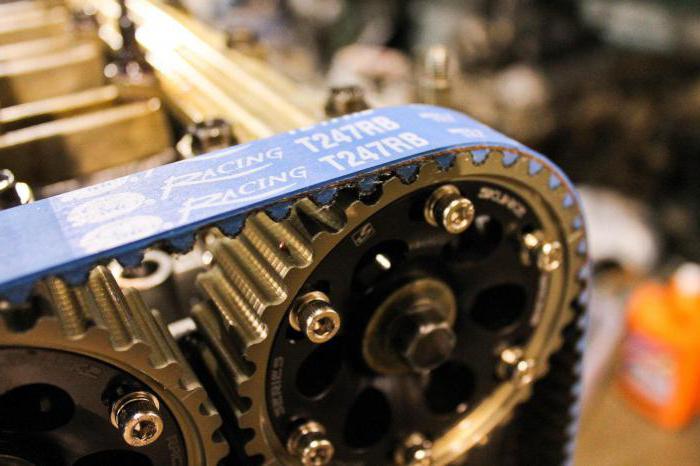

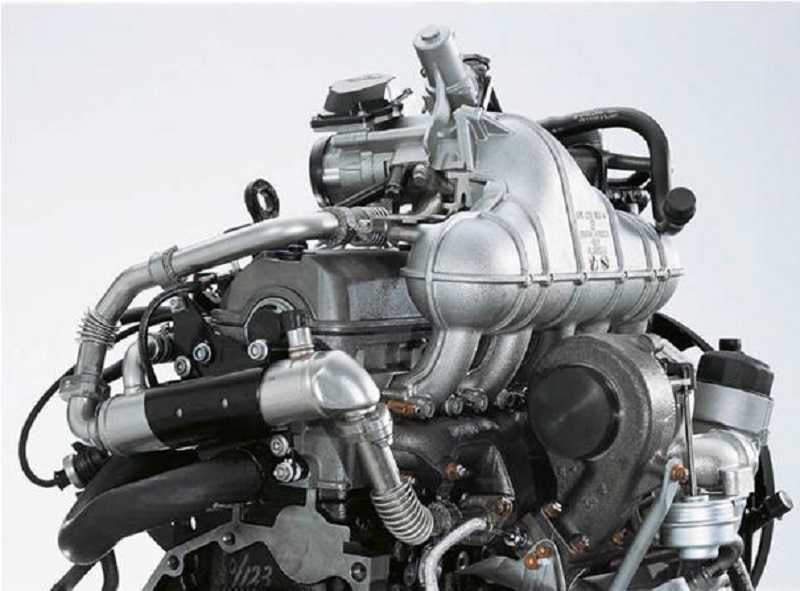

As for the work of the TRM belt, it is based on the transmission of torque from the crankshaft of the motor to the generator, the gas distribution mechanism, the fan and other nodes, the full composition of which directly depends on the vehicle model. Today, wedge, polyclinic and gear belts are the most common. Structurally, the toothed belt is the most difficult, however, the most efficient.

What is made, or types of timing belt, dignity and disadvantages of each type of timing belt

Of course, the chain drive has a lot of advantages. Firstly, reliability, because its service life is significantly superior to the belt. In addition, it is maintained much easier, because it is distinguished by the presence of a system of automatic tension of the chain. These significant positive moments of the chain drive are accounted for by some manufacturers and so on, and the release of such transport continues to today, although in significantly smaller volumes.

With the purpose of release of cheaper and lightweight car engines, the manufacturers have been implemented by belt drive. At the same time, the noise of the operating engine was reduced to a significant extent. However, they paid for all ordinary consumers. Changes in terms of mounting the belt of the gas distribution mechanism caused problems in replacing and maintenance. The life of the belt drive is much lower, and during its operation, it is necessary to check its tension and state all the time.

Designers were meant that the belt belt itself should simultaneously be quite wear-resistant and elastic, and also possess high strength, which is close enough to the chain. As a result, the three-layer belt design of the gas distribution mechanism arose. The first main layer is called Cord, which is a totality of threads from fiberglass. This material is quite durable, as well as resistant to the effects of the aggressive medium and mechanical loads.

The next layer is the internal working elements of the belt and directly the teeth. Most often it is made of nylon. Its wear resistance and durability gave the moment when the scope of the belt of the gas distribution mechanism is happening and it will be necessary to replace it. The third layer is a kind of case, worn on the main elements of the belt. This is a sheath of rubber thick in a half-meter, depending on the manufacturer. It gives the belt much more elasticity and partly protects his inner layers.

For all the existence of automotive production, a number of variations of the timing belts were invented:

- Leather mechanisms.

- Metal chains.

- Metallized belts on a rubber basis.

To date, the most common is the last option, since rubber samples are reliable, easy to use and inexpensive. It is these factors that determine huge demand. Metal chains have a complex design. In addition, they are not suiced. Well, leather products have a relatively small operational period.

The main causes of breakdowns

The reasons for the belt of the gas distribution mechanism can break through, there is too much, so we will focus on the most basic:

- Enclosing a crankshaft.

- Jumping camshaft.

- Swimming or spontaneous release of the tensioning roller.

- Pump jamming.

- Fit under the teeth of different foreign elements.

- Regular dipping dirt and oil.

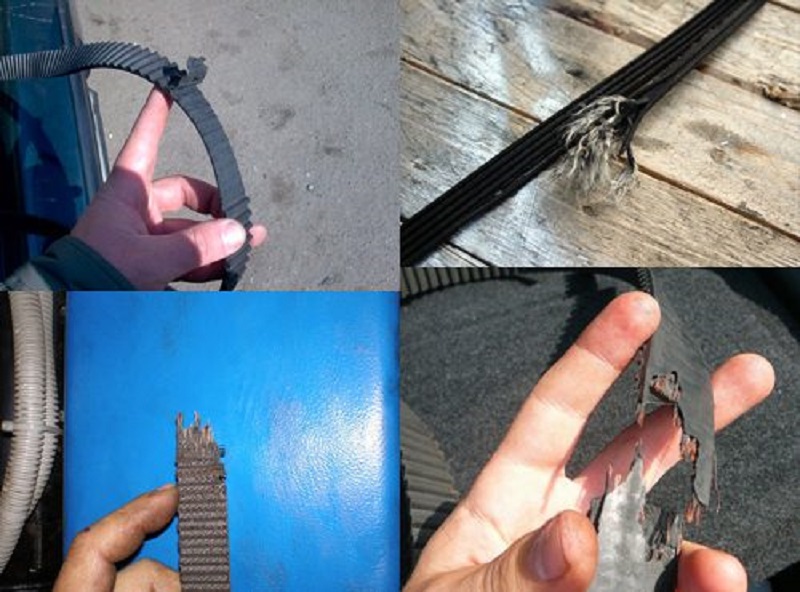

- Senior belt, its natural wear or initial marriage of the manufacturer.

Consequences of the timing belt

To begin with, refer to the laws of mechanics and physics. The consequences of the belt remover of the gas distribution mechanism directly depend on the engine design. Essentially, the easier the engine is arranged, the higher the probability that in the event of a breakage will not be damaged. If on the motor in the position of the DVN (upper dead point), the valve piston in the open state does not reach the bottom of the piston, it can be considered a luck - only the belt itself will have to change when the belt is changed.

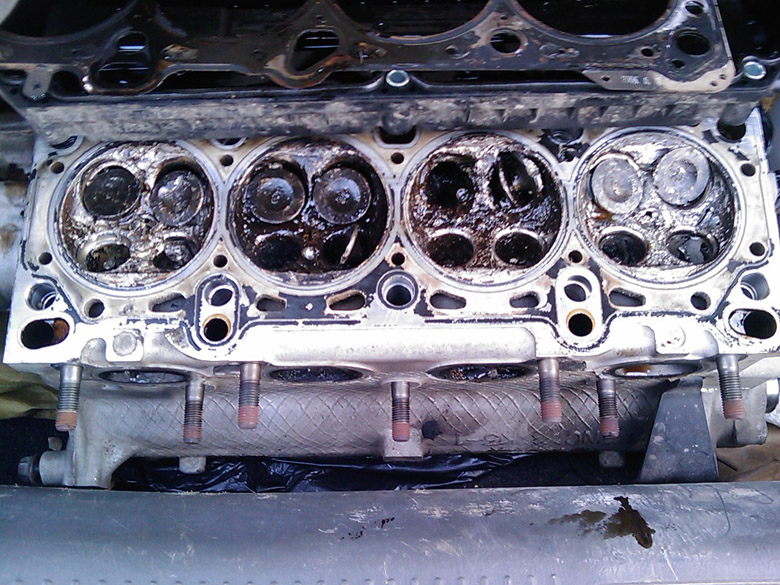

However, it is not always possible to get rid so easily. Today's multiclapped power units are aimed at an increase in power characteristics and are deprived of deep samples under the valve plates. As a result, when the belt is cutting the gas distribution mechanism, gas distribution shafts stop at that point, which was during the cliff.

The crankshaft is promoted by the flywheel, as a result of its inertial movement, it does not stop the rotation and faces the piston. The simplest thing that may be due to the valve bend occur. In this case, dismantling the head of the block should be done. If the belt of the gas distribution mechanism broke down at idle, then the practice testifies, it will take a replacement only to the top three valves, but if on transmission, then, most likely, all. In any case, experienced mechanics recommend the complete replacement of all valves. In addition, guide sleeves can burst, which will not rarely entail the repair of the cylinder block or its replacement. It happens less often the destruction of the piston, for example, due to the blow of the heads on it.

It also happens that the belt torn at high speed contributes to the bending of all 16 valves, Lopan's sleeves, as well as punching pistons with fragments. Engine repair in this case will be very expensive. As statistics shows, some motors tend to obtain such damage when the timing belt breaks, mostly power units from Japanese manufacturers. Lidate here Subaru, Toyota, Mazda, Dohc Nissan and others.

However, the most serious consequences are manifested in diesel engines. As a result of its special design, in the DVN position, the valves actually do not have the move, which is immediately destroyed by a whole chain of parts - camshaft with bearings, pushers, deformation of connectors. The opening at a high frequency of rotation of the engine threatens even overhaul of the cylinder block.

Signs of timing belt

There are a number of main signs of the timing belt cliff:

- Suddenly stamped the engine.

- It fails to re-start it.

- In the process of starter operation, a kind of metal knock is possible in the upper part of the power unit - the valves beat pistons.

To determine exactly whether the belt was really born, you can only look under the hood. Most likely, there will be a broken belt itself, and his spoiled casing.

Who must change the timing belt

It is worth noting that the belt of the gas distribution mechanism relates to a group of consumables and is not subject to recovery. Undoubtedly, in our country there is a mass of craftsmen who are able to return to life any device, but it requires greater experience and a huge amount of special skills and knowledge. Even the recovered belt of the gas distribution mechanism will serve only in order to get to the nearest one hundred. Therefore, it is not worth spending your nerves and time for thorough attempts to bring the torn strap of the gas distribution mechanism into the working condition. The best option is to address the services of qualified specialists who quickly and efficiently replace the device failed.

How to follow the timing belt

The timing belt of the gas distribution mechanism must be stretched correctly. There are a lot of benefits that are available explain how to do it. For cars with an automatic tensioner, the question of its correct work is fairly relevant. Most often, as a result of his problems, the belt is stretched too weak. However, not always the defective defects have natural reasons - quite popular his breakdowns, as the result of low qualifications of masters of a hundred.

An important condition for the correct work of the belt is the ease of rotation of the shafts. If in the process of replacing the belt of the gas distribution mechanism you noticed that one of the shafts encourages, then, first of all, it is necessary to eliminate the cause of this, otherwise the new belt will not last long. Equally, it is important to monitor oil leaks. If the lubricant falls on the timing belt, it is necessary to eliminate the leakage and rinse it, and even better replace it with a new one.

Also do not forget about the most simple rule - the belt should always be kept clean. Otherwise, he will very often break.

How often do you need to change the timing belt

The most common reasons for the belt break are associated with the carelessness of the motorist. The main among them is a late belt replacement. Automotive manufacturers, as a rule, set the time intervals between the replacements of sixty thousand kilometers, although the real resource of a really high-quality belt exceeds this interval by 5-10 thousand kilometers.

Tips Prof.

In the process of operation of the vehicle, the car owner should always know when the last time was replaced by the components of the gas distribution mechanism. No less important information about the value of the so-called. interservice mileage of the car. Information on the mileage at which the last replacement was carried out is usually written to the car's service book. In the absence of such a book, you can contact the maintenance center for information. If you purchased a used car, find out by the last owner when he replaced the rollers and timing belts. But even better - immediately replace all the components of the mechanism.

Related Materials

- Stove 2110, bad warm stove 2110, VAZ 2110 heating system, repairing the heating system VAZ 2110 with their own hands

- VAZ 2114 stove blows with cold air, stove 2114, bad warm stove VAZ 2114, device and repair of heating VAZ 2114 do-it-yourself, removing the stove VAZ 2114

- How to subdominize the car. How to put a jack. Types of jacks for cars.

- VAZ 2109 Fuse Block, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Old VAZ 2109 Fuse Block, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Car exhaust gas catalyst, faulty catalyst, pluses and cons of the catalyst, how to change the catalyst on the planeencitel

- Stove blowing cold air VAZ 2114, badly blowing the stove VAZ 2114, why badly blowing the stove VAZ 2114

- How to find out the owner of the car by the number of his car, check the car by the number of the traffic police machine, check the car by the state number of the car for free

- How to choose Used tires, Useful Tips

- Winter car road, pressure in passenger car tires in winter, good battery for the car in winter, whether to warm the car in winter

- In winter, the car is poorly started. How to make a car in winter, do you need to warm up the car in winter, useful tips

- Economy fuel consumption machines, the most economical car consumption

- Tires brands for passenger cars, labeling of car tire labeling, residual passenger car tire protector, how to pick a tire on a car brand, car tire tread pattern

- Working transmission operation, mechanical gearbox clutch work, driving with manual gearbox, useful tips

- Rear beam Peugeot 206 sedan, rear beam device Peugeot 206. Rear beam Peugeot 206 Malfunction, repair of the rear beam Peugeot 206

- Diesel fuel in winter, additive for diesel fuel in winter, how to choose the best diesel fuel

- Diesel winter does not start. How to start diesel in winter, heating diesel in winter.

- Japanese bridgestone tires, winter studded bridgestone tires, bridgestone tires brand

- Tire marking decoding for passenger cars, labeling wheels, how to choose the right tires on the disks

- Diesel engine in winter, launch of the diesel engine in winter, what oil to fill in a diesel engine in winter, useful tips

- LED backlight of the car, the backlight of the bottom of the car, the backlight of the legs in the car, the backlight in the door of the car, the backlight of the car is fine

- Recovered tires, bus tire, restored tire protector, can I use them

- Choose winter tires, which is a winter tires, which pressure in winter tires should be marked with winter tires, how to choose the right winter tires, the best winter tires 2019

- Steering rail rail, knock of steering rack, reasons for the knock and repair of the steering rack do it yourself

- Cameless car tires, a set for repair of tubeless tires, repair of the cannon-free tire do it yourself

- Russian tires, Russian tires Winter, Russian All-season tires, Voronezh AMTEL tires, Tires "Matador Omsk Tire", Kama-tires are world-class bus

- How to open a car without a key. Lost the key from the car what to do, the key from the car inside the car

- Silent tires, quiet winter tires, quiet studded bus, which tires to choose, overview tires

- Tires and safety, safety of the bus, why it is necessary to constantly monitor car tires

- Rules of safe driving of the car in the rain and slush, safe driving of the car for beginners

- Rust converter which is better for cars, rust converters to choose how to use rust transducer, professionals

- Polishing the body of the car do it yourself, how to choose a polishing paste, useful tips

- Engine durability, engine life, how to extend engine life

- Knock in the car. Knock when moving the car. What can knock in the car. How to determine the cause of the knock.

- ABS car, what is ABS car, ABS system malfunction, ABS diagnostics

- Overtaking a car when you can start overtaking a car, rules of traffic rules

- Fuel pump VAZ 2110, VAZ 2110 gas station scheme, VAZ 2110 fuel pump device, VAZ 2110 gas station repair,

- Automotive antennas for radio, automotive antenna device, car antenna do it yourself

- Front suspension Kalina, device front suspension Kalina, knock in front suspension Kalina, repair of front suspension Kalina

- Shock absorber Oil, best oil shock absorbers, pumping oil shock absorbers, how to properly pump oil shock absorber

- Clutch malfunctions, touches clutch, causes a clutch malfunction, how to eliminate

Comments